Home>Furniture & Design>Interior Design Trends>What Is Gorilla Glass

Interior Design Trends

What Is Gorilla Glass

Published: February 3, 2024

Discover the latest interior design trends with our comprehensive guide to Gorilla Glass. Learn how this innovative material can elevate your space.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Gorilla Glass has revolutionized the world of glass technology, offering unparalleled strength and durability in a sleek and elegant form. This innovative material has become a staple in modern design, seamlessly blending form and function to meet the demands of today's fast-paced and dynamic world.

The introduction of Gorilla Glass has significantly impacted various industries, from consumer electronics to architecture and automotive design. Its exceptional properties have made it a sought-after material for manufacturers and designers seeking to elevate their products and structures to new heights of durability and aesthetic appeal.

As we delve into the history, composition, properties, applications, and future developments of Gorilla Glass, we will uncover the fascinating journey of this remarkable material and gain a deeper understanding of its profound impact on the design and technology landscape.

Key Takeaways:

- Gorilla Glass is a super strong and durable material that started with iPhones but is now used in many things like cars, buildings, and even medical devices. It’s like a superhero for glass!

- Gorilla Glass is really good at resisting scratches, impacts, and chemicals. It’s also clear, thin, and light, making it perfect for phones, cars, and even fancy architectural designs. It’s like a tough, clear shield for all kinds of cool stuff!

Read more: How Strong Is Gorilla Glass 4

History of Gorilla Glass

Gorilla Glass, a product of Corning Inc., has a captivating history that traces its roots back to the early 1960s. Initially, the company focused on developing a chemically strengthened glass for industrial applications. However, it wasn't until the early 2000s that Corning's innovative spirit led to the creation of the exceptional material known as Gorilla Glass.

The journey of Gorilla Glass began with a quest to address the growing demand for durable and scratch-resistant glass in the emerging smartphone market. In 2007, Apple's visionary iPhone design team sought a reliable material that could withstand the rigors of daily use while maintaining a sleek and elegant appearance. This pivotal moment sparked a collaboration between Corning and Apple, leading to the development of the first-generation Gorilla Glass.

The successful integration of Gorilla Glass into the iPhone marked a significant turning point, catapulting the material into the spotlight and setting a new standard for durability in consumer electronics. The widespread adoption of Gorilla Glass by leading smartphone manufacturers further solidified its position as an industry game-changer.

As the demand for Gorilla Glass surged, Corning continued to refine and enhance its composition, resulting in the introduction of subsequent generations of the material. Each iteration brought improvements in strength, scratch resistance, and overall performance, cementing Gorilla Glass as the go-to choice for premium electronic devices.

The evolution of Gorilla Glass didn't stop at smartphones. Its exceptional properties soon found applications in tablets, laptops, wearables, and even automotive displays. This diversification underscored the material's versatility and reinforced its status as a cornerstone of modern design and technology.

The history of Gorilla Glass is a testament to the power of innovation and collaboration. From its humble beginnings as a solution for industrial needs to its ubiquitous presence in consumer electronics and beyond, Gorilla Glass has reshaped the possibilities of glass technology, setting a new standard for strength, durability, and aesthetic appeal.

This journey of innovation and adaptation continues to drive the evolution of Gorilla Glass, ensuring that it remains at the forefront of cutting-edge design and engineering, inspiring the creation of products that seamlessly blend form and function in the modern world.

Composition of Gorilla Glass

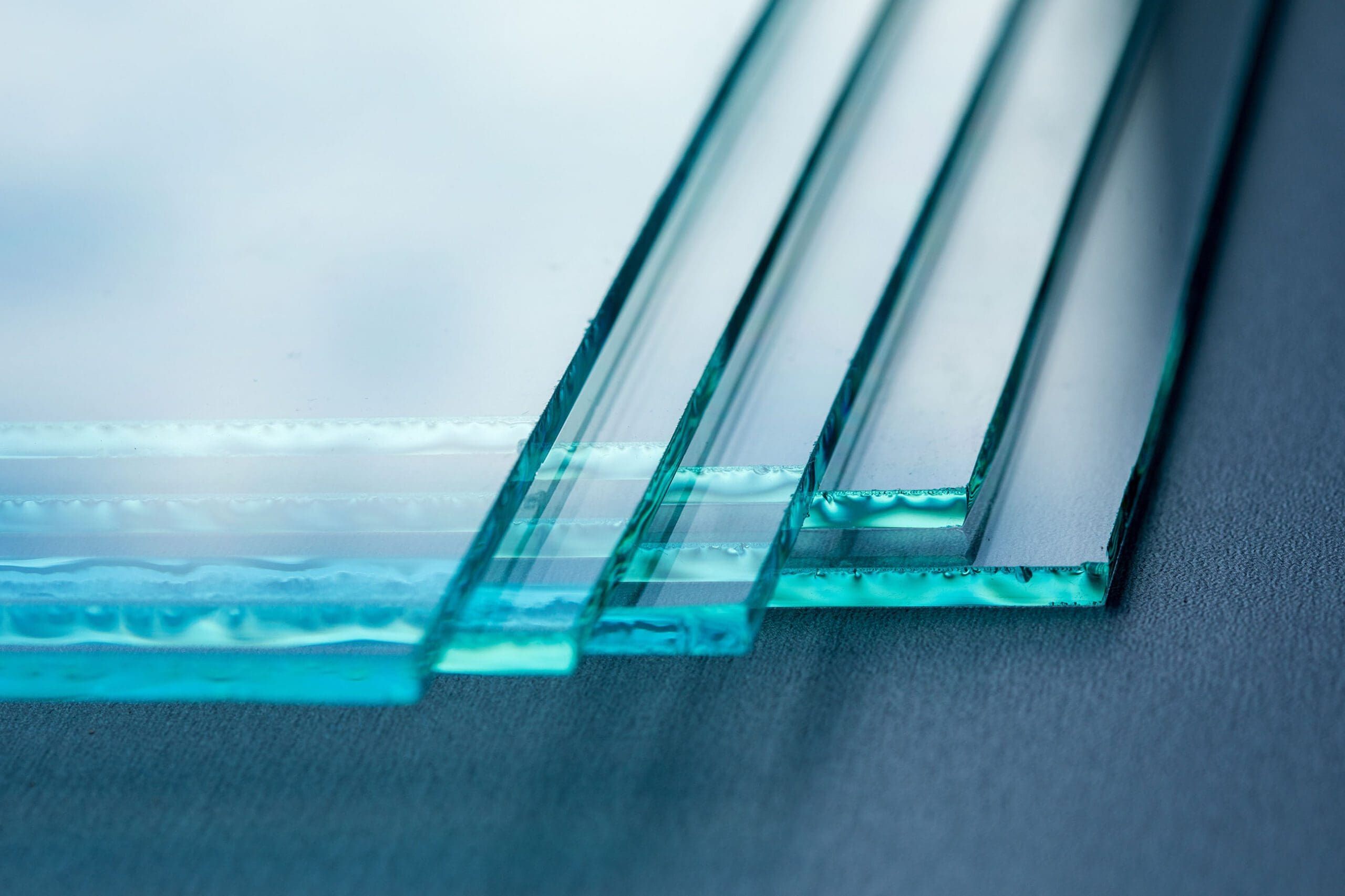

Gorilla Glass, renowned for its exceptional strength and durability, is crafted from a unique composition that sets it apart from traditional glass materials. At its core, Gorilla Glass is a type of alkali-aluminosilicate glass, a specialized form of glass that undergoes a series of intricate processes to achieve its remarkable properties.

The composition of Gorilla Glass begins with a fusion of high-purity raw materials, including silica sand, alumina, and other proprietary components. These elements are carefully selected to ensure the optimal balance of strength, clarity, and chemical resistance in the final product. The precise combination of these raw materials forms the foundation of Gorilla Glass, laying the groundwork for its exceptional performance in various applications.

Once the raw materials are meticulously blended, they undergo a process of melting and refining at high temperatures, resulting in a pristine molten glass mixture. This molten glass is then carefully shaped and cooled to form a pristine sheet of glass with uniform thickness and exceptional surface quality.

However, the defining characteristic of Gorilla Glass lies in its innovative ion-exchange strengthening process. This process involves immersing the pristine glass in a bath of molten salt at elevated temperatures. Through a controlled exchange of sodium ions in the glass with larger potassium ions in the salt bath, the surface of the glass undergoes a transformative compression, enhancing its strength and resistance to damage.

The ion-exchange process induces a state of compression in the outer layer of the glass, creating a robust surface that can withstand scratches, impacts, and daily wear and tear. This unique strengthening mechanism sets Gorilla Glass apart from conventional glass materials, elevating it to a class of its own in terms of durability and reliability.

Furthermore, the composition of Gorilla Glass is meticulously engineered to minimize surface flaws and imperfections, ensuring exceptional optical clarity and a smooth, pristine finish. This attention to detail not only enhances the visual appeal of Gorilla Glass but also contributes to its resilience and longevity in demanding environments.

In essence, the composition of Gorilla Glass represents a harmonious fusion of advanced materials science and precision engineering, resulting in a material that defies the limitations of traditional glass. This carefully crafted composition forms the backbone of Gorilla Glass, empowering it to excel in diverse applications, from consumer electronics to architectural marvels, and beyond.

Properties of Gorilla Glass

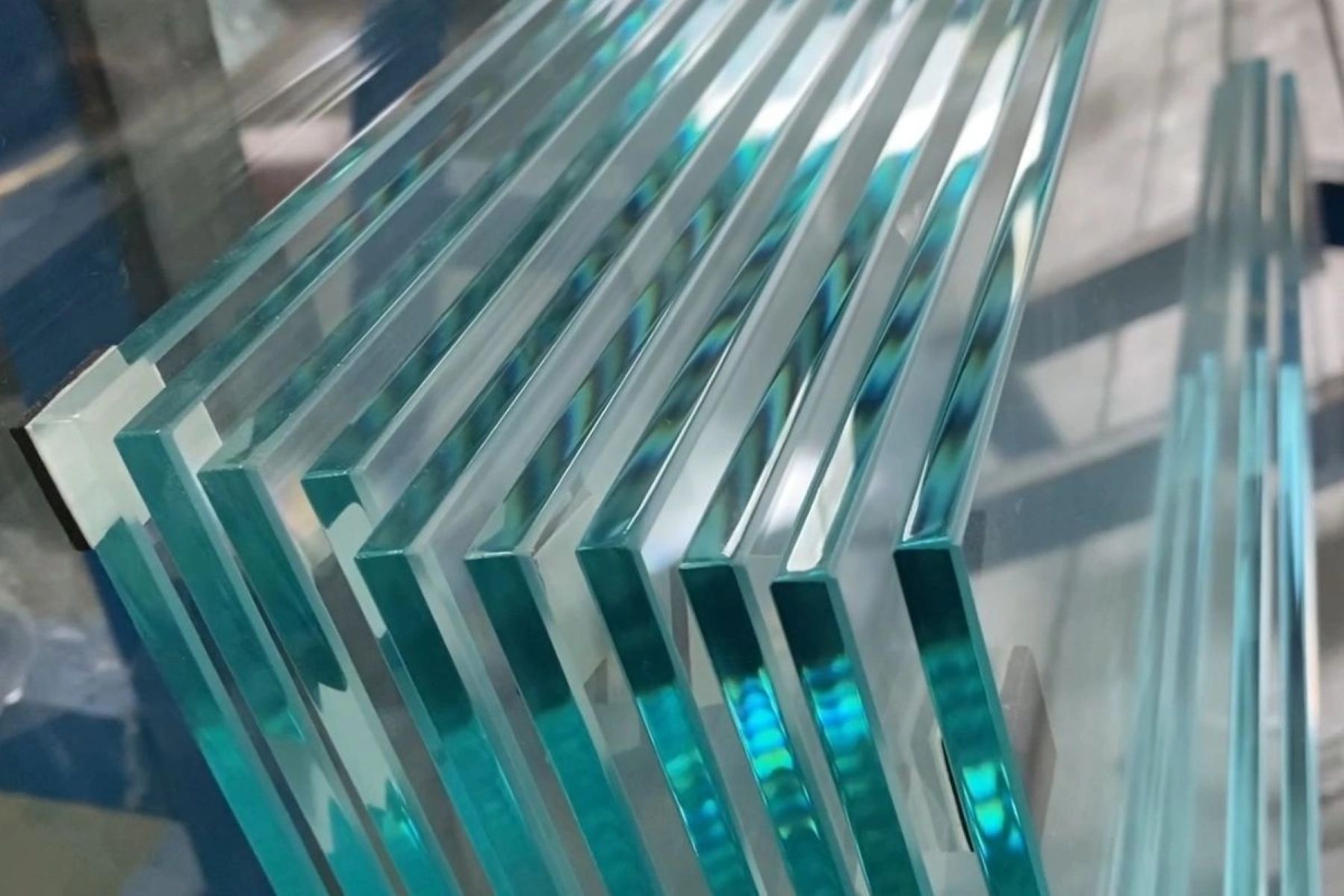

Gorilla Glass boasts a remarkable array of properties that distinguish it as a premier material in the realm of glass technology. Its exceptional strength, durability, and versatility have positioned it as a preferred choice for a wide range of applications, from consumer electronics to architectural marvels. Let's delve into the captivating properties that define Gorilla Glass:

1. Unrivaled Strength:

Gorilla Glass is renowned for its exceptional strength, surpassing that of traditional glass by a significant margin. The innovative ion-exchange strengthening process imbues the glass with remarkable resistance to scratches, impacts, and surface damage. This unparalleled strength ensures that devices and structures incorporating Gorilla Glass can withstand the rigors of daily use without compromising their integrity.

Read more: How To Get Gorilla Glue Off Glass

2. Enhanced Durability:

In addition to its impressive strength, Gorilla Glass exhibits enhanced durability, making it an ideal choice for products and structures that require long-term reliability. Its resistance to scratches and abrasions ensures that surfaces retain their pristine appearance, maintaining a sleek and polished aesthetic even after prolonged use.

3. Optical Clarity:

Gorilla Glass is engineered to deliver exceptional optical clarity, allowing for vivid displays and unobstructed viewing experiences. Its pristine surface quality and minimal distortion enable the faithful reproduction of colors and details, enhancing the visual appeal of devices such as smartphones, tablets, and televisions.

4. Thin and Lightweight:

Despite its exceptional strength and durability, Gorilla Glass maintains a remarkably thin and lightweight profile. This characteristic is particularly advantageous in the design of sleek and portable electronic devices, where minimizing weight and thickness is paramount without compromising on robustness.

5. Chemical Resistance:

Gorilla Glass exhibits impressive resistance to chemical damage, making it suitable for applications where exposure to harsh substances is a concern. This property ensures that the glass remains resilient in diverse environments, from industrial settings to everyday consumer use.

Read more: How To Store Gorilla Glue

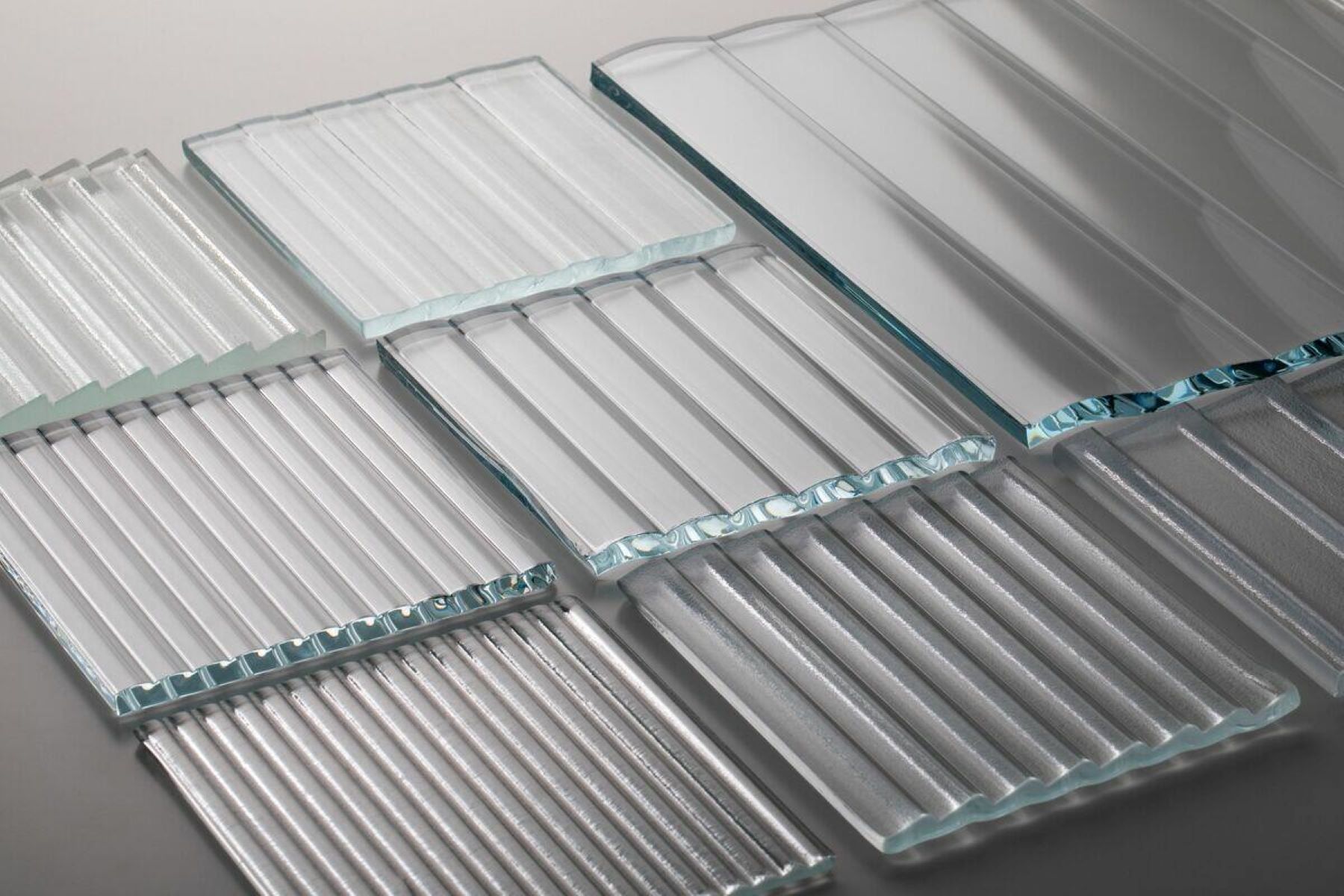

6. Versatility:

The versatility of Gorilla Glass is a key attribute that has propelled its widespread adoption across various industries. Its ability to be shaped, curved, and integrated into complex designs expands the possibilities for innovative product development and architectural applications.

7. Environmental Sustainability:

In line with evolving sustainability initiatives, Gorilla Glass is engineered to align with environmentally conscious practices. Its longevity and resistance to damage contribute to the reduction of material waste, while its recyclability further underscores its eco-friendly credentials.

The amalgamation of these properties positions Gorilla Glass as a material of unparalleled distinction, offering a harmonious blend of strength, durability, and aesthetic appeal. Its transformative impact on design and technology continues to unfold, shaping the landscape of innovation and inspiring the creation of products and structures that embody the pinnacle of glass engineering.

Applications of Gorilla Glass

Gorilla Glass, with its exceptional properties and versatile nature, has found widespread applications across diverse industries, redefining the possibilities of glass technology. Its remarkable strength, durability, and aesthetic appeal have positioned it as a material of choice for an array of innovative products and architectural marvels.

Consumer Electronics:

Gorilla Glass has made a profound impact in the realm of consumer electronics, where its strength, scratch resistance, and optical clarity are highly valued. It is prominently featured in smartphones, tablets, laptops, and wearable devices, serving as a protective and visually stunning cover glass. The integration of Gorilla Glass in electronic displays ensures robustness against daily wear and tear, contributing to the longevity and visual appeal of these devices.

Read more: Where To Buy Gorilla Ladder

Automotive Design:

The automotive industry has embraced Gorilla Glass for its ability to enhance both functionality and aesthetics. It is utilized in vehicle infotainment systems, heads-up displays, and instrument clusters, where its durability and optical clarity elevate the driving experience. Additionally, Gorilla Glass is employed in automotive exterior applications, such as panoramic sunroofs and sleek windshield designs, adding a touch of sophistication while ensuring safety and resilience.

Architectural Innovations:

Gorilla Glass has transcended traditional applications to make its mark in architectural design. Its versatility allows for the creation of stunning glass facades, skylights, and interior partitions that exude modernity and elegance. The material's strength and resistance to environmental factors make it an ideal choice for exterior glazing, enabling the realization of striking architectural visions while ensuring structural integrity and longevity.

Medical Devices and Touch Surfaces:

In the realm of medical technology, Gorilla Glass plays a pivotal role in the development of durable and hygienic touch surfaces for diagnostic equipment and interactive displays. Its robust nature and ease of cleaning make it well-suited for medical environments, where reliability and cleanliness are paramount. The integration of Gorilla Glass in medical devices enhances user interaction while maintaining stringent hygiene standards.

Home Appliances and Furniture:

Gorilla Glass has extended its influence to home appliances and furniture, where its sleek and resilient properties are leveraged to elevate the design and functionality of various products. From cooktops and oven doors to elegant glass tabletops, the material adds a touch of sophistication while offering durability and ease of maintenance. Its application in these domains underscores its adaptability and ability to enhance everyday living spaces.

Read also: 9 Amazing Gorilla Ladder for 2025

Wearable Technology:

The rise of wearable technology has seen the integration of Gorilla Glass in smartwatches, fitness trackers, and other wearable devices. Its thin and lightweight profile, coupled with exceptional durability, makes it an ideal choice for protecting delicate electronic components while maintaining a sleek and modern aesthetic. The use of Gorilla Glass in wearables exemplifies its seamless integration into cutting-edge technologies.

The diverse applications of Gorilla Glass underscore its transformative impact on modern design and technology. Its ability to enhance the functionality, durability, and visual appeal of products and structures across various industries cements its status as a material of unparalleled versatility and innovation. As the evolution of Gorilla Glass continues, its influence on design and engineering is poised to inspire further advancements and creative possibilities.

Advantages and Disadvantages of Gorilla Glass

Gorilla Glass stands as a pinnacle of glass technology, offering a host of advantages that have propelled its widespread adoption across diverse industries. However, alongside its remarkable strengths, it is essential to acknowledge the limitations and considerations associated with this innovative material.

Advantages

-

Exceptional Strength and Durability: Gorilla Glass exhibits unparalleled resistance to scratches, impacts, and surface damage, ensuring the longevity and pristine appearance of products and structures.

-

Enhanced Optical Clarity: The material's exceptional transparency and minimal distortion enable vivid displays and unobstructed viewing experiences, enhancing the visual appeal of electronic devices and architectural installations.

-

Versatility in Design: Gorilla Glass can be shaped, curved, and integrated into complex designs, expanding the creative possibilities for innovative product development and architectural applications.

-

Thin and Lightweight Profile: Despite its exceptional strength, Gorilla Glass maintains a remarkably thin and lightweight profile, making it an ideal choice for sleek and portable electronic devices and architectural elements.

-

Chemical Resistance: The material exhibits impressive resistance to chemical damage, ensuring resilience in diverse environments and applications.

-

Environmental Sustainability: Gorilla Glass aligns with sustainability initiatives through its longevity, resistance to damage, and recyclability, contributing to the reduction of material waste.

Disadvantages

-

Cost Considerations: The production of Gorilla Glass involves intricate processes and specialized materials, leading to higher manufacturing costs compared to conventional glass.

-

Brittleness: While Gorilla Glass excels in scratch resistance and surface durability, it may exhibit brittleness under extreme impact, potentially leading to shattering in certain scenarios.

-

Complex Manufacturing Process: The ion-exchange strengthening process and precise composition requirements contribute to the complexity of manufacturing Gorilla Glass, necessitating advanced facilities and expertise.

-

Limited Heat Resistance: Gorilla Glass may have limitations in high-temperature environments, where its thermal expansion characteristics and heat resistance may pose challenges in certain applications.

-

Environmental Impact: Despite its recyclability, the energy-intensive manufacturing processes and raw material extraction for Gorilla Glass may have environmental implications that warrant careful consideration.

Understanding the advantages and disadvantages of Gorilla Glass is crucial for informed decision-making in product design, architectural applications, and technological innovations. By leveraging its strengths while addressing potential limitations, designers and manufacturers can harness the full potential of Gorilla Glass, driving the evolution of resilient and visually captivating solutions across diverse domains.

Future Developments in Gorilla Glass Technology

The future of Gorilla Glass technology holds immense promise, fueled by ongoing research, innovation, and a relentless pursuit of excellence. As the demands for advanced materials continue to evolve, Corning Inc. remains at the forefront of pioneering developments that are poised to redefine the capabilities of Gorilla Glass.

One of the key areas of focus for future advancements in Gorilla Glass technology lies in enhancing its resilience to extreme conditions. This includes efforts to further improve its resistance to impact and shattering, addressing potential brittleness under severe stress. By refining the material's molecular structure and strengthening mechanisms, Corning aims to elevate Gorilla Glass to new heights of durability, ensuring its reliability in a wide spectrum of applications, from consumer electronics to architectural installations.

Moreover, the quest for thinner yet stronger glass presents an exciting avenue for future innovation. Corning's dedication to pushing the boundaries of material science seeks to achieve a delicate balance between reducing thickness and enhancing strength, thereby enabling the creation of even sleeker and more lightweight devices without compromising on robustness. This pursuit aligns with the evolving design trends that prioritize slim and portable form factors across various industries.

In parallel, the integration of advanced functionalities within Gorilla Glass is a focal point for future developments. This encompasses the incorporation of features such as enhanced scratch resistance, antimicrobial properties, and even interactive capabilities directly within the glass substrate. By seamlessly integrating these functionalities, Gorilla Glass is poised to transcend its conventional role as a protective cover, evolving into an active component that contributes to the overall performance and user experience of devices and structures.

Furthermore, the exploration of sustainable practices and eco-friendly formulations represents a pivotal direction for the future of Gorilla Glass technology. Corning's commitment to environmental stewardship drives the pursuit of manufacturing processes that minimize energy consumption and waste generation, while also exploring the use of recycled materials in the production of Gorilla Glass. This sustainable approach aligns with the global shift towards eco-conscious design and production, positioning Gorilla Glass as a responsible choice for sustainable innovations.

As the trajectory of Gorilla Glass technology unfolds, the convergence of these advancements is set to redefine the boundaries of glass engineering, empowering designers, manufacturers, and innovators to realize bold and visionary concepts. The future developments in Gorilla Glass technology are poised to elevate the material to unprecedented levels of strength, functionality, and sustainability, shaping a new era of possibilities in design, technology, and beyond.

Frequently Asked Questions about What Is Gorilla Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Gorilla Glass”