Home>Home Appliances>Bathroom Appliances>How Does A Spring Scale Measure Weight

Bathroom Appliances

How Does A Spring Scale Measure Weight

Published: February 13, 2024

Learn how a spring scale measures weight and its importance in bathroom appliances. Find out the working principle and uses of spring scales.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to measuring weight, spring scales play a pivotal role in various applications, from everyday household tasks to industrial and scientific endeavors. These ingenious devices have been a cornerstone of weight measurement for centuries, offering a simple yet effective method for determining the mass of an object. Understanding the fundamental principles and inner workings of spring scales is essential for appreciating their significance in our daily lives.

From the humble bathroom scale to the sophisticated equipment used in laboratories and manufacturing facilities, spring scales are ubiquitous in their utility. Whether you're weighing ingredients for a recipe, determining the force required to compress a spring, or measuring the tension in a suspension bridge, the underlying concept remains the same. By harnessing the mechanical properties of springs, these devices provide a reliable means of quantifying weight.

In this comprehensive exploration of spring scales, we will delve into the underlying principles that govern their functionality, uncover the intricate mechanisms that enable their operation, and examine the factors that influence their accuracy. Furthermore, we will uncover the diverse applications of spring scales across various industries and gain a deeper appreciation for their indispensable role in modern society.

As we embark on this journey of discovery, we will unravel the mysteries behind the deceptively simple yet remarkably effective technology that underpins spring scales. By shedding light on the inner workings of these devices, we aim to foster a deeper understanding of their significance and empower readers to grasp the profound impact of spring scales on our daily lives.

Key Takeaways:

- Spring scales measure weight by using the deformation of a spring, which is directly proportional to the force of gravity acting on an object. This simple yet effective principle allows for reliable and precise weight measurements.

- Factors such as spring stiffness, calibration, and environmental conditions can affect the accuracy of spring scales. Understanding and addressing these factors is crucial for maintaining the reliability of weight measurements.

Read more: How To Reset A Weight Scale

The Principle of Spring Scales

At the heart of spring scales lies a fundamental principle rooted in Hooke's Law, a cornerstone of classical physics that governs the behavior of elastic materials such as springs. Hooke's Law states that the force required to extend or compress a spring is directly proportional to the displacement of the spring from its equilibrium position. This linear relationship forms the basis for the operation of spring scales, enabling them to accurately measure weight through the deformation of a spring.

When an object is placed on the weighing platform of a spring scale, the force of gravity acting on the object causes the spring to compress or extend, depending on the design of the scale. As the spring deforms, it exerts a counteracting force that opposes the gravitational force acting on the object. This results in an equilibrium state where the force exerted by the spring matches the gravitational force, thereby indicating the weight of the object.

The principle of spring scales hinges on the concept of restoring force, which is the force exerted by the spring to return to its original shape after being deformed. This restoring force is directly proportional to the displacement of the spring, as per Hooke's Law. By calibrating the spring and incorporating a calibrated scale, the amount of deformation can be translated into a numerical weight value, providing a precise measurement of the object's mass.

In essence, the principle of spring scales revolves around the interplay between gravitational force and the elastic properties of springs. By harnessing the predictable behavior of springs under load, these devices offer a reliable and consistent method for quantifying weight. Whether it's the tension in a hanging spring scale or the compression in a traditional bathroom scale, the underlying principle remains rooted in the elegant simplicity of Hooke's Law.

By understanding the principle of spring scales, we gain insight into the foundational physics that underpins their functionality. This knowledge forms the basis for the design and calibration of spring scales, ensuring their accuracy and reliability in diverse applications. As we unravel the intricacies of spring scale operation, we pave the way for a deeper appreciation of the role these devices play in our daily lives.

How Spring Scales Work

Spring scales operate on the fundamental principle of converting the force exerted by an object's weight into the deformation of a spring. This ingenious mechanism allows for the precise measurement of weight through the calibrated response of the spring to the applied force. The inner workings of spring scales can be elucidated through the following steps:

-

Application of Weight: When an object is placed on the weighing platform of a spring scale, the force of gravity acting on the object causes the spring to deform. This deformation is directly proportional to the weight of the object, as per Hooke's Law.

-

Deformation of the Spring: As the object's weight compresses or extends the spring, the spring exerts a counteracting force to maintain equilibrium. This results in the deformation of the spring, with the magnitude of deformation directly correlating to the weight of the object.

-

Translation to Measurement: The calibrated scale attached to the spring scale is designed to quantify the amount of spring deformation in terms of weight units, such as pounds or kilograms. This allows for the direct translation of spring deformation into a numerical weight value, providing a clear indication of the object's mass.

-

Display of Weight: The measured weight is typically displayed on a dial, digital screen, or indicator, providing a convenient readout for the user. This allows for quick and accurate assessment of the object's weight, making spring scales invaluable tools in various settings.

The elegant simplicity of this mechanism underscores the effectiveness of spring scales in providing reliable weight measurements. Whether it's the familiar bathroom scale or the precision instruments used in scientific research, the underlying principle remains consistent. By harnessing the mechanical properties of springs and leveraging the principles of physics, spring scales offer a straightforward yet robust method for determining weight.

In essence, the functionality of spring scales hinges on the seamless integration of mechanical components and calibrated measurements. This synergy enables the conversion of mechanical force into quantifiable weight values, empowering users with a practical and accessible means of measuring mass. As we unravel the inner workings of spring scales, we gain a deeper appreciation for the ingenuity and precision that underpin these ubiquitous devices.

Factors Affecting the Accuracy of Spring Scales

The accuracy of spring scales, crucial for obtaining precise weight measurements, is influenced by various factors that warrant careful consideration. Understanding these factors is essential for ensuring reliable and consistent results in diverse applications. Let's delve into the key elements that can impact the accuracy of spring scales:

1. Spring Stiffness:

The stiffness of the spring directly affects the sensitivity and accuracy of the scale. A stiffer spring may provide a higher level of precision in measuring small weights, while a less stiff spring could be more suitable for measuring heavier loads. Proper selection and calibration of the spring stiffness are critical for optimizing the accuracy of the scale across a wide range of weights.

Read more: How Does A Weight Scale Measure Body Fat

2. Calibration and Zeroing:

Accurate calibration of the spring scale is paramount for reliable measurements. Over time, factors such as wear and tear or environmental conditions can affect the calibration, leading to inaccuracies. Regular calibration and zeroing procedures are necessary to maintain the scale's accuracy and ensure that it consistently reflects true weight values.

3. Environmental Conditions:

External factors, including temperature variations and humidity levels, can impact the performance of spring scales. Changes in temperature can alter the properties of the spring, leading to deviations in measurement accuracy. Similarly, high humidity levels may affect the materials used in the scale, potentially influencing its precision. Shielding the scale from extreme environmental conditions and conducting periodic checks can mitigate these effects.

4. Overloading and Mechanical Stress:

Subjecting a spring scale to loads beyond its capacity can compromise its accuracy and lead to permanent deformation of the spring. Additionally, applying sudden or excessive force to the scale can introduce mechanical stress, affecting its long-term performance. Adhering to the specified weight limits and handling the scale with care are essential for preserving its accuracy.

5. Material Fatigue:

Continuous use of a spring scale can lead to material fatigue, potentially impacting its accuracy over time. The repetitive deformation of the spring during measurements can contribute to wear and degradation, necessitating periodic inspection and maintenance to address any signs of material fatigue and ensure consistent accuracy.

By acknowledging and addressing these factors, users can optimize the accuracy of spring scales and uphold their reliability in diverse weighing applications. Through proactive maintenance, meticulous calibration, and prudent usage, the impact of these influencing elements can be mitigated, allowing spring scales to deliver precise and dependable weight measurements.

Understanding the nuances of these factors empowers users to make informed decisions regarding the selection, maintenance, and utilization of spring scales, ultimately enhancing their effectiveness and reliability in various settings.

Read more: How Much Weight Does Shoes Add To The Scale

Applications of Spring Scales

Spring scales find diverse and indispensable applications across a wide spectrum of industries and everyday scenarios, showcasing their versatility and practical utility. From household tasks to industrial processes, the reliable measurement of weight facilitated by spring scales underpins numerous essential activities. Let's explore the multifaceted applications of spring scales:

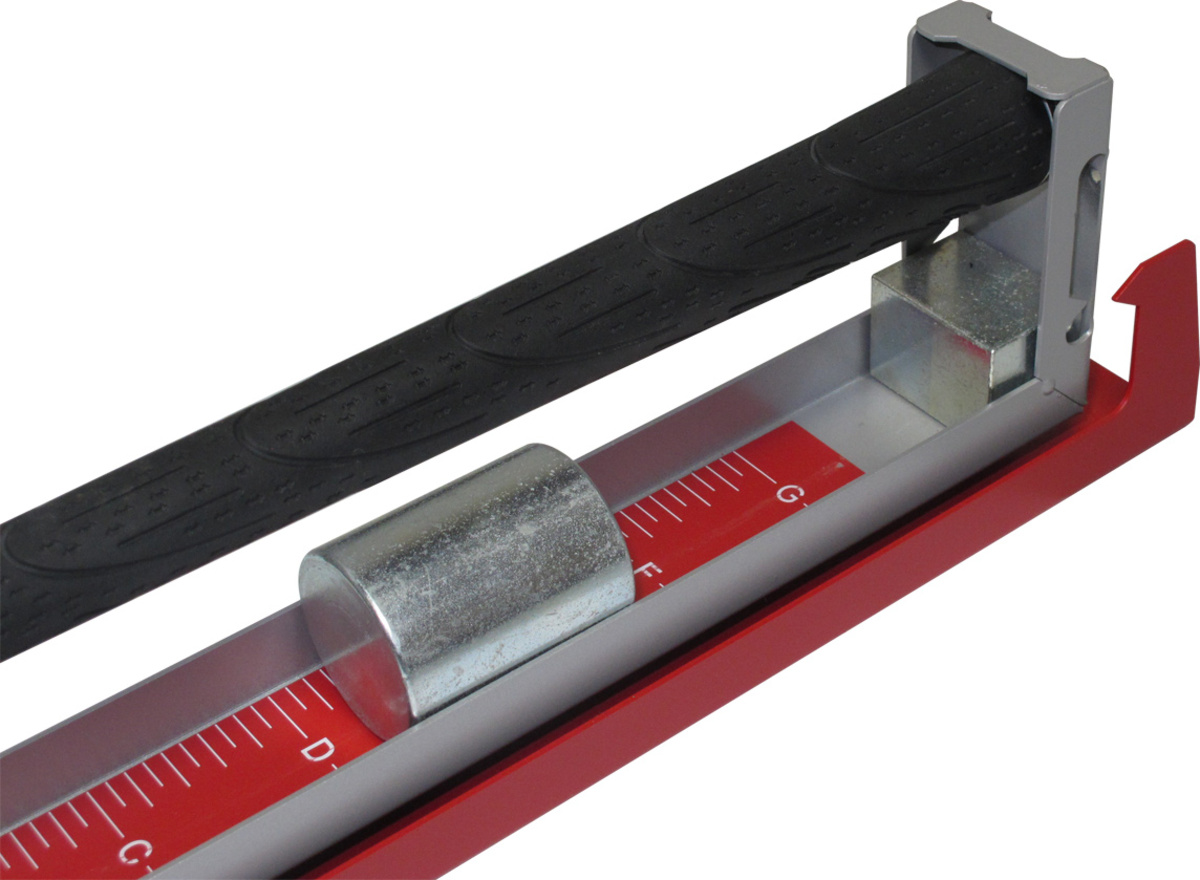

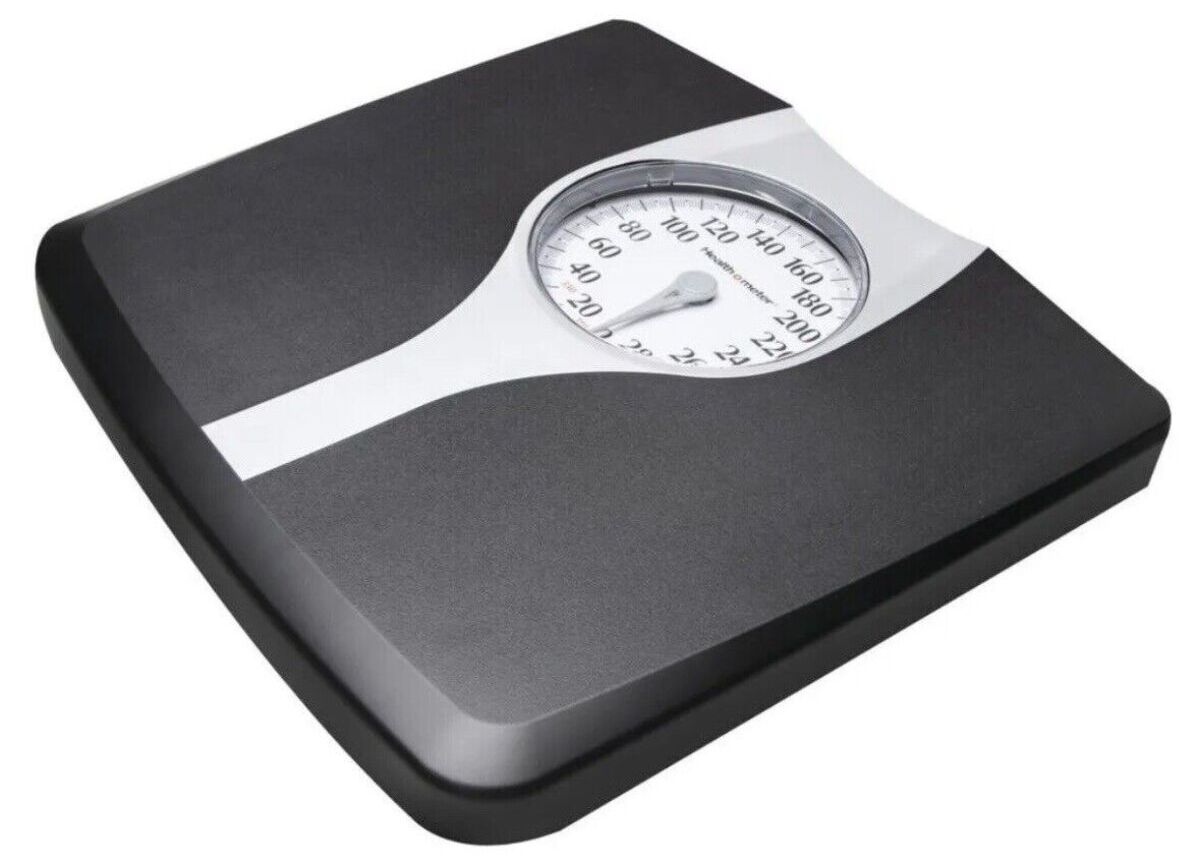

1. Household Weighing:

In households, spring scales are commonly used for weighing ingredients during cooking and baking, ensuring precise measurements for recipes. Additionally, bathroom scales, a specific type of spring scale, provide individuals with a convenient means of monitoring their body weight and managing their health.

2. Commercial and Retail:

In retail environments, spring scales are utilized for weighing fruits, vegetables, and other products at grocery stores, markets, and delis. These scales enable accurate portioning and pricing of items, contributing to efficient and fair transactions.

3. Industrial Manufacturing:

In industrial settings, spring scales play a crucial role in quality control and production processes. They are employed for measuring the weight of raw materials, components, and finished products, ensuring adherence to specifications and standards.

Read more: What Is A Weight Scale

4. Laboratory Experiments:

In scientific laboratories, spring scales are utilized for conducting experiments and research activities that require precise weight measurements. From physics and chemistry experiments to material testing, these scales provide essential data for scientific investigations.

5. Fishing and Outdoor Activities:

Spring scales are commonly used in fishing to weigh catches and determine the weight of fish. Outdoor enthusiasts also rely on spring scales for activities such as luggage weighing, camping gear assessment, and other weight-dependent tasks.

6. Educational Purposes:

In educational settings, spring scales serve as valuable teaching aids for demonstrating principles of force, gravity, and measurement. They enable students to gain hands-on experience with weight quantification and the behavior of springs in response to applied forces.

7. Industrial Tension Measurement:

Specialized spring scales are employed for measuring tension in cables, wires, and other structural elements in construction, engineering, and maintenance applications. These scales aid in assessing the integrity and load-bearing capacity of various materials and components.

Read more: How To Measure Weight On A Scale

8. Agricultural and Farming:

In agricultural contexts, spring scales are utilized for weighing produce, feed, and livestock, contributing to efficient management and trade within the farming industry.

9. Material Testing and Analysis:

Spring scales are integral to material testing procedures, where the measurement of weight and force is essential for evaluating the properties and performance of materials in diverse applications, including engineering and manufacturing.

10. Medical and Healthcare:

In medical facilities, spring scales are employed for measuring the weight of patients, medical equipment, and supplies. They contribute to accurate assessments and treatment protocols in healthcare settings.

The widespread applications of spring scales underscore their significance in facilitating precise weight measurements across various domains. From enhancing culinary precision to supporting scientific exploration and industrial operations, these devices continue to be indispensable tools in diverse environments, exemplifying their enduring relevance and utility.

Conclusion

In conclusion, the enduring relevance and practical utility of spring scales are evident across a myriad of applications, ranging from household tasks to industrial processes and scientific endeavors. These versatile devices, rooted in the fundamental principles of physics and engineering, offer a reliable and accessible means of measuring weight, underpinned by the elegant simplicity of Hooke's Law and the mechanical properties of springs.

The seamless integration of calibrated measurements and mechanical components enables spring scales to convert the force exerted by an object's weight into quantifiable weight values, empowering users with precise measurements in diverse settings. Whether it's the meticulous portioning of ingredients in culinary pursuits, the assessment of structural integrity in engineering applications, or the monitoring of body weight for health management, spring scales continue to play an indispensable role in our daily lives.

By understanding the principle of spring scales and the factors influencing their accuracy, users can optimize their performance and reliability, ensuring consistent and precise weight measurements. The careful consideration of factors such as spring stiffness, calibration, environmental conditions, and material fatigue is essential for upholding the accuracy of spring scales across various applications.

Furthermore, the diverse applications of spring scales underscore their versatility and adaptability, from retail environments and industrial manufacturing to educational settings and scientific laboratories. These devices serve as essential tools for facilitating fair transactions, conducting experiments, managing agricultural produce, and supporting material testing and analysis, among numerous other vital functions.

As we reflect on the enduring legacy of spring scales, it becomes evident that their significance transcends mere weight measurement. They embody the convergence of scientific principles, practical ingenuity, and everyday utility, enriching our lives through their seamless integration into a multitude of tasks and activities.

In essence, spring scales stand as a testament to the enduring impact of simple yet elegant technology, serving as steadfast companions in our pursuit of precision, accuracy, and efficiency. Their timeless relevance and unwavering reliability position them as indispensable instruments, perpetuating their role as essential components of our daily routines and professional endeavors.

Frequently Asked Questions about How Does A Spring Scale Measure Weight

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does A Spring Scale Measure Weight”