Home>Articles>At What Temperature Does An Electric Pressure Cooker Seal

Articles

At What Temperature Does An Electric Pressure Cooker Seal

Modified: February 20, 2024

Learn about the optimum temperature for sealing an electric pressure cooker in this informative article. Get expert advice and tips on pressure cooking.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric pressure cookers have revolutionized the way we cook, enabling us to prepare delicious meals in a fraction of the time it would take using traditional cooking methods. One important aspect of electric pressure cookers is their sealing mechanism, which plays a crucial role in their efficiency and effectiveness.

In this article, we will delve into the world of electric pressure cookers and explore the intriguing question: At what temperature does an electric pressure cooker seal?

Understanding the sealing temperature of an electric pressure cooker is key to getting the best results and ensuring that the cooking process is both safe and efficient. By gaining insight into the factors that affect the sealing process and learning how to maintain the ideal sealing temperature, you can make the most of this remarkable kitchen appliance.

So, let’s dive in and uncover the mysteries behind the sealing temperature of an electric pressure cooker!

Key Takeaways:

- Maintaining the ideal sealing temperature (230°F to 250°F) in an electric pressure cooker is crucial for efficient and flavorful cooking. Factors like gasket condition, lid alignment, and proper maintenance play a significant role in achieving this optimal temperature.

- Common issues such as gasket problems, debris on sealing surfaces, and overfilling the pot can impact the sealing mechanism. Regular inspection, cleaning, and following recipe instructions are essential for mastering the art of cooking with an electric pressure cooker.

Understanding Electric Pressure Cookers

Electric pressure cookers are appliances that use the power of steam and pressure to cook food quickly and efficiently. They consist of a sealed pot with a pressure release valve, a heating element, and a control panel for setting the cooking time and pressure level.

These modern-day marvels are designed to create an airtight cooking environment, allowing the steam and pressure to build up inside the pot. As the pressure increases, the boiling point of water rises, resulting in faster cooking times.

Electric pressure cookers offer several advantages over traditional cooking methods. Firstly, they significantly reduce cooking time, allowing you to prepare meals in a matter of minutes rather than hours. Secondly, they retain more nutrients in the food compared to other cooking methods, as the shorter cooking time helps to preserve vitamins and minerals.

Additionally, electric pressure cookers are incredibly versatile. They can be used to cook a wide range of dishes, from hearty stews and tender meats to flavorful grains and perfectly steamed vegetables. They also provide the convenience of set-it-and-forget-it cooking, as you can simply program the desired cooking time and pressure level and let the appliance do the rest.

To ensure the safety of the user, electric pressure cookers are equipped with several safety features. These include pressure release valves to prevent the pressure from building up to dangerous levels, locking mechanisms to prevent the pot from being opened while under pressure, and automatic shut-off functions to turn off the heating element once the cooking process is complete.

Now that we have a basic understanding of electric pressure cookers, let’s explore the fascinating mechanism behind their sealing process.

The Sealing Mechanism in Electric Pressure Cookers

The sealing mechanism is a crucial component of electric pressure cookers. It ensures that no steam or pressure escapes during the cooking process, allowing the appliance to reach and maintain the desired pressure level for efficient cooking.

Electric pressure cookers achieve this airtight seal through the use of a rubber or silicone gasket. This gasket is placed between the lid and the pot, creating a tight seal when the lid is securely closed. When the pressure cooker is turned on and the pressure starts to build up, the gasket expands and forms an even tighter seal, preventing any steam from escaping.

The sealing mechanism also includes a pressure release valve. This valve allows excess pressure to be released safely, preventing the pressure cooker from becoming over-pressurized. The pressure release valve is typically located on the lid of the pressure cooker and can be manually operated or set to release pressure automatically when a certain pressure level is reached.

Another component of the sealing mechanism is the locking mechanism. This mechanism ensures that the pressure cooker cannot be opened while it is still under pressure. It is designed to hold the lid securely in place until the pressure has been released and it is safe to open.

Overall, the sealing mechanism in electric pressure cookers is designed to create a secure and airtight environment for efficient cooking. It prevents steam and pressure from escaping, allowing the appliance to reach and maintain the desired pressure level, which ultimately results in faster cooking times and evenly cooked food.

Now that we understand the sealing mechanism, let’s explore the factors that affect the sealing temperature of an electric pressure cooker.

Factors Affecting Sealing Temperature

The sealing temperature of an electric pressure cooker can be influenced by various factors. Understanding these factors will help you optimize the cooking process and ensure that your pressure cooker operates at its best efficiency.

1. Gasket Condition: The condition of the gasket plays a significant role in the sealing temperature. Over time, the gasket may wear out or become damaged, compromising its ability to create a tight seal. Regularly inspect the gasket for any signs of wear or deterioration. Replace it if necessary to maintain optimal sealing temperature.

2. Lid Alignment: Proper alignment of the lid is crucial for achieving an airtight seal. If the lid is not aligned correctly, it may not make full contact with the pot, leading to steam and pressure leakage. Ensure that the lid is properly aligned and securely locked in place before starting the cooking process.

3. Pressure Release Valve: The pressure release valve regulates the pressure inside the cooker. If the valve is not functioning correctly or is blocked, it may impact the sealing temperature. Ensure that the valve is clean and free from any obstructions to allow proper pressure regulation.

4. Cooking Liquid: The amount and type of cooking liquid used in the pressure cooker can affect the sealing temperature. The liquid creates steam, which builds pressure inside the pot. It is important to follow the manufacturer’s guidelines for the recommended liquid quantity to ensure proper sealing temperature and avoid excessive pressure buildup.

5. Ambient Temperature: The ambient temperature in your kitchen can also affect the sealing temperature of the pressure cooker. Higher room temperatures can result in higher sealing temperatures, while colder room temperatures may require longer cooking times to reach the desired pressure. Consider the ambient temperature when planning your cooking process.

6. Maintenance and Cleaning: Regular maintenance and cleaning of your pressure cooker are essential for optimal performance. Ensure that the sealing ring, lid, and pressure release valve are thoroughly cleaned and free from any debris or food particles. This will help maintain the sealing temperature and prevent any issues with steam and pressure leakage.

By taking these factors into consideration, you can ensure that your electric pressure cooker operates at an optimal sealing temperature, resulting in efficient and flavorful cooking.

Next, let’s explore the ideal sealing temperature for electric pressure cookers.

The electric pressure cooker sealing typically occurs at temperatures between 230-245°F (110-118°C). It’s important to ensure the sealing ring is properly in place to maintain pressure.

Ideal Sealing Temperature for Electric Pressure Cookers

The ideal sealing temperature for electric pressure cookers typically ranges between 230°F (110°C) and 250°F (121°C). This temperature range allows the pressure cooker to create and maintain the desired pressure level for efficient cooking.

At these temperatures, the steam generated inside the pressure cooker increases in pressure, which helps to cook food faster. The higher the pressure, the higher the boiling point of water, resulting in shorter cooking times compared to traditional cooking methods.

Most electric pressure cookers have pre-set pressure levels, such as low, medium, and high. The low pressure setting is generally around 230°F (110°C), while the high pressure setting can reach up to 250°F (121°C). These temperature ranges ensure that the pressure cooker can cook a variety of foods, from delicate vegetables to tough cuts of meat.

It’s important to note that different recipes may require specific pressure levels and cooking times. Therefore, it’s essential to follow the recipe instructions to achieve the best results. The recommended cooking time and pressure level will vary depending on the type and quantity of food being cooked.

By maintaining the ideal sealing temperature in your electric pressure cooker, you can enjoy the benefits of fast and efficient cooking. However, it’s also important to be aware of common issues that may affect the sealing temperature.

Let’s explore some common issues with sealing in electric pressure cookers and how to overcome them.

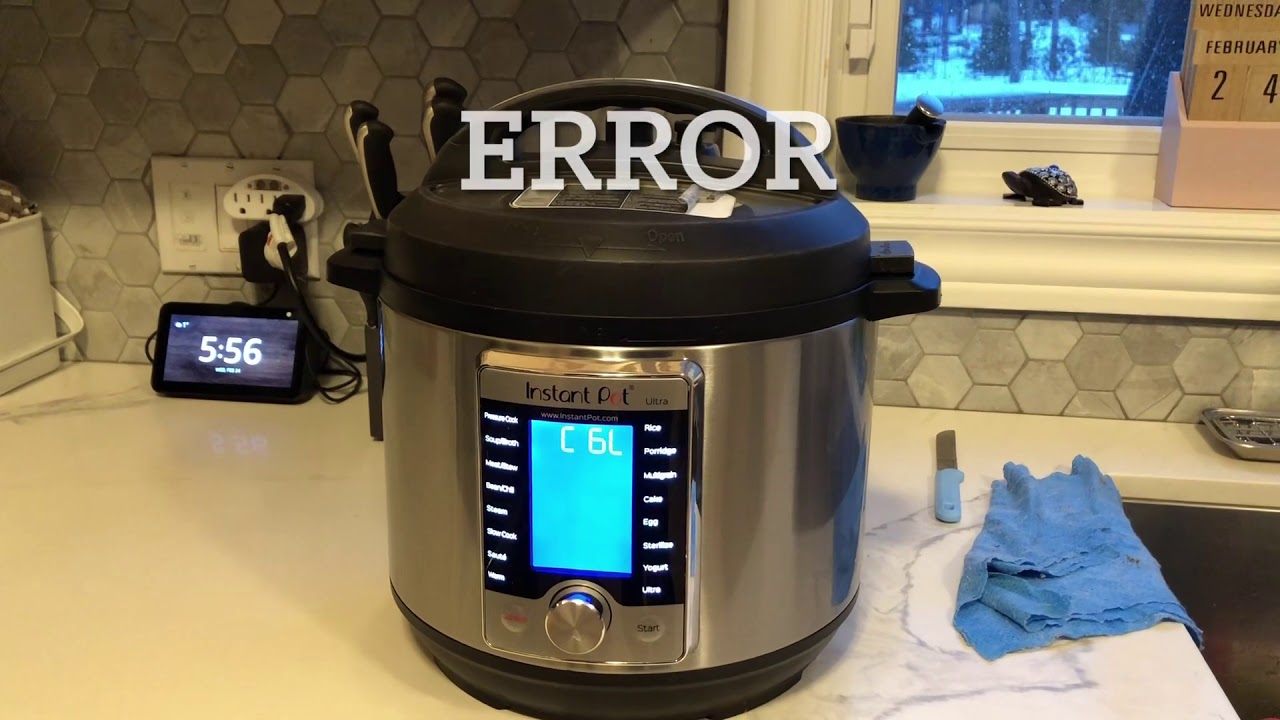

Common Issues with Sealing in Electric Pressure Cookers

While electric pressure cookers are generally reliable and efficient, there are a few common issues that can affect the sealing mechanism and impact the cooking process. Being aware of these issues will help you troubleshoot and overcome any problems that may arise.

1. Gasket Problems: Over time, the gasket in your electric pressure cooker may become worn out, damaged, or misaligned. This can result in poor sealing and steam leakage. Regularly inspect the gasket for any signs of wear and replace it if necessary. Ensure that the gasket is properly seated and aligns with the pot and lid for a secure seal.

2. Debris on Sealing Surfaces: Any debris or food particles on the sealing surfaces, such as the gasket and lid rim, can prevent a proper seal from forming. Clean these surfaces thoroughly before each use to ensure a tight seal. Use a soft cloth or sponge to wipe away any residue and ensure a clean contact surface for sealing.

3. Pressure Release Valve Issues: The pressure release valve is crucial for regulating the pressure inside the pressure cooker. If the valve is damaged, dirty, or not properly aligned, it can cause steam to escape and prevent an airtight seal. Clean and inspect the pressure release valve regularly, and ensure it is functioning correctly.

4. Overfilled Pot: Overfilling the pressure cooker beyond the maximum fill line can lead to excessive steam and pressure buildup, which can affect the sealing mechanism. Follow the manufacturer’s guidelines and avoid exceeding the recommended fill level. Leave sufficient space for the food to expand during the cooking process.

5. Lid Misalignment: Improper lid alignment can result in steam leakage and an ineffective seal. Double-check that the lid is correctly aligned and securely locked in place before starting the cooking process. If the lid is not aligned properly, adjust it until it fits snugly on the pot.

6. Faulty or Worn-out Safety Components: Electric pressure cookers are equipped with safety features, such as the pressure release valve and locking mechanism. If these components are faulty or worn out, they may impact the sealing and overall performance of the pressure cooker. Regularly inspect and maintain these safety components to ensure their proper functioning.

By being aware of these common sealing issues in electric pressure cookers and taking the necessary steps to address them, you can ensure a tight seal and optimal cooking results.

Now that we’ve discussed the common issues with sealing, let’s explore some tips for maintaining the proper sealing temperature in your electric pressure cooker.

Tips for Maintaining Proper Sealing Temperature

Maintaining the proper sealing temperature in your electric pressure cooker is essential for efficient and successful cooking. Here are some valuable tips to help you achieve and maintain the ideal sealing temperature:

1. Inspect and Clean the Sealing Components: Regularly inspect the gasket, lid, and pressure release valve for any signs of wear, damage, or debris. Clean these components thoroughly before each use to ensure a tight and secure seal.

2. Properly Align the Lid: Ensure that the lid is aligned properly with the pot before starting the cooking process. The lid should fit snugly and securely to create an airtight seal. Double-check the alignment and lock the lid in place securely.

3. Use the Recommended Cooking Liquid: Follow the manufacturer’s instructions and use the recommended amount of cooking liquid. This ensures the proper steam generation and pressure buildup inside the pot, resulting in the desired sealing temperature.

4. Avoid Overfilling the Pot: Do not exceed the maximum fill line indicated on the pressure cooker. Overfilling can lead to excessive steam and pressure buildup, affecting the sealing mechanism. Leave enough space for the food to expand during cooking.

5. Maintain the Sealing Ring: The sealing ring or gasket is a crucial component for achieving an airtight seal. Regularly inspect the condition of the sealing ring and replace it if necessary. Lubricate the sealing ring according to the manufacturer’s instructions to keep it in optimal condition.

6. Check the Pressure Release Valve: Ensure that the pressure release valve is clean and in proper working condition. Remove any obstructions or debris that may hinder its functionality. Test the valve to confirm that it releases pressure correctly when needed.

7. Monitor Ambient Temperature: Keep in mind that the ambient temperature in your kitchen can affect the sealing temperature. Higher room temperatures may result in higher sealing temperatures, while lower temperatures may require longer cooking times. Adjust the cooking time accordingly to achieve the desired results.

8. Follow Recipe Instructions: Different recipes may require specific pressure levels and cooking times. Follow the recipe instructions carefully to ensure that you achieve the best results. This includes setting the appropriate pressure level, cooking time, and release method for each recipe.

By implementing these tips, you can maintain the proper sealing temperature in your electric pressure cooker and enjoy efficient and flavorful cooking.

Now that we have explored the tips for maintaining optimal sealing temperature, let’s conclude our discussion.

Conclusion

Understanding the sealing temperature of an electric pressure cooker is essential for efficient and successful cooking. By maintaining the ideal sealing temperature, you can enjoy the benefits of fast, flavorful, and nutrient-rich meals prepared in a fraction of the time.

We have explored the key components of electric pressure cookers, including the sealing mechanism, which ensures an airtight cooking environment. The sealing temperature typically ranges between 230°F (110°C) and 250°F (121°C), allowing the pressure cooker to reach and maintain the desired pressure level for optimal results.

Factors such as gasket condition, lid alignment, pressure release valve functionality, cooking liquid, ambient temperature, and proper maintenance all play a role in achieving and maintaining the sealing temperature. Being aware of common sealing issues and following the recommended tips will help troubleshoot any problems and maintain a tight seal for efficient cooking.

Electric pressure cookers have revolutionized the way we cook, providing convenience, versatility, and speed without compromising flavor or nutrition. Whether you’re preparing a savory stew, tender meat dish, or perfectly steamed vegetables, understanding and maintaining the sealing temperature will ensure that each meal turns out consistently delicious.

Remember to regularly inspect and clean the sealing components, align the lid correctly, use the recommended amount of cooking liquid, and avoid overfilling the pot. Pay attention to the condition of the sealing ring and ensure the pressure release valve is in good working order. Adjust your cooking time based on the ambient temperature and always follow recipe instructions.

By following these guidelines, you can master the art of cooking with your electric pressure cooker. Enjoy the convenience and efficiency it offers, while delighting your taste buds with flavorful, healthy meals.

So, next time you’re in the kitchen, confidently set the ideal sealing temperature in your electric pressure cooker and let it work its magic. Bon appétit!

Frequently Asked Questions about At What Temperature Does An Electric Pressure Cooker Seal

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “At What Temperature Does An Electric Pressure Cooker Seal”