Articles

How To Choose The Right Conduit Size

Modified: August 27, 2024

Learn how to determine the correct size of conduit you need for your electrical installation with our informative articles.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

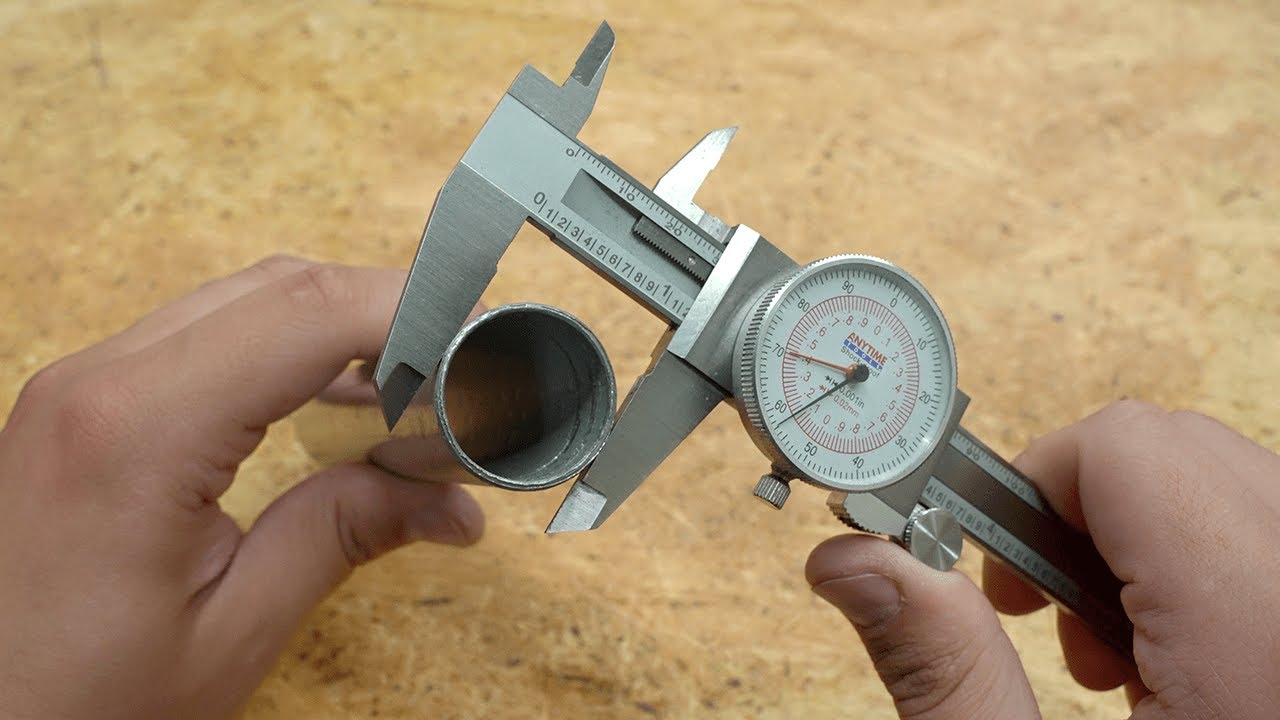

When it comes to electrical installations and wiring, conduits play a crucial role in protecting and organizing the cables. Conduits act as a protective pathway that shields the wires from external factors such as moisture, heat, and physical damage. They also help to maintain a neat and organized appearance, making it easier to identify and access the cables when needed.

However, choosing the right size of conduit is important to ensure that it can accommodate the number and size of the cables that will be installed. Using the wrong size of conduit can lead to overcrowding, difficulty in pulling the wires through, and potential safety hazards.

In this article, we will delve into the factors that need to be considered when determining the size of conduit for your electrical installation. We will also discuss how to calculate the conduit size and provide some examples for better understanding.

So, if you’ve ever wondered, “How big of a conduit do I need?” read on to find the answers and gain a deeper understanding of this essential aspect of electrical wiring.

Key Takeaways:

- Choosing the right conduit size is crucial for electrical installations. Consider factors like cable size, bends, and future expansion to ensure safety and efficiency.

- Calculating conduit size involves determining fill capacity, considering bends, and checking local codes. Proper sizing is essential for safety and functionality.

Read more: How To Choose The Right Bean Bag Chair Size

Understanding Conduits

Before we dive into the process of determining the right size of conduit, let’s first understand what conduits are and how they function.

A conduit is a pipe or tube that is used to protect and route electrical wires and cables. It is typically made of materials such as PVC (Polyvinyl Chloride), metal, or fiberglass. Conduits serve three main purposes:

- Protection: Conduits protect the electrical cables from external elements such as moisture, chemicals, abrasion, and physical damage. This is especially important in areas where the wiring is exposed or in environments that pose potential hazards.

- Organization: By providing a dedicated pathway for the cables, conduits help to keep the installation neat and organized. This makes it easier to identify and access specific cables when maintenance or repairs are required.

- Ease of Installation: Conduits make the process of pulling and replacing cables more straightforward. They act as a guide, allowing for a smooth and efficient installation process.

Conduits are available in various sizes and types, with each serving different purposes. Some common types of conduits include:

- Rigid Metal Conduit (RMC): This type of conduit is made of galvanized steel or aluminum. It provides the highest level of protection and is suitable for heavy-duty and outdoor applications.

- Electrical Metallic Tubing (EMT): EMT is made of thin-walled steel tubing and is more flexible than RMC. It is commonly used in residential and commercial buildings.

- Rigid Non-Metallic Conduit (RNC): RNC, also known as PVC conduit, is made of a durable plastic material. It is lightweight, affordable, and resistant to moisture, making it a popular choice in various installations.

Understanding the different types of conduits and their properties will help you make an informed decision when selecting the appropriate conduit for your specific electrical installation project.

Factors to Consider

Now that we have a basic understanding of conduits, let’s explore the factors that need to be considered when determining the size of conduit for your electrical installation:

- Number and Size of Cables: The primary consideration is the number and size of the cables that will be installed in the conduit. Each cable requires a certain amount of space, known as “fill capacity.” The fill capacity depends on factors such as the diameter of the cables, insulation thickness, and the type of conductor material. It is important to ensure that the conduit can accommodate all the cables without exceeding its maximum fill capacity.

- Bends and Turns: Conduits often need to navigate around corners, bends, or turns. It is crucial to consider the impact of these changes in direction on the overall fill capacity of the conduit. Bends and turns can reduce the available space for cables and may require a larger conduit size to compensate for the increased difficulty in pulling the wires through.

- Future Expansion: It is wise to plan for future expansions or additions to the electrical system. This means considering the potential need for additional cables in the conduit. It is recommended to leave some extra space in the conduit to accommodate future wiring changes or additions.

- Environmental Factors: The environment in which the conduit will be installed plays a role in determining the conduit size. Factors such as temperature, humidity, exposure to chemicals, and the presence of corrosive substances can affect the choice of conduit material and size.

- Building Codes and Regulations: Local building codes and regulations may have specific requirements regarding conduit sizing. It is essential to consult the relevant codes and adhere to the guidelines to ensure compliance and safety.

Considering these factors will help you determine the appropriate conduit size that can accommodate the current and future wiring needs while ensuring compliance with safety standards.

When determining the size of conduit needed, consider the number and size of the wires or cables that will be running through it. A general rule of thumb is to size the conduit at least 25% larger than the total diameter of all the wires or cables.

Calculating Conduit Size

Now that we understand the factors to consider, let’s delve into the process of calculating the size of conduit required for your electrical installation:

- Determine the Fill Capacity: Start by determining the fill capacity of the conduit. This can be done using a conduit fill chart, which provides information on the maximum number and size of cables that can be safely installed in a specific conduit size.

- Calculate Cable Fill: Calculate the fill capacity required by each cable based on its diameter and insulation thickness. This information can usually be found in manufacturer specifications or cable diameter tables.

- Sum Up Cable Fill: Add up the cable fill capacities for all the cables that will be installed in the conduit.

- Consider Bend Radius: If there are bends, turns, or offsets in the conduit, you need to consider the impact on the available space. The National Electrical Code (NEC) provides guidelines on the bend radius and conduit fill adjustment factors to account for these changes in direction.

- Factor in Future Expansion: As mentioned earlier, it is recommended to leave some extra space in the conduit for future expansion. Consider the potential need for additional cables and increase the conduit size accordingly.

- Check Local Codes: Lastly, cross-check your calculations and conduit size selection with the local building codes and regulations to ensure compliance.

Using these steps, you can accurately calculate the conduit size required for your specific electrical installation project. It is crucial to ensure that the calculated conduit size meets the fill capacity requirements and allows for future expansions if needed.

Conduit Sizing Examples

Let’s take a look at a couple of examples to illustrate how conduit sizing works in practical situations:

Example 1:

You are planning to install a conduit for a residential electrical wiring project. The project involves running three 12-gauge THHN copper cables.

- Determine the fill capacity: Refer to the conduit fill chart and find the appropriate conduit size for three 12-gauge THHN copper cables.

- Calculate cable fill: Determine the fill capacity required for each 12-gauge cable based on its diameter and insulation thickness.

- Sum up cable fill: Add up the fill capacities required for the three 12-gauge cables.

- Consider bend radius: If there are any bends or turns in the conduit, ensure to adjust the conduit fill capacity accordingly.

- Factor in future expansion: Determine if there is a likelihood of future wiring additions and adjust the conduit size accordingly.

- Check local codes: Verify that your conduit size selection is compliant with local building codes and regulations.

Example 2:

You are working on a commercial building project that requires conduit sizing for multiple electrical circuits. You have a mix of 14-gauge and 10-gauge THHN aluminum cables that need to be installed.

- Determine the fill capacity: Refer to the conduit fill chart and find the appropriate conduit size for the number and size of cables you will be installing.

- Calculate cable fill: Determine the fill capacity required for each cable based on its diameter and insulation thickness.

- Sum up cable fill: Add up the fill capacities required for all the cables that will be installed in the conduit.

- Consider bend radius: Take into account any bends or turns in the conduit and adjust the fill capacity accordingly.

- Factor in future expansion: Leave sufficient space in the conduit to accommodate any future wiring additions or expansions.

- Check local codes: Ensure that your conduit size selection complies with the local building codes and regulations.

By following these examples and considering the factors discussed earlier, you can accurately determine the appropriate conduit size for your electrical installation projects.

Conclusion

Choosing the right size of conduit is crucial for any electrical installation project. It ensures the proper protection and organization of cables while facilitating ease of installation and maintenance. By considering factors such as the number and size of cables, bends and turns, future expansion, environmental factors, and local codes, you can accurately determine the appropriate conduit size.

Remember, using a conduit that is too small can lead to overcrowding, difficulty in cable pulling, and potential safety hazards. On the other hand, using a conduit that is too large can waste resources and create an unnecessary cluttered appearance.

To calculate the conduit size, you need to determine the fill capacity required for the cables, consider bends and turns, factor in future expansions, and check local codes. By following these steps, you can ensure that the chosen conduit size meets the necessary requirements.

It is essential to consult conduit fill charts, cable diameter specifications, and local building codes to make informed decisions. Additionally, seeking the guidance of a qualified professional can provide valuable insights and ensure compliance with safety standards.

Proper conduit sizing is essential for both residential and commercial electrical installations. It not only guarantees the safety and functionality of the electrical system but also allows for flexibility and future expansions.

So, the next time you find yourself asking, “How big of a conduit do I need?” take the time to carefully assess the factors and calculations involved. By doing so, you can ensure a successful and efficient electrical installation that meets all the necessary requirements.

Frequently Asked Questions about How To Choose The Right Conduit Size

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Choose The Right Conduit Size”