Articles

How To Store Paper Pulp

Modified: December 7, 2023

Learn how to properly store paper pulp and protect your articles for long-term use. Find tips and techniques for preserving the quality and lifespan of your valuable paper products.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of paper pulp storage! In this article, we will explore the best practices for storing paper pulp to ensure its quality and longevity. Paper pulp is a vital ingredient in the production of various paper-based products such as paper sheets, cardboard, and packaging materials. Proper storage of paper pulp is crucial to preserve its properties and ensure its usability when needed.

Whether you are a paper manufacturer, a supplier, or someone who uses paper pulp in their business, understanding the fundamentals of paper pulp storage is essential. By implementing the right storage techniques, you can minimize waste, reduce costs, and maintain the integrity of the pulp.

In this article, we will delve into the factors to consider when storing paper pulp, explore the different storage containers available, and provide valuable tips on preparing and maintaining the pulp during storage. We will also discuss the importance of monitoring and best practices to ensure the optimum condition of your paper pulp.

So, let’s dive into the fascinating world of paper pulp storage and learn how to store it effectively!

Key Takeaways:

- Proper storage of paper pulp is crucial to maintain its quality and usability. Factors such as temperature, humidity, and ventilation play a vital role in creating the ideal storage conditions for paper pulp.

- Choosing the right storage containers, preparing the paper pulp for storage, and implementing best practices contribute to minimizing waste, reducing costs, and ensuring the delivery of high-quality paper-based products.

Read more: How To Store Almond Pulp

Understanding Paper Pulp

Before we delve into the details of paper pulp storage, let’s first understand what paper pulp is. Paper pulp is the raw material used to make paper and paper-based products. It is produced by breaking down wood fibers, typically from trees, into a fibrous slurry through a process called pulping.

The pulping process involves extracting cellulose fibers from wood using mechanical or chemical methods. Mechanical pulping, such as stone grinding or refining, produces coarser pulp with good strength but lower brightness. On the other hand, chemical pulping, such as the popular kraft pulping method, uses chemicals to dissolve lignin, resulting in a more refined and higher-quality pulp.

Paper pulp can also be made from other sources besides wood. Recycled paper, agricultural residues, and even non-wood fibers like bamboo can be used as raw materials for pulp production. The type of pulp used depends on the end product’s desired characteristics, cost considerations, and environmental factors.

It’s worth noting that paper pulp can have varying levels of moisture content, depending on the pulping process and intended use. Controlling moisture levels is crucial in paper pulp storage to prevent mold growth, pulp degradation, and quality issues.

Now that we have a basic understanding of paper pulp, let’s explore the key factors to consider when storing it to ensure its optimal condition and usability.

Factors to Consider for Paper Pulp Storage

When it comes to storing paper pulp, several factors should be taken into consideration to ensure its preservation and usability. Let’s explore these factors in detail:

- Temperature and Humidity: Paper pulp should be stored in a controlled environment with stable temperature and humidity levels. Fluctuations in temperature and humidity can cause moisture absorption or loss, leading to dimensional changes, reduced strength, and mold growth. Aim for a temperature between 20-25 degrees Celsius and a relative humidity of 45-55%.

- Ventilation: Proper ventilation is crucial in paper pulp storage to prevent the buildup of moisture and the development of odors. Ensure that the storage area is well-ventilated to allow air circulation and minimize the risk of condensation and mold formation.

- Light Exposure: Paper pulp is sensitive to light, especially ultraviolet (UV) radiation. Prolonged exposure to sunlight or artificial light can cause yellowing, fading, and degradation of the fibers. Store paper pulp in a dark or low-light area to protect it from light damage.

- Cleanliness: The storage area should be clean and free from dust, dirt, and other contaminants. Any impurities in the storage environment can affect the quality of the paper pulp and potentially introduce foreign particles into the final paper product. Regular cleaning and maintenance of the storage area are essential in this regard.

- Stacking and Handling: Correct stacking and handling of paper pulp is crucial to prevent damage and maintain its integrity. Avoid excessive stacking heights to prevent compression and deformation of the pulp. Use proper lifting and handling equipment to minimize the risk of tearing or ripping the pulp sheets.

- Proximity to Water and Chemicals: It is important to store paper pulp away from water sources, such as pipes, leaking roofs, or areas prone to flooding. Additionally, keep the pulp away from chemicals or substances that can contaminate or react with the fibers and affect the quality of the paper pulp.

- Inventory Management: Implement a proper inventory management system to ensure the rotation of paper pulp stock. Use a “first in, first out” (FIFO) approach to prevent storing the pulp for excessive periods and to avoid potential deterioration or quality issues with older stock.

By considering these factors and implementing appropriate measures, you can ensure that your paper pulp remains in optimal condition throughout the storage duration.

Storage Containers for Paper Pulp

Choosing the right storage containers for paper pulp is crucial in maintaining its quality and protecting it from external factors. Let’s explore some common storage container options:

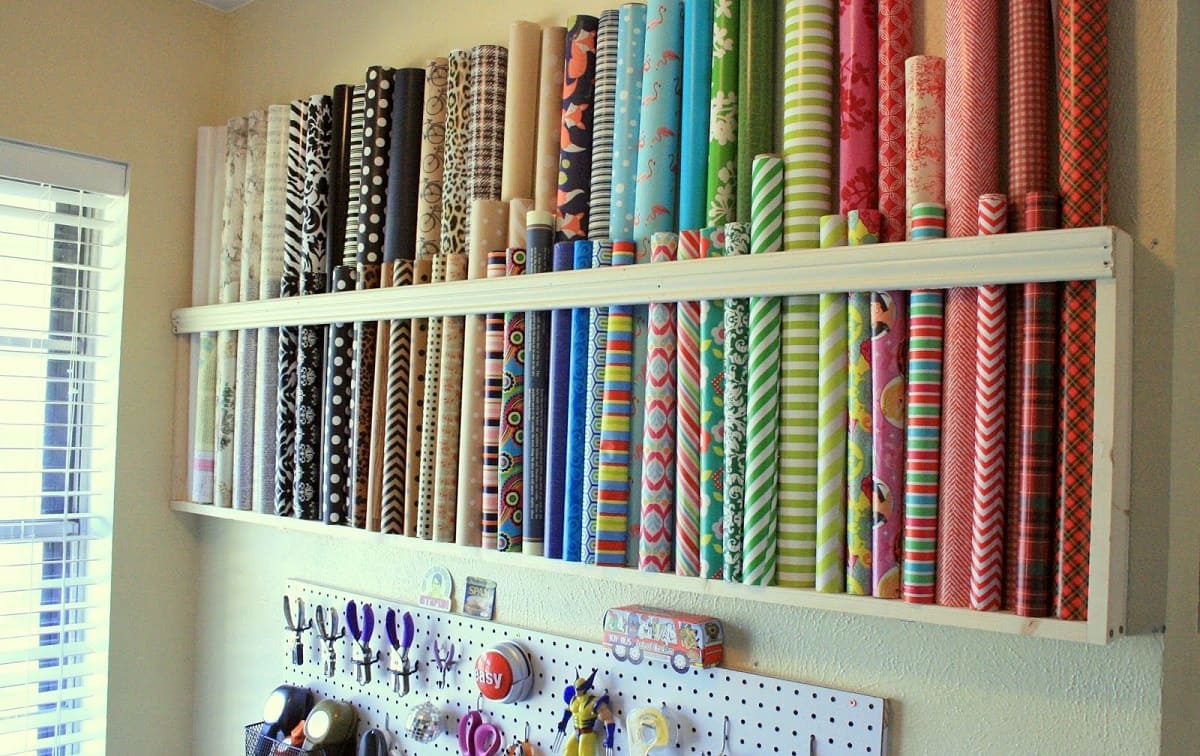

- Paper Rolls and Reels: Paper rolls and reels are commonly used for storing large quantities of paper pulp. These containers provide efficient storage and allow for easy unwinding and usage. Make sure to store the rolls in a dry and clean area to prevent moisture absorption and damage to the pulp.

- Plastic or Steel Drums: Plastic or steel drums are suitable for storing smaller volumes of paper pulp. They provide protection against moisture, dust, and contaminants. Ensure that the drums are sealed tightly to prevent air and moisture intrusion.

- Pallets and Skids: Pallets and skids are excellent options for bulk storage of paper pulp. They provide stability, easy handling, and prevent direct contact of the pulp with the ground. Stack the pallets or skids in a suitable storage area, ensuring proper ventilation and avoiding excessive stacking heights.

- Insulated Silos: Insulated silos are ideal for large-scale storage of paper pulp. They provide temperature control, protection from external elements, and efficient space utilization. Implement a monitoring system to track the temperature and humidity levels inside the silos and ensure they are within the desired range.

- Sealed Containers or Bags: For small-scale or short-term storage, sealed containers or bags made of moisture-resistant materials can be used. Ensure that the containers or bags are properly sealed and stored in a clean and dry environment to prevent moisture absorption and contamination.

When selecting storage containers, consider factors such as the volume of pulp, duration of storage, ease of handling, and the specific requirements of your pulp type. It’s essential to choose containers that provide adequate protection, minimize exposure to external elements, and facilitate easy access and retrieval of the pulp when needed.

Remember to label each container with relevant information such as pulp type, date of storage, and any special instructions to ensure proper identification and inventory management.

By using suitable storage containers, you can significantly contribute to the longevity and preservation of your paper pulp supply.

Preparing Paper Pulp for Storage

Properly preparing paper pulp for storage is crucial in ensuring its long-term preservation and usability. Here are some essential steps to follow when preparing paper pulp for storage:

- Drainage and Drying: If the paper pulp has high moisture content after production, it is crucial to allow for proper drainage and drying before storage. Use appropriate equipment such as screens or filters to remove excess water from the pulp. Spread the pulp on drying racks or trays in a well-ventilated area until it reaches the desired moisture level.

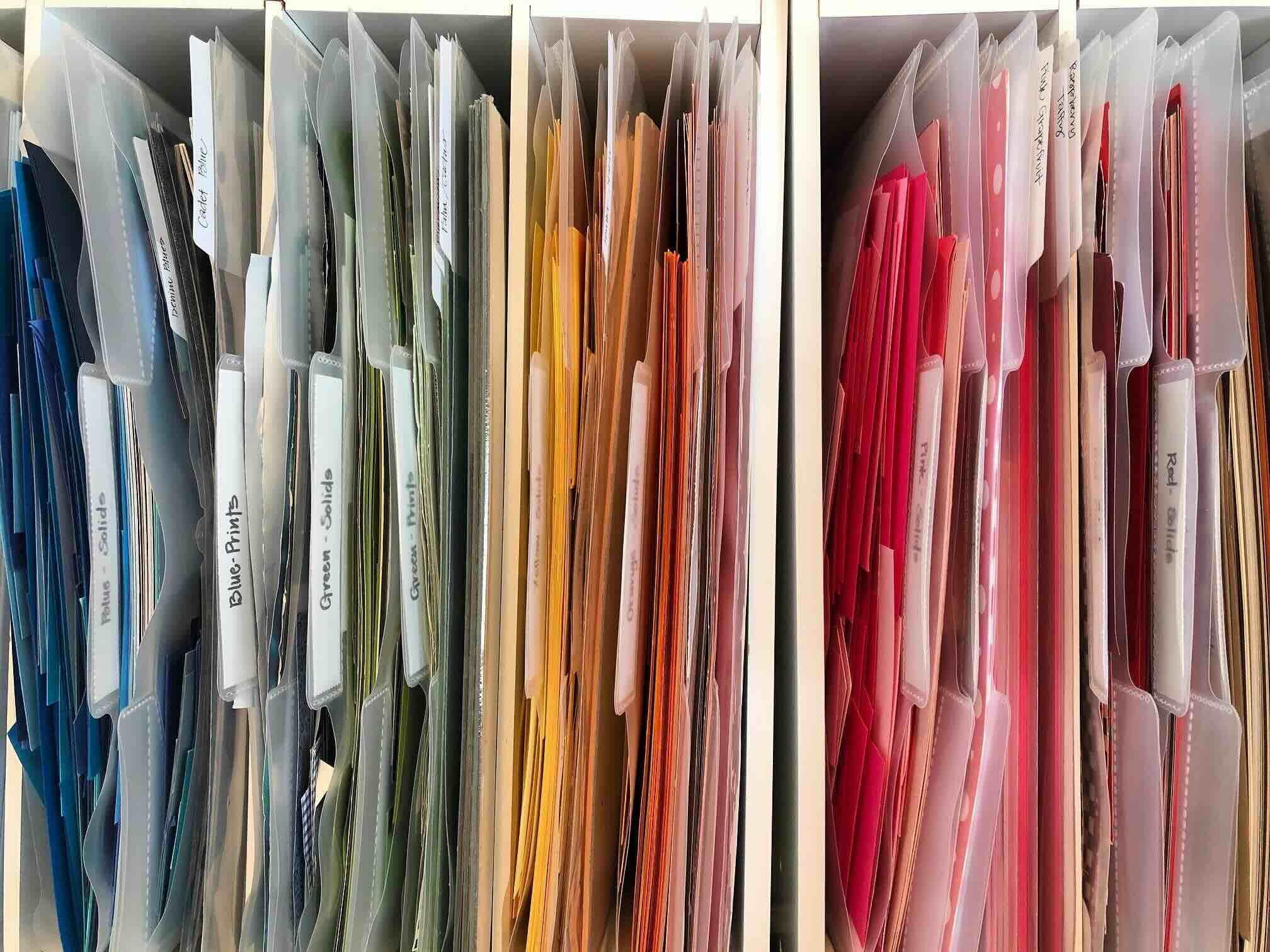

- Sheet Formation: To facilitate easier handling and storage of paper pulp, consider transforming it into sheets or manageable sizes. Using appropriate equipment, such as a sheet former or hydraulic press, create uniform sheets of the desired thickness. Ensure that the sheets are free from wrinkles, tears, or any other physical defects that may compromise their quality during storage.

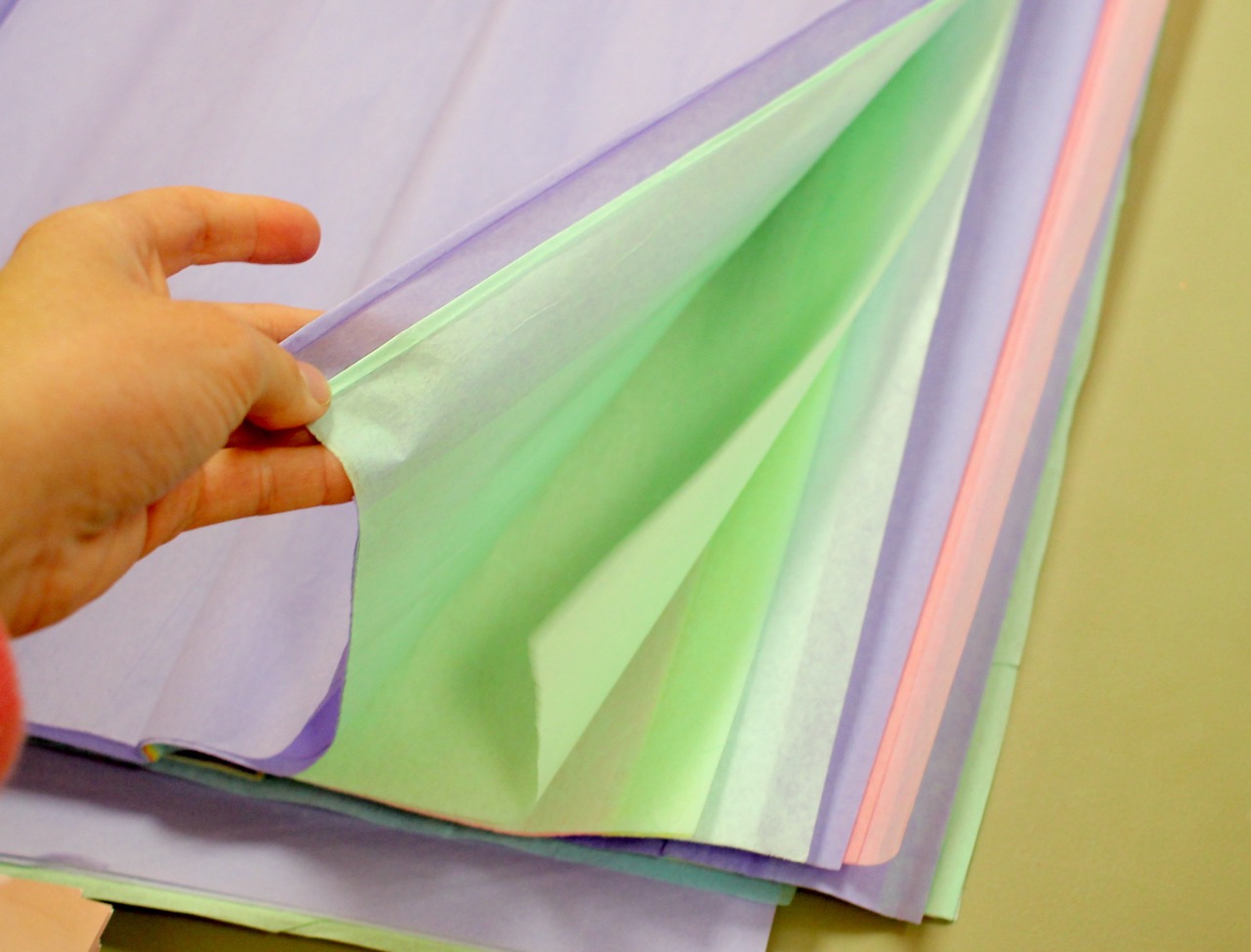

- Interleaving: If you stack paper pulp sheets for storage, it is advisable to use interleaving materials between the layers. Interleaving helps prevent sticking and fiber transfer between sheets, especially if the pulp has high moisture content. Use materials such as silicone-release paper or non-stick plastic sheets to separate the layers effectively.

- Quality Inspection: Before storing the paper pulp, perform a thorough quality inspection to ensure that it meets the desired specifications. Check for any abnormalities, such as color variations, foreign particles, or contamination. Remove any defective or substandard pulp from the storage inventory to maintain the overall quality.

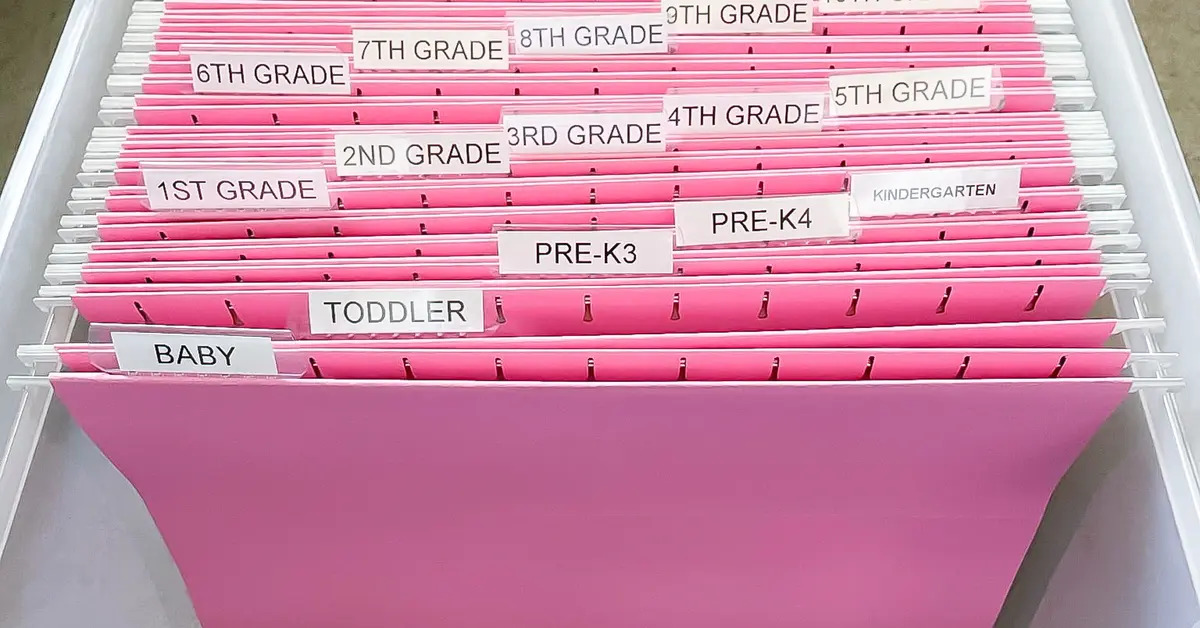

- Labeling and Documentation: Properly label each batch or package of paper pulp with relevant information such as pulp type, date of preparation, production batch, and any specific instructions for storage or usage. Maintain accurate documentation to track the movement and condition of the stored pulp effectively.

By following these preparatory steps, you can optimize the condition of your paper pulp before storage and minimize the risk of quality degradation. It’s important to note that each paper pulp type may have specific preparation requirements, so consult the manufacturer’s guidelines or industry standards for best practices specific to your pulp.

Remember, proper preparation sets the foundation for successful paper pulp storage and ensures its usability when needed for production or further processing.

When storing paper pulp, make sure to keep it in a dry and well-ventilated area to prevent mold and mildew growth. It’s also important to protect it from direct sunlight and moisture to maintain its quality.

Read more: How To Store Important Papers

Proper Storage Conditions for Paper Pulp

Maintaining the right storage conditions is essential to preserve the quality and integrity of paper pulp. Here are some key considerations for maintaining proper storage conditions:

- Temperature: Paper pulp should be stored at a controlled temperature to prevent any adverse effects on its properties. Ideal storage temperatures range from 20 to 25 degrees Celsius (68 to 77 degrees Fahrenheit). Avoid storing pulp in areas that are subject to extreme temperature fluctuations or direct exposure to heat sources.

- Humidity: Maintaining the correct humidity level is critical in preventing moisture-related issues with paper pulp. Aim for a relative humidity between 45% and 55%. Excessive moisture can lead to mildew growth, fiber degradation, and mold formation. Conversely, overly dry conditions can cause the pulp to become brittle and prone to cracking.

- Ventilation: Proper ventilation is necessary to ensure adequate airflow in the storage area. Well-ventilated spaces help control humidity levels, minimize the risk of condensation, and prevent the accumulation of odors. Avoid storing pulp in cramped or poorly ventilated areas that can restrict air circulation.

- Light: Paper pulp is sensitive to light, particularly ultraviolet (UV) radiation, which can cause discoloration and degradation. Store pulp in a dark or low-light area to minimize light exposure. If natural or artificial lighting is necessary, ensure it does not directly illuminate the stored pulp.

- Cleanliness: The storage area should be clean and free from dust, dirt, and other contaminants that can compromise the quality of the pulp. Regularly clean and maintain the storage area to prevent the introduction of foreign particles into the pulp.

- Protection from Water: Paper pulp should be safeguarded against contact with water or excessive moisture. Ensure that the storage area is well-protected from potential water sources, such as leaks or moisture intrusion. Store the pulp away from areas prone to flooding or high humidity, and use water-resistant containers or pallets to elevate the pulp off the floor.

- Pest Control: Implement measures to prevent pest infestations in the storage area. Pests, such as insects or rodents, can damage the pulp and introduce contaminants. Regularly inspect the storage area for signs of pests and take appropriate measures to control and eliminate them.

By adhering to these proper storage conditions, you can maintain the quality and usability of your paper pulp over an extended period. It is important to regularly monitor the storage area to ensure that the conditions are well-maintained and to address any potential issues promptly.

Remember, maintaining the optimal storage conditions for paper pulp is vital for preserving its properties, ensuring efficient production processes, and delivering high-quality paper-based products to your customers.

Maintaining Paper Pulp Quality During Storage

Proper storage practices are essential for maintaining the quality of paper pulp over prolonged periods. Here are some key steps you can take to ensure the integrity of your paper pulp during storage:

- Regular Inspections: Perform regular inspections of the stored paper pulp to check for any signs of degradation or damage. Look for changes in color, odor, or the presence of mold or pests. Early detection allows for timely intervention, preventing further deterioration and minimizing potential losses.

- Rotation and Usage: Implement a first-in, first-out (FIFO) system when using the stored paper pulp. By utilizing the oldest stock first, you can prevent pulp deterioration due to prolonged storage. Rotate the inventory regularly to maintain freshness and quality.

- Temperature and Humidity Control: Continuously monitor and maintain the desired temperature and humidity levels in the storage area. Fluctuations or extremes in temperature and humidity can cause moisture absorption, mold growth, or fiber degradation. Use monitoring devices such as hygrometers and thermometers to ensure optimum conditions.

- Handling with Care: Practice proper handling techniques when retrieving or moving paper pulp from storage. Avoid excessive roughness or impact that could cause tearing, wrinkling, or fiber damage. Use appropriate lifting equipment and handle the pulp with clean, dry hands or gloves to prevent contamination.

- Protection from Contaminants: Safeguard the stored paper pulp from potential contaminants that can affect its quality. Ensure that the storage area is kept clean, free of dust, and away from chemicals or substances that could react with the pulp. Use sealed containers or packaging to prevent the entry of foreign particles or contaminants.

- Proper Stacking and Space Utilization: When stacking paper pulp, ensure that the weight and height of the stacks are within safe limits. Avoid excessive compression or deformation of the pulp. Allow for adequate space between stacks to promote air circulation and prevent moisture buildup.

- Record-keeping: Maintain accurate records of the stored pulp, including dates of storage, batch numbers, and relevant quality information. This documentation helps track storage duration and allows for traceability in case of issues or quality concerns.

By consistently following these maintenance practices, you can preserve the quality of your paper pulp during storage. Remember that proper storage conditions, regular inspections, and careful handling are key to preventing quality degradation and ensuring the pulp’s usability when it is needed for production or processing.

Implementing a proactive approach to maintaining paper pulp quality during storage can have significant benefits, such as minimizing waste, reducing costs, and delivering high-quality products to your customers.

Monitoring Paper Pulp Storage

Monitoring the storage conditions of paper pulp is crucial to ensure its quality and prevent any issues that may arise during storage. Here are some key aspects to consider when monitoring paper pulp storage:

- Temperature and Humidity: Regularly monitor the temperature and humidity levels in the storage area using appropriate devices such as thermometers and hygrometers. Check these readings periodically to ensure they remain within the desired range. Deviations from optimal conditions can indicate potential problems and prompt necessary adjustments.

- Moisture Content: Periodically measure the moisture content of the paper pulp to ensure it remains within the appropriate range. Utilize moisture meters or other testing techniques to determine the moisture level accurately. Monitoring moisture content is especially crucial for preventing mold growth, maintaining dimensional stability, and preserving fiber integrity.

- Visual Inspections: Regularly visually inspect the stored paper pulp for any signs of damage, contamination, or degradation. Look for changes in color, texture, or the presence of foreign particles. Visual inspections help identify issues at an early stage and allow for immediate corrective actions to be taken.

- Pest Control: Keep a vigilant eye for any signs of pest infestation, such as insects or rodents, in the storage area. Employ pest control measures to prevent and control any potential pest problems. Regularly inspect the surroundings and take appropriate actions if pests are detected.

- Record-keeping: Maintain detailed records of the storage conditions, inspections, and any corrective actions taken. Document temperature and humidity readings, moisture content levels, visual observations, and any relevant changes or incidents. This documentation helps track the history of the storage environment and serves as a reference for future assessments and audits.

- Communication and Collaboration: Foster open communication and collaboration between the storage team, quality control personnel, and relevant stakeholders. Regularly share monitoring results, observations, and recommendations to ensure everyone is aware of the storage conditions and any necessary improvements or actions.

- Continuous Improvement: Use the monitoring data and observations to identify patterns or trends that can lead to process improvements. Analyze the information collected over time to make informed decisions about storage practices, equipment, and environmental control measures. Constantly evaluate and refine your storage procedures to optimize the conditions for storing paper pulp.

By implementing a robust monitoring system, you can proactively identify and address any issues that may affect the quality of your stored paper pulp. Regular monitoring ensures that the storage conditions remain optimal, prevents potential problems from escalating, and helps maintain the integrity of the pulp for its intended use.

Remember, monitoring is an integral part of an effective paper pulp storage management system, contributing to the overall quality and usability of the stored pulp.

Best Practices for Paper Pulp Storage

To ensure the longevity and quality of your paper pulp during storage, it is important to follow these best practices:

- Create a Suitable Storage Area: Designate a specific storage area for paper pulp that meets the necessary requirements. This area should be clean, well-ventilated, and free from potential sources of moisture or contaminants.

- Implement Proper Inventory Management: Establish an efficient inventory management system to keep track of the stored paper pulp. Use labels, identification codes, or barcodes to easily identify and locate different batches or types of pulp.

- Train Staff on Handling and Storage: Provide proper training to employees responsible for handling and storing paper pulp. Teach them techniques for gentle handling, safe stacking, and maintaining proper storage conditions.

- Maintain an Adequate Stock Rotation: Adhere to a “first in, first out” (FIFO) method when using the paper pulp to prevent excessive storage time and quality deterioration. Rotate the inventory regularly to ensure that older stock is used first.

- Regularly Monitor Storage Conditions: Continuously monitor and record the temperature, humidity, and moisture content in the storage area. Conduct visual inspections to identify any signs of damage, pests, or contamination.

- Take Preventive Measures for Pest Control: Implement preventative measures to deter pests from the storage area. This can include using traps, regular cleaning, sealing any entry points, and maintaining cleanliness throughout the facility.

- Utilize Proper Storage Containers: Choose appropriate storage containers, such as paper rolls, drums, pallets, or silos, based on the volume and type of paper pulp. Ensure that the containers are clean, sturdy, and provide protection against moisture and contaminants.

- Establish Clear Communication Channels: Foster effective communication among team members involved in the storage process. Encourage regular updates, share inspection findings, and address any concerns or suggestions for improvement.

- Routine Maintenance and Cleaning: Regularly inspect and maintain the storage area and equipment to ensure proper functioning. Conduct routine cleaning to remove dust, dirt, and any potential contaminants that could compromise the quality of the paper pulp.

- Adhere to Manufacturer Guidelines: Follow the guidelines provided by the paper pulp manufacturer regarding storage conditions, handling recommendations, and shelf-life. These guidelines are specific to the type of pulp and ensure optimal storage practices.

By implementing these best practices, you can minimize the risk of quality degradation, ensure the long-term usability of paper pulp, and optimize the efficiency of your storage operations.

Remember, effective paper pulp storage practices contribute to cost savings, reduced waste, and the delivery of high-quality pulp for your production needs.

Read more: How To Store Paper Artwork

Conclusion

Proper storage of paper pulp is essential for preserving its quality and ensuring its usability in various paper-based products. By understanding the factors to consider, selecting suitable storage containers, and following best practices, you can maintain the integrity of your paper pulp throughout the storage period.

Factors such as temperature, humidity, ventilation, and cleanliness play a crucial role in creating the ideal storage conditions for paper pulp. Monitoring these conditions, along with conducting regular inspections and implementing preventive measures for pest control, are essential for avoiding quality degradation.

Choosing the right storage containers, such as paper rolls, drums, or pallets, helps protect the pulp from moisture, contaminants, and physical damage. Preparing the paper pulp for storage through drainage, sheet formation, and proper interleaving contributes to its long-term preservation and easy retrieval.

Maintaining the quality of paper pulp during storage requires continuous monitoring, effective communication among team members, and the establishment of sound inventory management practices. Regular rotation of stock, adherence to FIFO principles, and proper handling techniques contribute to minimizing waste and maintaining freshness.

By implementing these best practices for paper pulp storage, you can optimize the lifespan of your pulp, reduce costs, and ensure the delivery of high-quality products. Remember to consult the guidelines provided by the manufacturer and continually evaluate and refine your storage procedures to meet your specific requirements.

So, whether you are a paper manufacturer, supplier, or user of paper pulp, make sure to prioritize proper storage practices to maximize the value of your paper pulp and maintain its quality throughout its shelf life.

Frequently Asked Questions about How To Store Paper Pulp

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Store Paper Pulp”