Articles

What Is T12 Fluorescent Tubes

Modified: August 27, 2024

Discover everything you need to know about T12 fluorescent tubes in this informative article. Learn about their features, benefits, and how to use them effectively.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Fluorescent lighting has been a popular choice for illuminating various spaces, from homes to offices and commercial buildings, due to its energy efficiency and long lifespan. Among the different types of fluorescent tubes available, the T12 fluorescent tube has held a significant place in the market for many years.

In this article, we will explore the history, functionality, advantages, and disadvantages of T12 fluorescent tubes. We will also compare them with other types of fluorescent tubes, discuss their environmental impact, and highlight the applications and maintenance considerations associated with T12 tubes.

Whether you are an individual looking to upgrade your lighting system or a professional seeking a deeper understanding of fluorescent tube options, this article will provide valuable insights into T12 fluorescent tubes and their role in the world of lighting.

Key Takeaways:

- T12 fluorescent tubes, while historically significant and cost-effective, are being phased out due to lower energy efficiency and environmental impact. Transitioning to more efficient options like T8 and T5 tubes is crucial for sustainable lighting solutions.

- Regular maintenance, proper disposal, and consideration of upgrades to newer technologies are essential for maximizing lighting performance and minimizing environmental impact. Consulting with professionals can guide informed decisions for lighting system upgrades.

Read also: 8 Best Fluorescent Tubes T12 for 2024

History of T12 Fluorescent Tubes

The development of fluorescent lighting technology dates back to the early 20th century, with many inventors contributing to its evolution. In the 1930s, General Electric introduced the T12 fluorescent tube, which quickly gained popularity and became a standard choice for lighting fixtures.

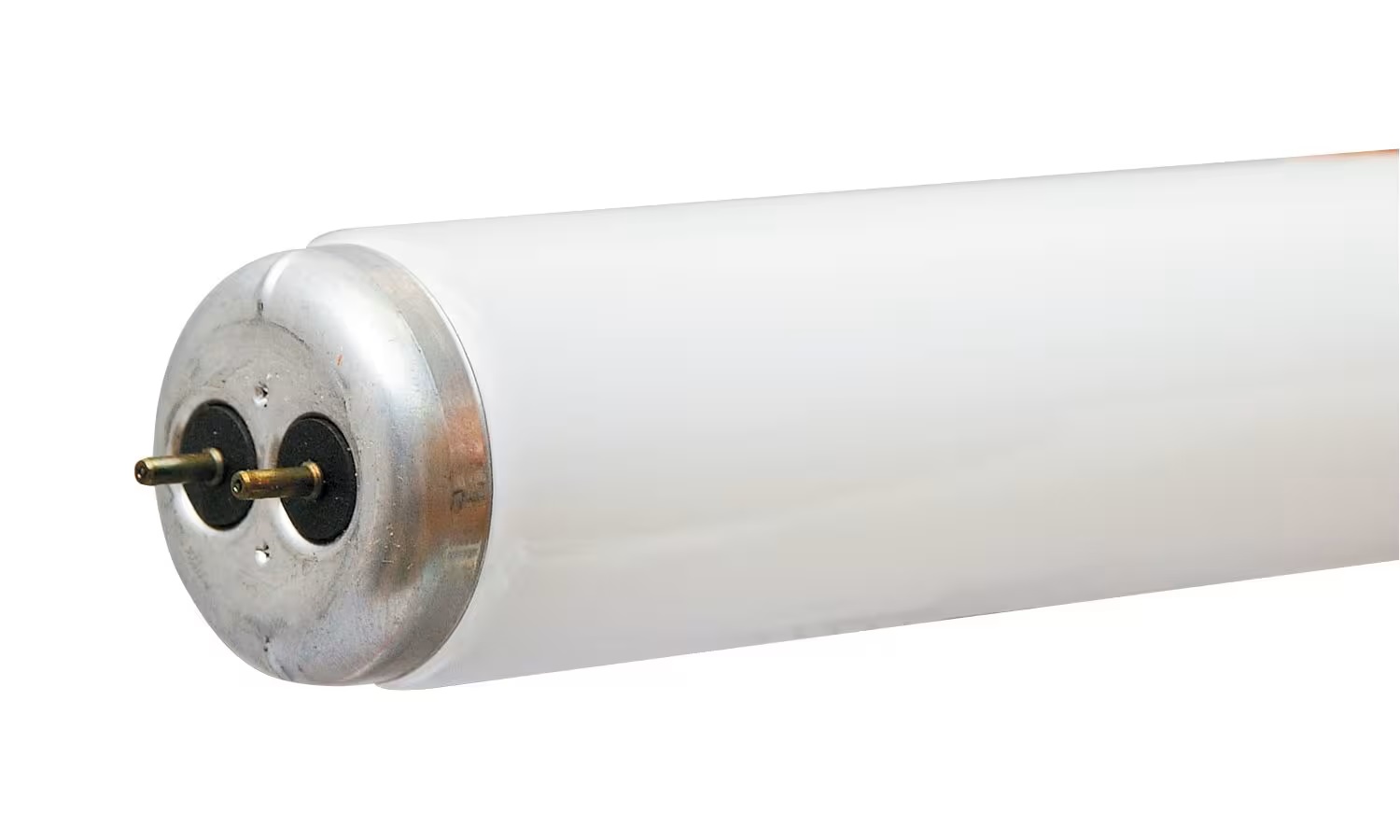

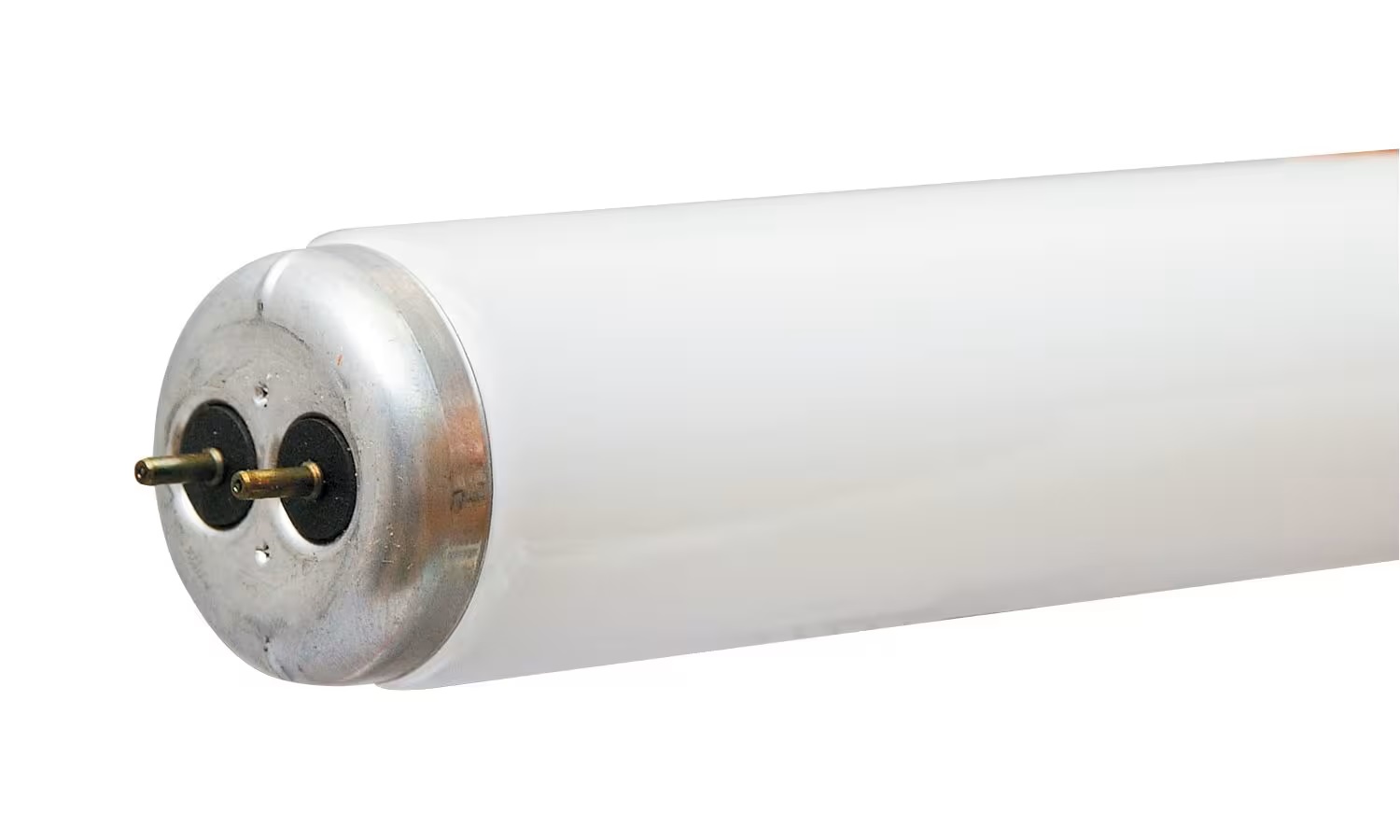

The “T” in T12 stands for “tubular,” referring to the shape of the lamp. The number 12 represents the diameter of the tube in eighths of an inch, which means that a T12 tube has a diameter of 1.5 inches (38 mm). This large diameter gives T12 tubes a distinctive appearance compared to newer, more streamlined fluorescent tubes.

During its early years, T12 fluorescent lighting offered significant advancements over traditional incandescent lighting. The T12 tubes were more energy-efficient and had a longer lifespan, making them a cost-effective choice for both residential and commercial lighting needs.

In the 1950s and 1960s, T12 fluorescent tubes became widespread, with their use expanding in various applications including schools, factories, and offices. They were known for providing bright, cool-white light and were used extensively in lighting fixtures such as troffers and strip lights.

However, as technology advanced, more efficient and compact fluorescent tube options, such as T8 and T5 tubes, were introduced to the market. These newer models offered improved energy efficiency and better lighting performance. As a result, the popularity of T12 tubes began to decline.

In recent years, the phasing out of T12 fluorescent tubes has been implemented in many regions due to their lower energy efficiency compared to newer options. The focus has shifted towards promoting more environmentally friendly and energy-saving lighting solutions in an effort to reduce carbon emissions and energy consumption.

While the general trend is to move away from T12 tubes, they can still be found in some older buildings or specialty applications where the existing fixtures are not compatible with newer fluorescent tubes.

Overall, the history of T12 fluorescent tubes reflects the continuous evolution of lighting technology and the constant drive to develop more efficient and sustainable lighting solutions.

How T12 Fluorescent Tubes Work

T12 fluorescent tubes use a process called fluorescence to produce light. Unlike traditional incandescent bulbs, which rely on a heated filament to emit light, fluorescent tubes operate through a combination of gas and phosphor coatings.

Inside a T12 fluorescent tube, there is a small amount of mercury vapor and a mixture of inert gases. The tube is coated with a phosphor powder on the inside surface. When an electric current flows through the tube, it excites the mercury vapor, causing it to emit ultraviolet (UV) light.

The UV light then interacts with the phosphor coating, resulting in a process called fluorescence. The phosphor absorbs the UV light and re-emits it as visible light. The type of phosphor used determines the color temperature, from warm white to cool white, of the light produced by the T12 tube.

In order to start the ionization process, T12 tubes require a ballast. The ballast regulates the electrical current flowing through the fluorescent tube and provides the initial voltage required to start the ionization process. Once the tube is illuminated and the current is stabilized, the ballast maintains a steady flow of electricity to keep the tube glowing.

One unique characteristic of T12 fluorescent tubes is their use of rapid-start ballasts. These ballasts provide a constant high voltage across the tube’s electrodes, ensuring a quick and consistent start-up. However, the drawback of rapid-start ballasts is that they consume more energy compared to newer electronic ballasts used in newer fluorescent tube models.

T12 fluorescent tubes are available in various lengths, wattages, and color temperatures to suit different lighting needs. They are compatible with a range of fixtures, including overhead lighting, task lighting, and indirect lighting applications.

Despite their declining popularity in recent years, T12 fluorescent tubes continue to provide reliable and cost-effective lighting solutions in certain contexts where they are still in use. However, it’s important to note that due to their lower energy efficiency compared to newer options, replacing T12 tubes with more efficient alternatives is often recommended to reduce energy consumption and environmental impact.

Advantages of T12 Fluorescent Tubes

T12 fluorescent tubes, despite becoming less common in today’s lighting market, still offer several advantages in certain situations and applications. Let’s explore some of the key benefits:

- Cost-effective: T12 tubes are generally more affordable compared to newer fluorescent tube models. They provide a cost-effective lighting solution, especially in situations where existing fixtures are compatible with T12 tubes.

- Bright Illumination: T12 tubes are known for their bright and uniform illumination. They produce a high level of light output, making them suitable for applications where a substantial amount of light is needed, such as in workspaces, factories, and commercial settings.

- Long Lifespan: T12 fluorescent tubes have a relatively long lifespan, lasting around 20,000 to 24,000 hours on average. This translates to several years of use before requiring replacement, reducing maintenance and replacement costs.

- Wide Variety: T12 tubes are available in a wide range of lengths, wattages, and color temperatures, providing flexibility in meeting diverse lighting needs. From warm white to cool white, there is a T12 tube to suit different environments and preferences.

- Compatibility: T12 tubes are compatible with a variety of fixtures, including troffers, strip lights, and other fluorescent lighting systems. This makes it easier to retrofit existing fixtures with T12 tubes, allowing for a seamless transition and minimizing the need for additional modifications.

- Familiarity: T12 fluorescent tubes have been in use for several decades, and many maintenance personnel and electricians are familiar with their installation and operation. This familiarity can be an advantage in situations where specific fixtures or systems are designed for T12 tubes.

While T12 fluorescent tubes continue to offer these advantages, it’s important to note that their lower energy efficiency compared to newer fluorescent tube options, such as T8 or T5 tubes, has led to their phasing out in many regions. In order to reduce energy consumption and environmental impact, transitioning to more energy-efficient alternatives is often recommended.

It’s also worth mentioning that as the availability and demand for T12 tubes decline, finding replacement tubes and ballasts for maintenance purposes may become more challenging. This is another factor to consider when evaluating the advantages of T12 fluorescent tubes.

Disadvantages of T12 Fluorescent Tubes

While T12 fluorescent tubes have served as a reliable lighting solution for many years, there are several disadvantages associated with their use, particularly compared to newer fluorescent tube options. Let’s explore some of these drawbacks:

- Lower Energy Efficiency: T12 tubes have lower energy efficiency compared to newer models like T8 and T5 tubes. They consume more energy to produce the same amount of light output, resulting in higher energy costs.

- Phasing Out: Many regions and governments have implemented regulations phasing out T12 fluorescent tubes due to their lower energy efficiency. This makes it increasingly difficult to find replacement tubes and accessories, and may require upgrading or retrofitting lighting fixtures.

- Bulkier Size: T12 tubes have a larger diameter compared to newer fluorescent tubes, making them bulkier and less visually appealing. Their size can limit their application in certain fixtures where a slimmer tube is preferred.

- Less Light Output Control: T12 tubes provide limited options for controlling light output. They typically offer a fixed output level and are less compatible with dimming controls, reducing the flexibility to adjust lighting levels according to specific needs or preferences.

- Shorter Lifespan: While T12 tubes do have a relatively long lifespan compared to incandescent bulbs, they generally have a shorter lifespan compared to more efficient fluorescent tube options. This means they may require more frequent replacement and maintenance.

- High Heat Generation: T12 tubes tend to generate more heat compared to newer fluorescent tubes. This can contribute to increased cooling needs in the space where they are installed, potentially adding to energy consumption and HVAC costs.

Considering these disadvantages, it becomes clear why many organizations and governments have been transitioning away from T12 fluorescent tubes in favor of more energy-efficient and environmentally friendly options.

When evaluating lighting solutions, it’s essential to consider the specific needs of the space, cost considerations, energy efficiency goals, and the available alternatives. Consulting with a lighting professional can provide valuable insights and help determine the most suitable lighting solution for a particular application.

When replacing T12 fluorescent tubes, be sure to match the wattage and length of the existing tube. Upgrading to more energy-efficient T8 or T5 tubes may also be a cost-effective option.

Read also: 8 Best 48 In T12 Fluorescent Tubes for 2024

Comparison with Other Types of Fluorescent Tubes

When it comes to fluorescent lighting, there are various options available, each with its own characteristics and advantages. Let’s compare T12 fluorescent tubes with two other common types: T8 and T5 tubes.

- T12 vs. T8 Tubes:

- T8 tubes are significantly more energy-efficient than T12 tubes. They require less energy to produce the same amount of light output, resulting in lower electricity costs.

- T8 tubes have a smaller diameter of 1 inch (25 mm), making them more visually appealing and compatible with a wider range of fixtures.

- The ballasts used with T8 tubes are typically electronic, which are more efficient and consume less energy compared to the rapid-start ballasts commonly used with T12 tubes.

- T8 tubes have a longer lifespan than T12 tubes, typically lasting around 30,000 to 36,000 hours. This reduces the frequency of replacements and maintenance.

- T8 tubes are available in a range of color temperatures, allowing for greater customization and flexibility in lighting design.

- T12 vs. T5 Tubes:

- T5 tubes are the most energy-efficient of the three options, consuming the least amount of energy to produce the same level of light output.

- T5 tubes offer a higher light output and better color rendering than T12 and T8 tubes, making them ideal for applications where precise and vibrant lighting is required.

- The small diameter of T5 tubes allows for more design flexibility and compatibility with narrow and sleek fixtures, expanding the range of lighting possibilities.

- T5 tubes have the longest lifespan, typically lasting around 35,000 to 42,000 hours, further reducing maintenance requirements.

- Due to their higher efficiency, T5 tubes generate less heat compared to T12 and T8 tubes, resulting in lower cooling costs and a more comfortable environment.

T8 fluorescent tubes are the most commonly used fluorescent tubes today. When compared to T12 tubes, T8 tubes offer several advantages:

T5 fluorescent tubes, which have a diameter of 5/8 inch (16 mm), are even more energy-efficient and compact compared to both T12 and T8 tubes. Here are some key differences:

When considering which type of fluorescent tube to use, factors such as energy efficiency, light output, sizing, compatibility with fixtures, and cost-effectiveness should be taken into account. While T12 tubes were widely used in the past, the transition to T8 and T5 tubes is more common today due to their higher efficiency and improved lighting performance.

It’s important to assess individual lighting needs and consult with a lighting professional to determine the most suitable fluorescent tube option for specific applications.

Environmental Impact of T12 Fluorescent Tubes

T12 fluorescent tubes, like all fluorescent lighting, have both positive and negative environmental impacts. Let’s examine the environmental factors associated with T12 tubes:

- Energy Consumption: T12 fluorescent tubes are less energy efficient than their newer counterparts, such as T8 and T5 tubes. This means they require more electricity to produce the same amount of light output, resulting in higher energy consumption and greenhouse gas emissions.

- Mercury Content: T12 tubes contain a small amount of mercury, a toxic substance. While the mercury is enclosed within the tube, proper disposal is crucial to prevent its release into the environment. Improper disposal, such as throwing T12 tubes in regular trash, can contaminate landfills and potentially expose the mercury to the surrounding ecosystem.

- Disposal Challenges: Due to the mercury content, T12 tubes are classified as hazardous waste and require special handling during disposal. This poses a challenge as many people may not be aware of the proper disposal procedures or may not have access to recycling facilities equipped to handle fluorescent tubes.

- Recycling Potential: Despite the challenges, T12 tubes can be recycled, and it is encouraged to do so whenever possible. Recycling facilities can safely recover the mercury and properly dispose of other components, such as the glass and metal, minimizing the environmental impact associated with T12 tube disposal.

- Phasing Out Initiatives: Many regions and governments have initiated programs to phase out T12 fluorescent tubes, primarily due to their lower energy efficiency and potential environmental impact. These initiatives aim to encourage the adoption of more energy-efficient and environmentally friendly lighting alternatives.

Considering the environmental impact of T12 fluorescent tubes, it is recommended to transition to more efficient options, such as T8 or T5 tubes whenever feasible. These newer models offer substantial energy savings, longer lifespans, and improved lighting performance, thereby reducing environmental harm and carbon emissions.

For existing T12 tube users, proper disposal is crucial. Contact local recycling centers or waste management facilities to find out about proper disposal options and recycling programs specifically designed for fluorescent tubes. By following environmentally responsible practices, we can mitigate the impact of T12 fluorescent tubes on our planet.

Use and Applications of T12 Fluorescent Tubes

T12 fluorescent tubes have been widely used in various applications due to their versatility and reliability. While their popularity has declined in recent years, they still find application in specific contexts. Let’s explore some of the common uses of T12 fluorescent tubes:

- Commercial Spaces: T12 tubes have been extensively utilized in commercial spaces, including offices, retail stores, and warehouses. Their bright and uniform illumination is well-suited for illuminating large areas, such as open office spaces or retail floors, providing adequate and consistent light distribution.

- Industrial Facilities: In industrial settings, where ample lighting is crucial for safety and productivity, T12 tubes have been commonly employed. Their high light output and durability make them suitable for illuminating manufacturing floors, assembly lines, and workstations where task visibility is essential.

- Educational Institutions: T12 fluorescent tubes have been used in educational institutions, such as schools and universities, where lighting plays a vital role in creating an effective learning environment. They provide bright, white light, allowing students and teachers to see clearly without straining their eyes.

- Healthcare Facilities: Hospitals, clinics, and medical facilities have utilized T12 fluorescent tubes due to their ability to render colors accurately. This is important for medical professionals who need precise color distinction when examining patients, reading medical charts, or performing surgical procedures.

- Indoor Agriculture: T12 tubes have also found application in indoor gardening and horticulture. Their wide spectrum of colors and high intensity can support healthy plant growth during all stages, from propagation to flowering. However, more energy-efficient alternatives like T5 or LED grow lights are often preferred in modern indoor agriculture practices.

- Residential Spaces: While T12 tubes are less commonly used in residential settings today, they were once popular for overhead lighting fixtures in homes, especially in garages, basements, and utility rooms. Their bright illumination and long lifespan made them a practical choice for these areas.

It’s important to note that as the lighting industry evolves towards more energy-efficient options, T12 tubes are being replaced with newer models like T8 and T5 fluorescent tubes, as well as LED lighting technology. These alternatives offer better energy efficiency, longer lifespans, and improved lighting performance, meeting the increasing demand for sustainable lighting solutions.

If you are considering implementing or upgrading a lighting system, it is recommended to consult with a lighting professional to assess your specific needs and select the most suitable lighting retrofit or replacement solution.

Maintenance and Replacement of T12 Fluorescent Tubes

Maintaining and replacing T12 fluorescent tubes is an important aspect of ensuring optimal lighting performance and energy efficiency. Here are some key considerations to keep in mind:

- Regular Cleaning: Dust and dirt can accumulate on the surface of T12 tubes, reducing their light output. Regularly clean the tubes using a soft cloth or a mild cleaning solution to keep them free of debris and maintain optimal illumination.

- Ballast Inspection: The ballast is an essential component of T12 lighting systems. Regularly inspect the ballast for signs of damage, such as discoloration, burning smell, or flickering lights. Faulty ballasts should be replaced to avoid potential safety hazards or decreased performance.

- Replacement Schedule: T12 fluorescent tubes have a lifespan of around 20,000 to 24,000 hours, depending on usage. Create a replacement schedule based on the manufacturer’s recommendations to ensure old tubes are replaced promptly and maintain consistent lighting quality. This also helps prevent sudden failures or periods of inadequate illumination.

- Upgrading to Newer Technology: Due to their lower energy efficiency, it is recommended to consider upgrading from T12 tubes to more efficient options, such as T8 or T5 tubes, or even LED lighting. These alternatives offer better energy savings and can dramatically reduce maintenance and replacement frequency.

- Recycling and Disposal: Due to the mercury content, improper disposal of T12 tubes can harm the environment. Follow proper recycling procedures and dispose of used tubes at designated recycling centers or through specialized fluorescent tube recycling programs. Check with your local waste management facilities for specific guidelines.

- Working with Professionals: When it comes to maintenance and replacement of T12 fluorescent tubes, it is advisable to work with experienced lighting professionals or electricians. They can provide professional guidance, ensure proper installation, and recommend suitable alternatives if necessary.

It is important to note that as T12 tubes are gradually being phased out, finding replacement tubes and ballasts may become more difficult in the future. Upgrading to more energy-efficient lighting systems not only reduces maintenance and replacement costs but also aligns with the global push for sustainable and environmentally friendly lighting solutions.

Consulting with professionals and staying informed about the latest lighting technologies will help you make well-informed decisions regarding the maintenance and replacement of T12 fluorescent tubes, ensuring you achieve the best lighting performance while minimizing environmental impact.

Conclusion

T12 fluorescent tubes have played a significant role in the lighting industry for many years, offering reliable and bright illumination in various applications. However, as technology advances and energy efficiency becomes a priority, the popularity of T12 tubes has declined, giving way to more efficient options such as T8 and T5 tubes, as well as LED lighting.

Although T12 tubes still have their advantages, including cost-effectiveness, wide availability, and familiarity, their lower energy efficiency and environmental impact have led to their phasing out in many regions. Transitioning to more energy-efficient alternatives not only reduces electricity costs but also minimizes greenhouse gas emissions and promotes a sustainable future.

Understanding the history, functionality, advantages, and disadvantages of T12 fluorescent tubes provides a comprehensive perspective on their role in the lighting industry. From their invention and widespread use to their impact on energy consumption and the environment, T12 tubes have undoubtedly left their mark.

Maintenance and replacement of T12 tubes require regular cleaning, ballast inspection, and adherence to proper disposal procedures to ensure maximum efficiency and safety. Additionally, considering upgrades to newer technologies like T8 or T5 tubes, or even transitioning to LED lighting, can greatly enhance lighting performance and reduce maintenance costs in the long run.

As we navigate the evolving landscape of lighting technologies, it is essential to prioritize energy efficiency, environmental responsibility, and the overall quality of lighting in our daily lives. By making informed decisions and embracing sustainable lighting solutions, we can contribute to a brighter and greener future.

Whether you are an individual looking to upgrade your lighting system or a professional seeking the best lighting options for your space, understanding the ins and outs of T12 fluorescent tubes will empower you to make informed choices and embrace the advances in lighting technology.

Frequently Asked Questions about What Is T12 Fluorescent Tubes

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is T12 Fluorescent Tubes”