Home>Construction & Tools>Building Materials>What Is Brick Moulding

Building Materials

What Is Brick Moulding

Modified: October 19, 2024

Discover the uses and benefits of brick moulding as a versatile building material. Learn how it can enhance the aesthetics and functionality of your construction projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of construction materials, where each component plays a crucial role in shaping the built environment. In this article, we delve into the realm of brick moulding, a fundamental aspect of construction that has stood the test of time. Brick moulding, often overlooked in its significance, holds a rich history and serves as a cornerstone in the creation of durable and aesthetically pleasing structures.

Throughout this exploration, we will uncover the definition, historical significance, various types, the intricate process, and the diverse applications of brick moulding. Additionally, we will weigh the advantages and disadvantages of this technique, shedding light on its impact on construction practices.

Join us as we embark on a journey to unravel the intricacies of brick moulding, gaining a deeper understanding of its role in the construction industry and the built environment at large.

Key Takeaways:

- Brick moulding is a historic technique that shapes bricks into different designs, helping create durable and visually appealing structures. It has evolved from ancient civilizations to modern construction, offering versatility and aesthetic potential.

- Brick moulding produces various brick types, from standard to decorative, with advantages such as durability and sustainability. However, it also has challenges like cost and environmental impact, requiring informed decision-making in construction projects.

Read more: How To Stop Mould In Wardrobe

Definition of Brick Moulding

Brick moulding is a technique that involves shaping and forming bricks into specific designs and dimensions to meet the requirements of construction projects. This process is integral to the production of various types of bricks, including standard bricks, facing bricks, and special-shaped bricks. The primary goal of brick moulding is to create uniform and precise brick components that align with the architectural and structural needs of a building.

At its core, brick moulding encompasses the manipulation of raw materials, such as clay or concrete, into molds that define the shape and size of the final brick products. These molds, often crafted from metal or wood, serve as the blueprint for the desired brick designs. Through the use of these molds, the malleable raw materials are carefully pressed and formed, resulting in bricks with consistent dimensions and surface characteristics.

Furthermore, brick moulding extends beyond the mere shaping of bricks; it also involves the creation of intricate patterns, textures, and surface finishes that contribute to the visual appeal and structural integrity of the final construction. This process allows for the production of bricks with unique features, enabling architects and builders to realize their design visions and meet the specific requirements of diverse construction projects.

As a foundational element of construction, brick moulding plays a pivotal role in ensuring the quality, durability, and aesthetic coherence of brick-based structures. Its significance lies in its ability to transform raw materials into precision-engineered components that form the building blocks of resilient and visually captivating edifices.

History of Brick Moulding

The history of brick moulding is deeply intertwined with the evolution of human civilization and the development of construction techniques. Dating back to ancient civilizations, such as the Mesopotamian, Egyptian, and Indus Valley civilizations, the use of bricks in construction has been well-documented. The earliest forms of brick moulding involved shaping clay into rudimentary brick forms by hand, allowing for the creation of simple yet effective building materials.

Over time, as civilizations advanced and architectural practices became more sophisticated, the art of brick moulding evolved alongside these progressions. The invention of wooden and metal molds revolutionized the brick moulding process, enabling builders to produce bricks with greater precision and uniformity. This technological advancement marked a significant turning point in the history of brick moulding, paving the way for the mass production of standardized bricks that could be used in large-scale construction projects.

During the industrial revolution, the mechanization of brick production further propelled the practice of brick moulding into the modern era. Innovations such as steam-powered brick presses and automated molding machines streamlined the manufacturing process, leading to increased efficiency and output. This period of industrialization witnessed the widespread adoption of brick moulding techniques in construction, as the demand for durable and cost-effective building materials surged.

Today, brick moulding continues to be an integral part of construction practices, with contemporary advancements in materials, technology, and design further enriching its legacy. From traditional red clay bricks to modern concrete and composite materials, the versatility of brick moulding has allowed for the creation of diverse brick types, catering to the dynamic needs of architectural and structural designs.

As we reflect on the history of brick moulding, we recognize its enduring significance as a foundational process that has shaped the built environment across centuries, leaving an indelible imprint on the architectural heritage of civilizations worldwide.

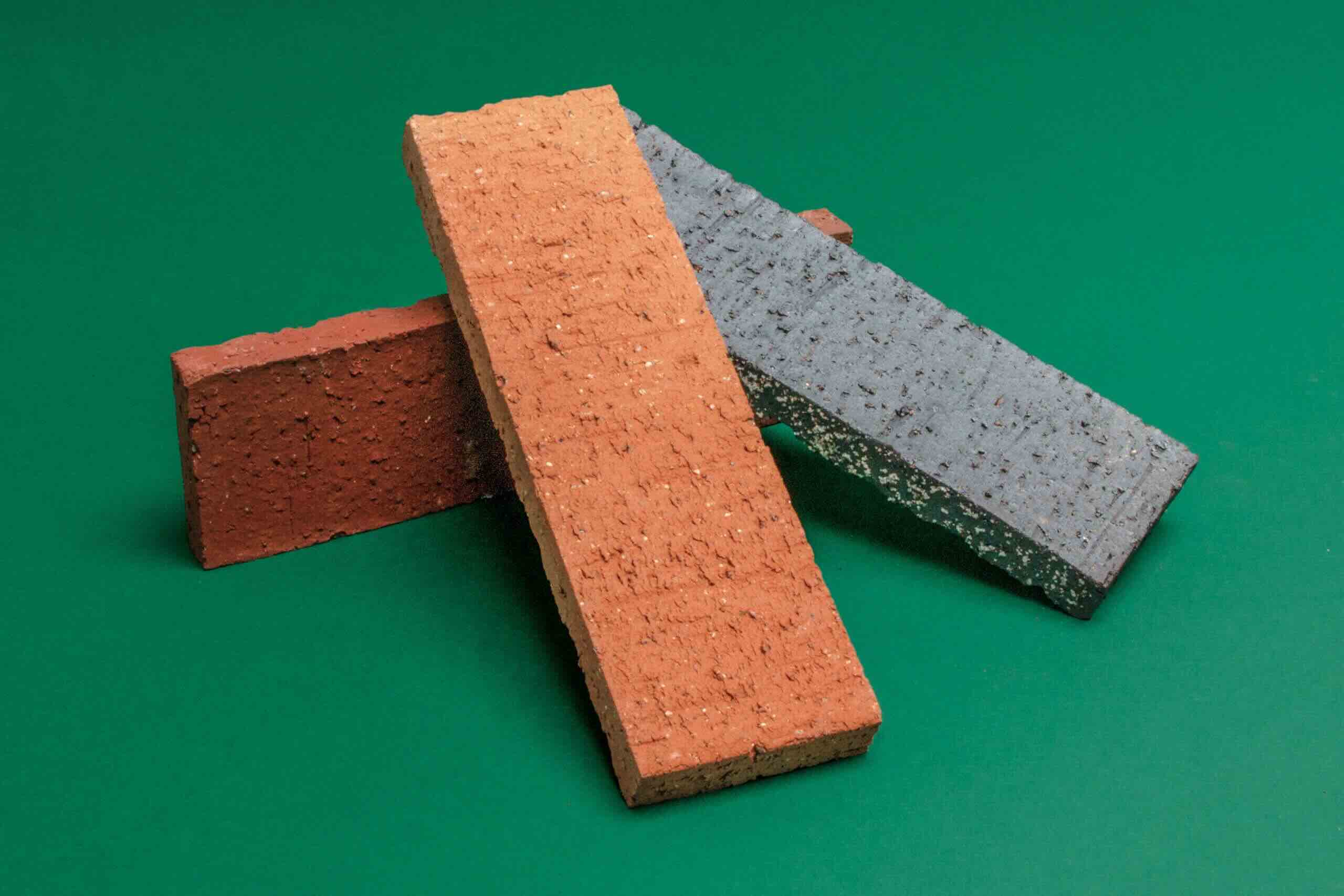

Types of Brick Moulding

Brick moulding encompasses a diverse array of techniques and methods, resulting in various types of bricks that cater to different construction needs and design preferences. Understanding the different types of brick moulding is essential for architects, builders, and construction professionals seeking to leverage the versatility of bricks in their projects.

1. Standard Brick Moulding:

Standard brick moulding involves the production of traditional rectangular bricks, characterized by their uniform dimensions and smooth surfaces. These bricks are widely used in both structural and decorative applications, providing stability and a timeless aesthetic appeal to buildings.

2. Facing Brick Moulding:

Facing brick moulding focuses on creating bricks with enhanced visual appeal and surface textures. These bricks are designed to be prominently displayed on building facades, adding character and charm to the exterior of structures. Facing bricks come in a variety of colors, textures, and finishes, allowing for creative expression in architectural design.

3. Special-Shaped Brick Moulding:

Special-shaped brick moulding caters to the production of bricks with non-standard dimensions and unique configurations. These bricks are tailored to fit specific architectural requirements, such as curved walls, arches, and intricate design elements. Special-shaped bricks enable architects to realize complex and custom-designed structures with precision and artistry.

4. Perforated Brick Moulding:

Perforated brick moulding involves the creation of bricks with perforations or voids within their structure. These perforations serve functional and aesthetic purposes, allowing for improved ventilation, reduced weight, and distinctive visual patterns in masonry construction. Perforated bricks offer versatility in design and performance, making them suitable for diverse building applications.

5. Decorative Brick Moulding:

Decorative brick moulding encompasses the crafting of bricks with ornamental features, intricate patterns, and artistic detailing. These decorative bricks serve as focal points in architectural designs, adding a touch of elegance and individuality to building exteriors and interiors. From geometric motifs to sculptural elements, decorative brick moulding offers a canvas for creative expression in construction.

By recognizing and leveraging the diverse types of brick moulding, construction professionals can harness the inherent flexibility and aesthetic potential of bricks, enriching the visual and structural aspects of their architectural endeavors.

Brick moulding is a process of creating bricks by shaping clay or other materials into a rectangular form and then drying and firing them in a kiln. This process has been used for centuries to create durable building materials.

Process of Brick Moulding

The process of brick moulding involves a series of intricate steps that transform raw materials into precisely shaped and textured bricks, ready for use in construction projects. This meticulous process combines craftsmanship, precision, and technological innovation to produce bricks that meet the functional and aesthetic demands of architectural designs.

1. Raw Material Preparation:

The brick moulding process begins with the preparation of raw materials, typically clay or concrete, which serve as the foundational components of the bricks. The raw materials are carefully selected and blended to achieve the desired characteristics, including plasticity, strength, and color consistency.

2. Molding and Shaping:

Once the raw materials are prepared, they are fed into molds that define the shape and dimensions of the bricks. These molds, often made of metal or wood, are precision-engineered to create uniformity and accuracy in the brick forms. The malleable raw materials are then pressed and shaped within the molds, taking on the distinct profiles and textures of the intended bricks.

3. Surface Finishing:

After the initial molding process, the bricks undergo surface finishing treatments to achieve specific textures, patterns, and visual characteristics. This may involve techniques such as wire-cutting, sandblasting, or application of surface coatings to enhance the aesthetic appeal and tactile qualities of the bricks.

4. Drying and Curing:

Following the shaping and finishing stages, the newly formed bricks undergo a controlled drying and curing process to remove excess moisture and strengthen their structural integrity. This phase is crucial in preventing cracking and warping while ensuring that the bricks attain the necessary durability for construction use.

5. Firing or Setting:

For clay-based bricks, the final stage of the process involves firing the dried bricks in kilns at high temperatures, a process known as vitrification. This transforms the clay into a durable, hardened material through the fusion of particles, resulting in robust and weather-resistant bricks. In the case of concrete bricks, a setting process is employed to solidify the material and achieve the desired strength and durability.

6. Quality Assurance and Packaging:

Throughout the entire brick moulding process, quality control measures are implemented to ensure that the produced bricks meet industry standards for strength, dimensional accuracy, and aesthetic consistency. Once verified, the bricks are packaged and prepared for distribution to construction sites, where they will contribute to the creation of enduring and visually striking structures.

By understanding the meticulous process of brick moulding, we gain insight into the craftsmanship and precision involved in the creation of this essential building material, underscoring its role in shaping the architectural landscape.

Read more: What Is A Brick

Uses of Brick Moulding

Brick moulding serves as a versatile and indispensable technique in the construction industry, offering a myriad of applications across architectural, structural, and decorative contexts. The precision-engineered bricks produced through moulding processes find diverse uses, contributing to the durability, aesthetics, and functionality of built environments.

1. Structural Construction:

One of the primary uses of brick moulding lies in structural construction, where bricks form the foundational elements of buildings, walls, and load-bearing structures. The uniformity and strength of moulded bricks make them ideal for providing stability and support in various architectural configurations, ensuring the structural integrity of constructed edifices.

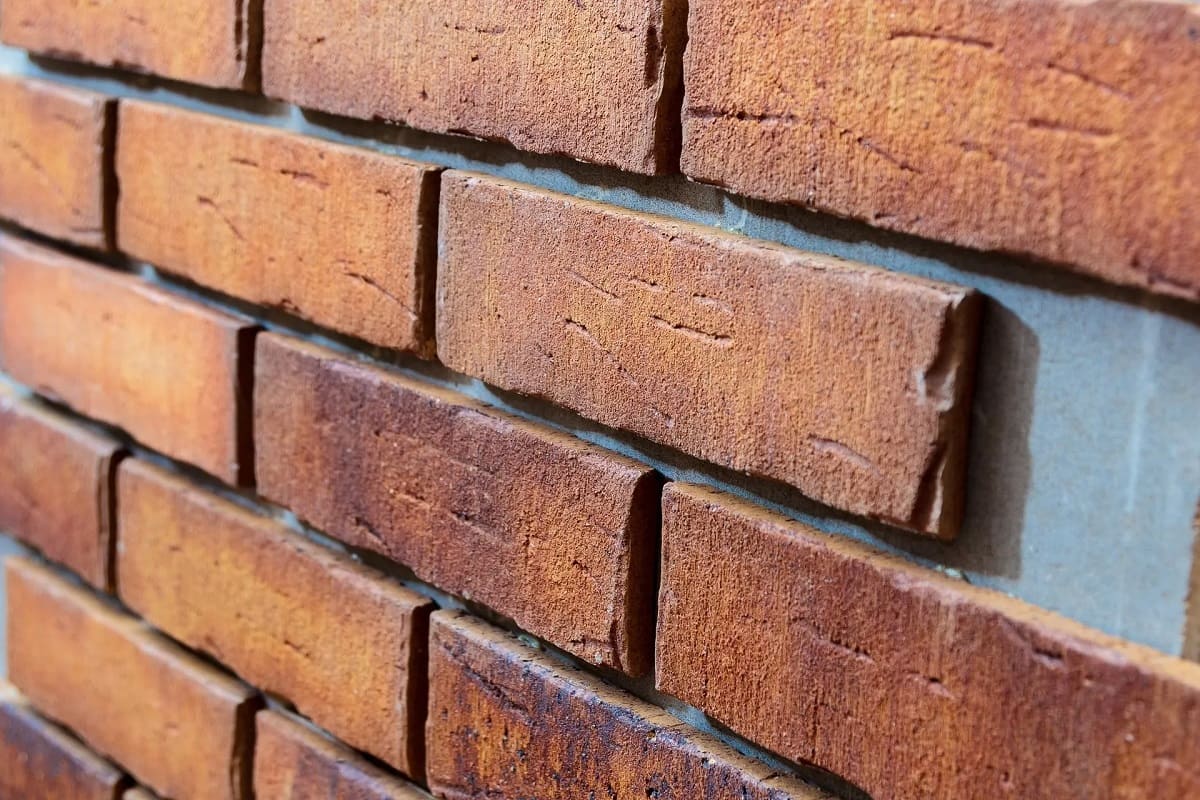

2. Facade and Cladding Systems:

Brick moulding enables the creation of facing bricks that adorn building facades, serving as decorative and protective cladding systems. These facing bricks not only enhance the visual appeal of structures but also provide insulation, weather resistance, and durability, contributing to the longevity and aesthetic coherence of building exteriors.

3. Paving and Landscaping:

Special-shaped bricks produced through moulding processes find application in paving and landscaping projects, where they are used to create walkways, patios, garden borders, and architectural features. The versatility of brick moulding allows for the customization of paving elements, adding character and functionality to outdoor spaces.

4. Interior Design and Finishes:

Decorative and perforated bricks crafted through moulding techniques are employed in interior design applications, enriching the visual and tactile experiences within built environments. From accent walls to decorative partitions, these bricks contribute to the aesthetic appeal and spatial differentiation within interior spaces, elevating the overall design ambiance.

5. Restoration and Preservation:

Brick moulding plays a crucial role in the restoration and preservation of historic and heritage structures, providing bespoke bricks that align with the original architectural features and design motifs. The ability to replicate intricate details and specialized brick forms through moulding techniques aids in the conservation of architectural heritage, ensuring the continuity of cultural legacies.

6. Artistic and Sculptural Installations:

Brick moulding extends into artistic and sculptural realms, where decorative bricks are utilized in the creation of public art installations, architectural ornamentation, and sculptural elements. The adaptability of moulded bricks allows for the realization of imaginative and expressive designs that enrich urban landscapes and public spaces.

By embracing the diverse uses of brick moulding, architects, designers, and builders unlock a spectrum of creative possibilities, harnessing the enduring appeal and functional versatility of bricks in shaping the built environment.

Advantages and Disadvantages of Brick Moulding

Brick moulding offers a range of advantages and disadvantages that influence its application in construction projects, shaping architectural designs, and structural solutions. Understanding these inherent strengths and limitations is essential for informed decision-making in utilizing brick moulding techniques.

Advantages:

1. Versatility: Brick moulding allows for the production of a diverse range of brick types, including standard, facing, special-shaped, and decorative bricks, catering to varied construction needs and design preferences.

2. Aesthetic Flexibility: Moulding processes enable the creation of bricks with intricate textures, patterns, and surface finishes, offering architects and designers the freedom to realize visually compelling and expressive architectural designs.

3. Durability: Moulded bricks exhibit consistent dimensions and structural integrity, contributing to the longevity and resilience of constructed buildings, walls, and facades, especially when fired in kilns for enhanced strength.

4. Thermal Performance: Brick moulding results in bricks with inherent thermal mass and insulation properties, regulating indoor temperatures and contributing to energy efficiency in buildings, thereby reducing heating and cooling costs.

5. Sustainable Material: Bricks produced through moulding processes are environmentally friendly and recyclable, contributing to sustainable construction practices and reducing the carbon footprint of building materials.

Disadvantages:

1. Cost and Labor Intensity: The intricate nature of brick moulding, especially for specialized and decorative bricks, can lead to higher production costs and labor requirements, impacting the overall project budget.

2. Limited Design Complexity: While versatile, certain brick moulding techniques may have limitations in realizing highly complex and non-standard brick forms, necessitating alternative construction solutions for intricate architectural designs.

3. Environmental Impact: The firing process for clay-based bricks, a common outcome of moulding, consumes energy and may produce emissions, contributing to environmental concerns unless sustainable firing methods are employed.

4. Weight and Handling: Moulded bricks, particularly those with perforations or specialized shapes, may pose challenges in handling and installation due to their weight and specific design requirements, necessitating careful planning and structural considerations.

5. Maintenance and Repair: While durable, bricks produced through moulding may require specialized maintenance and repair techniques, especially for decorative and facing bricks, impacting long-term upkeep costs.

By weighing the advantages and disadvantages of brick moulding, construction professionals can make informed decisions that align with project objectives, sustainability goals, and design aspirations, optimizing the use of this time-honored building material.

Conclusion

Brick moulding stands as a testament to the enduring legacy of craftsmanship, innovation, and artistic expression in the realm of construction materials. From its ancient origins to its contemporary applications, brick moulding has left an indelible mark on the architectural landscape, shaping the built environment with its versatility, durability, and aesthetic allure.

As we reflect on the multifaceted nature of brick moulding, we recognize its pivotal role in providing architects, builders, and designers with a canvas for creativity and structural ingenuity. The ability to produce an array of brick types, from standard building blocks to decorative embellishments, underscores the adaptability and expressive potential of moulding techniques in meeting diverse construction needs.

Furthermore, the advantages of brick moulding, including its thermal performance, sustainability, and durability, position it as a sustainable and resilient building material that resonates with contemporary architectural and environmental priorities. However, it is essential to acknowledge the associated challenges, such as cost implications, design limitations, and environmental considerations, in order to navigate the complexities of integrating brick moulding into construction projects effectively.

Looking ahead, the legacy of brick moulding continues to evolve, driven by technological advancements, material innovations, and a renewed emphasis on sustainable practices. As the construction industry embraces the principles of eco-conscious design, adaptive reuse, and heritage preservation, brick moulding remains a cornerstone in the pursuit of architectural excellence and responsible stewardship of the built environment.

In conclusion, brick moulding transcends its functional role as a building material, embodying the craftsmanship, artistry, and resilience that define the timeless appeal of brick-based structures. Its enduring presence in architectural history and its ongoing relevance in contemporary construction practices underscore its significance as a foundational element in the narrative of human creativity and the art of construction.

As we navigate the dynamic landscape of architectural design and construction, brick moulding stands as a testament to the enduring legacy of craftsmanship, innovation, and artistic expression in the realm of construction materials. Its versatility, durability, and aesthetic allure continue to shape the built environment, providing architects, builders, and designers with a canvas for creativity and structural ingenuity.

Frequently Asked Questions about What Is Brick Moulding

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Brick Moulding”