Home>Furniture & Design>Interior Design Trends>How Does Bulletproof Glass Work

Interior Design Trends

How Does Bulletproof Glass Work

Published: February 4, 2024

Discover the latest interior design trends and learn how bulletproof glass works to enhance both safety and aesthetics in modern spaces. Explore innovative solutions for stylish and secure environments.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Bulletproof glass, also known as ballistic glass or transparent armor, is a remarkable material that has revolutionized safety and security in various industries. Its ability to withstand the impact of bullets, explosives, and other high-velocity projectiles has made it an indispensable component in the design of secure facilities, vehicles, and even residential properties. The development and widespread use of bulletproof glass have significantly enhanced protection against armed attacks, robberies, and acts of terrorism.

The demand for bulletproof glass has surged in recent years, driven by the growing concerns for personal and public safety. From banks and government buildings to VIP vehicles and high-end residences, the applications of bulletproof glass continue to expand, reflecting the increasing need for advanced security measures in today's unpredictable world.

Understanding the intricacies of bulletproof glass, including its composition, manufacturing process, and scientific principles, is crucial for appreciating its effectiveness and potential applications. This article delves into the fascinating realm of bulletproof glass, shedding light on its construction, functionality, and the rigorous testing procedures that ensure its reliability. By exploring the science behind bulletproof glass and its diverse applications, we can gain a deeper insight into this innovative material and its pivotal role in safeguarding lives and assets.

Key Takeaways:

- Bulletproof glass is a special type of glass that can stop bullets and other high-speed objects. It’s made by layering glass with strong plastics, and it’s used in vehicles, buildings, and even homes to keep people safe.

- The science behind bulletproof glass is all about using layers of glass and plastic to absorb and spread out the energy from bullets. It’s tested to make sure it can stop different kinds of bullets, and it’s used in places like banks, government buildings, and even in armored vehicles to protect people and important places.

Read more: How Expensive Is Bulletproof Glass?

What is Bulletproof Glass?

Bulletproof glass, also referred to as ballistic glass or transparent armor, is a specialized type of glass designed to provide protection against ballistic threats such as bullets, shrapnel, and other high-velocity projectiles. Unlike conventional glass, which shatters upon impact, bulletproof glass is engineered to absorb and dissipate the energy of incoming projectiles, thereby preventing penetration and maintaining the integrity of the barrier.

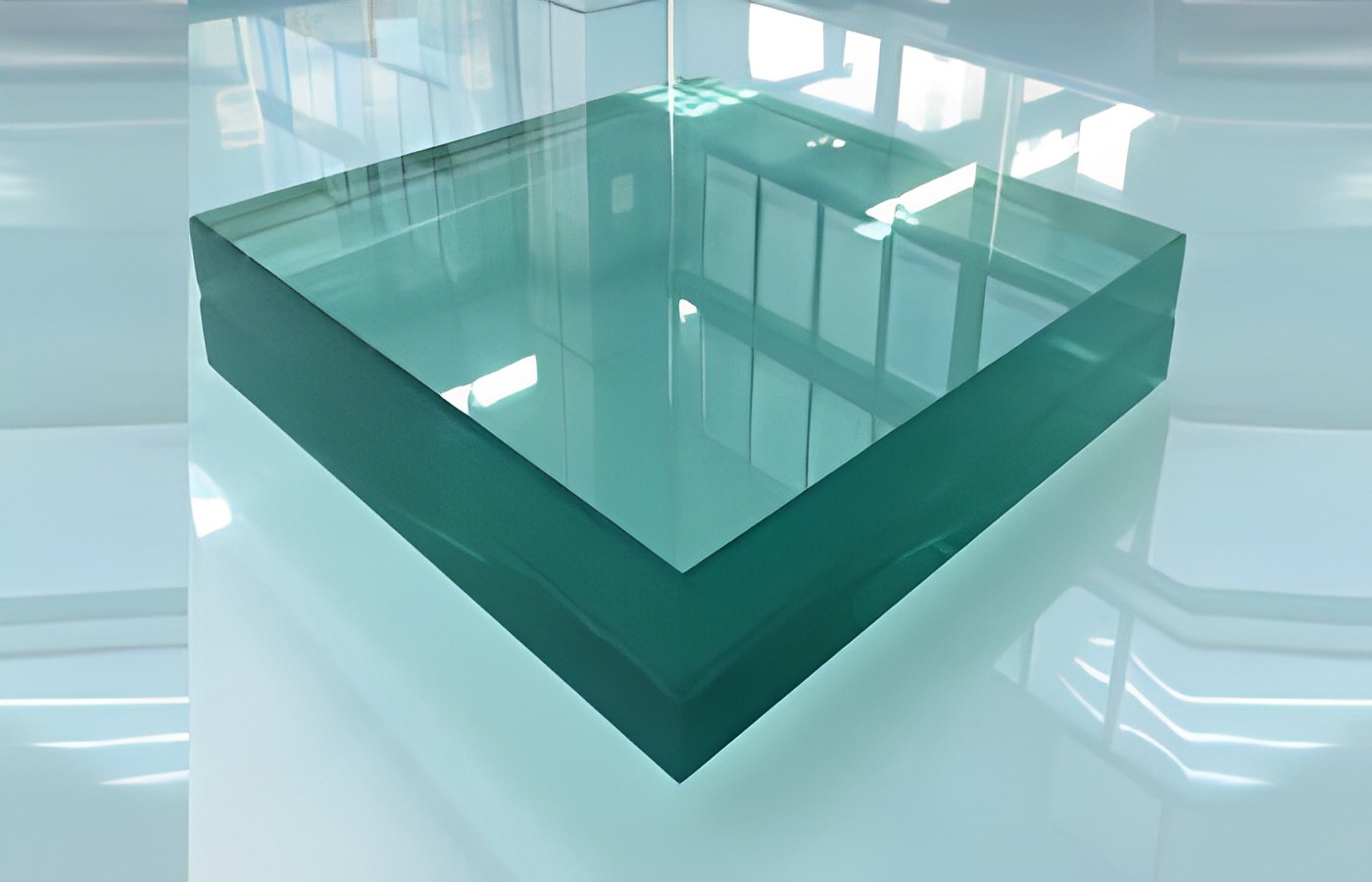

This extraordinary material is constructed through a meticulous process that involves layering multiple sheets of glass with interlayers made of polycarbonate or other high-strength plastics. The combination of these materials results in a composite structure that exhibits exceptional resistance to impact and penetration, effectively mitigating the destructive force of ballistic threats.

Bulletproof glass is available in various levels of protection, each tailored to withstand specific types of ammunition and kinetic energy. These levels are classified according to recognized standards such as the UL (Underwriters Laboratories) rating system and the NIJ (National Institute of Justice) ballistic resistance standards, providing a clear indication of the glass's ballistic capabilities.

In addition to its ballistic resistance, bulletproof glass offers the added benefit of enhanced security without compromising visibility. This feature makes it an ideal choice for applications where transparency and protection are equally important, such as armored vehicles, bank teller windows, government buildings, and high-security facilities.

The widespread adoption of bulletproof glass underscores its pivotal role in safeguarding individuals and assets in high-risk environments. Its ability to withstand armed attacks and explosive threats has made it an indispensable component in the security infrastructure of numerous industries, including law enforcement, military, banking, and transportation.

In essence, bulletproof glass represents a remarkable fusion of advanced materials science and security technology, offering a formidable defense against the ever-present risks of ballistic threats. Its versatility, reliability, and proven effectiveness make it an invaluable asset in fortifying security measures and ensuring the safety of occupants in an unpredictable world.

How is Bulletproof Glass Made?

Bulletproof glass is meticulously crafted through a sophisticated manufacturing process that involves the strategic layering of specialized materials to achieve unparalleled strength and resilience. The construction of bulletproof glass begins with the selection of high-quality glass sheets, which serve as the foundation for the multi-layered composite structure. These glass sheets are typically made from tempered or laminated glass, renowned for their durability and impact-resistant properties.

The key to the exceptional protective capabilities of bulletproof glass lies in the incorporation of interlayers, which are strategically positioned between the glass sheets. These interlayers, often composed of polycarbonate or other advanced plastics, play a pivotal role in absorbing and dispersing the energy of incoming projectiles, thereby preventing penetration and maintaining the structural integrity of the glass.

The layering process is conducted with meticulous precision, ensuring that each component is seamlessly integrated to maximize the overall strength and ballistic resistance of the glass. The number and composition of the layers are carefully tailored to meet specific ballistic protection requirements, resulting in a diverse range of bulletproof glass products designed to withstand varying levels of ballistic threats.

Once the layering process is complete, the assembled components undergo a rigorous bonding procedure to ensure optimal adhesion and structural cohesion. This bonding process is essential for enhancing the overall integrity of the bulletproof glass, effectively uniting the individual layers into a unified, formidable barrier against ballistic threats.

Following the bonding stage, the bulletproof glass undergoes meticulous quality control measures to verify its ballistic resistance, optical clarity, and overall performance. This stringent testing process is crucial for certifying the glass's compliance with recognized ballistic resistance standards, such as those established by the UL and NIJ, and ensuring its suitability for diverse applications.

The result of this intricate manufacturing process is a remarkable material that embodies the fusion of advanced materials science and security technology. Bulletproof glass stands as a testament to human ingenuity, offering a robust defense against ballistic threats while maintaining transparency and visibility—a testament to the remarkable capabilities of modern engineering and innovation.

The Science Behind Bulletproof Glass

The remarkable effectiveness of bulletproof glass in withstanding ballistic threats is rooted in the intricate scientific principles that govern its composition and behavior. At its core, bulletproof glass is engineered to counteract the destructive force of high-velocity projectiles by leveraging the unique properties of its constituent materials.

The science behind bulletproof glass begins with the strategic layering of specialized components, typically comprising multiple sheets of glass interspersed with resilient interlayers made of polycarbonate or other high-strength plastics. This composite structure is designed to dissipate the energy of incoming projectiles, effectively preventing penetration and maintaining the integrity of the glass.

The interlayers play a pivotal role in the ballistic resistance of bulletproof glass, exhibiting exceptional toughness and elasticity to absorb and disperse the kinetic energy of projectiles. Upon impact, the interlayers deform and stretch, effectively absorbing the force and preventing the propagation of cracks or penetration through the glass. This mechanism of energy dissipation is a testament to the remarkable resilience of the materials used in bulletproof glass, showcasing their ability to withstand extreme forces without compromising structural integrity.

Furthermore, the molecular composition and physical properties of the glass and interlayers contribute to the overall ballistic performance of the bulletproof glass. The tempered or laminated glass sheets exhibit exceptional hardness and impact resistance, serving as a robust foundation for the composite structure. Meanwhile, the interlayers possess remarkable tensile strength and flexibility, enabling them to effectively mitigate the force of ballistic impacts.

In addition to the material composition, the thickness and number of layers in bulletproof glass are meticulously calibrated to optimize its ballistic resistance. These factors are carefully tailored to meet specific protection requirements, resulting in a diverse range of bulletproof glass products designed to withstand varying levels of ballistic threats.

The scientific precision and engineering ingenuity behind bulletproof glass underscore its status as a pinnacle of advanced materials science and security technology. By harnessing the principles of energy dissipation, material resilience, and structural integrity, bulletproof glass stands as a testament to human innovation in fortifying safety and security against the ever-present risks of ballistic threats.

The science behind bulletproof glass not only exemplifies the convergence of cutting-edge materials and engineering expertise but also serves as a testament to the unwavering commitment to enhancing protective measures in an increasingly unpredictable world.

Bulletproof glass works by sandwiching layers of glass and plastic together. When a bullet hits the glass, the layers absorb and distribute the force, preventing it from penetrating through.

Testing and Certification of Bulletproof Glass

The testing and certification of bulletproof glass are integral components of ensuring its reliability and effectiveness in mitigating ballistic threats. Rigorous testing procedures are employed to evaluate the glass's ballistic resistance, structural integrity, and overall performance, providing a comprehensive assessment of its capabilities in real-world scenarios.

One of the primary standards used for testing and certifying bulletproof glass is the UL (Underwriters Laboratories) rating system. This widely recognized system encompasses various levels of ballistic protection, ranging from UL 752 Level 1 to UL 752 Level 10, each corresponding to specific ballistic threat levels. The testing process involves subjecting the bulletproof glass to controlled ballistic impacts using standardized ammunition and velocities, with the glass's performance assessed based on its ability to withstand penetration and maintain structural integrity.

The National Institute of Justice (NIJ) ballistic resistance standards also play a crucial role in the testing and certification of bulletproof glass. The NIJ standards provide a comprehensive framework for evaluating the glass's ability to resist ballistic threats, taking into account factors such as projectile velocity, impact energy, and penetration resistance. By adhering to the NIJ standards, bulletproof glass manufacturers can demonstrate the reliability and effectiveness of their products in diverse security applications.

During the testing process, bulletproof glass undergoes meticulous examination to assess its ballistic performance, optical clarity, and durability. The glass is subjected to multiple ballistic impacts, simulating real-world scenarios to evaluate its ability to withstand repeated attacks without compromising its protective capabilities. Additionally, the optical quality of the glass is scrutinized to ensure that it maintains transparency and visibility, essential for applications where visual clarity is paramount.

Upon successful completion of the testing procedures, bulletproof glass that meets the stringent ballistic resistance standards is awarded certification, signifying its compliance with recognized industry benchmarks. This certification serves as a testament to the glass's ability to provide reliable protection against ballistic threats, instilling confidence in its suitability for diverse applications, including armored vehicles, government facilities, financial institutions, and high-security environments.

The meticulous testing and certification processes underscore the commitment to upholding the highest standards of safety and security. By subjecting bulletproof glass to rigorous evaluation and validation, manufacturers and regulatory bodies ensure that it delivers uncompromising protection against ballistic threats, thereby enhancing the resilience of security infrastructure and safeguarding lives and assets in an unpredictable world.

Read more: How Thick Is Bulletproof Glass

Applications of Bulletproof Glass

Bulletproof glass finds diverse and critical applications across various industries, where the need for enhanced security and protection against ballistic threats is paramount. Its exceptional ballistic resistance and transparency make it an indispensable component in safeguarding lives, assets, and critical infrastructure. The versatility and reliability of bulletproof glass have led to its widespread adoption in the following key applications:

-

Armored Vehicles: Bulletproof glass is extensively utilized in the automotive industry for the manufacturing of armored vehicles, including military transport vehicles, VIP limousines, and high-security personnel carriers. The installation of bulletproof glass in these vehicles provides occupants with crucial protection against ballistic threats while maintaining visibility and situational awareness.

-

Financial Institutions: Banks, currency exchange centers, and other financial institutions rely on bulletproof glass to fortify their security measures. Teller windows, cashier booths, and secure areas are equipped with bulletproof glass to mitigate the risk of armed robberies and unauthorized access, ensuring the safety of employees and customers.

-

Government Buildings: Government facilities, embassies, and consulates utilize bulletproof glass to enhance security and protect against potential threats. The installation of bulletproof glass in entry points, sensitive areas, and diplomatic premises serves as a critical defense mechanism, safeguarding personnel and sensitive information.

-

Retail Environments: High-end retail establishments, jewelry stores, and luxury boutiques employ bulletproof glass to secure valuable merchandise and protect against theft and vandalism. The transparent armor provides a robust barrier against unauthorized access and criminal activities, offering peace of mind to business owners and customers.

-

Law Enforcement and Military: Police stations, correctional facilities, and military installations integrate bulletproof glass into their infrastructure to bolster security and protect personnel from potential attacks. The use of bulletproof glass in observation towers, control rooms, and detention facilities enhances safety and operational resilience.

-

Residential Properties: High-profile individuals, public figures, and individuals in high-risk environments opt for bulletproof glass to fortify their residences against potential threats. Bulletproof windows, doors, and safe rooms offer a heightened level of security and peace of mind, ensuring the safety of occupants and their assets.

-

Critical Infrastructure: Vital installations such as power plants, telecommunications centers, and emergency response facilities rely on bulletproof glass to safeguard critical infrastructure from external threats. The use of bulletproof glass in control rooms, command centers, and sensitive areas reinforces the resilience of essential services.

The diverse applications of bulletproof glass underscore its pivotal role in fortifying security measures and mitigating the risks associated with ballistic threats. Its seamless integration into various environments reflects the unwavering commitment to safety and protection, offering a tangible defense against the unpredictable challenges of the modern world.

Conclusion

In conclusion, the evolution of bulletproof glass represents a remarkable fusion of advanced materials science, engineering ingenuity, and a steadfast commitment to enhancing safety and security in an increasingly unpredictable world. The comprehensive understanding of bulletproof glass, from its composition and manufacturing process to its scientific principles and diverse applications, underscores its pivotal role in fortifying protective measures and mitigating the risks associated with ballistic threats.

The development of bulletproof glass has revolutionized security infrastructure across various industries, offering a formidable defense against armed attacks, robberies, and acts of terrorism. Its ability to withstand ballistic threats while maintaining transparency and visibility has led to its widespread adoption in critical applications, including armored vehicles, financial institutions, government buildings, retail environments, and residential properties.

The meticulous construction of bulletproof glass, characterized by the strategic layering of specialized materials and rigorous testing procedures, ensures its reliability and effectiveness in real-world scenarios. The adherence to recognized ballistic resistance standards, such as those established by the UL and NIJ, provides assurance of the glass's ability to provide uncompromising protection against ballistic threats, instilling confidence in its suitability for diverse security applications.

The science behind bulletproof glass, rooted in the principles of energy dissipation, material resilience, and structural integrity, exemplifies the convergence of cutting-edge materials and engineering expertise. The remarkable effectiveness of bulletproof glass in withstanding ballistic threats is a testament to the unwavering commitment to enhancing protective measures and ensuring the safety of occupants in high-risk environments.

As the demand for advanced security solutions continues to grow, the role of bulletproof glass in fortifying safety and protection becomes increasingly significant. Its seamless integration into critical infrastructure, high-profile residences, and sensitive environments reflects the unwavering dedication to safeguarding lives, assets, and essential services.

In essence, the remarkable capabilities of bulletproof glass serve as a testament to human innovation and resilience, offering a tangible defense against the ever-present risks of ballistic threats. The ongoing advancements in materials science and security technology will undoubtedly further elevate the effectiveness and versatility of bulletproof glass, reinforcing its status as a cornerstone of modern security infrastructure.

Frequently Asked Questions about How Does Bulletproof Glass Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does Bulletproof Glass Work”