Home>Furniture & Design>Interior Design Trends>How Thick Is Bulletproof Glass

Interior Design Trends

How Thick Is Bulletproof Glass

Published: February 4, 2024

Discover the latest interior design trends and learn about the thickness of bulletproof glass. Enhance your space with modern style and security.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Bulletproof glass is a fascinating and crucial component in various industries, from security and law enforcement to automotive and architectural design. Its ability to withstand high-velocity impacts while maintaining transparency makes it an indispensable material for protecting people and property. Understanding the thickness of bulletproof glass is essential for comprehending its protective capabilities and applications. In this article, we will delve into the intricacies of bulletproof glass, exploring its composition, manufacturing process, and the factors influencing its thickness. By the end, you will have a comprehensive understanding of this remarkable material and its significance in modern safety and design.

Key Takeaways:

- Bulletproof glass is a specialized material designed to protect against bullets and projectiles. Its thickness is crucial for withstanding different levels of impact, from low-velocity threats to high-powered projectiles.

- Factors such as the level of anticipated threat, intended use, and optical clarity influence the thickness of bulletproof glass. Engineers and designers carefully balance protection and visibility to create tailored solutions for diverse applications.

Read more: How Expensive Is Bulletproof Glass?

What is Bulletproof Glass?

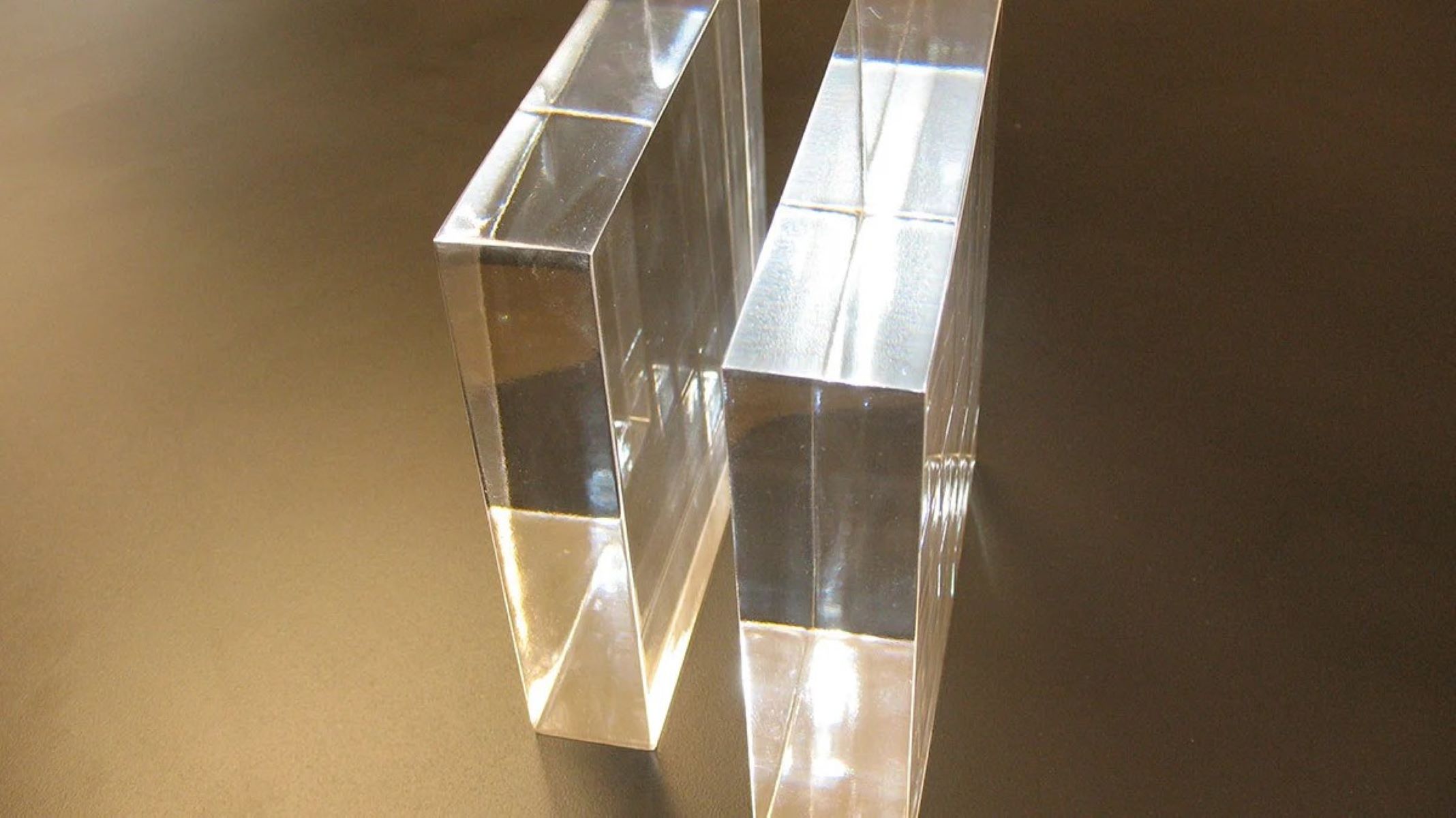

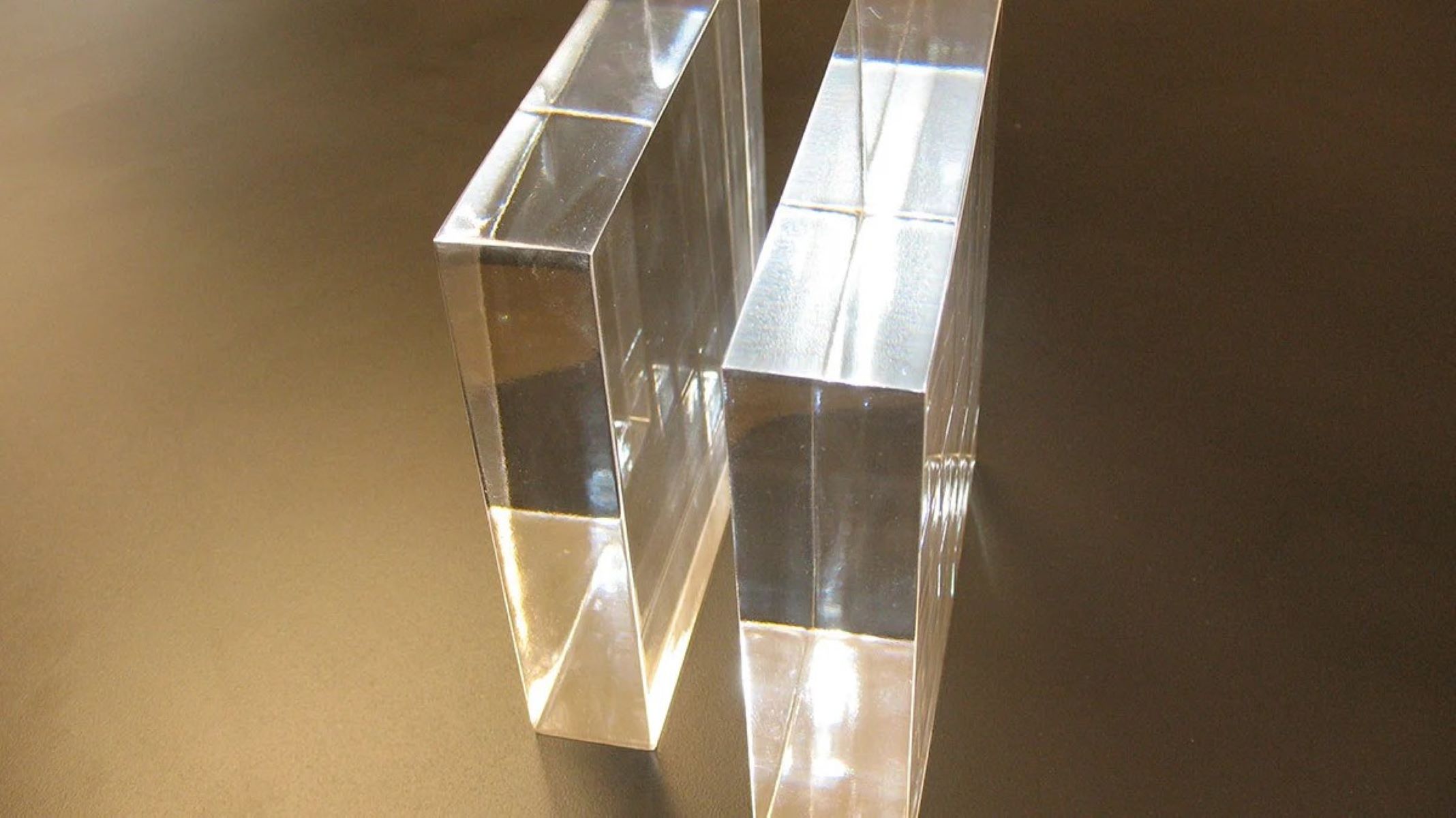

Bulletproof glass, also known as ballistic glass or transparent armor, is a specialized type of glass designed to provide protection against ballistic threats such as bullets and projectiles. Unlike traditional glass, which shatters upon impact, bulletproof glass is engineered to absorb and dissipate the energy of incoming projectiles, preventing them from penetrating the material and causing harm.

This remarkable material is constructed using multiple layers of glass and synthetic materials, carefully bonded together to create a composite structure with exceptional strength and resilience. The composition of bulletproof glass may vary depending on its intended application, with different formulations tailored to withstand specific levels of ballistic impact.

In addition to its protective properties, bulletproof glass is also engineered to maintain optical clarity, allowing for unobstructed visibility through the material. This feature is crucial in applications where transparency is essential, such as armored vehicle windows, security barriers, and architectural elements.

The development of bulletproof glass has revolutionized safety and security measures across various industries, offering a reliable means of safeguarding individuals and assets against potential threats. From high-security facilities and military installations to civilian vehicles and public infrastructure, the widespread adoption of bulletproof glass underscores its indispensable role in modern safety and design.

In the next section, we will explore the intricate process of manufacturing bulletproof glass, shedding light on the techniques and materials involved in creating this advanced protective material.

How is Bulletproof Glass Made?

The manufacturing process of bulletproof glass is a sophisticated and meticulously orchestrated endeavor, involving the strategic assembly of multiple layers of specialized materials to achieve the desired level of ballistic resistance. The construction of bulletproof glass typically begins with the selection of high-quality glass panels, which serve as the foundational component of the composite structure. These glass panels are subjected to rigorous testing and quality control measures to ensure their integrity and uniformity.

Once the glass panels are prepared, they undergo a lamination process where they are bonded with interlayers made of polycarbonate, polyurethane, or other impact-resistant materials. These interlayers play a pivotal role in enhancing the overall strength and resilience of the bulletproof glass, effectively absorbing and dispersing the energy of incoming projectiles. The lamination process is carried out under precise conditions to achieve optimal adhesion and structural integrity.

After the lamination phase, the composite assembly undergoes a series of pressing and heating procedures to facilitate the bonding of the glass and interlayer materials. This thermal consolidation process is essential for ensuring a cohesive and durable union between the individual components, resulting in a unified structure with enhanced ballistic performance.

In some cases, additional layers of specialized coatings or films may be applied to the surface of the bulletproof glass to further enhance its protective properties, such as resistance to forced entry, impact mitigation, or UV protection. These supplementary treatments are tailored to meet specific performance requirements based on the intended application of the bulletproof glass.

The final product is subjected to rigorous testing and certification processes to validate its ballistic resistance and optical clarity, ensuring that it meets the stringent standards for safety and performance. This comprehensive approach to manufacturing bulletproof glass underscores the meticulous attention to detail and engineering precision involved in creating a material that offers unparalleled protection without compromising visibility.

In the subsequent section, we will delve into the critical aspect of determining the thickness of bulletproof glass, shedding light on the factors that influence this fundamental characteristic.

Bulletproof glass thickness varies depending on the level of protection needed. For example, a Level 1 bulletproof glass is typically around 0.75 inches thick, while a Level 3 glass can be up to 3 inches thick.

The Thickness of Bulletproof Glass

The thickness of bulletproof glass is a critical determinant of its ballistic resistance and protective capabilities. It plays a pivotal role in mitigating the impact of projectiles and ensuring the structural integrity of the material under high-stress conditions. The selection of an appropriate thickness for bulletproof glass is a meticulous process that takes into account various factors, including the level of ballistic threat anticipated, the intended application of the glass, and the desired balance between protection and optical clarity.

In general, the thickness of bulletproof glass can range from a few millimeters to several inches, depending on the specific requirements of the protective barrier. For applications where the risk of ballistic threats is relatively low, such as residential security or low-level impact resistance, thinner configurations of bulletproof glass may be sufficient to provide adequate protection. These thinner variants offer the advantage of reduced weight and improved optical clarity, making them suitable for applications where a balance between protection and aesthetics is paramount.

On the other hand, high-security installations and military-grade applications often necessitate thicker configurations of bulletproof glass to withstand the formidable force of high-velocity projectiles and explosive impacts. In these scenarios, the thickness of the bulletproof glass is meticulously engineered to provide an optimal level of protection without compromising visibility or architectural design requirements. The multi-layered composition of bulletproof glass, coupled with its varying thicknesses, enables it to effectively dissipate the energy of incoming projectiles, thereby preventing penetration and minimizing the risk of injury or damage.

The determination of the appropriate thickness for bulletproof glass involves a comprehensive assessment of the specific ballistic threats it is expected to encounter. This assessment takes into consideration the velocity, caliber, and potential trajectory of projectiles, as well as the likelihood of multiple or sustained impacts. By analyzing these factors, engineers and security experts can prescribe the most suitable thickness of bulletproof glass to meet the unique security needs of a given environment.

In essence, the thickness of bulletproof glass is a crucial parameter that directly influences its ability to withstand ballistic threats and provide reliable protection. By tailoring the thickness of bulletproof glass to the specific requirements of diverse applications, from armored vehicles and secure facilities to architectural elements and protective barriers, this remarkable material continues to redefine safety standards and design possibilities across a myriad of industries.

Factors Affecting the Thickness of Bulletproof Glass

The determination of the appropriate thickness for bulletproof glass is influenced by a multitude of factors that collectively shape its ballistic resistance, optical clarity, and overall performance. These factors are meticulously evaluated to ensure that the bulletproof glass meets the specific security and design requirements of diverse applications. Understanding the key considerations that affect the thickness of bulletproof glass is essential for engineering tailored solutions that effectively mitigate ballistic threats while maintaining the desired level of transparency and functionality.

-

Ballistic Threat Level: The anticipated level of ballistic threat is a primary determinant of the thickness of bulletproof glass. Different environments and applications may face varying degrees of risk, ranging from low-velocity impacts to high-powered projectiles. The thickness of the bulletproof glass is calibrated to withstand the specific ballistic threats prevalent in a given setting, ensuring that it provides adequate protection without unnecessary overengineering.

-

Application Specificity: The intended application of the bulletproof glass plays a pivotal role in determining its thickness. For instance, bulletproof glass used in civilian vehicles may have different thickness requirements compared to that used in military-grade armored vehicles. Similarly, the thickness of bulletproof glass utilized in architectural elements, such as windows and doors, is tailored to harmonize with the aesthetic and functional aspects of the design.

-

Optical Clarity: Balancing ballistic resistance with optical clarity is a critical consideration in determining the thickness of bulletproof glass. Thicker configurations of bulletproof glass may offer enhanced protection, but they can also impact the visual transparency of the material. Engineers and designers strive to optimize the thickness of bulletproof glass to maintain unobstructed visibility while meeting the requisite safety standards.

-

Weight and Structural Impact: The thickness of bulletproof glass directly influences its weight and structural impact on the overall design. In applications where weight restrictions and architectural considerations are paramount, such as in aerospace or marine environments, the thickness of bulletproof glass is carefully tailored to minimize structural load while delivering the necessary protective capabilities.

-

Regulatory Compliance: Compliance with industry standards and regulatory requirements is a crucial factor in determining the thickness of bulletproof glass. Various safety and security standards dictate the minimum thickness and performance criteria for bulletproof glass used in different applications, necessitating meticulous adherence to these guidelines during the engineering and installation processes.

By meticulously evaluating these factors and their interplay, engineers and designers can prescribe the optimal thickness of bulletproof glass for diverse applications, ensuring that it delivers uncompromising protection without sacrificing functionality or visual appeal. The dynamic interplay of these factors underscores the intricate balance between ballistic resilience, optical clarity, and design integration in the realm of bulletproof glass applications.

Read more: How To Break Bulletproof Glass

Conclusion

In conclusion, the thickness of bulletproof glass is a pivotal aspect of its design and performance, playing a crucial role in providing reliable protection against ballistic threats while maintaining essential transparency. The intricate process of manufacturing bulletproof glass involves the strategic assembly of multiple layers of specialized materials, meticulously engineered to withstand high-velocity impacts and potential ballistic threats. The selection of an appropriate thickness for bulletproof glass is a meticulous endeavor that takes into account various factors, including the level of anticipated ballistic threat, the intended application of the glass, and the imperative balance between protection and optical clarity.

By tailoring the thickness of bulletproof glass to meet the specific requirements of diverse applications, from civilian security and architectural design to military-grade installations and vehicular protection, this remarkable material continues to redefine safety standards and design possibilities across a myriad of industries. The dynamic interplay of factors such as ballistic threat level, application specificity, optical clarity, weight and structural impact, and regulatory compliance collectively shapes the thickness of bulletproof glass, ensuring that it delivers uncompromising protection without sacrificing functionality or visual appeal.

The evolution of bulletproof glass represents a remarkable fusion of advanced engineering, material science, and security innovation, offering a tangible solution to the ever-present need for reliable protection in an increasingly complex and dynamic world. As technology continues to advance and new materials and manufacturing techniques emerge, the future of bulletproof glass holds the promise of even greater ballistic resilience, enhanced optical clarity, and expanded design versatility. This ongoing evolution underscores the enduring significance of bulletproof glass as a transformative element in safeguarding lives, assets, and infrastructure against potential threats.

In essence, the thickness of bulletproof glass stands as a testament to the ingenuity and precision of modern engineering, serving as a tangible embodiment of safety, security, and design excellence. As we look to the future, the continued refinement and innovation in the realm of bulletproof glass are poised to redefine the boundaries of protection and transparency, ushering in a new era of safety and design possibilities across a diverse spectrum of applications.

Frequently Asked Questions about How Thick Is Bulletproof Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Thick Is Bulletproof Glass”