Home>Furniture & Design>Interior Design Trends>What Is Borosilicate Glass

Interior Design Trends

What Is Borosilicate Glass

Modified: August 28, 2024

Discover the benefits of borosilicate glass in interior design trends. Learn why it's a popular choice for modern and stylish home decor.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

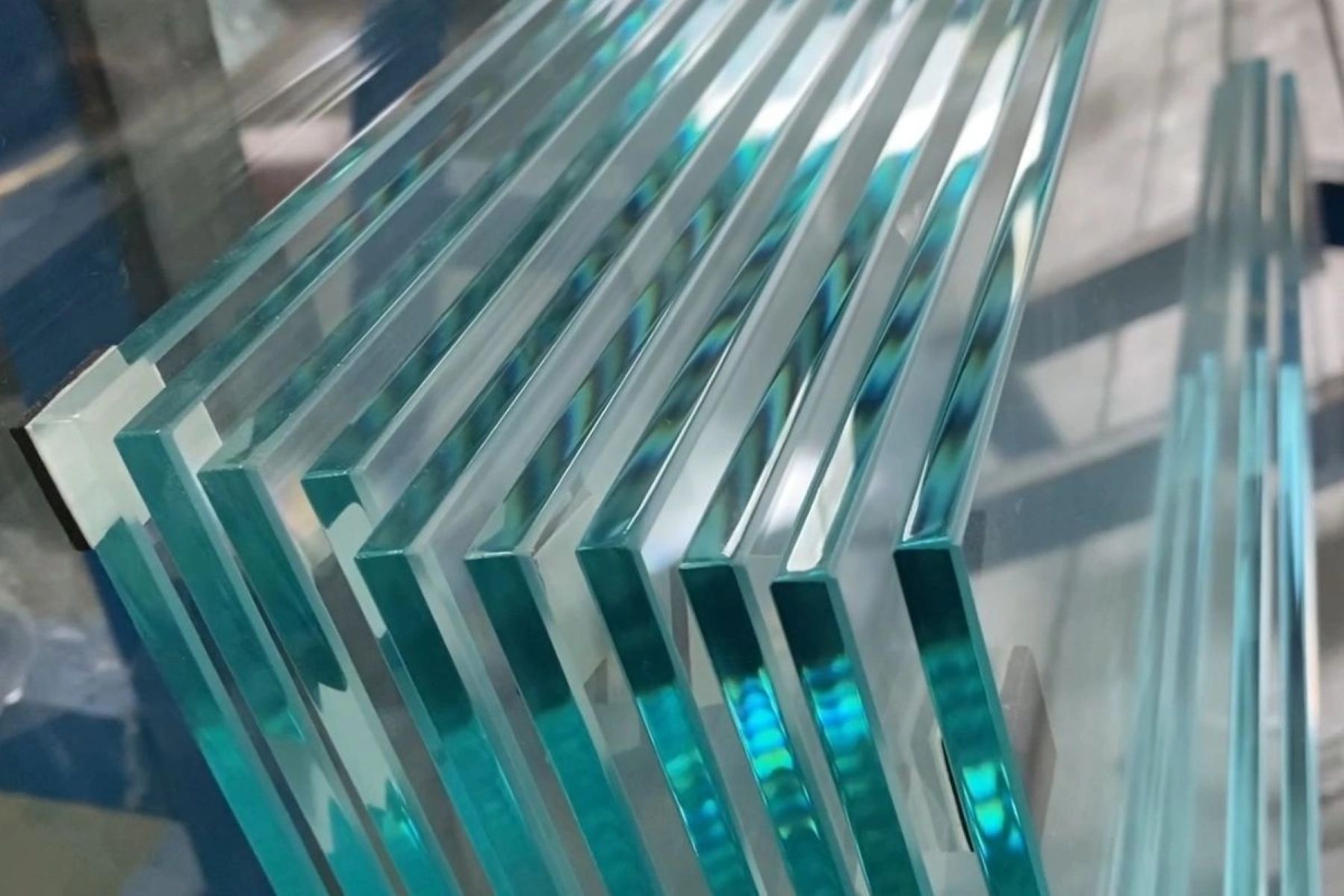

Borosilicate glass is a type of glass renowned for its exceptional durability, thermal resistance, and chemical inertness. This unique material has found its way into various industries and applications, ranging from laboratory equipment to kitchenware and even high-end art glass. Its versatility and remarkable properties have made it a popular choice for a wide array of products.

The origins of borosilicate glass can be traced back to the late 19th century, when German glassmaker Otto Schott developed the first borosilicate glass under the brand name "Duran." Since then, borosilicate glass has gained widespread recognition and has become synonymous with quality and reliability.

In this article, we will delve into the history, properties, uses, advantages, and disadvantages of borosilicate glass. By exploring these aspects, we can gain a comprehensive understanding of this remarkable material and its significance in various fields. Let's embark on a journey to unravel the secrets and wonders of borosilicate glass.

Key Takeaways:

- Borosilicate glass, developed in the late 19th century, is a durable and heat-resistant material used in lab equipment, kitchenware, and art. Its unique properties make it ideal for various applications.

- Borosilicate glass offers exceptional thermal resistance, chemical inertness, and durability, making it versatile across industries. While it has advantages, such as reliability, it also has limitations, like cost and brittleness.

Read more: What Is Glass Used For

History of Borosilicate Glass

Borosilicate glass has a rich and intriguing history that dates back to the late 19th century. Its story begins with the pioneering work of German glassmaker Otto Schott, who, along with his colleagues Ernst Abbe and Carl Zeiss, embarked on a quest to develop a new type of glass with exceptional properties. Their efforts led to the creation of borosilicate glass, a material that would revolutionize various industries and applications.

In 1887, Otto Schott, in collaboration with his partners, succeeded in producing the first borosilicate glass under the brand name "Duran." This groundbreaking achievement marked the beginning of a new era in glass technology. The unique composition of borosilicate glass, which includes boron trioxide as a key component, contributed to its remarkable thermal and chemical properties. This innovation quickly garnered attention and acclaim, propelling borosilicate glass into the spotlight as a material of unparalleled quality and versatility.

The introduction of borosilicate glass brought about significant advancements in laboratory equipment, as its superior resistance to thermal shock and chemical corrosion made it an ideal choice for scientific experiments and research. Its ability to withstand extreme temperatures without cracking or shattering set a new standard for glassware used in laboratories and industrial settings.

Over the years, the use of borosilicate glass expanded beyond the realm of scientific applications. Its exceptional durability and heat resistance made it an ideal material for various consumer products, including cookware, bakeware, and high-quality glass art. The versatility of borosilicate glass has allowed it to transcend traditional boundaries and become a staple in modern manufacturing and design.

Today, borosilicate glass continues to be celebrated for its rich history and enduring legacy. Its evolution from a groundbreaking scientific innovation to a ubiquitous material in everyday products is a testament to its enduring impact on the world of glass technology. The history of borosilicate glass serves as a testament to human ingenuity and the relentless pursuit of excellence in material science, leaving an indelible mark on numerous industries and shaping the way we interact with glass in our daily lives.

Properties of Borosilicate Glass

Borosilicate glass is renowned for its exceptional properties, making it a highly sought-after material in various industries. The unique composition of borosilicate glass contributes to its remarkable characteristics, setting it apart from conventional glass types. Here are the key properties that define borosilicate glass:

-

Thermal Resistance: One of the most notable properties of borosilicate glass is its exceptional thermal resistance. This glass type can withstand a wide range of temperatures, making it ideal for applications where thermal shock resistance is crucial. Whether exposed to high heat or rapid temperature changes, borosilicate glass remains stable and intact, minimizing the risk of breakage or damage.

-

Chemical Inertness: Borosilicate glass exhibits high chemical inertness, making it resistant to corrosion from acids, bases, and other reactive substances. This property is particularly valuable in laboratory settings, where glassware comes into contact with a variety of chemicals during experiments and analyses. The ability of borosilicate glass to maintain its integrity in the presence of corrosive substances enhances its reliability and longevity in demanding environments.

-

Durability: With its robust composition, borosilicate glass is highly durable and less prone to breakage compared to traditional soda-lime glass. This durability makes it suitable for a wide range of applications, from industrial equipment to consumer products. Its resilience to mechanical stress and impact contributes to its longevity and safety in various usage scenarios.

-

Transparency and Clarity: Borosilicate glass possesses excellent optical properties, providing exceptional transparency and clarity. This makes it an ideal material for optical components, precision instruments, and high-quality glassware. The ability of borosilicate glass to transmit light without distortion or impurities enhances its suitability for applications where visual clarity is essential.

-

Electrical Insulation: Due to its low electrical conductivity, borosilicate glass serves as an effective electrical insulator. This property is valuable in electronic and electrical applications, where the insulation of components is critical to prevent electrical leakage and ensure safety.

-

Hygienic and Non-Porous: Borosilicate glass is non-porous, making it resistant to staining and retaining odors. This property is particularly advantageous in kitchenware and food storage containers, where cleanliness and hygiene are paramount. The non-porous nature of borosilicate glass also simplifies cleaning and maintenance, contributing to its appeal in household and culinary products.

-

Lightweight: Despite its exceptional strength and durability, borosilicate glass is relatively lightweight, offering ease of handling and portability in various applications.

The combination of these properties makes borosilicate glass a versatile and highly desirable material across diverse industries, from scientific research and industrial manufacturing to consumer goods and artistic endeavors. Its unique blend of thermal, chemical, and mechanical attributes has positioned borosilicate glass as a material of choice for applications that demand reliability, performance, and safety.

Uses of Borosilicate Glass

Borosilicate glass's exceptional properties have paved the way for its widespread utilization across various industries and applications. Its unique combination of thermal resistance, chemical inertness, and durability has positioned it as a material of choice for a diverse range of products and technologies. Here are some of the key uses of borosilicate glass:

Laboratory Equipment:

Borosilicate glass is extensively employed in the manufacturing of laboratory glassware and equipment. Its ability to withstand extreme temperatures and resist chemical corrosion makes it indispensable for scientific experiments, chemical analyses, and pharmaceutical research. Beakers, test tubes, pipettes, and petri dishes crafted from borosilicate glass offer reliable performance and safety in laboratory settings.

Read more: What Is Optical Glass

Industrial Applications:

In industrial settings, borosilicate glass finds applications in sight glasses, level gauges, and high-pressure glass piping systems. Its robustness and resistance to thermal shock make it suitable for monitoring processes and containing corrosive substances in challenging industrial environments. The transparency and durability of borosilicate glass contribute to its effectiveness in industrial instrumentation and equipment.

Kitchenware and Cookware:

The thermal resistance and non-porous nature of borosilicate glass make it an ideal material for kitchenware and cookware. From baking dishes and casserole dishes to measuring cups and storage containers, borosilicate glass products offer a safe and reliable option for food preparation, cooking, and storage. Their ability to withstand oven temperatures and rapid temperature changes enhances their practicality in culinary applications.

Artistic Glasswork:

Borosilicate glass has gained popularity in the realm of artistic glasswork and craftsmanship. Glass artists and artisans utilize its clarity, workability, and resilience to create intricate sculptures, decorative pieces, and functional art. The versatility of borosilicate glass allows artists to explore a wide range of creative possibilities, from delicate ornaments to elaborate glass installations.

Lighting and Optical Components:

The optical clarity and thermal stability of borosilicate glass make it well-suited for lighting fixtures and optical components. It is used in the production of high-quality lenses, glass fibers, and precision optics for scientific instruments, cameras, and lighting systems. The ability of borosilicate glass to transmit light without distortion or degradation enhances its utility in optical applications.

Read more: What Is Camphor Glass

Consumer Products:

Borosilicate glass has found its way into consumer products such as coffee makers, tea infusers, water bottles, and baby bottles. Its hygienic properties, resistance to odors, and ease of cleaning make it a preferred material for items that come into direct contact with food and beverages. The safety and reliability of borosilicate glass contribute to its appeal in household and lifestyle products.

Medical and Pharmaceutical Devices:

In the medical and pharmaceutical sectors, borosilicate glass is utilized in the production of vials, ampoules, syringes, and other drug delivery systems. Its compatibility with pharmaceutical formulations, inertness, and resistance to thermal stress make it an essential material for packaging and delivering medications safely and reliably.

The diverse applications of borosilicate glass underscore its significance across multiple industries, where its exceptional properties contribute to the performance, safety, and longevity of various products and technologies. From scientific research and industrial processes to everyday consumer goods and artistic creations, borosilicate glass continues to play a pivotal role in shaping modern innovations and enhancing the quality of numerous products and applications.

Advantages and Disadvantages of Borosilicate Glass

Borosilicate glass offers a host of advantages that have solidified its position as a preferred material in various industries. However, it also presents certain limitations that warrant consideration. Understanding the advantages and disadvantages of borosilicate glass is crucial for informed decision-making and effective utilization of this exceptional material.

Advantages

-

Thermal Resistance: Borosilicate glass excels in its ability to withstand extreme temperatures without compromising its structural integrity. This property makes it invaluable for applications requiring thermal shock resistance, such as laboratory equipment and industrial processes.

-

Chemical Inertness: The high resistance of borosilicate glass to chemical corrosion ensures its reliability in environments where exposure to reactive substances is common. This advantage is particularly significant in laboratory settings and pharmaceutical applications, where the integrity of glassware is paramount.

-

Durability: With its robust composition, borosilicate glass exhibits exceptional durability, making it less susceptible to breakage and damage compared to conventional glass types. This durability contributes to the longevity and safety of products crafted from borosilicate glass.

-

Clarity and Transparency: Borosilicate glass offers outstanding optical properties, providing exceptional clarity and transparency. This makes it an ideal material for optical components, precision instruments, and high-quality glassware where visual clarity is essential.

-

Hygienic and Non-Porous: The non-porous nature of borosilicate glass makes it resistant to staining and retaining odors, enhancing its suitability for kitchenware, food storage containers, and medical devices. Its hygienic properties contribute to its appeal in applications where cleanliness is paramount.

-

Versatility: Borosilicate glass's versatility allows it to be utilized in a wide range of applications, from laboratory equipment and industrial components to consumer products and artistic creations. Its adaptability and performance across diverse industries underscore its versatility.

Read more: What Is Monolithic Glass

Disadvantages

-

Cost: Borosilicate glass production involves specialized manufacturing processes and high-quality raw materials, resulting in a relatively higher production cost compared to standard soda-lime glass. This cost factor may influence its widespread adoption in certain applications.

-

Brittleness: While borosilicate glass is more resistant to thermal shock than other glass types, it is still inherently brittle. Extreme mechanical stress or impact can lead to breakage, necessitating careful handling and consideration of its limitations in high-impact environments.

-

Weight: Borosilicate glass, despite being relatively lightweight, may be heavier than alternative materials in certain applications. This can impact portability and handling, especially in products where weight is a critical consideration.

-

Workability: The unique composition of borosilicate glass, while contributing to its exceptional properties, can also pose challenges in terms of workability and shaping during manufacturing processes. This may limit its feasibility in certain intricate or complex designs.

-

Specialized Expertise: Working with borosilicate glass may require specialized knowledge and expertise due to its unique properties and manufacturing requirements. This can influence the accessibility of skilled labor and expertise in utilizing this material effectively.

By weighing these advantages and disadvantages, stakeholders can make informed decisions regarding the incorporation of borosilicate glass in various applications, leveraging its strengths while addressing its limitations to maximize its potential across diverse industries.

Conclusion

In conclusion, borosilicate glass stands as a testament to the remarkable advancements in glass technology, offering a unique combination of properties that have propelled it into diverse industries and applications. From its origins in the late 19th century to its pervasive presence in modern manufacturing and design, borosilicate glass has left an indelible mark on the world of materials science and innovation.

The rich history of borosilicate glass, marked by the pioneering work of Otto Schott and his collaborators, underscores the relentless pursuit of excellence and the quest for materials with exceptional properties. Its evolution from a revolutionary scientific innovation to a ubiquitous material in everyday products reflects the enduring impact of human ingenuity and the relentless pursuit of excellence in material science.

The properties of borosilicate glass, including its thermal resistance, chemical inertness, durability, transparency, and versatility, have positioned it as a material of choice across diverse industries. Its applications in laboratory equipment, industrial processes, kitchenware, artistic glasswork, optical components, consumer products, and medical devices underscore its significance in shaping modern innovations and enhancing the quality of numerous products and technologies.

While borosilicate glass offers a host of advantages, including its exceptional thermal resistance, chemical inertness, durability, and versatility, it also presents certain limitations that warrant consideration. Understanding the advantages and disadvantages of borosilicate glass is crucial for informed decision-making and effective utilization of this exceptional material.

In essence, borosilicate glass continues to play a pivotal role in shaping modern innovations and enhancing the quality of numerous products and applications. Its enduring legacy and enduring impact on various industries underscore its significance as a material that embodies resilience, reliability, and ingenuity. As we look to the future, the legacy of borosilicate glass will continue to inspire advancements in materials science and contribute to the development of innovative solutions across diverse fields.

Frequently Asked Questions about What Is Borosilicate Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Borosilicate Glass”