Home>Furniture & Design>Interior Design Trends>What Is Sapphire Glass

Interior Design Trends

What Is Sapphire Glass

Modified: October 18, 2024

Discover the latest interior design trends with our guide to sapphire glass. Learn how this stunning material can elevate your home decor. Explore the possibilities today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Sapphire glass, also known as synthetic sapphire, is a remarkable material that has gained significant attention in various industries due to its exceptional properties. Despite its name, sapphire glass is not a type of glass at all; rather, it is a form of crystalline aluminum oxide, or corundum, which is one of the hardest minerals on Earth, second only to diamond. This unique composition gives sapphire glass unparalleled strength, durability, and scratch resistance, making it a highly sought-after material for a wide range of applications.

The origins of sapphire glass can be traced back to the early 20th century when scientists began experimenting with synthetic corundum for industrial purposes. Over time, advancements in manufacturing techniques have allowed for the production of large, high-quality sapphire crystals, paving the way for their use in cutting-edge technologies and luxury products.

Sapphire glass has garnered attention for its use in high-end timepieces, such as luxury watches, due to its ability to withstand scratches and maintain a pristine appearance over time. Beyond the realm of horology, sapphire glass has found its way into the world of consumer electronics, where its exceptional hardness and optical clarity make it an ideal material for smartphone screens, camera lenses, and other electronic displays.

The unique properties of sapphire glass have also made it a popular choice for specialized applications in industries such as aerospace, defense, and medical technology. Its exceptional resistance to extreme temperatures, corrosion, and abrasion make it an invaluable material for critical components in these demanding environments.

As we delve deeper into the properties, applications, and manufacturing process of sapphire glass, it becomes evident that this extraordinary material is poised to play a pivotal role in shaping the future of various industries, offering unparalleled performance and durability in a wide array of products and technologies.

Key Takeaways:

- Sapphire glass is not your typical glass; it’s a super-strong material made of crystalline aluminum oxide. It’s like a superhero of materials, resisting scratches, standing up to extreme temperatures, and even being biocompatible for medical use!

- From luxury watches to smartphone screens, sapphire glass is everywhere! Its exceptional hardness and clarity make it perfect for high-end products and critical components in industries like aerospace and defense. It’s like the VIP of materials!

Properties of Sapphire Glass

Sapphire glass possesses a remarkable set of properties that distinguish it from traditional glass and other materials. These properties make it an ideal choice for a wide range of applications across diverse industries. Let's delve into the key characteristics that define sapphire glass:

-

Exceptional Hardness: One of the most notable properties of sapphire glass is its exceptional hardness, ranking just below diamond on the Mohs scale. This outstanding hardness makes sapphire glass highly resistant to scratches and abrasions, ensuring that products incorporating this material maintain their pristine appearance even after prolonged use.

-

Outstanding Transparency: Sapphire glass exhibits exceptional optical clarity, allowing for high light transmission with minimal distortion. This property makes it an ideal material for optical components, such as lenses and windows, where maintaining precise and clear visibility is crucial.

-

High Thermal Resistance: Another significant property of sapphire glass is its remarkable thermal resistance. It can withstand extreme temperatures, making it suitable for applications in harsh environments where conventional glass or plastics would fail.

-

Chemical Inertness: Sapphire glass is highly resistant to chemical corrosion, making it an excellent choice for applications that involve exposure to harsh chemicals or corrosive substances. This property ensures the longevity and reliability of products incorporating sapphire glass in chemically challenging environments.

-

Exceptional Strength: In addition to its hardness, sapphire glass exhibits exceptional tensile strength, making it highly resistant to breakage and fracture. This property is particularly valuable in applications where mechanical stress or impact resistance is critical.

-

Biocompatibility: Sapphire glass is biocompatible, meaning it is well-tolerated by the human body and does not elicit adverse reactions. This property makes it suitable for use in medical implants and other biomedical applications.

-

Electrical Insulation: Sapphire glass is an excellent electrical insulator, making it valuable for electronic and semiconductor applications where electrical isolation and high-performance characteristics are essential.

The combination of these properties positions sapphire glass as a versatile and high-performance material, offering durability, clarity, and reliability across a wide spectrum of applications. Its unique set of properties continues to drive innovation and expand its use in cutting-edge technologies and luxury products.

Applications of Sapphire Glass

Sapphire glass, with its exceptional properties, has found diverse and innovative applications across various industries. Its remarkable hardness, outstanding transparency, and high thermal resistance make it an ideal choice for a wide range of products and technologies. Let's explore the diverse applications of sapphire glass:

1. Luxury Watches and Timepieces

Sapphire glass has become synonymous with luxury watches, where its exceptional scratch resistance and durability make it the material of choice for watch crystals. The use of sapphire glass in high-end timepieces ensures that the watch faces remain pristine and free from scratches, maintaining their aesthetic appeal over time.

2. Consumer Electronics

In the realm of consumer electronics, sapphire glass is utilized in smartphone screens, camera lenses, and other electronic displays. Its exceptional hardness and optical clarity make it an ideal material for protecting delicate electronic components, ensuring durability and maintaining visual clarity in electronic devices.

Read more: What Is Glass Used For

3. Optical Components

Sapphire glass is widely used in optical components such as lenses, windows, and prisms due to its outstanding transparency and resistance to scratches. Its optical clarity and durability make it an essential material for high-performance optical systems in scientific, industrial, and aerospace applications.

4. Aerospace and Defense

The aerospace and defense industries leverage sapphire glass for its exceptional thermal resistance and durability. It finds applications in aircraft windows, missile domes, and sensor windows, where its ability to withstand extreme temperatures and harsh environmental conditions is crucial for reliable performance.

5. Medical Technology

Sapphire glass is utilized in medical devices and equipment, including endoscopes, surgical instruments, and medical implants. Its biocompatibility, exceptional hardness, and resistance to corrosion make it a valuable material for critical medical applications, ensuring safety, reliability, and longevity in medical settings.

6. Industrial and Scientific Instruments

In industrial and scientific settings, sapphire glass is employed in a wide range of instruments and equipment, including high-pressure cells, spectroscopy components, and laser systems. Its exceptional properties make it an ideal material for demanding industrial and scientific applications, where durability, clarity, and reliability are paramount.

Read more: What Is Optical Glass

7. High-Performance Windows and Transparent Armor

Sapphire glass is used in high-performance windows and transparent armor for military vehicles and security applications. Its exceptional hardness and resistance to impact make it a critical material for providing protection and visibility in demanding security and defense scenarios.

The diverse applications of sapphire glass across luxury products, consumer electronics, aerospace, defense, medical technology, and industrial and scientific instruments underscore its versatility and high-performance capabilities. As technology continues to advance, sapphire glass is poised to play an increasingly significant role in shaping the future of various industries, offering unparalleled durability, clarity, and reliability in a wide array of products and technologies.

Manufacturing Process of Sapphire Glass

The manufacturing process of sapphire glass involves intricate steps to transform raw materials into high-quality synthetic sapphire crystals. The process begins with aluminum oxide powder, which serves as the primary raw material for producing sapphire glass. The key steps in the manufacturing process include:

-

Crystal Growth: The crystal growth process is typically carried out using the Verneuil method, also known as the flame fusion method. In this method, aluminum oxide powder is melted at high temperatures using a flame or electric arc. As the molten material cools, synthetic sapphire crystals begin to form. The controlled cooling process is crucial for achieving the desired crystal structure and minimizing defects within the material.

-

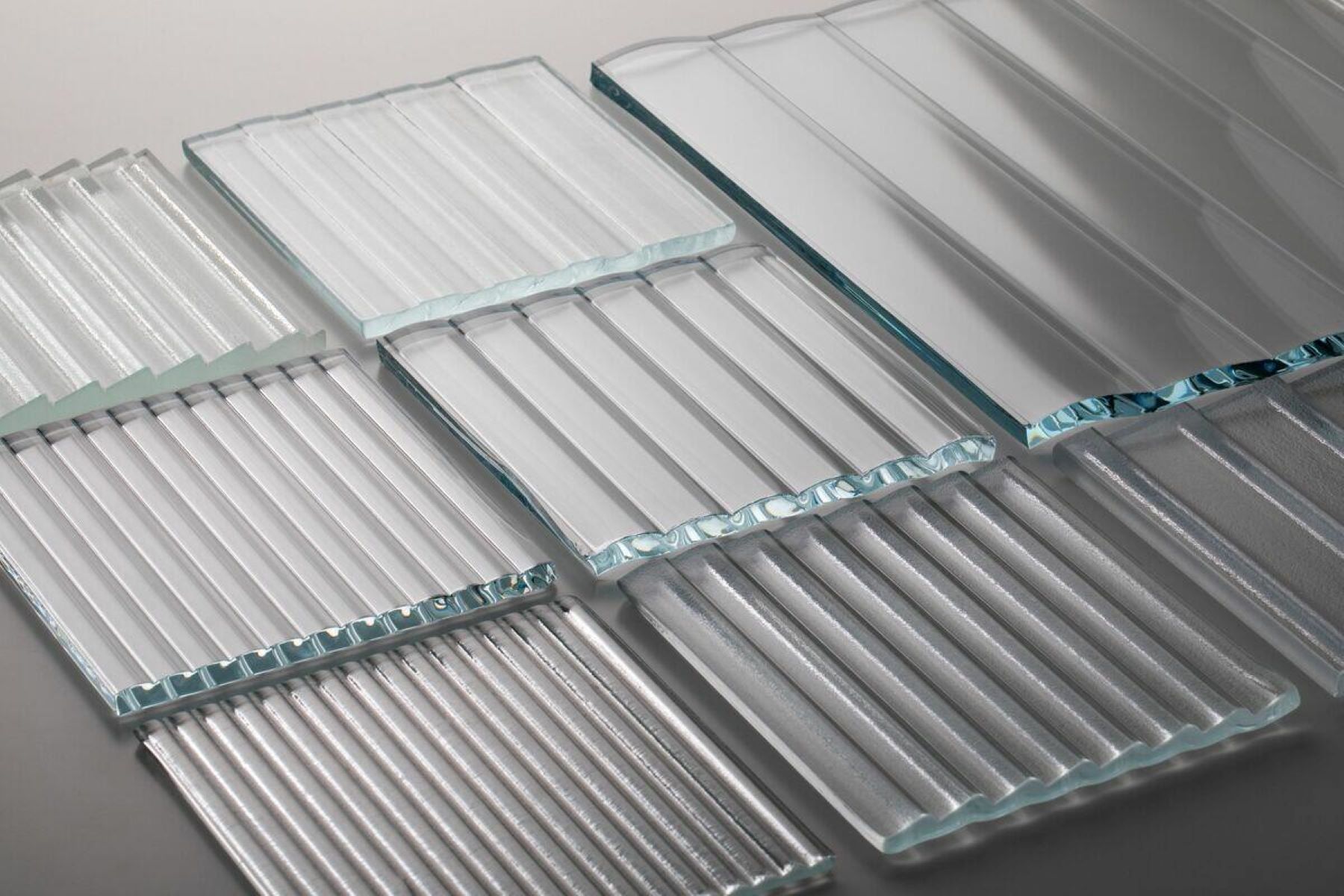

Crystal Formation: Once the sapphire crystals have been grown, they undergo shaping and processing to achieve the desired dimensions and specifications. This may involve cutting, grinding, and polishing the crystals to create flat, smooth surfaces with precise thickness and optical clarity.

-

Quality Control and Inspection: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the sapphire crystals meet stringent standards for purity, transparency, and structural integrity. Advanced inspection techniques, such as optical microscopy and spectroscopic analysis, are employed to assess the quality of the crystals and identify any imperfections or irregularities.

-

Surface Treatment: After the sapphire crystals have been formed and inspected, they may undergo surface treatments to enhance their performance characteristics. This can include applying anti-reflective coatings, strengthening treatments, or other surface modifications to improve durability, optical properties, and resistance to environmental factors.

-

Final Processing and Integration: The processed sapphire crystals are then integrated into specific products or applications based on their intended use. This may involve further shaping, cutting, or bonding the sapphire glass to create components such as watch crystals, smartphone screens, optical lenses, or other specialized products.

The manufacturing process of sapphire glass demands precision, expertise, and advanced technology to produce high-quality synthetic sapphire crystals with the desired properties. As the demand for sapphire glass continues to grow across various industries, ongoing advancements in manufacturing techniques and process optimization are driving the production of increasingly sophisticated and versatile sapphire glass products.

The detailed manufacturing process of sapphire glass underscores the intricate craftsmanship and technological innovation involved in creating this exceptional material, which continues to elevate the standards of durability, clarity, and performance in a wide range of products and applications.

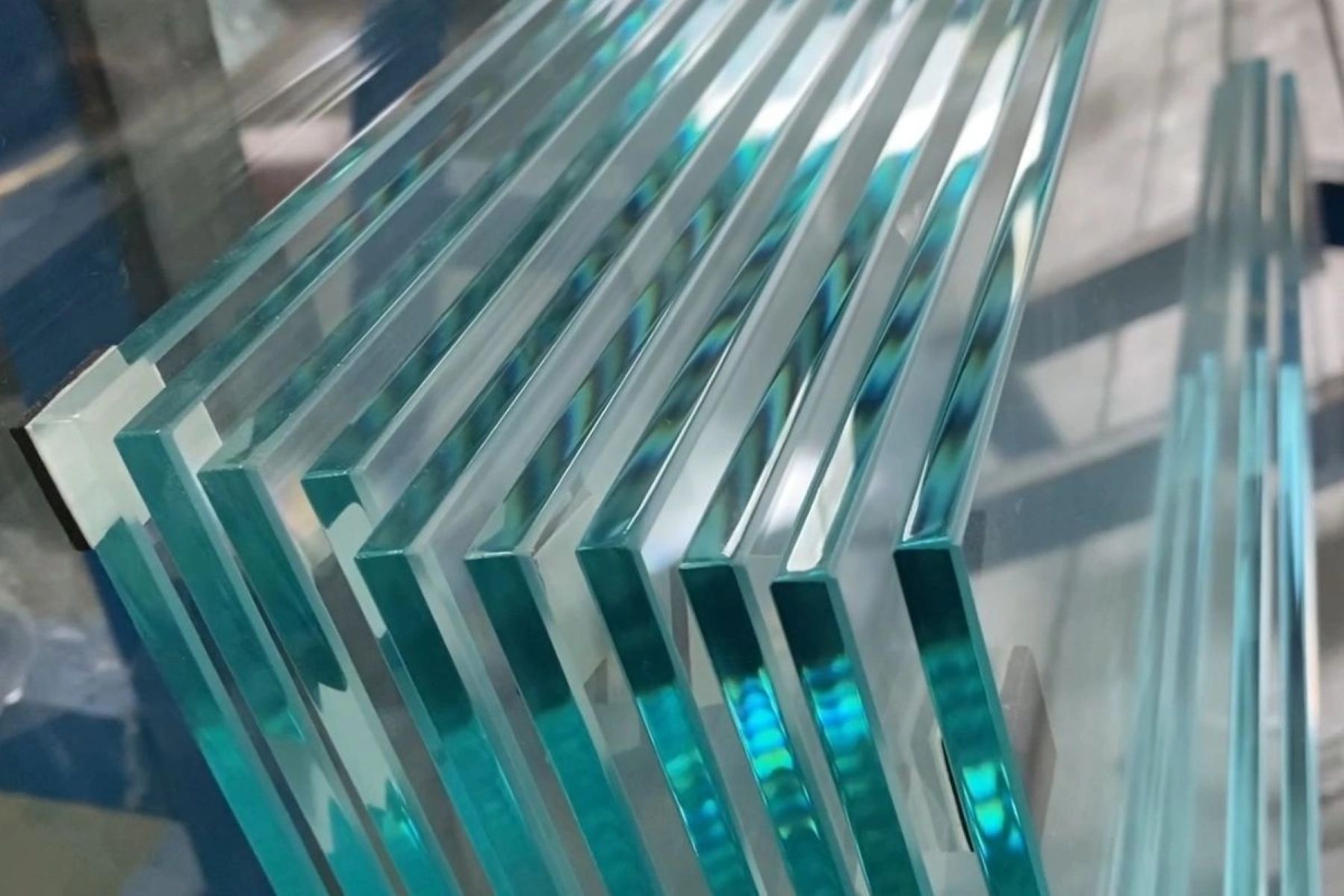

Comparison with Other Types of Glass

Sapphire glass stands out distinctly when compared to traditional glass and other advanced glass materials due to its exceptional properties and performance characteristics. Let's explore how sapphire glass compares to other types of glass in terms of hardness, transparency, durability, and applications.

Hardness and Scratch Resistance

Traditional glass, such as soda-lime glass, is significantly softer than sapphire glass, making it more susceptible to scratches and abrasions. In contrast, sapphire glass, with its exceptional hardness just below that of diamond on the Mohs scale, offers unparalleled scratch resistance, ensuring that products incorporating sapphire glass maintain their pristine appearance over time. This remarkable hardness sets sapphire glass apart as an ideal choice for applications where durability and scratch resistance are paramount.

Read more: What Is Camphor Glass

Optical Clarity and Transparency

When compared to traditional glass, sapphire glass exhibits superior optical clarity and transparency. While traditional glass may have slight distortions and impurities, sapphire glass provides exceptional light transmission with minimal distortion, making it an ideal material for optical components, high-end watch crystals, and electronic displays. The optical clarity of sapphire glass surpasses that of traditional glass, offering enhanced visual performance in various applications.

Thermal and Chemical Resistance

In terms of thermal and chemical resistance, sapphire glass outperforms traditional glass by a significant margin. Traditional glass is susceptible to thermal shock and chemical corrosion, limiting its use in harsh environments. On the other hand, sapphire glass demonstrates exceptional resistance to extreme temperatures and chemical corrosion, making it suitable for aerospace, defense, and industrial applications where traditional glass would be unsuitable. The superior thermal and chemical resistance of sapphire glass expands its potential applications in demanding environments.

Applications and Specialized Uses

While traditional glass finds widespread use in everyday products such as windows, containers, and household items, sapphire glass is employed in specialized and high-performance applications. The exceptional properties of sapphire glass make it the material of choice for luxury watches, high-end smartphones, optical lenses, medical devices, and aerospace components, where its durability, clarity, and reliability are indispensable. The diverse and specialized applications of sapphire glass set it apart as a material that enables cutting-edge technologies and luxury products.

In summary, the comparison between sapphire glass and traditional glass highlights the remarkable advantages of sapphire glass in terms of hardness, transparency, durability, and specialized applications. As technology continues to advance, sapphire glass is poised to play an increasingly significant role in shaping the future of various industries, offering unparalleled performance and reliability across a wide array of products and technologies.

Conclusion

In conclusion, sapphire glass stands as a testament to human ingenuity and technological advancement, offering a unique combination of exceptional properties that set it apart as a material of unparalleled strength, durability, and clarity. From luxury watches to cutting-edge electronics, aerospace components to medical devices, sapphire glass has found its way into an array of applications, reshaping industries and redefining the standards of performance and reliability.

The exceptional hardness of sapphire glass, ranking just below diamond on the Mohs scale, ensures that products incorporating this material maintain their pristine appearance, free from scratches and abrasions. Its outstanding transparency and resistance to thermal and chemical factors make it an ideal choice for optical components, high-performance windows, and electronic displays, where maintaining precise visibility and durability is crucial.

The manufacturing process of sapphire glass demands precision, expertise, and advanced technology to produce high-quality synthetic sapphire crystals with the desired properties. Ongoing advancements in manufacturing techniques and process optimization are driving the production of increasingly sophisticated and versatile sapphire glass products, expanding its potential applications across diverse industries.

When compared to traditional glass, sapphire glass emerges as a material of superior performance, offering enhanced hardness, optical clarity, and resistance to environmental factors. Its specialized uses in luxury products, high-tech devices, and critical components underscore its versatility and high-performance capabilities, paving the way for continued innovation and advancement in various fields.

As technology continues to evolve, sapphire glass is poised to play an increasingly significant role in shaping the future of industries, offering unparalleled durability, clarity, and reliability in a wide array of products and technologies. The remarkable properties and diverse applications of sapphire glass position it as a material that continues to push the boundaries of what is possible, inspiring innovation and driving progress across the global landscape.

In essence, sapphire glass represents a triumph of material science and engineering, embodying the pursuit of excellence and the relentless quest for pushing the limits of what materials can achieve. Its impact on industries and technologies is profound, and its journey of innovation and advancement is poised to continue, shaping the future with its exceptional properties and limitless potential.

Frequently Asked Questions about What Is Sapphire Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Sapphire Glass”