Articles

How Does The Incandescent Light Bulb Work

Modified: August 25, 2024

Discover how incandescent light bulbs work and learn more about articles on this topic.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

The incandescent light bulb is one of the most iconic and recognizable inventions in human history. For decades, it has been the primary source of lighting in homes, offices, and public spaces. Despite the rise of more energy-efficient options such as LED and fluorescent lighting, incandescent bulbs still have a place in our lives and continue to be used in various applications.

The concept behind the incandescent light bulb is relatively simple. When an electric current passes through a filament, it heats up to the point where it emits visible light. This process, known as incandescence, forms the basis for how these bulbs operate.

In this article, we will delve into the inner workings of the incandescent light bulb, exploring its components, function, and advantages and disadvantages. By gaining a deeper understanding of this technology, we can appreciate the legacy of the incandescent bulb and its place in the evolution of lighting.

Key Takeaways:

- Despite its warm glow and dimming capability, the incandescent light bulb is highly inefficient, converting most of the electricity into heat rather than light, leading to higher energy consumption and environmental impact.

- While incandescent bulbs have a nostalgic appeal, transitioning to energy-efficient alternatives like LEDs and CFLs offers significant benefits, including longer lifespan, reduced maintenance costs, and lower carbon footprint.

Read more: How Does An LED Light Bulb Work

Components of an Incandescent Light Bulb

An incandescent light bulb consists of several key components that work together to produce light. Let’s take a closer look at each of these components:

- Glass Envelope: The outer protective shell of the bulb is usually made of glass. It serves to provide insulation and shield the filament from external factors.

- Incandescent Light Bulb Filament: The filament is the heart of the bulb, responsible for emitting light when heated. It is typically made of tungsten and is wound into a coil or helix shape. The filament is carefully designed to withstand high temperatures and resist breaking.

- Tungsten Support Wires: These thin metal wires hold the filament in place and provide electrical connections between the filament and the base of the bulb.

- Noble Gas Filling: Many incandescent bulbs are filled with a small amount of an inert gas, such as argon or krypton. The gas helps prevent oxidation of the filament, which would otherwise cause it to burn out more quickly.

- Base: The base of the bulb serves as the connection point for the electrical supply. It typically has a screw or pin configuration that allows the bulb to be easily screwed into a socket.

- Socket: The socket is the receptacle that holds the bulb in place and provides electrical contact between the bulb and the power source. It is usually made of metal or heat-resistant plastic and is designed to fit a specific bulb base type.

These components work together to create the conditions necessary for the incandescence process to occur. When the bulb is connected to a power source, an electrical current flows through the filament, causing it to heat up and emit light. The glass envelope and noble gas filling help maintain the integrity of the filament and enhance the bulb’s overall performance.

Understanding the components of an incandescent light bulb provides insight into how this technology has been used to illuminate our lives for over a century. Despite its simplicity, the incandescent bulb continues to offer a warm and familiar glow that is unmatched by other lighting options.

The Incandescent Light Bulb Filament

The filament is a crucial component of an incandescent light bulb. It is responsible for producing light through the process of incandescence. The filament is typically made of tungsten, a robust and heat-resistant metal that can withstand the high temperatures required for light emission.

When an electric current is passed through the filament, it resists the flow of electricity and heats up as a result. As the temperature of the filament increases, it begins to emit visible light. The specific composition and structure of the filament play a significant role in determining the brightness and efficiency of the bulb.

Tungsten is the preferred material for filaments due to its unique characteristics. It has a high melting point of around 3,400 degrees Celsius (6,200 degrees Fahrenheit), making it suitable for withstanding the extreme temperatures generated during operation. Furthermore, tungsten has excellent electrical conductivity, allowing for efficient energy transfer through the filament.

The filament is typically formed into a coiled or helical shape to maximize the surface area and increase light output. This design also helps distribute the heat evenly across the filament, preventing localized hot spots that could lead to premature failure.

The thickness of the filament wire also plays a role in the bulb’s performance. Thicker filaments are more robust and can handle higher currents, resulting in brighter light output. However, thicker filaments also consume more energy and have a shorter lifespan. Manufacturers strike a balance between brightness, efficiency, and longevity when designing the filament for a specific bulb.

It’s worth noting that incandescent bulbs generate a significant amount of heat due to the filament’s high operating temperature. This heat is considered wasted energy since it doesn’t contribute to light production. In fact, approximately 90% of the energy consumed by an incandescent bulb is converted into heat rather than light, which is why these bulbs are not as energy-efficient as LED or fluorescent alternatives.

Despite their relatively low efficiency, incandescent light bulbs have remained popular due to their warm and familiar glow. The filament’s unique design and tungsten material contribute to the characteristic quality of incandescent light, making it the preferred choice for certain applications where color rendering and ambiance are important considerations.

The Role of Tungsten in Incandescent Light Bulbs

Tungsten plays a crucial role in the functioning of incandescent light bulbs. It is the primary material used for the filament, which emits light when heated. Tungsten is chosen for its unique properties that make it ideal for this application.

One of the key characteristics of tungsten is its extremely high melting point, which is around 3,400 degrees Celsius (6,200 degrees Fahrenheit). This property allows the filament to operate at high temperatures without melting or breaking. By comparison, other metals like iron or copper would quickly melt under the intense heat generated by the electric current passing through the filament.

Tungsten also has excellent electrical conductivity, ensuring efficient energy transfer through the filament. This means that a greater proportion of the electrical energy is converted into light rather than wasted as heat. The combination of high melting point and good electrical conductivity makes tungsten an ideal material for filament construction, as it can withstand the high temperatures required for incandescent light production.

Another advantage of tungsten is its low vapor pressure at high temperatures. When exposed to heat, tungsten slowly evaporates but at a significantly lower rate than other metals. This characteristic helps to maintain the integrity of the filament over its lifespan, preventing it from degrading or thinning too quickly. The use of tungsten allows incandescent light bulbs to have a longer operating life compared to bulbs that use other materials for the filament.

Tungsten filaments can be manufactured in various shapes and sizes to achieve different levels of light output and energy efficiency. Thicker filaments produce more light but consume more energy, while thinner filaments require less energy but produce lower light output. The choice of filament design depends on the intended usage and desired balance between brightness and efficiency.

While tungsten is a vital component of incandescent light bulbs, it’s worth noting that these bulbs are not very energy-efficient. The majority of the energy consumed by an incandescent bulb is converted into heat rather than light. This inefficiency has led to the phasing out of traditional incandescent bulbs in many countries, as more energy-efficient alternatives like LED and fluorescent lighting have become available.

Nonetheless, tungsten’s unique properties continue to make it an essential component in incandescent light bulbs, ensuring their continued use in certain applications where color rendering, dimmability, and ambiance are valued over energy efficiency.

Gas Filling in Incandescent Light Bulbs

In addition to the filament, incandescent light bulbs often contain a small amount of gas, typically an inert gas such as argon or krypton. This gas filling serves several important purposes in the operation of the bulb.

One of the primary functions of the gas filling is to prevent oxidation of the filament. When the filament operates at high temperatures, it can react with the oxygen in the air and slowly deteriorate over time. By filling the bulb with an inert gas, the oxygen is displaced, reducing the rate at which the filament oxidizes. This helps to extend the lifespan of the bulb and maintain its light output.

The gas filling also helps to dissipate heat more effectively. As the filament heats up, it radiates thermal energy in the form of heat. The presence of the gas facilitates the transfer of this heat away from the filament, preventing it from overheating and potentially causing the bulb to fail prematurely. By enhancing the bulb’s thermal management, the gas filling contributes to the overall durability and reliability of the incandescent light bulb.

Moreover, the gas filling affects the color temperature of the emitted light. Different gases have different spectral properties, which can influence the perceived color of the light produced. For example, filling the bulb with argon gas tends to result in a warmer, yellowish light, while krypton can produce a slightly whiter light. Manufacturers carefully select the gas filling to achieve the desired color characteristics of the bulb, catering to specific lighting preferences and applications.

It’s important to note that the amount of gas present in an incandescent light bulb is relatively small compared to the volume of the bulb. The concentration of the gas is carefully controlled to achieve the desired effects without interfering with the bulb’s overall performance.

While gas filling helps optimize the performance and lifespan of incandescent light bulbs, it’s worth mentioning that this design element also contributes to their relatively low energy efficiency. The gas filling does not directly contribute to light production but rather serves to enhance other aspects of the bulb’s operation. As a result, the majority of the electrical energy consumed by incandescent bulbs is still converted into heat rather than light.

The use of gas filling in incandescent light bulbs highlights the attention to detail and engineering considerations involved in their design. While these bulbs may not be as energy-efficient as newer lighting technologies, they continue to have their place in specific applications where color rendering, dimming performance, and ambiance are primary concerns.

Read more: How Does Wifi Light Bulb Work?

The Function of the Incandescent Light Bulb Base

The base of an incandescent light bulb serves as a critical component that provides both electrical and mechanical support. It is the part of the bulb that connects to the socket and ensures a secure and reliable connection to the power source.

One of the primary functions of the bulb base is to provide the electrical contact necessary for the flow of electricity to the filament. The base typically features metal contacts that connect with corresponding contacts in the socket. When the bulb is screwed or inserted into the socket, these contacts establish a connection, allowing the electrical current to flow through the filament and generate light.

The design of the bulb base can differ depending on the type of socket it is intended to fit. Common types of bulb bases include the Edison screw base (E26/E27), which is widely used in household lighting, and the bi-pin base (GU10, G9, etc.), often found in smaller bulbs used for task lighting or decorative purposes.

In addition to facilitating electrical connection, the bulb base also provides mechanical support to the bulb. It ensures that the bulb is securely held in place within the socket, preventing accidental dislodgement or movement. The base is designed with threads or pins that align with the corresponding features in the socket, allowing for a tight fit. This ensures proper alignment of the bulb filament with respect to the reflector or lens within the fixture, optimizing light distribution and focus.

The choice of base design depends on various factors, including the intended application and compatibility with the socket and fixture. Different bases have specific requirements for voltage, wattage, and dimension, so it is essential to use the correct base type for a particular lighting fixture to ensure safe and optimal performance.

It’s worth noting that the base material is often made of heat-resistant plastic or metal to withstand the high temperatures generated by the bulb. This helps to prevent deformation or degradation of the base and maintain its structural integrity throughout the life of the bulb.

Overall, the function of the incandescent light bulb base is to provide a secure electrical connection and mechanical support. Its design and compatibility with different sockets ensure proper operation and enable the bulb to deliver light effectively and reliably.

The Incandescent Light Bulb Socket

The incandescent light bulb socket is an essential component involved in connecting the bulb to the power source and providing a secure and stable electrical connection. It is responsible for holding the bulb in place and ensuring compatibility with the fixture or socket it is installed in.

The socket serves as the receptacle for the bulb base, which is designed to fit into the socket securely. It is typically made of metal or heat-resistant plastic and features contacts that align with the contacts on the bulb’s base. These contacts provide the electrical connection needed for the flow of electricity to the filament.

The socket plays a crucial role in facilitating ease of installation and removal of the bulb. It is designed to accommodate the specific base type of the bulb, whether it is an Edison screw base, bi-pin base, or any other type. The socket’s size, shape, and configuration are determined by the standards and specifications of the base type it is compatible with.

In addition to electrical connection, the socket provides mechanical support to hold the bulb securely in place. It ensures that the bulb is positioned correctly within the fixture, allowing for proper alignment of the filament with respect to the reflector or lens. This alignment ensures optimal light distribution and focus, improving the overall performance of the lighting fixture.

Socket designs can vary depending on the specific application or fixture requirements. For example, some sockets are designed to be compatible with dimming switches, allowing users to adjust the brightness of the incandescent bulb. Other sockets may be designed for specific voltage or wattage ratings to ensure safe and reliable operation.

It is important to note that the socket should be compatible with the electrical specifications of the light fixture and the bulb being used. Using an incorrect socket may result in improper electrical connections, reduced performance, or even potential safety hazards. Therefore, it is crucial to follow manufacturer guidelines and ensure proper compatibility when selecting a socket for an incandescent light bulb.

With the advancements in lighting technology and the transition to more energy-efficient options, it is important to note that the design of the incandescent light bulb socket has evolved to accommodate newer bulb types, such as LEDs and compact fluorescent bulbs. However, the basic function of the socket, providing an electrical and mechanical connection, remains the same regardless of the bulb technology used.

The incandescent light bulb socket plays a vital role in ensuring a secure and reliable connection between the bulb and the power source. It contributes to the overall functionality and performance of the lighting fixture, allowing for effective lighting solutions in various applications.

The incandescent light bulb works by passing an electric current through a filament, which heats up and produces light. The filament is usually made of tungsten to withstand the high temperatures.

Incandescent Light Bulb Voltage and Power

Incandescent light bulbs are designed to operate within a specific voltage range, and understanding the relationship between voltage and power is crucial for selecting the appropriate bulb for a particular application.

Most incandescent bulbs are designed to operate at either 120 volts or 240 volts, depending on the electrical system used in a specific region or country. There are also bulbs engineered to accommodate lower voltages, such as 12 volts, which are commonly used in low-voltage lighting systems.

The voltage rating of an incandescent bulb is an indication of the electrical potential required to produce light. If the voltage supplied to the bulb exceeds or falls below the rated voltage, the bulb’s performance can be affected. Too high of a voltage may cause the bulb to burn brighter and hotter, shortening its lifespan and potentially leading to premature failure. Conversely, a lower voltage may result in dimmer light output and reduced bulb efficiency.

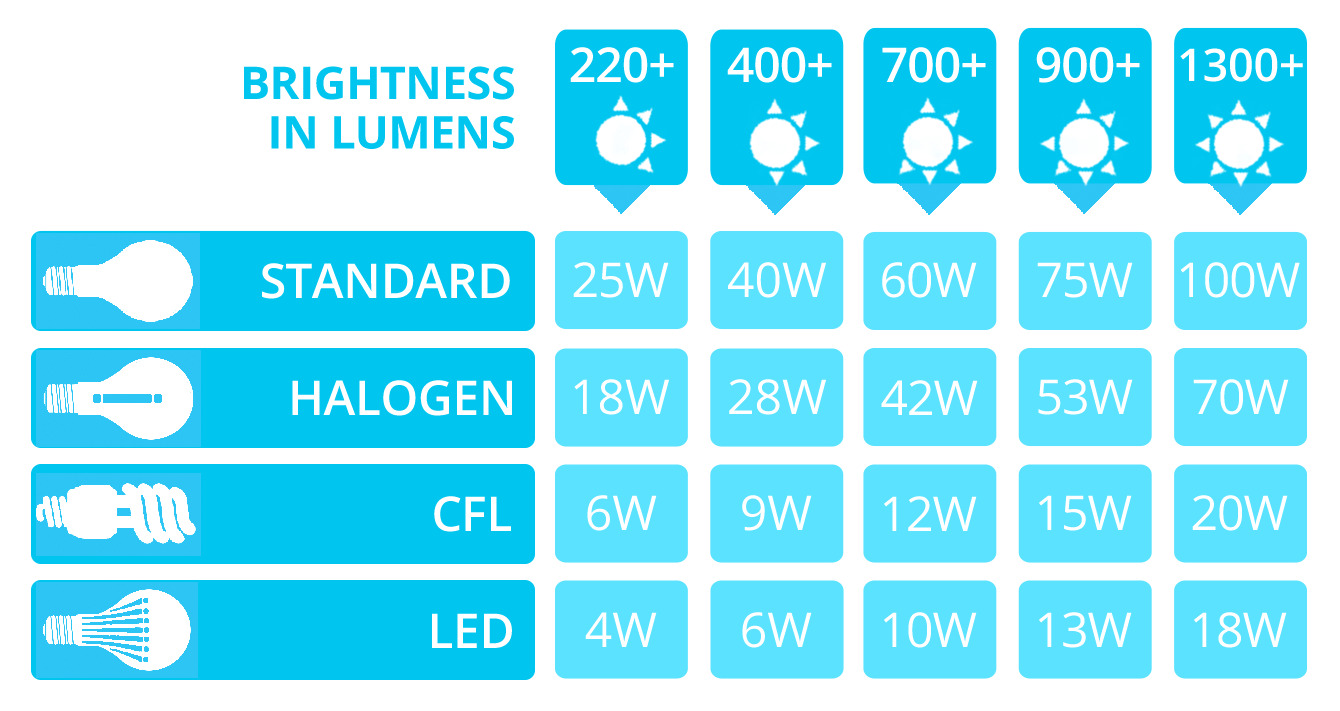

The power consumption of an incandescent light bulb is determined by its wattage rating. The wattage indicates the amount of electrical power the bulb uses, with higher wattages consuming more power and producing brighter light. Incandescent bulbs typically range from around 40 to 150 watts, with higher wattage bulbs commonly used for applications where more intense illumination is required.

It’s important to note that the relationship between voltage, power, and brightness is not a linear one. While a higher voltage may result in a brighter light output, it also leads to increased power consumption and heat generation. On the other hand, reducing the voltage may dim the light output but can also lead to energy savings. However, it’s crucial to ensure that the voltage remains within the bulb’s specified operating range to avoid damage or reduced performance.

When selecting an incandescent light bulb, it is essential to consider the voltage and wattage requirements of the lighting fixture or application. Using a bulb with an incorrect voltage rating could result in improper electrical connections, safety hazards, or reduced performance. It’s always recommended to consult the manufacturer’s guidelines or seek professional advice when choosing the right incandescent bulb for a specific lighting setup.

It’s worth noting that incandescent bulbs are not as energy-efficient as newer lighting technologies like LEDs or CFLs. The majority of the energy consumed by an incandescent bulb is converted into heat rather than light, making them less efficient and more expensive to operate over time. As a result, many countries have phased out or restricted the use of traditional incandescent bulbs in favor of more energy-efficient alternatives.

Despite their lower efficiency, incandescent bulbs still have certain advantages, such as their warm color rendering and dimmability. However, for applications that require high energy efficiency and long-lasting performance, it is recommended to explore alternative lighting options like LEDs or CFLs.

The Incandescent Light Bulb’s Warm-up Period

When you turn on an incandescent light bulb, you may notice that it takes a brief moment for the bulb to reach its full brightness. This delay, known as the warm-up period, is a characteristic feature of incandescent bulbs and is a result of the physics behind their operation.

During the warm-up period, the filament inside the bulb gradually heats up until it reaches a temperature that is sufficient to emit visible light. When you initially switch on the bulb, the filament is cool, and the resistance to the flow of electricity is relatively low. As electricity passes through the filament, it heats up, causing it to glow and emit light.

However, because the filament has an initial low resistance, the current passing through it is higher at the start, which increases the rate of heating. As the filament temperature rises, its resistance also increases. This increase in resistance helps to regulate the current flow and prevent the bulb from overheating.

As the filament gradually heats up, the emitted light becomes more visible, and the bulb reaches its full brightness. This warm-up period typically lasts for a few seconds to a minute, depending on the bulb wattage and design.

It’s important to note that the warm-up period is more noticeable with higher wattage incandescent bulbs compared to lower wattage bulbs. Higher wattage bulbs have thicker filaments, which require more energy to heat up and reach the necessary temperature for light emission. Lower wattage bulbs, on the other hand, have thinner filaments and require less time to reach full brightness.

While the warm-up period may be seen as a minor inconvenience, it is a characteristic feature of incandescent bulbs and should be accounted for when using them in applications where immediate full brightness is desired. Incandescent bulbs may not be the optimal choice for situations that require immediate illumination, such as security lighting or areas where constant on/off switching is frequent.

It’s worth mentioning that newer lighting technologies, such as LEDs, do not have a visible warm-up period and provide instant, full brightness. LEDs are solid-state devices that do not rely on heating a filament to emit light. This quick startup time is one of the many advantages of LED lighting in terms of energy efficiency and convenience.

Nevertheless, the warm-up period of incandescent bulbs is a characteristic that many people are familiar with and have grown accustomed to over the years. It adds to the nostalgia and charm associated with these traditional light sources. Despite their lower energy efficiency compared to newer technologies, incandescent bulbs still have their place in applications that value their warm color rendering and dimmability.

Efficiency and Lifespan of Incandescent Light Bulbs

Incandescent light bulbs have been a popular lighting choice for many years due to their warm and familiar glow. However, compared to newer lighting technologies, such as LEDs and CFLs, incandescent bulbs are significantly less efficient and have a shorter lifespan.

When it comes to efficiency, incandescent bulbs are relatively inefficient in converting electricity into light. Approximately 90% of the energy consumed by an incandescent bulb is converted into heat, while only around 10% is transformed into visible light. This inefficiency is primarily due to the way incandescent bulbs produce light through the process of incandescence, where a filament is heated to a high temperature to emit light. The vast amount of energy wasted as heat contributes to the higher energy consumption and makes incandescent bulbs costly to operate compared to more energy-efficient alternatives. This inefficiency has led to the phase-out of incandescent bulbs in many countries in an effort to reduce energy consumption and combat climate change.

Additionally, the lifespan of incandescent bulbs is relatively short compared to other lighting options. On average, incandescent bulbs have a lifespan of about 1,000 to 2,000 hours. This means that they need to be replaced more frequently, adding to the overall cost of maintaining them. The fragility of the filament also contributes to their shorter lifespan, as it can break easily when exposed to mechanical stress or voltage fluctuations.

Furthermore, incandescent bulbs are more susceptible to damage from factors such as humidity, vibration, and frequent switching on and off. These external influences can significantly impact their lifespan and reliability. It’s worth noting that newer lighting technologies, especially LEDs, have much longer lifespans, often ranging from 25,000 to 50,000 hours or even more. This extended lifespan reduces the need for frequent bulb replacement and lowers maintenance costs in the long run.

Despite their lower efficiency and shorter lifespan, incandescent bulbs do have some advantages. Their warm color temperature and ability to be dimmed make them suitable for certain applications where ambiance and color rendering are important, such as residential lighting. Incandescent bulbs also have instant startup, eliminating any warm-up time for full brightness.

However, to improve energy efficiency and reduce environmental impact, it is recommended to transition to more energy-efficient lighting options like LED or CFL bulbs. LED bulbs, in particular, have seen significant advancements in recent years, offering improved energy efficiency, longer lifespans, and a wide range of color temperatures to suit various preferences and applications.

As incandescent bulbs continue to be phased out in many parts of the world, it is important to consider the potential benefits of transitioning to more sustainable lighting options. While incandescent bulbs may still have their place in specific scenarios, embracing energy-efficient alternatives can help reduce energy consumption, lower carbon emissions, and contribute to a greener future.

Advantages and Disadvantages of Incandescent Light Bulbs

Incandescent light bulbs have been a staple in lighting for over a century, offering a warm and familiar glow. However, compared to newer lighting technologies, such as LEDs and CFLs, incandescent bulbs come with several advantages and disadvantages that should be considered when choosing the right lighting solution for a particular application.

Advantages:

- Warm Color Rendering: Incandescent bulbs have a warm color temperature that closely resembles natural sunlight, providing a cozy and comfortable ambiance in residential settings. They are often favored for their ability to display colors accurately and enhance the aesthetics of a space.

- Dimming Capability: Incandescent bulbs can be easily dimmed without affecting their performance or lifespan. This makes them suitable for creating various lighting atmospheres and adjusting brightness levels according to specific preferences or needs.

- Instant On: Incandescent bulbs provide instant full brightness as soon as they are turned on, without any warm-up time or delay. This immediate illumination can be advantageous in situations where instantaneous lighting is required.

- Affordability: Incandescent bulbs tend to be more affordable to purchase upfront compared to other lighting technologies. They have been widely available for many years, and their low initial cost can make them an attractive option for budget-conscious consumers.

Disadvantages:

- Low Energy Efficiency: Incandescent bulbs are highly inefficient in converting electricity into light, with approximately 90% of the energy consumed being wasted as heat. They consume more energy than newer technologies like LEDs or CFLs, resulting in higher electricity bills and a greater environmental impact.

- Shorter Lifespan: Incandescent bulbs have a relatively short lifespan compared to alternatives like LEDs or CFLs. On average, they last for about 1,000 to 2,000 hours. Frequent bulb replacements can be time-consuming and add to maintenance costs over time.

- Fragility: The delicate filament inside an incandescent bulb makes it susceptible to breakage due to vibrations or rough handling. This fragility can be a disadvantage in environments where the bulb may be exposed to mechanical stress or frequent movement.

- Environmental Impact: Due to their lower efficiency and higher energy consumption, incandescent bulbs contribute to increased carbon emissions and environmental harm compared to energy-efficient alternatives. Many countries have implemented regulations to phase out or restrict incandescent bulbs in an effort to promote more sustainable lighting options.

It’s important to consider these advantages and disadvantages when selecting the appropriate lighting solution. While incandescent bulbs have a nostalgic appeal and are suitable for specific applications where color rendering, dimming, and instant illumination are valued, it is recommended to explore energy-efficient alternatives like LEDs or CFLs for most residential and commercial lighting needs. These alternatives offer longer lifespans, greater energy efficiency, and reduced environmental impact, contributing to cost savings and a greener future.

Read more: What Is An Incandescent Bulb

Conclusion

The incandescent light bulb has played a significant role in providing illumination for over a century. While it has been a popular choice for its warm color rendering, dimming capability, and affordability, advancements in lighting technology have introduced more energy-efficient alternatives.

Understanding the components and functioning of incandescent bulbs has shed light on their unique characteristics. The filament, typically made of tungsten, emits light through the process of incandescence. Gas fillings, such as argon or krypton, help maintain the filament’s integrity and regulate the bulb’s performance. The bulb base and socket ensure proper electrical and mechanical connections.

Despite their advantages, incandescent bulbs have significant drawbacks. They are highly inefficient, converting most of the electricity into heat rather than light. Moreover, their shorter lifespan and fragility require frequent replacements, adding to maintenance costs. The environmental impact of incandescent bulbs and their contribution to carbon emissions are also significant concerns.

In today’s world, energy efficiency, sustainability, and longer lifespan are paramount. LED and CFL bulbs offer significant advantages over incandescent bulbs, including higher energy efficiency, lower environmental impact, longer lifespan, and instant startup without warm-up periods. These advancements have led to the phasing out of incandescent bulbs in many countries.

While incandescent bulbs still have their place in certain contexts, such as environments that demand warm color rendering and dimming capability, it is crucial to make informed choices about lighting to maximize energy efficiency and minimize environmental impact.

As we move towards a more sustainable future, it is recommended to explore energy-efficient alternatives like LEDs and CFLs. These lighting options offer significant benefits in terms of energy savings, reduced maintenance costs, and reduced carbon footprint. By embracing newer technologies, we can create well-lit spaces that are not only visually appealing but also environmentally responsible.

In summary, while the incandescent light bulb holds a nostalgic appeal and offers specific advantages, it is essential to consider the broader implications and benefits of transitioning to more sustainable and energy-efficient lighting options.

Frequently Asked Questions about How Does The Incandescent Light Bulb Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does The Incandescent Light Bulb Work”