Articles

How Much Does A 200 HP Electric Motor Weight

Modified: January 4, 2024

Discover the weight of a 200 HP electric motor with our informative article. Learn more about electric motor weights and find helpful tips and insights.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of electric motors! They are an essential component of many industries, powering everything from cars and appliances to industrial machinery. When it comes to electric motors, one important aspect that engineers and manufacturers consider is the weight of the motor. In this article, we will delve into the topic of how much a 200 horsepower (HP) electric motor weighs.

Electric motors are devices that convert electrical energy into mechanical energy. They play a crucial role in various applications by providing rotational motion. Horsepower is a unit of power that measures the rate at which work is done. It is widely used to determine the performance capabilities of an electric motor.

So, why is the weight of a 200 HP electric motor significant? Weight is an important consideration for several reasons. Firstly, it relates to the overall size and compactness of the motor. Secondly, it affects the installation process, as heavier motors may require additional supports or equipment. Lastly, weight can impact the efficiency and performance of the motor, especially in applications where portability and space constraints are critical.

Several factors influence the weight of an electric motor. These include the motor’s design, construction materials, cooling systems, and additional features. In the next section, we will explore these factors in more detail to understand their impact on the weight of a 200 HP electric motor.

Key Takeaways:

- The weight of a 200 HP electric motor can range from 1000 to 3000 pounds, influenced by factors like design, construction materials, and cooling systems. Consider power density and application requirements when choosing a motor.

- When selecting a 200 HP electric motor, consider factors such as efficiency, environmental conditions, maintenance needs, and budget constraints. Research and consult with experts to make an informed decision aligned with your application’s requirements.

Read more: How Much Copper Is In A 50 HP Electric Motor

Understanding Electric Motors

Before we dive into the weight considerations of a 200 HP electric motor, let’s first gain a basic understanding of how electric motors work. Electric motors operate on the principle of electromagnetic induction, utilizing the interaction between magnetic fields and electric currents to generate mechanical motion.

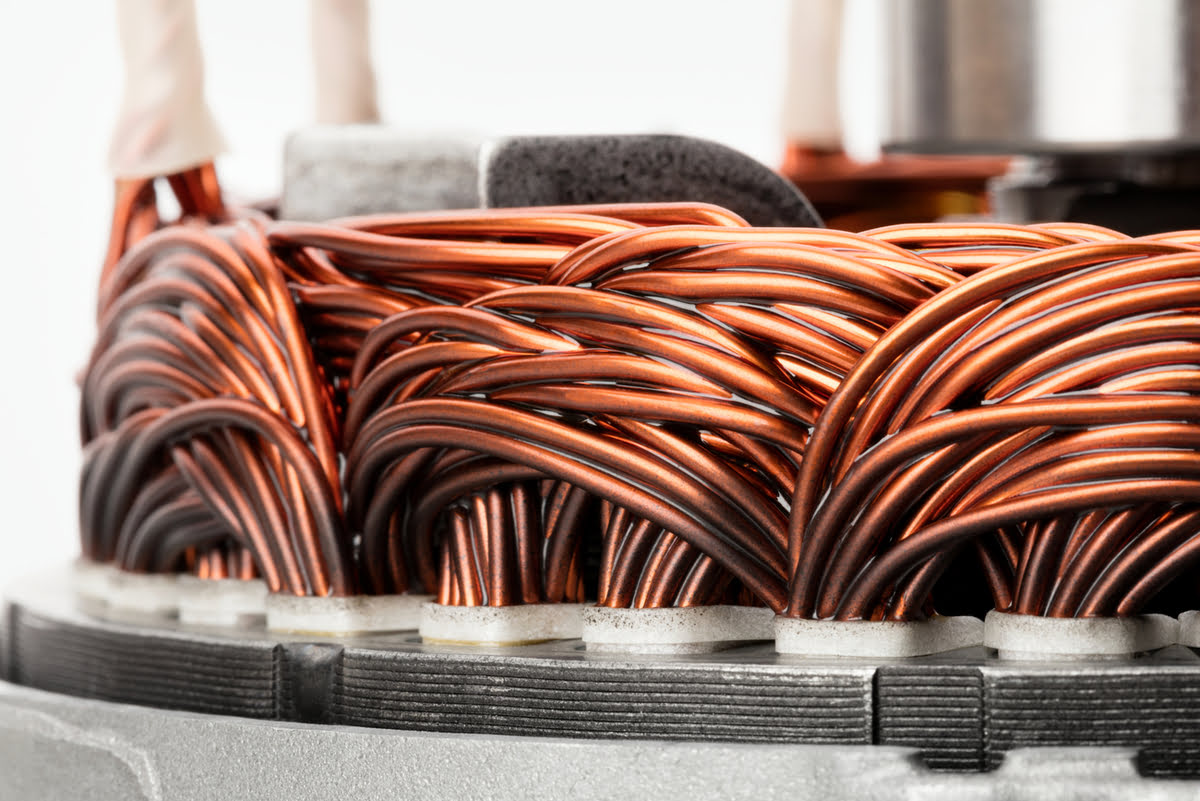

An electric motor consists of several key components, including a stator, a rotor, and a commutator or an electronic controller. The stator is the stationary part of the motor and houses the windings, which are typically made of copper or aluminum. These windings create a magnetic field when an electric current passes through them.

The rotor, on the other hand, is the rotating part of the motor and is placed within the stator. The rotor can be either a permanent magnet or an electromagnet. When the electric current flows through the windings in the stator, it creates a rotating magnetic field which interacts with the static magnetic field of the rotor. This interaction produces a torque that drives the rotor and results in rotational motion.

Electric motors come in various types, including DC (Direct Current) motors and AC (Alternating Current) motors. Both types have their advantages and are suitable for different applications. DC motors are commonly found in applications where precise control over speed and torque is required, such as robotics and electric vehicles. AC motors, on the other hand, are more commonly used in industrial applications due to their efficiency and reliability.

Now that we have a foundational understanding of electric motors, let’s move on to the importance of horsepower and its relevance to the weight of a 200 HP electric motor.

Importance of Horsepower

Horsepower is a measure of power that determines the rate at which work is performed. It was first introduced by engineer James Watt to compare the power output of steam engines to the power of horses. Today, horsepower is commonly used to evaluate the performance and capabilities of various machines, including electric motors.

When it comes to electric motors, horsepower indicates the motor’s power output. The higher the horsepower rating, the greater the motor’s ability to perform work. In the case of a 200 HP electric motor, it has a significant power output, making it suitable for demanding applications that require substantial torque and speed.

The horsepower rating of an electric motor is determined by various factors, including the torque required for the specific application, the speed at which the motor needs to operate, and the efficiency of the motor. It is crucial to select an electric motor with the appropriate horsepower rating to ensure optimum performance and avoid overloading or underutilizing the motor.

When considering the weight of a 200 HP electric motor, the horsepower rating can have a direct influence. Higher horsepower motors often require more robust construction and additional components, which can contribute to an increase in weight. It is important to strike a balance between power output and weight to meet the requirements of the application effectively.

Now that we understand the significance of horsepower, let’s explore the various factors that can affect the weight of a 200 HP electric motor.

Factors Affecting Electric Motor Weight

The weight of an electric motor can vary based on several factors. These factors include the motor’s design, construction materials, cooling systems, and additional features. Let’s take a closer look at each of these factors:

- Design: The design of an electric motor plays a crucial role in determining its weight. Motors with more compact and efficient designs can often achieve higher power outputs while reducing overall weight. Factors such as the arrangement of the windings, the shape of the rotor, and the layout of the internal components can impact the weight.

- Construction Materials: The materials used in the construction of the motor can significantly influence its weight. Traditional electric motors are often made with cast iron or steel components, which can add substantial weight. However, advancements in materials have led to the development of motors that incorporate lightweight alloys and composite materials, resulting in reduced weight without compromising performance.

- Cooling Systems: Electric motors generate heat during operation, and proper cooling is essential to maintain optimal performance and prevent overheating. Cooling systems, such as fans, heat sinks, and liquid cooling, can add weight to the motor. The choice of the cooling system will depend on factors such as the motor’s power output, operating environment, and cooling requirements.

- Additional Features: Some electric motors may have additional features or components that contribute to their weight. These features can include advanced control systems, integrated sensors, and specialized enclosures or housings. While these features can enhance motor performance and functionality, they may also add to the overall weight.

It’s important to note that the weight of an electric motor is not solely determined by its horsepower rating. Motors with the same horsepower can differ in weight due to variations in these factors. Thus, it’s crucial to consider these factors when evaluating the weight of a 200 HP electric motor.

Now that we have a better understanding of the factors affecting electric motor weight, let’s explore the typical weight range for a 200 HP electric motor.

The weight of a 200 hp electric motor can vary depending on the specific model and manufacturer. However, as a general guideline, a 200 hp electric motor can weigh anywhere from 2000 to 3000 pounds.

Typical Weight Range for 200 HP Electric Motors

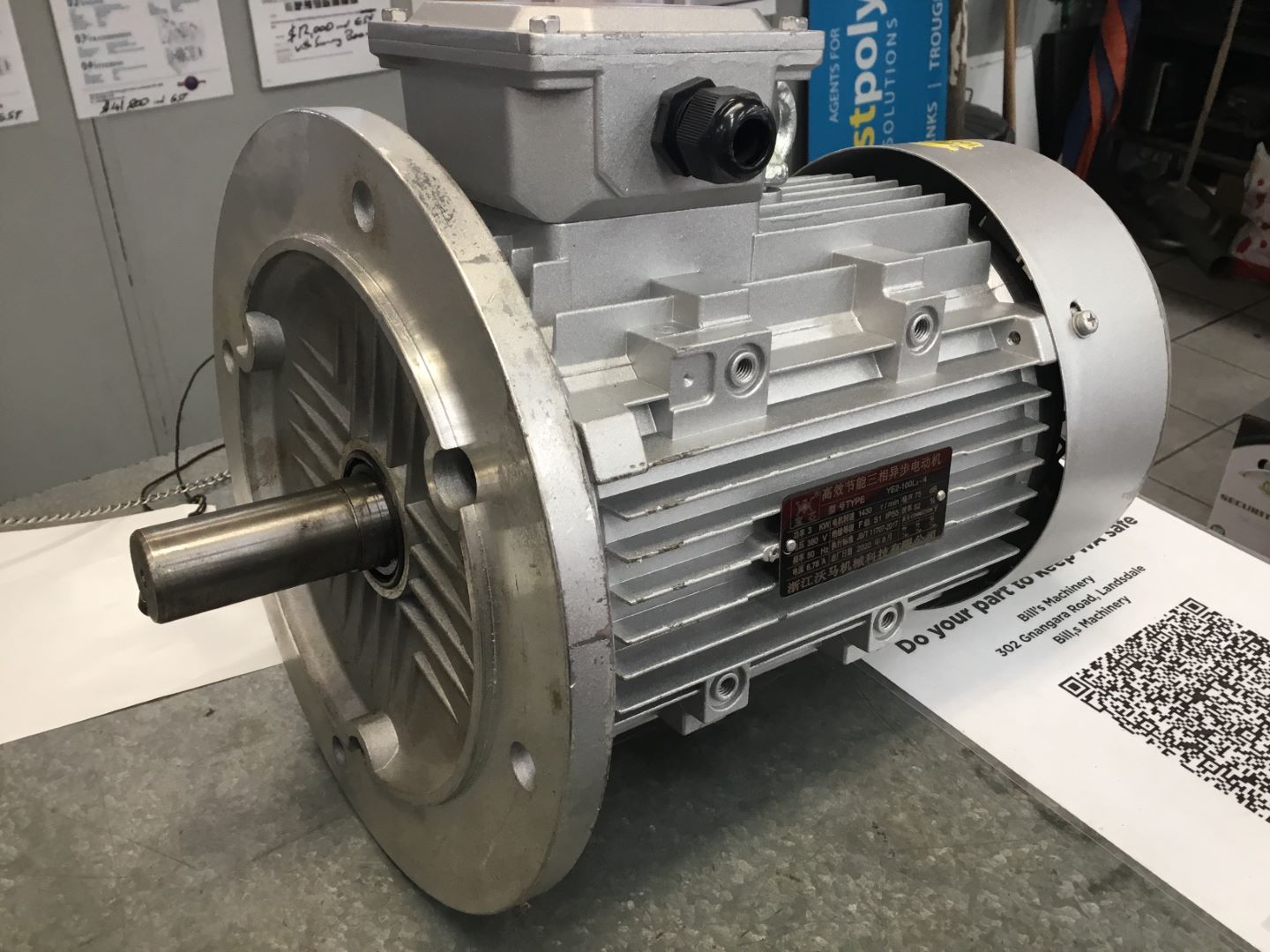

The weight of a 200 horsepower (HP) electric motor can vary depending on different factors and manufacturers. However, there is a typical weight range that can provide a general idea of what to expect.

In general, 200 HP electric motors can range in weight from around 1000 pounds (450 kilograms) to 3000 pounds (1360 kilograms). This weight range includes the motor’s frame, end brackets, windings, insulation, and other internal components.

It’s important to note that the weight provided is an estimate and can vary based on several factors, including the motor’s design, construction materials, cooling systems, and additional features. Some manufacturers may offer more lightweight options by utilizing advanced materials or unique designs, while others may focus on sturdiness and opt for heavier components.

The weight of a 200 HP electric motor is significant due to its power output. Installations that require high horsepower motors often have robust support structures in place to handle the weight and ensure stability during operation.

While the weight of a 200 HP electric motor may seem substantial, it is essential to consider the motor’s power density. Power density refers to the amount of power output relative to the weight of the motor. Motors with higher power densities can deliver more horsepower per unit of weight, making them more efficient in terms of power-to-weight ratio.

When evaluating the weight of a 200 HP electric motor, it’s crucial to consider the specific requirements of the application, including the available space, portability needs, and installation considerations. Balancing weight and performance is key to selecting the right electric motor for a given application.

Now that we understand the general weight range of a 200 HP electric motor, let’s explore how the weight can vary based on the type of motor.

Read more: How To Calculate HP Of Electric Motor

Variations in Weight Based on Motor Type

The weight of a 200 horsepower (HP) electric motor can vary depending on the specific type of motor. Different motor types have unique characteristics that can influence their weight. Let’s explore some common motor types and their associated weight considerations:

- AC Induction Motors: AC induction motors are widely used in industrial applications due to their robustness and efficiency. These motors have a relatively compact design and often utilize aluminum or copper windings. The weight of a 200 HP AC induction motor can range from approximately 1000 pounds (450 kilograms) to 2500 pounds (1134 kilograms), depending on factors such as cooling requirements and additional features.

- DC Motors: DC motors are known for their precise control over speed and torque. They are commonly used in applications such as robotics, electric vehicles, and elevators. The weight of a 200 HP DC motor can vary depending on the type, such as brushed or brushless DC motors. Brushed DC motors typically weigh less compared to brushless DC motors due to their simpler construction. The weight of a 200 HP DC motor can range from approximately 800 pounds (363 kilograms) to 2000 pounds (907 kilograms).

- Synchronous Motors: Synchronous motors are AC motors that operate at a constant speed determined by the frequency of the power supply. These motors are often used in applications that require high efficiency and precise synchronization. The weight of a 200 HP synchronous motor can range from approximately 1200 pounds (544 kilograms) to 3000 pounds (1360 kilograms) or more, depending on factors such as the cooling system and rotor design.

It’s important to note that the weights provided here are estimates and can vary based on factors such as the motor’s specific design, construction materials, cooling systems, and additional features.

When choosing an electric motor, it’s crucial to consider the requirements of the application and the specific characteristics of each motor type. While weight is an important factor, other considerations such as efficiency, speed control capabilities, and maintenance requirements should also be taken into account.

Now that we have explored the weight variations based on motor type, let’s move on to some considerations to keep in mind when choosing a 200 HP electric motor.

Considerations When Choosing an Electric Motor

Choosing the right electric motor for your application is crucial to ensure optimal performance and efficiency. When considering a 200 horsepower (HP) electric motor, there are several important factors to keep in mind. Let’s explore these considerations:

- Application Requirements: Understand the specific requirements of your application, including the desired torque, speed, and power output. Consider the operating conditions, duty cycle, and any special considerations unique to your application.

- Efficiency: Evaluate the motor’s efficiency rating to ensure you select a motor that will operate efficiently while minimizing energy consumption. Look for motors with high efficiency ratings, as they can help reduce operational costs and environmental impact.

- Power Density: Consider the power-to-weight ratio, or power density, of the motor. A lighter motor with higher power density can provide the same horsepower output with less weight, allowing for easier handling and installation.

- Environmental Factors: Take into account the operating environment and any specific environmental conditions the motor will be subjected to. Factors such as temperature, humidity, dust, and corrosive substances can impact the motor’s performance and longevity.

- Maintenance Requirements: Evaluate the maintenance needs of the motor. Look for motors that have easy access to key components for maintenance and repairs. Consider factors such as lubrication requirements, availability of spare parts, and the reputation of the manufacturer for reliability.

- Budget: Consider your budgetary constraints and balance them with the required specifications and quality. It’s essential to choose a motor that provides the necessary performance without overspending or compromising on quality.

- Manufacturer Reputation: Research and consider the reputation and track record of the motor manufacturer. Look for companies known for producing high-quality motors with reliable performance and excellent customer support.

By carefully evaluating these considerations, you can make an informed decision when selecting a 200 HP electric motor that best suits your needs and requirements. Don’t hesitate to consult with experts or seek guidance from reputable suppliers who can assist you in the selection process.

Now that we have explored the considerations for choosing an electric motor, let’s conclude our article.

Conclusion

Choosing the right electric motor is crucial for any application, especially when considering the weight and power requirements of a 200 horsepower (HP) motor. Understanding the factors that influence motor weight, such as design, construction materials, cooling systems, and additional features, allows for a better understanding of the weight variations that can be expected.

Typically, a 200 HP electric motor can range in weight from around 1000 pounds (450 kilograms) to 3000 pounds (1360 kilograms), depending on the specific motor type, design, and construction materials used. However, it’s important to note that these weight estimates are approximate and can vary among manufacturers.

When choosing a 200 HP electric motor, it’s essential to consider the specific requirements of the application, such as torque, speed, and power output. Other crucial factors include motor efficiency, power density, environmental considerations, maintenance requirements, budget constraints, and the reputation of the manufacturer.

By carefully evaluating these factors and considering the unique needs of your application, you can select the most appropriate 200 HP electric motor that provides optimal performance, efficiency, and reliability.

Remember, selecting the right electric motor is an investment in the success of your application. Take the time to research and consult with experts to ensure you make an informed decision that aligns with your specific requirements and operational goals.

We hope that this article has provided valuable insights into the weight considerations and factors to keep in mind when choosing a 200 HP electric motor. With the right motor in place, you can power your applications with confidence and efficiency.

Frequently Asked Questions about How Much Does A 200 HP Electric Motor Weight

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much Does A 200 HP Electric Motor Weight”