Home>Articles>How Often Should You Inspect An Extension Cord?

Articles

How Often Should You Inspect An Extension Cord?

Modified: January 6, 2024

Learn the importance of inspecting extension cords regularly for safety. Find articles on how often you should check your extension cord to prevent potential hazards.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

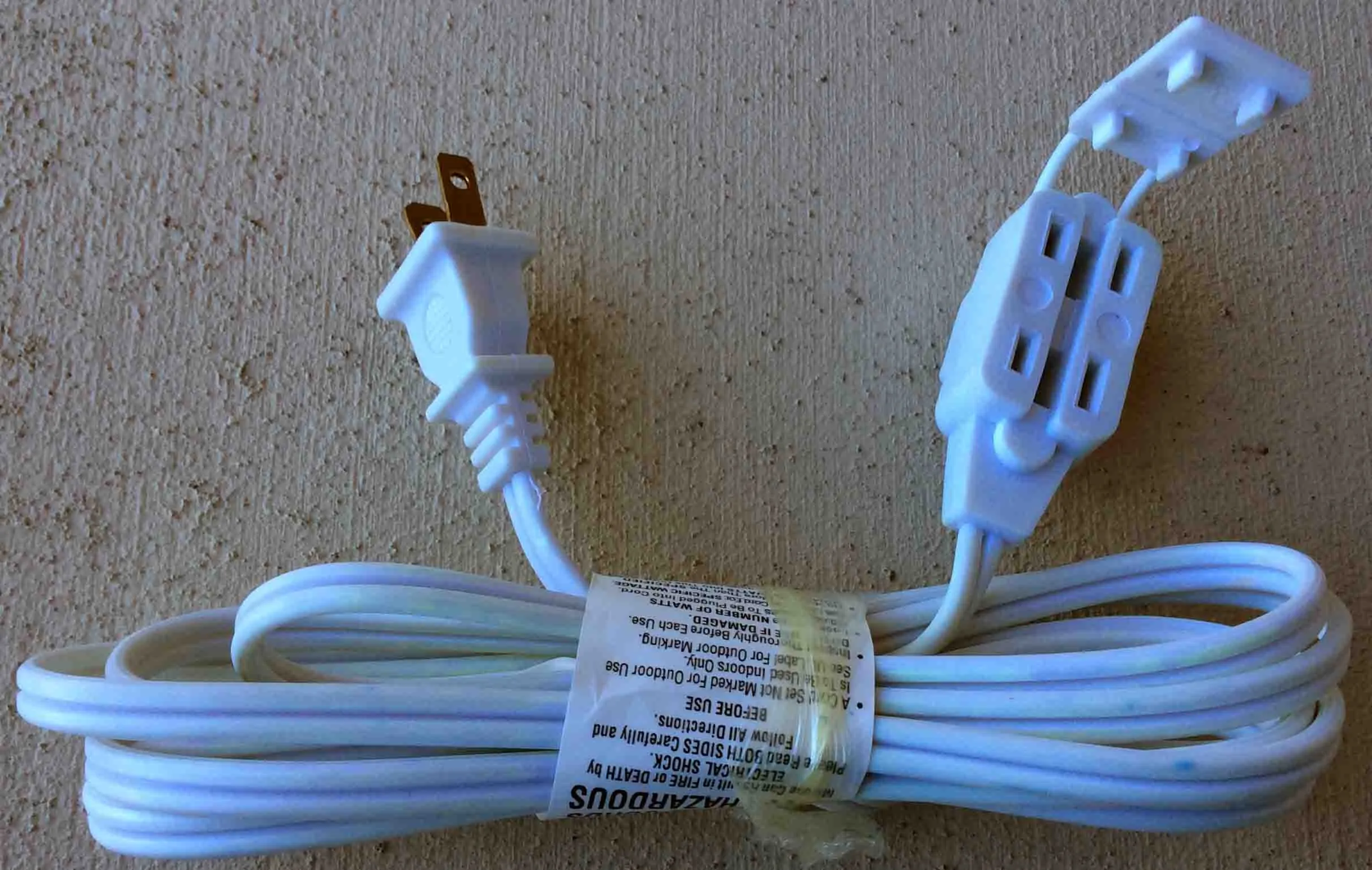

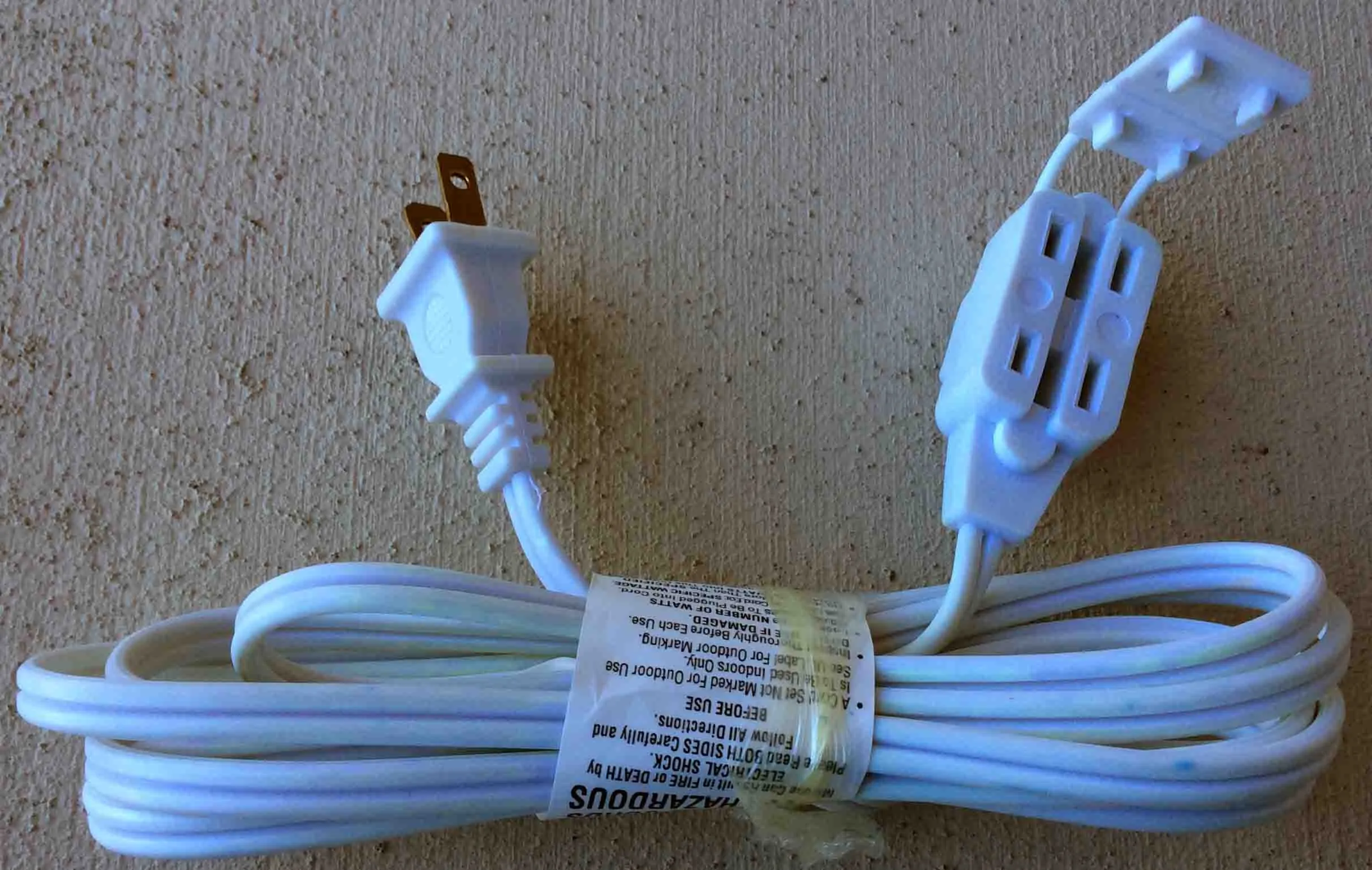

Extension cords are an everyday convenience that we often take for granted. Whether you’re using them to power up your electronic devices, appliances, or tools, extension cords play a crucial role in providing electricity where it’s needed most. However, like any other electrical equipment, extension cords require regular inspection to ensure they are safe to use.

Inspecting extension cords on a regular basis is not only important for your safety but also for the longevity and reliability of the cords themselves. By identifying potential issues early on, you can prevent accidents, electrical hazards, and even damage to your electronic devices.

Key Takeaways:

- Regularly inspect extension cords to prevent electrical hazards, maintain equipment efficiency, safeguard property, and ensure compliance with safety standards. Consider usage frequency, environmental conditions, cord age, and application load when determining inspection frequency.

- Follow visual and electrical testing checklists to identify common issues such as frayed wires, damaged insulation, loose plugs, and overheating during extension cord inspections. Promptly address any problems detected by repairing or replacing the cord to ensure electrical safety.

Read more: How Often Should You Clean A Dryer Vent

Importance of Inspecting Extension Cords

Regularly inspecting extension cords is essential for maintaining electrical safety. As extension cords are often subjected to frequent use and various environmental conditions, they can degrade over time and pose significant risks if not properly maintained. Here are some reasons why inspecting extension cords is of utmost importance:

- Preventing Electrical Hazards: Inspecting extension cords helps identify any frayed wires, damaged insulation, loose connections, or other issues that could lead to electrical shocks, short circuits, or fires. By addressing these problems promptly, you can minimize the risk of electrocution or electrical accidents.

- Maintaining Equipment Efficiency: Damaged extension cords can affect the performance and efficiency of connected devices. Inspecting the cords allows you to detect any power loss or fluctuation that may occur due to wiring issues, ensuring that your equipment runs smoothly and optimally.

- Safeguarding Property: Electrical fires can quickly cause extensive damage to your property and possessions. Regular extension cord inspections enable you to identify potential fire hazards before they become a major problem, protecting your valuable assets from the devastating consequences of a fire.

- Ensuring Compliance: By inspecting your extension cords regularly and adhering to safety guidelines, you demonstrate a commitment to electrical safety standards. This is particularly important for businesses, as non-compliance can result in legal consequences, fines, or insurance issues.

Remember, the proactive step of inspecting your extension cords can prevent accidents, equipment damage, and potential safety hazards.

Factors Determining Inspection Frequency

The frequency at which you should inspect your extension cords depends on several factors. While there are general guidelines to follow, it’s important to consider these specific factors that can influence the inspection frequency:

- Usage Frequency: Extension cords used in high-traffic areas or in environments with heavy machinery or equipment should be inspected more frequently. Regular wear and tear from constant use can accelerate the degradation of the cords, making more frequent inspections necessary.

- Environmental Conditions: Extension cords exposed to extreme temperatures, moisture, dust, or chemicals are more susceptible to damage. Inspect these cords more frequently to ensure they remain in good condition and can withstand the environmental stress.

- Cord Age and Condition: Older extension cords are more prone to damage and may require more frequent inspections. Additionally, if you notice any visible signs of wear and tear, such as cracks, frays, or exposed wires, consider increasing the inspection frequency to catch potential issues before they worsen.

- Application and Load: The type of equipment or appliances connected to the extension cord can impact the inspection frequency. Higher power loads and equipment that generate heat can put more strain on the cords. Regular inspections are crucial to identify any overheating, melting, or signs of electrical overload.

- Industry Standards and Regulations: Certain industries may have specific guidelines or regulations concerning the inspection frequency of extension cords. It’s important to familiarize yourself with these standards and adhere to them accordingly.

Considering these factors will help you determine the appropriate frequency for inspecting your extension cords. However, it’s always better to err on the side of caution and inspect them more frequently if you have any concerns about their condition or safety.

General Guidelines for Inspecting Extension Cords

When it comes to inspecting extension cords, there are some general guidelines that you can follow to ensure a thorough examination. These guidelines serve as a starting point for your inspection routine:

- Unplug the Cord: Before inspecting any extension cord, make sure it is unplugged from the power source. This eliminates the risk of electric shock during the inspection process.

- Visual Inspection: Start by visually examining the entire length of the extension cord. Look for any visible signs of damage such as frayed or exposed wires, cracked insulation, or loose connections. Pay close attention to the plugs, sockets, and connectors as well.

- Tactile Examination: Run your hands along the cord to feel for any abnormalities. Be mindful of any rough spots, bulges, or areas where the insulation may be compromised.

- Bend and Flex: Gently bend and flex the cord along its length. This helps identify any internal wire breakage or loose connections. It should remain flexible and free of any crackling or popping sounds.

- Evaluate the Plug and Socket: Inspect the plug and socket for any signs of damage or wear. Ensure that the prongs are intact and properly aligned. Loose or bent prongs could indicate a potential safety hazard.

- Check Grounding Prong: If your extension cord has a grounding prong, make sure it is intact and not bent or broken. The grounding prong is essential for preventing electric shocks and should be in good condition.

- Inspect Insulation: Examine the insulation along the entire length of the cord. It should be intact, without any cracks, cuts, or exposed wires. If you spot any damage, consider replacing the cord rather than attempting to repair it.

- Test Continuity: Use a continuity tester or a multimeter to check the continuity of the wires inside the cord. This ensures that the conductive path is intact throughout the length of the cord and there are no breaks or interruptions.

- Document and Label: If you come across any issues during the inspection, document them and label the cord appropriately. This will help you keep track of any cords that require repair or replacement.

By following these guidelines, you can perform a comprehensive inspection of your extension cords, identifying any potential safety hazards or issues that require attention.

Visual Inspection Checklist

A visual inspection is an essential part of inspecting extension cords. It allows you to identify visible signs of damage or wear that may pose a safety risk. Use the following checklist as a guide during your visual inspection:

- Inspect the Cord: Examine the entire length of the cord for any signs of fraying, cuts, or breaks in the outer insulation. Look for any exposed wires or bare conductors.

- Check the Plug and Socket: Inspect the plug and socket for any damage, such as bent prongs, loose connections, or signs of burning or charring. Ensure that the plug fits securely into the socket without any wobbling.

- Examine the Insulation: Check the insulation along the length of the cord. Look for any cracks, splits, or punctures in the outer sheath. Pay attention to the area near the ends of the cord, where it may have experienced more stress or bending.

- Inspect Connectors: If your extension cord has connectors or adapters, examine them closely. Ensure they are in good condition, without any signs of damage or loose connections.

- Check for Heat Damage: Feel the cord along its length, focusing on areas that generate heat such as near plugs or where the cord may be in contact with hot surfaces. If you notice any melting, discoloration, or signs of overheating, it could indicate an underlying issue.

- Look for Water or Moisture Damage: Moisture can damage extension cords, so check for any signs of water exposure or moisture damage. Look for rusted or corroded connectors, as well as any water stains or discoloration on the cord.

- Inspect Grounding Prong: If your extension cord has a grounding prong, ensure it is intact and securely attached. A loose or missing grounding prong can compromise the safety of the cord.

- Check for Proper Labeling: Look for the appropriate safety markings, such as a UL (Underwriters Laboratories) listing or other recognized certification. This ensures that the cord meets safety standards and has been tested for safety.

By diligently going through this visual inspection checklist, you can identify any visible issues with your extension cords and take appropriate action to ensure electrical safety.

Inspect extension cords for damage or wear before each use. Look for frayed or exposed wires, cracked insulation, or loose connections. Replace any damaged cords immediately.

Electrical Testing Checklist

In addition to a visual inspection, conducting electrical testing on your extension cords helps ensure that they are functioning properly and are safe to use. Here is a checklist of electrical tests that can be performed:

- Continuity Test: Use a continuity tester or a multimeter to check the continuity of the wires within the cord. This test confirms that there are no breaks or interruptions in the conductive path and that the cord can effectively transmit electricity.

- Insulation Resistance Test: Measure the insulation resistance of the cord using an insulation resistance tester. This test helps identify any insulation breakdown or leakage in the cord. Higher insulation resistance indicates better safety and insulation quality.

- Polarity Test: If your extension cord has a polarized plug, ensure that it is properly wired. Use a polarity tester to verify that the hot wire (typically black or red) and the neutral wire (typically white) are connected correctly. Incorrect polarity can pose a safety hazard.

- Grounding Test: If your extension cord has a grounding prong, check its effectiveness using a ground continuity tester. This test ensures that the grounding wire is connected and properly grounded, reducing the risk of electric shocks.

- Voltage Drop Test: Measure the voltage drop across the length of the cord using a multimeter. Excessive voltage drop can indicate wiring issues or too high a load, affecting the performance and safety of the connected devices.

- Load Testing: Connect the extension cord to a load, such as a power tool or appliance, and monitor its performance. Ensure that there are no unusual fluctuations, overheating, or power loss during the operation. Excessive heat or other abnormalities can indicate a problem with the cord.

- GFCI Testing: If your extension cord or the device it powers is equipped with a Ground Fault Circuit Interrupter (GFCI), test its functionality regularly. Press the “test” button on the GFCI to simulate a ground fault, and ensure that the circuit trips and cuts off power correctly.

Performing these electrical tests can provide further assurance of the safety and functionality of your extension cords. It is important to have the necessary electrical testing equipment and to follow proper safety precautions while conducting these tests.

Common Issues to Look Out for During Inspection

During the inspection of your extension cords, it is important to be aware of common issues that may arise. Identifying these issues early on can help prevent accidents and ensure the safe and efficient use of your extension cords. Here are some common issues to look out for:

- Frayed or Damaged Wires: Check for any frayed or damaged wires, as they can pose a significant safety risk. Exposed wires can lead to electric shock or short circuits.

- Cracked or Damaged Insulation: Inspect the insulation along the length of the cord for any cracks, cuts, or signs of damage. Damaged insulation exposes the wires and can lead to electrical hazards.

- Loose or Damaged Plugs and Sockets: Ensure that the plugs and sockets are in good condition and securely connected. Loose or damaged plugs can result in electrical arcing or disconnection while in use.

- Overheating or Melting: Look for any signs of overheating, such as discoloration, melting, or burning smells. Overheating can cause damage to the cord and surrounding materials.

- Worn Connectors: Examine the connectors or adapters for any signs of wear or damage. Loose or worn connectors can lead to poor electrical connections and potential power interruptions.

- Lack of Proper Grounding: If your extension cord has a grounding prong, ensure that it is intact and functioning properly. Improper grounding can increase the risk of electric shock.

- Tangled or Knotted Cords: Check for any excessively tangled or knotted cords. These can create strain on the wires, leading to damage and increased risk of electrical hazards.

- Insufficient Ampacity: Ensure that the extension cord is capable of handling the electrical load required by the connected devices. Using a cord with insufficient ampacity can result in overheating and potential safety hazards.

- Water or Moisture Damage: Look for any signs of water exposure, such as rusted connectors or water stains on the cord. Moisture can lead to electrical shorts and pose significant safety risks.

By being vigilant and addressing these common issues during inspection, you can maintain the safety and longevity of your extension cords, minimizing the risk of accidents or electrical hazards.

Steps to Take if a Problem is Detected

If you detect any issues during the inspection of your extension cords, it is crucial to take immediate action to address the problem. Here are the steps to take if a problem is detected:

- Stop Using the Cord: If you identify any safety concerns, immediately unplug and stop using the extension cord. Continuing to use a damaged cord can increase the risk of electrical accidents, fires, and damage to your equipment.

- Isolate the Cord: Keep the problematic extension cord separate from others to avoid accidentally using it or confusing it with cords that are safe to use.

- Document the Issue: Take note of the specific issue you observed during the inspection. This documentation will help you track the problem and communicate it to others if necessary.

- Repair or Replace the Cord: Depending on the nature and severity of the issue, you can either attempt to repair the cord or replace it entirely. Minor issues, such as a loose connection, may be fixable, but it is generally safer to replace a cord with significant damage or wear.

- Repairing the Cord: If you choose to repair the cord, ensure that you have the knowledge and skills to do so safely. Follow manufacturer guidelines or consult a professional electrician for guidance. Avoid using temporary solutions (like tape) and use approved repair methods and materials.

- Replacing the Cord: If the cord has extensive damage or if you’re unsure about the repair process, it is best to replace it. Look for a cord that meets your specific electrical requirements and the quality standards necessary for your intended use.

- Dispose of the Damaged Cord: Properly dispose of the damaged cord to prevent it from being accidentally used or causing potential harm to others. Check with your local recycling or waste management center for proper disposal methods.

- Continue Regular Inspections: After addressing the issue, resume regular inspections of your extension cords to prevent future problems. Establish a schedule for inspection and make it a routine part of your maintenance practices.

Remember, the safety of your extension cords is paramount. Taking prompt action when problems are detected helps to ensure the well-being of yourself, others, and your electrical equipment.

Maintenance Tips for Extension Cords

To keep your extension cords in optimal condition and prolong their lifespan, regular maintenance is essential. Here are some maintenance tips to follow:

- Proper Storage: When not in use, coil the extension cord loosely and store it in a dry, cool place. Avoid tightly coiling the cord, as this can cause damage to the wires over time.

- Avoid Overloading: Be mindful of the electrical load you’re placing on the extension cord. Overloading the cord by connecting too many devices or appliances can lead to overheating and potential hazards. Use power strips or multiple cords when necessary.

- Unplug Correctly: When unplugging the cord, ensure that you grip the plug itself rather than pulling on the cord. Pulling on the cord can cause strain on the connection points and lead to damage over time.

- Inspect Regularly: Conduct visual inspections of your extension cords on a routine basis, following the guidelines mentioned earlier. Regular inspections help detect any issues promptly and reduce the risk of accidents or electrical hazards.

- Keep it Clean: Periodically clean the extension cord using a dry cloth or a mild detergent solution. This helps remove dirt, dust, and any potential contaminants that could compromise the cord’s insulation or connections.

- Avoid Wet Conditions: Extension cords are not designed for use in wet or outdoor conditions unless specified for such use. Keep the cords away from water sources and avoid using them in damp areas to prevent electrical shorts and damage.

- Repair with Caution: If you decide to repair a damaged cord yourself, make sure you have the necessary expertise and tools. Follow proper repair procedures and use suitable materials to ensure the repaired cord is safe to use.

- Replace Worn-Out Cords: Extension cords have a limited lifespan, and continuous use can cause wear and tear. If a cord shows signs of significant damage or deterioration, it is best to replace it rather than risking safety issues.

- Use Cord Covers: If you need to use extension cords in high-traffic areas or areas prone to tripping hazards, consider using cord covers to protect the cord and prevent accidents.

- Follow Manufacturer Guidelines: Always refer to the manufacturer’s guidelines and instructions for your specific extension cord. They may provide additional maintenance tips or precautions tailored to your cord’s design and usage.

By following these maintenance tips, you can ensure that your extension cords remain safe, reliable, and in excellent working condition for years to come.

Read more: How Should You Unplug An Electrical Cord

Conclusion

Inspecting extension cords regularly is vital for maintaining electrical safety and preventing potential hazards. By following general guidelines and considering factors such as usage frequency, environmental conditions, and cord age, you can determine the appropriate inspection frequency for your extension cords.

A visual inspection allows you to identify visible issues such as frayed wires, damaged insulation, loose connections, or signs of overheating. Additionally, electrical testing helps ensure that the cords are functioning correctly and safe to use.

During the inspection, common issues to watch out for include frayed wires, cracked insulation, loose plugs, overheating, and water damage. If any problems are detected, it is important to promptly repair or replace the cord.

Maintaining extension cords is equally crucial. Proper storage, avoiding overloading, regular inspections, and keeping them clean contribute to their durability and safety. Following manufacturer guidelines and replacing worn-out cords are also essential practices to uphold electrical safety standards.

By incorporating these inspection and maintenance practices into your routine, you can ensure the long-term reliability and safety of your extension cords. Remember, a proactive approach to inspection and maintenance is key to preventing accidents, electrical hazards, and equipment damage.

Frequently Asked Questions about How Often Should You Inspect An Extension Cord?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Often Should You Inspect An Extension Cord?”