Articles

How To Use HVAC Gauges

Modified: January 19, 2024

Learn how to effectively use HVAC gauges in articles. Gain insights and knowledge to improve your HVAC skills and troubleshooting abilities.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

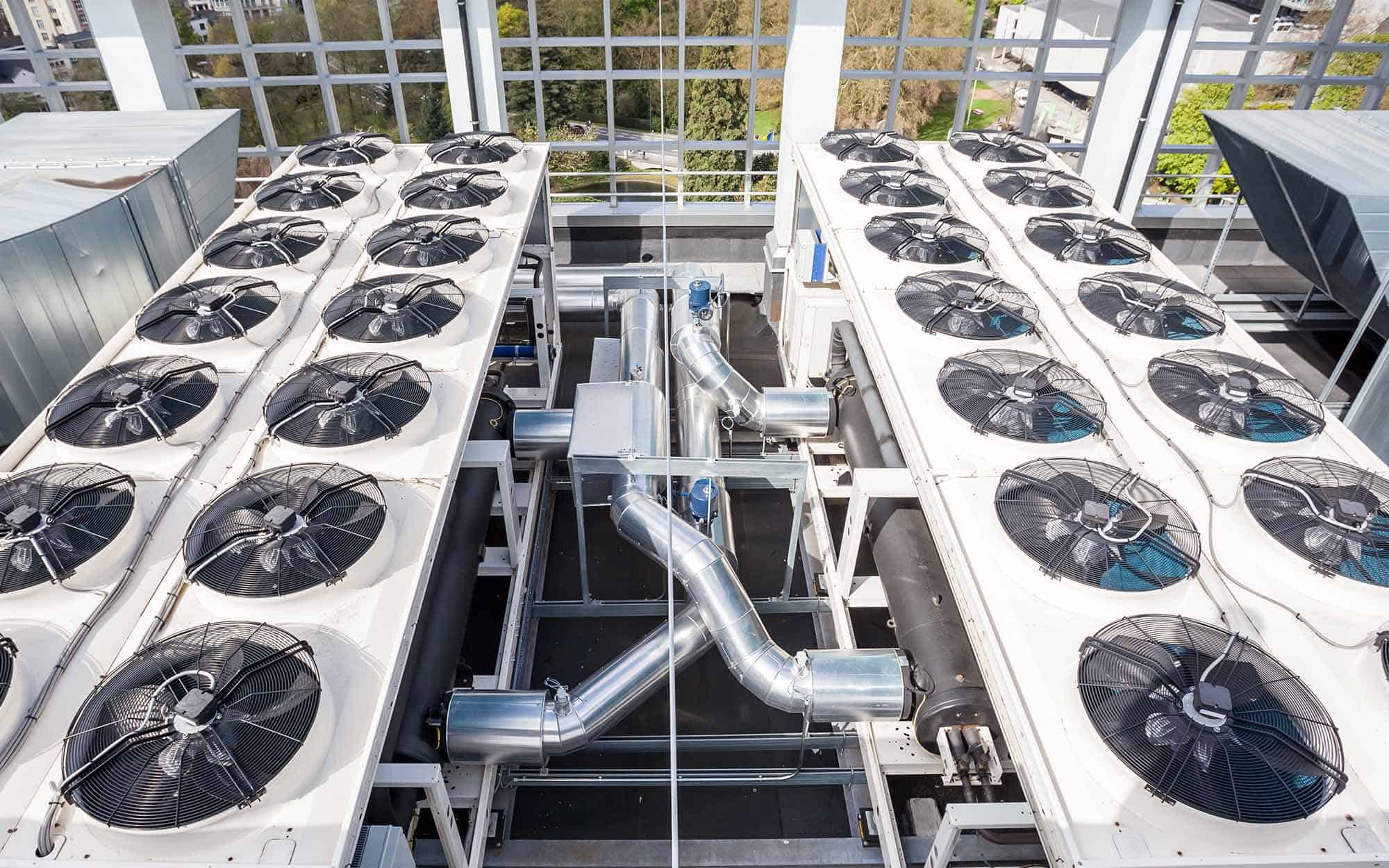

In the world of heating, ventilation, and air conditioning (HVAC), gauges play a crucial role. These sophisticated instruments help professionals maintain, troubleshoot, and monitor the performance of HVAC systems to ensure optimal efficiency and functionality. Whether you’re a seasoned HVAC technician or a DIY enthusiast looking to tackle some HVAC maintenance tasks, understanding how to use HVAC gauges is essential.

In this article, we will explore the different types of HVAC gauges, their essential components, and the step-by-step process of using them. We will also discuss important safety precautions and troubleshooting common gauge issues.

So, if you’re ready to dive into the world of HVAC gauges and learn how to confidently monitor and maintain your HVAC system, let’s get started!

Key Takeaways:

- Mastering the use of HVAC gauges is essential for maintaining optimal efficiency and functionality of HVAC systems. Understanding gauge types, components, safety precautions, and troubleshooting techniques is crucial for both professionals and DIY enthusiasts.

- Properly connecting, interpreting, and troubleshooting HVAC gauges ensures accurate system evaluation. Prioritizing safety, understanding gauge readings, and addressing common gauge issues are key to maximizing the effectiveness of HVAC gauges.

Read also: 9 Incredible HVAC Gauges For 2025

What Are HVAC Gauges?

HVAC gauges, also known as manifold gauges, are specialized instruments used to measure and monitor the various pressures and temperatures within an HVAC system. These gauges consist of multiple dials or digital displays that provide essential information about the system’s operation.

The primary purpose of HVAC gauges is to measure the pressures of the refrigerant in the HVAC system. These pressure readings help professionals diagnose system issues, determine if the system has the correct charge or is low on refrigerant, and identify any potential leaks.

There are two main types of HVAC gauges: low-pressure gauges and high-pressure gauges. Low-pressure gauges are used to measure the pressure on the suction side of the HVAC system, typically between the evaporator coil and the compressor. High-pressure gauges, on the other hand, measure the pressure on the discharge side of the system, between the compressor and the condenser coil.

By connecting the gauges to specific pressure ports on the HVAC system, technicians can accurately assess the system’s performance and make necessary adjustments to ensure optimal efficiency. These gauges are also equipped with valves that allow technicians to control the flow of refrigerant and adjust the system’s pressure as needed.

Additionally, some HVAC gauges are equipped with temperature sensors that provide readings of the refrigerant temperature at various points in the system. These temperature readings are crucial for diagnosing issues such as freezing coils or overheating components.

Overall, HVAC gauges are indispensable tools for HVAC professionals. They enable technicians to make informed decisions about the system’s operation, troubleshoot problems, and ensure the HVAC system is functioning correctly. Understanding how to properly use and interpret HVAC gauges is essential for anyone involved in HVAC maintenance and repair.

Types of HVAC Gauges

There are various types of HVAC gauges available in the market, each designed for specific purposes. Let’s explore some of the common types of HVAC gauges:

- Compound Gauges: Compound gauges, also known as dual gauges, are the most commonly used HVAC gauges. They consist of two dials or digital displays that measure both the high and low pressures in the HVAC system. The low-pressure side of the gauge measures the suction pressure, while the high-pressure side measures the discharge pressure. This allows technicians to monitor both pressures simultaneously.

- Digital Gauges: Digital HVAC gauges have gained popularity in recent years due to their ease of use and accuracy. These gauges use digital displays to provide precise readings of pressure and temperature. They often come with additional features like data logging, wireless connectivity, and programmable settings. Digital gauges are especially useful for technicians who prefer digital readings over analog dials.

- Vacuum Gauges: Vacuum gauges are specifically designed to measure and monitor the level of vacuum in an HVAC system. They are used during the evacuation process to ensure that the system is free of moisture and air. These gauges typically have a range of measurements in microns, allowing technicians to achieve the desired vacuum level for system reliability.

- Pressure-Only Gauges: Pressure-only gauges, as the name suggests, are used solely for measuring pressure and do not include temperature sensors. These gauges are commonly used for quick pressure readings when temperature measurements are not necessary.

- Specialty Gauges: In addition to the common types mentioned above, there are specialty gauges available for specific HVAC applications. For example, refrigerant scales measure the weight of refrigerant in a system, and airflow meters measure the volume of air passing through the HVAC system. These specialty gauges provide additional data to further assess and optimize system performance.

It’s important to choose the right type of HVAC gauge based on your needs and the specific requirements of the HVAC system you are working on. By selecting the appropriate gauge, you can ensure accurate readings and efficient troubleshooting of the HVAC system.

Essential Components of HVAC Gauges

HVAC gauges consist of several essential components that work together to provide accurate measurements and readings. Understanding these components is crucial for using HVAC gauges effectively. Let’s explore the essential components of HVAC gauges:

- Pressure Connections: HVAC gauges feature pressure connections or ports that allow technicians to connect the gauges to the HVAC system. These connections typically come in different sizes to accommodate various systems. There are separate pressure ports for the high and low sides of the system, which ensure accurate pressure readings.

- Gauge Body: The gauge body houses the dials or digital displays that indicate pressure or temperature readings. It is usually made of durable materials, often reinforced with rubber or plastic to protect it from accidental drops or damage during use.

- Gauge Face or Display: The gauge face or display is where the readings are shown. Analog gauges have dial faces with needles, while digital gauges have LCD or LED displays. The gauge face may include units of measurement, such as psi (pounds per square inch) or bar, to provide clear and accurate readings.

- Valves: Most HVAC gauges have built-in valves that allow technicians to control the flow of refrigerant and adjust pressure during the system diagnosis and maintenance process. These valves prevent refrigerant leakage and enable technicians to isolate different sections of the HVAC system for specific measurements.

- Hoses: Hoses play a crucial role in connecting the HVAC gauges to the pressure ports of the HVAC system. These hoses are designed to withstand high pressure and are typically color-coded to differentiate between the high and low sides of the system. It is essential to use hoses that are compatible with the refrigerant being used in the HVAC system.

- Temperature Sensors: Some HVAC gauges are equipped with temperature sensors. These sensors provide temperature readings at various points in the HVAC system, helping technicians identify potential issues such as freezing coils or overheating components.

- Carry Case: Many HVAC gauge sets come with a convenient carry case to store and transport the gauges and accessories. A well-designed carry case helps protect the gauges from damage and keeps all the components organized.

Understanding the essential components of HVAC gauges ensures that you can use them effectively and get accurate readings. It is crucial to handle the gauges and their components with care to maintain their accuracy and prolong their lifespan.

Safety Precautions

Using HVAC gauges involves working with potentially hazardous substances and high-pressure systems. It is essential to prioritize safety to prevent accidents and injuries. Here are some important safety precautions to follow when using HVAC gauges:

- Protective Gear: Always wear appropriate personal protective equipment (PPE) when working with HVAC gauges. This may include safety goggles, gloves, and long sleeves to protect against chemical spills, refrigerant leaks, and other potential hazards.

- Ventilation: Ensure proper ventilation when working with HVAC gauges to prevent the buildup of potentially harmful gases or fumes. Open doors and windows if working in an enclosed space and make sure there is sufficient fresh air circulation.

- Refrigerant Handling: Follow proper refrigerant handling procedures, as refrigerants can be toxic or flammable. Avoid direct contact with refrigerant and always use approved recovery and recycling equipment to prevent environmental damage.

- Pressure Release: Before connecting or disconnecting the gauges, release system pressure to avoid sudden releases of high-pressure refrigerant. This can be done by slowly opening the valves or following the manufacturer’s instructions.

- Secure Connections: Ensure tight and secure connections between the gauges and the HVAC system to prevent refrigerant leaks. A loose connection can result in hazardous exposure to refrigerant or damage to the system.

- System Shutdown: Before making any adjustments or repairs, ensure the HVAC system is shut down properly. This includes turning off the power supply and allowing the system to cool down before working on it.

- Professional Training: HVAC gauges should be used by trained professionals who have a thorough understanding of HVAC systems and safety procedures. If you are not trained in HVAC maintenance and repair, it is recommended to consult a qualified technician.

- Read the Manual: Familiarize yourself with the manufacturer’s instructions and safety guidelines specific to the HVAC gauges you are using. This will ensure proper usage and reduce the risk of accidents.

- Proper Storage: Store HVAC gauges and accessories in a secure and well-ventilated location, away from heat sources and flammable materials. Follow the manufacturer’s recommendations for storage conditions to maintain the gauges’ performance and safety.

Following these safety precautions when using HVAC gauges will help ensure the well-being of yourself, others, and the HVAC system. Safety should always be a top priority when working with any HVAC equipment or tools.

When using HVAC gauges, always ensure that the system is turned off before connecting the gauges. This will prevent any potential damage to the gauges and ensure safety during the process.

Read also: 8 Superior Micron Gauge HVAC For 2025

Step-by-Step Guide to Using HVAC Gauges

Using HVAC gauges may seem intimidating at first, but with the right knowledge and practice, you can confidently monitor and maintain your HVAC system. Here is a step-by-step guide to using HVAC gauges:

- Gather the necessary tools and equipment: Before starting, ensure you have the appropriate HVAC gauges for your system, as well as hoses, a manifold, and any additional accessories required.

- Familiarize yourself with the manufacturer’s instructions: Read the user manual and safety guidelines provided by the gauge manufacturer. Understand how to properly connect the gauges, operate the valves, and interpret the readings.

- Put on your personal protective equipment: Before you start working with HVAC gauges, ensure you are wearing safety goggles, gloves, and any other necessary protective gear to protect yourself from potential hazards.

- Shut down the HVAC system: Before connecting the gauges, ensure that the HVAC system is powered off and that the pressure has been released. This will prevent any sudden releases of high-pressure refrigerant.

- Connect the hoses: Attach the hoses from the gauge manifold to the appropriate pressure ports on the HVAC system. Use the correct color-coded hoses for the high and low sides of the system.

- Open the valves: Slowly open the valves on the manifold to allow the refrigerant to flow into the gauges. This will equalize the pressure and allow accurate readings.

- Interpret the readings: Read the measurements displayed on the gauge face or digital display. Pay attention to both the high and low pressure readings. Compare the readings to manufacturer specifications to determine if the system is within the desired range.

- Adjust the system as necessary: If the readings are outside the recommended range, you may need to make adjustments to the system. Consult the HVAC system’s manual or a qualified technician for guidance on adjusting the pressure or charge.

- Monitor the system: Keep an eye on the gauge readings as the system runs to ensure they remain within the desired range. This can help identify any potential issues or leaks.

- Record the readings: Keep a record of the gauge readings, including the date and time, for future reference. This will allow you to track any changes in the system’s performance over time and identify any recurring issues.

- Clean up and disconnect: Once you have finished using the HVAC gauges, close the valves on the manifold, release the pressure from the system, and disconnect the hoses. Properly store the gauges and accessories in a safe and secure location.

Remember, if you are unsure about using HVAC gauges or encounter any complex issues, it is best to consult a professional HVAC technician. They have the expertise to handle more complicated diagnostics and repairs.

By following this step-by-step guide and taking appropriate safety precautions, you can effectively use HVAC gauges to monitor and maintain your HVAC system, ensuring optimal performance and efficiency.

Connecting Gauges to the HVAC System

Connecting HVAC gauges to your system properly is crucial for accurate readings and safe operation. Follow these steps to connect gauges to your HVAC system:

- Ensure safety: Before starting, refer to the manufacturer’s instructions for any specific safety guidelines. Wear appropriate personal protective equipment (PPE) such as safety goggles and gloves to protect yourself from potential hazards.

- Locate the pressure ports: Identify the high and low-pressure ports on the HVAC system. These ports are typically located on the suction and discharge sides of the system. Refer to the system’s manual if you’re unsure about their location.

- Select the correct hoses: Choose hoses that are compatible with the refrigerant in your system. High and low-pressure hoses are typically color-coded for easy identification. Attach the high-pressure hose to the high-pressure port and the low-pressure hose to the low-pressure port.

- Secure the connections: Ensure that the hose connections are secure and tight. Loose connections can result in refrigerant leaks and inaccurate readings. Use a wrench or adjustable pliers to tighten the hose connections, but avoid over-tightening to prevent damage.

- Connect the hoses to the manifold: Attach the other ends of the hoses to the corresponding ports on the gauge manifold. The high-pressure hose should connect to the high-pressure port on the manifold, and the low-pressure hose should connect to the low-pressure port.

- Open the manifold valves: Open the valves on the manifold by turning them counterclockwise. This will allow refrigerant to flow from the HVAC system into the gauges. Open the valves gradually to avoid sudden pressure surges.

- Equalize the pressure: To equalize the pressure before taking readings, slowly open the valves on the manifold. This will ensure that the gauges are not exposed to sudden pressure changes that could affect the accuracy of the readings.

- Read the gauges: Once the pressure has stabilized, read the gauges to obtain the pressure readings. Refer to the gauge face or digital display to get the high and low-pressure measurements. Note any significant changes or abnormalities in the readings.

- Interpret the readings: Compare the gauge readings to manufacturer specifications or industry standards to determine if the system is operating within the recommended pressure range. Monitor for any signs of over- or under-pressurization that could indicate system issues.

- Record the readings: Keep a record of the gauge readings along with the date and time. This record can be helpful for future reference, troubleshooting, or system analysis.

- Close the manifold valves: Once you’ve obtained the necessary measurements, close the valves on the manifold by turning them clockwise. This will stop the refrigerant flow and prevent any potential leaks.

- Release system pressure: After closing the valves, release the pressure from the system by carefully opening the pressure relief valve or following the manufacturer’s instructions. This step ensures safe disconnection of the gauges.

- Disconnect the gauges: Safely disconnect the hoses from the manifold and the pressure ports on the HVAC system. Use caution to avoid any refrigerant leaks during the disconnection process.

- Properly store the gauges: Clean the gauges and hoses as needed, and store them in a secure and well-ventilated area. Protect them from extreme temperatures, moisture, and physical damage to ensure their longevity.

By following these steps, you can confidently connect your HVAC gauges to the system, obtain accurate readings, and maintain the efficiency of your HVAC system. Remember to always refer to the manufacturer’s instructions and take appropriate safety precautions during the entire process.

Interpreting Gauge Readings

Interpreting gauge readings is an essential skill when using HVAC gauges. It allows you to assess the performance of your HVAC system and identify potential issues. Here’s a guide to help you understand and interpret gauge readings:

- Refer to manufacturer specifications: Consult the manufacturer’s documentation or the system’s manual to determine the acceptable pressure ranges for your HVAC system. These specifications will serve as reference points for interpreting the gauge readings.

- High-pressure side: On the gauge manifold, the high-pressure side is typically colored red and measures the discharge pressure of the HVAC system. Ideal high-pressure readings can vary depending on the system, but typical ranges may be between 250 to 450 psi for residential and light commercial systems.

- Low-pressure side: The low-pressure side on the gauge manifold is usually colored blue and measures the suction pressure of the HVAC system. Ideal low-pressure readings can also vary, but common ranges may be between 60 to 80 psi for residential and light commercial systems.

- Temperature readings: Some HVAC gauges come with temperature sensors that can provide additional information. Monitor these temperature readings to ensure they are within the specified range. Abnormal temperatures can indicate issues such as refrigerant overcharge or inadequate airflow.

- Pressure differences: Analyze the pressure difference between the high and low sides of the system. The pressure difference, known as the pressure drop, indicates how well the HVAC system is functioning. A higher pressure drop than expected may indicate restrictions in the system, such as clogged filters or coils.

- Rate of change: Pay attention to the rate at which the pressure changes over time. Rapid fluctuations in pressure could indicate issues such as a faulty expansion valve or refrigerant leaks, while slow and steady pressure changes may indicate normal system operation.

- Compare with previous readings: If available, compare the current gauge readings with previous recordings to identify any significant deviations. Drastic changes in pressure or temperature can indicate issues that require further investigation or maintenance.

- Consider ambient conditions: Take into account the ambient conditions, such as temperature and humidity, as these factors can affect the gauge readings. Make adjustments or allowances for these factors when interpreting the readings.

- Consult a professional: If you are unsure about interpreting the gauge readings or notice any abnormal readings, it is best to consult a professional HVAC technician. They can provide expert analysis and diagnose any underlying issues with your HVAC system.

Interpreting gauge readings requires careful observation and understanding of the specific system’s requirements. By regularly monitoring the gauge readings and taking note of any irregularities, you can address potential problems before they escalate and ensure the optimum performance of your HVAC system.

Troubleshooting Common Gauge Issues

While using HVAC gauges, you may encounter certain issues that can affect the accuracy of the readings or hinder your ability to monitor the HVAC system effectively. Here are some common gauge issues and troubleshooting steps to address them:

- Incorrect Readings: If the gauge readings are consistently inaccurate or inconsistent, first double-check the connections between the gauges, hoses, and the HVAC system. Ensure that the connections are secure, and there are no leaks or obstructions causing pressure fluctuations. If the issue persists, it may indicate a faulty gauge that requires calibration or replacement.

- Slow Gauge Response: If the gauge readings are slow to respond or seem delayed, it could indicate a restriction or blockage in the hoses or manifold. Check for any kinks, debris, or contaminants that might interfere with the proper flow of refrigerant. Clear any obstructions and ensure smooth airflow through the system.

- Refrigerant Leaks: If you suspect a refrigerant leak, carefully inspect all connections and hoses for signs of leakage, such as oily residue or hissing sounds. Tighten any loose connections, replace damaged hoses, and use leak-detection tools or methods to pinpoint the exact location of the leak. It’s essential to repair any leaks promptly to maintain system efficiency and prevent environmental harm.

- Frozen or Stuck Gauges: In cold weather or when not in use for extended periods, gauges may freeze or become stuck. Allow the gauges to thaw naturally or use gentle heat to speed up the process. Do not force or exert excessive pressure on the gauges, as this could damage the internal components.

- Valve Issues: If the valves on the manifold are difficult to operate or do not close properly, they may require cleaning, lubrication, or replacement. Inspect the valves for debris or corrosion and clean them thoroughly using a suitable solvent. Lubricate the valves as per the manufacturer’s recommendations to ensure smooth and efficient operation.

- Calibration: Over time, HVAC gauges may require calibration to maintain accuracy. Consult the manufacturer’s guidelines or contact a professional calibration service to calibrate your gauges. Regular calibration ensures reliable and consistent readings, enhancing the effectiveness of your HVAC system diagnostics and maintenance.

- Damage to Gauge Components: If any gauge components, such as the face, display, or valves, are damaged, it can affect the performance of the gauges. Replace any damaged components promptly to ensure accurate readings and proper functionality.

- Professional Assistance: If you are unable to troubleshoot or resolve gauge issues on your own, it’s important to seek help from a qualified HVAC technician. They have the expertise to diagnose and address complex gauge problems, ensuring the safe and efficient operation of your HVAC system.

Regular maintenance, proper handling, and prompt resolution of gauge issues are essential for accurate diagnosis and maintenance of your HVAC system. By addressing common gauge issues effectively, you can ensure optimal performance and prolong the lifespan of your HVAC gauges.

Read more: How To Use Air Conditioning Gauges

Conclusion

Understanding how to use HVAC gauges is crucial for anyone involved in HVAC maintenance, troubleshooting, or repair. These powerful tools allow you to monitor and maintain the performance of your HVAC system, ensuring optimal efficiency and functionality. With the step-by-step guidance provided in this article, you can confidently connect, interpret, and troubleshoot HVAC gauges for effective system evaluation.

By utilizing the different types of HVAC gauges available, such as compound gauges, digital gauges, and vacuum gauges, you can accurately measure pressures, temperatures, and other vital parameters of the HVAC system. This information enables you to diagnose issues, adjust pressures, and make necessary repairs.

Remember to prioritize safety throughout the process. Wear appropriate personal protective equipment (PPE), follow safety guidelines, and be cautious when working with refrigerants and high-pressure systems. Maintaining a safe working environment will protect you and others while handling HVAC gauges.

Interpreting gauge readings is a critical skill that allows you to assess the performance of your HVAC system. By comparing the readings to manufacturer specifications, analyzing pressure differences, and considering temperature variations, you can identify potential issues and take appropriate actions to maintain system efficiency.

Troubleshooting common gauge issues, such as incorrect readings, slow response, or refrigerant leaks, ensures accurate and reliable results. By addressing these issues promptly and carrying out routine maintenance, you can maximize the effectiveness of your HVAC gauges and prevent system failures.

In conclusion, HVAC gauges are indispensable tools for HVAC professionals and DIY enthusiasts alike. By following the step-by-step guide, taking necessary safety precautions, and troubleshooting gauge issues effectively, you can confidently use HVAC gauges to monitor, maintain, and optimize the performance of your HVAC system.

Remember, if you’re unsure about any aspect of using HVAC gauges or encounter complex issues, it’s always advisable to consult a qualified HVAC technician. Their expertise and experience will ensure accurate diagnosis and efficient repairs for your HVAC system.

Frequently Asked Questions about How To Use HVAC Gauges

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Use HVAC Gauges”