Articles

What Refrigerant Is Used In HVAC

Modified: December 7, 2023

Discover the different types of articles on HVAC systems and find out which refrigerant is commonly used in the industry. Enhance your knowledge and make informed decisions.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to heating, ventilation, and air conditioning (HVAC) systems, refrigerants play a vital role in ensuring optimal performance. These systems are responsible for regulating indoor temperature, providing comfort, and improving indoor air quality. But have you ever wondered what refrigerant is used in HVAC systems and why it is so important?

In this article, we will delve into the world of HVAC refrigerants, exploring their significance, the different types commonly used, and the environmental considerations associated with their usage. By the end, you will have a deeper understanding of the role refrigerants play in HVAC systems and the choices available when selecting the right refrigerant for your needs.

Key Takeaways:

- The choice of refrigerant in HVAC systems is crucial for energy efficiency, environmental impact, and regulatory compliance. Transitioning to eco-friendly options like natural refrigerants and HFOs is essential for sustainability.

- Understanding the environmental impact of refrigerants and embracing the shift to low-GWP alternatives is vital for creating greener and more efficient HVAC systems. Collaboration and awareness are key to driving this transition.

Read more: What Is A Sight Glass Used For In HVAC

Overview of HVAC Systems

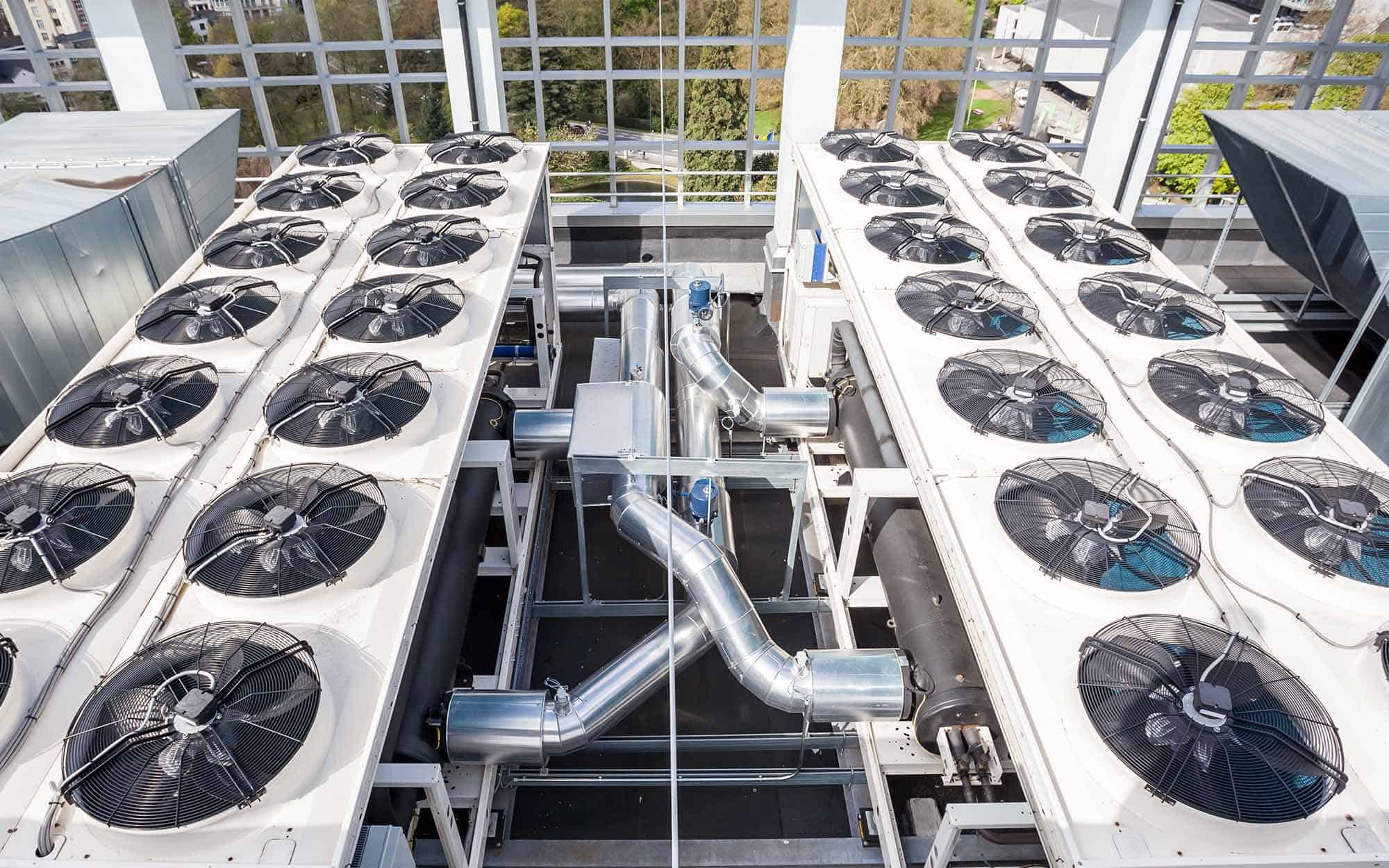

HVAC systems are a crucial component of residential, commercial, and industrial buildings. These systems are responsible for heating, cooling, and ventilating the indoor environment, ensuring comfort and maintaining air quality. The basic principle behind HVAC systems is the exchange of heat energy between the indoor and outdoor environment, facilitated by the use of refrigerants.

An HVAC system consists of several components, including a compressor, a condenser, an evaporator, and an air handler. These components work together to facilitate the transfer of heat. During the cooling process, the refrigerant absorbs heat from the indoor air, cooling it down. This heat is then expelled outside through the condenser, and the cooled air is circulated back into the building. During the heating process, the refrigerant absorbs heat from the outdoor air or a heat source, and this heat is then released indoors.

By controlling the temperature, humidity, and air quality, HVAC systems provide a comfortable and healthy indoor environment year-round. They are essential for maintaining the productivity and well-being of occupants, as well as preserving the integrity of equipment and materials in commercial and industrial settings.

Now that we have a basic understanding of HVAC systems, let’s explore the significance of refrigerants in these systems.

Importance of Refrigerants in HVAC Systems

Refrigerants play a crucial role in the functioning of HVAC systems. They are the substances responsible for transferring heat and enabling the cooling or heating process. Without refrigerants, HVAC systems would not be able to regulate temperature or provide the comfort we rely on.

One of the primary functions of refrigerants is to facilitate the transfer of heat from one location to another. In cooling mode, the refrigerant absorbs heat from the indoor air and releases it outside. In heating mode, it absorbs heat from the outdoor air or a source and releases it indoors. The efficiency and effectiveness of this heat transfer process depend largely on the properties of the refrigerant being used.

Another important aspect of refrigerants is their ability to change states at low temperatures. When the refrigerant absorbs heat from the indoor air, it evaporates and transforms into a gas. This gas is then compressed by the compressor, which increases its temperature and pressure. In the condenser, the refrigerant releases heat and condenses back into a liquid state. This cycle continues, allowing the refrigerant to continuously absorb and release heat, maintaining the desired temperature in the building.

Refrigerants also contribute to the overall energy efficiency of HVAC systems. The properties of the refrigerant, such as its boiling point and heat transfer capabilities, have a direct impact on the system’s efficiency. By using refrigerants with optimal properties, HVAC systems can achieve better energy efficiency, reducing energy consumption and operating costs.

Furthermore, the choice of refrigerant in HVAC systems can have environmental implications. Some refrigerants have been found to contribute to global warming and ozone depletion. This has led to the phase-out of certain refrigerants, such as CFCs (chlorofluorocarbons) and HCFCs (hydrochlorofluorocarbons). The transition to environmentally-friendly refrigerants is crucial for minimizing the environmental impact of HVAC systems and complying with regulations.

Now that we understand the importance of refrigerants in HVAC systems, let’s explore the common types of refrigerants used in these systems.

Common Refrigerants Used in HVAC Systems

There are several types of refrigerants commonly used in HVAC systems. Each type has its own unique properties and characteristics that make it suitable for specific applications. Let’s take a closer look at some of the most common refrigerants used in HVAC systems:

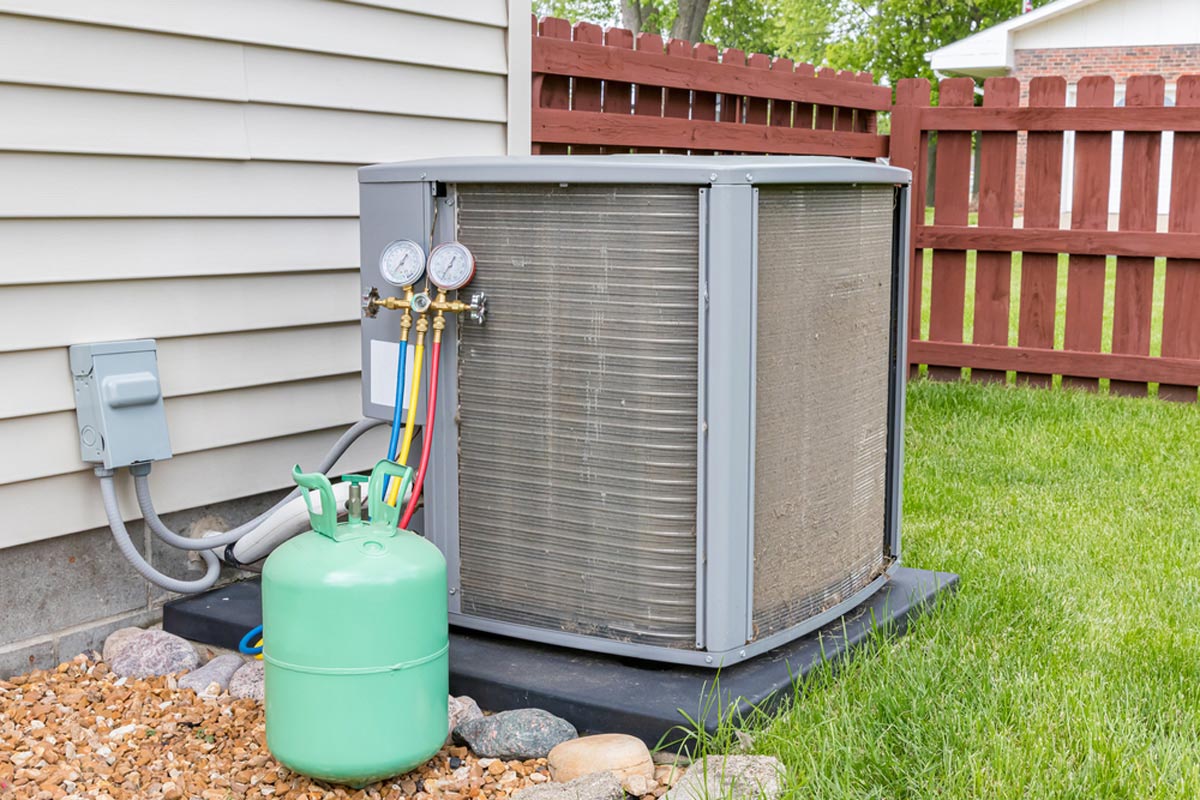

- R-410A: R-410A is a hydrofluorocarbon (HFC) refrigerant widely used as a replacement for older refrigerants, such as R-22, due to its superior cooling efficiency and zero ozone depletion potential. It is commonly used in residential and commercial air conditioning systems.

- R-134a: R-134a is another HFC refrigerant commonly used in automotive air conditioning systems. It is a non-toxic and non-flammable refrigerant with a lower environmental impact compared to previous generations of refrigerants.

- R-22: Although its production has been phased out due to its negative impact on ozone depletion, R-22 is still present in many existing HVAC systems. It is a hydrochlorofluorocarbon (HCFC) refrigerant that is being replaced with more environmentally friendly alternatives.

- R-290: Also known as propane, R-290 is a natural refrigerant derived from hydrocarbons. It has excellent thermodynamic properties and low global warming potential, making it an environmentally friendly choice. R-290 is commonly used in smaller air conditioning and refrigeration systems.

- R-404A: R-404A is a hydrofluorocarbon (HFC) refrigerant widely used in commercial refrigeration applications, such as supermarkets and cold storage facilities. It has good cooling efficiency and is considered a suitable replacement for older refrigerants, such as R-502.

It’s worth mentioning that the choice of refrigerant for an HVAC system depends on various factors, including system requirements, energy efficiency, environmental impact, and regulatory compliance. HVAC professionals carefully consider these factors when selecting the most appropriate refrigerant for a particular application.

Next, we’ll explore the criteria used for choosing the right refrigerant in HVAC systems.

R-410A is the most common refrigerant used in modern HVAC systems. It is a blend of two refrigerants and is known for its high efficiency and environmental friendliness.

Criteria for Choosing the Right Refrigerant

When selecting the right refrigerant for an HVAC system, several key criteria are taken into consideration. These criteria help ensure that the refrigerant meets the specific requirements of the system while considering factors such as energy efficiency, environmental impact, and regulatory compliance. Here are some of the main criteria used for choosing the right refrigerant:

- Thermodynamic Properties: The thermodynamic properties of a refrigerant, such as its boiling point, heat capacity, and pressure-temperature characteristics, play a crucial role in determining its efficiency and performance in an HVAC system.

- Energy Efficiency: Energy efficiency is a critical factor in selecting a refrigerant. Refrigerants with high heat transfer capabilities and low energy consumption contribute to the overall energy efficiency of the HVAC system, resulting in reduced operating costs.

- Environmental Impact: With increasing concerns about global warming and depletion of the ozone layer, the environmental impact of refrigerants has become a significant consideration. Refrigerants with low global warming potential (GWP) and ozone depletion potential (ODP) are preferred to minimize their impact on the environment.

- Safety: Safety is paramount when choosing a refrigerant. Factors such as flammability, toxicity, and compatibility with system components are evaluated to ensure the safety of the occupants and the HVAC system itself.

- Regulatory Compliance: Local and international regulations govern the use of refrigerants, especially those with high environmental impact. HVAC systems must comply with these regulations, which may include restrictions on the use and handling of certain refrigerants.

- System Compatibility: The selected refrigerant should be compatible with the specific HVAC system in terms of materials used, lubrication requirements, and operating conditions. Compatibility issues can lead to performance problems and potential system damage.

- Cost: Cost considerations, including the availability, cost of production, and maintenance requirements of the refrigerant, play a key role in the decision-making process. Balancing the cost of the refrigerant with its performance and environmental benefits is crucial.

Considering these criteria helps HVAC professionals make informed decisions when choosing the most suitable refrigerant for a specific application. It is essential to strike a balance between energy efficiency, environmental impact, safety, and regulatory compliance to ensure optimal system performance and sustainability.

Now, let’s delve into the environmental impact of refrigerants in HVAC systems and explore the transition to more environmentally friendly options.

Read more: What Filter Should I Use For HVAC

Environmental Impact of Refrigerants

The environmental impact of refrigerants used in HVAC systems has gained significant attention in recent years. Certain refrigerants have been found to contribute to global warming and ozone depletion, leading to the phasing out and the development of more environmentally friendly alternatives. Understanding the environmental impact of refrigerants is crucial for creating sustainable HVAC systems. Here are some key points to consider:

Ozone Depletion: The ozone layer in the Earth’s stratosphere helps protect life on Earth by absorbing harmful ultraviolet (UV) radiation from the sun. Substances known as ozone-depleting substances (ODS), including chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), were commonly used as refrigerants in the past. These compounds break down ozone molecules, leading to the thinning of the ozone layer. As a result, international agreements, such as the Montreal Protocol, were implemented to phase out the use of ODS and replace them with safer alternatives.

Global Warming Potential (GWP): The global warming potential of a refrigerant measures its ability to trap heat in the atmosphere over a specific period compared to carbon dioxide (CO2). CO2 is used as the baseline with a GWP value of 1. Refrigerants with high GWP contribute significantly to climate change. Examples of high-GWP refrigerants include hydrofluorocarbons (HFCs) like R-410A and R-404A. To mitigate climate change, there is a push to transition to refrigerants with lower or zero GWP.

Hydrofluorocarbons (HFCs): HFCs became widely used as a replacement for ozone-depleting refrigerants. While they do not harm the ozone layer, they have high GWP values and contribute to global warming. As a result, there is a global effort to phase out HFCs and find alternative refrigerants with lower environmental impact.

Natural and Low-GWP Refrigerants: Natural refrigerants, such as hydrocarbons (HCs) like R-290 (propane) and R-600a (isobutane), have gained popularity due to their low environmental impact. They have zero ozone depletion potential and very low GWP values. Additionally, some hydrofluoroolefin (HFO) refrigerants, like R-1234yf and R-1234ze, have been developed as alternatives to high-GWP HFCs. These low-GWP refrigerants offer potential solutions for reducing the environmental impact of HVAC systems.

Leakage and Emissions: It is important to note that the environmental impact of refrigerants not only depends on their properties but also on the management of their use in HVAC systems. Refrigerant leakage can occur during installation, maintenance, and operation of the system, resulting in direct emissions into the atmosphere. Regular maintenance and proper handling of refrigerants are necessary to minimize leakage and reduce their environmental impact.

By considering the environmental impact of refrigerants and transitioning to alternatives with low GWP and ozone-depleting potential, HVAC systems can play a significant role in mitigating climate change and protecting the ozone layer.

Next, let’s explore the transition to more environmentally friendly refrigerants and the future of HVAC systems.

Transitioning to Environmentally Friendly Refrigerants

With the growing concern over environmental impact, there is a global push to transition from high-GWP and ozone-depleting refrigerants to more environmentally friendly alternatives in HVAC systems. The industry is actively involved in research, development, and adoption of these alternatives. Here are some key points on the transition to environmentally friendly refrigerants:

Regulatory Measures: Governments worldwide have implemented regulations to phase out the use of high-GWP and ozone-depleting refrigerants. These regulations impose restrictions, such as bans on production, importation, and use of certain refrigerants. Compliance with these measures is crucial to promote the widespread adoption of environmentally friendly alternatives.

Natural Refrigerants: Natural refrigerants, including hydrocarbons (HCs) such as R-290 (propane), R-600a (isobutane), and R-717 (ammonia), have gained popularity as alternatives to synthetic refrigerants. They have low or zero GWP values, zero ozone depletion potential, and are energy efficient. HC refrigerants are commonly used in small-scale applications, such as household refrigerators and small air conditioning units.

Hydrofluoroolefins (HFOs): HFO refrigerants, such as R-1234yf and R-1234ze, have emerged as low-GWP alternatives to high-GWP HFCs. They have significantly lower GWP values and are highly efficient for HVAC applications. HFOs are being increasingly adopted in automotive air conditioning systems and larger-scale HVAC installations.

Blended Refrigerants: Blended refrigerants, such as R-410A and R-407C, are formulated to provide improved environmental performance compared to their predecessors. These blends consist of multiple refrigerants with different properties, aiming to minimize the overall environmental impact while maintaining system performance.

Technological Advancements: Advances in HVAC technology, such as improved system design, heat exchangers, and compressor technology, have contributed to the transition to environmentally friendly refrigerants. These advancements optimize system performance, energy efficiency, and compatibility with eco-friendly refrigerants.

Awareness and Training: Educating HVAC professionals, technicians, and end-users about the importance of transitioning to environmentally friendly refrigerants is vital. Training programs and certification courses provide valuable knowledge on handling, installation, and maintenance of systems using these alternative refrigerants.

Industry Collaboration: The transition to environmentally friendly refrigerants requires collaboration among various stakeholders, including manufacturers, distributors, contractors, and policymakers. Sharing knowledge, experiences, and best practices helps accelerate the adoption and implementation of eco-friendly refrigerants.

Transitioning to more environmentally friendly refrigerants is an ongoing process driven by the desire to mitigate climate change and protect the ozone layer. As technology and regulations continue to develop, HVAC systems will evolve to become more sustainable and energy-efficient while maintaining optimal indoor comfort.

As we conclude our exploration of refrigerants in HVAC systems, it’s evident that making informed choices regarding refrigerants is crucial for the long-term sustainability of these systems and the environment as a whole.

Conclusion

Refrigerants are a vital component in HVAC systems, playing a crucial role in regulating temperature, providing comfort, and maintaining indoor air quality. Understanding the impact of different refrigerants and making informed choices is essential for creating sustainable and efficient HVAC systems.

Throughout this article, we have explored the importance of refrigerants in HVAC systems and their role in heat transfer. We discussed the different types of refrigerants commonly used, ranging from hydrofluorocarbons (HFCs) to natural refrigerants like hydrocarbons (HCs). We also examined the criteria used to select the appropriate refrigerant, considering factors such as thermodynamic properties, energy efficiency, environmental impact, safety, regulatory compliance, system compatibility, and cost.

Additionally, we highlighted the environmental impact of refrigerants, including their contribution to ozone depletion and global warming. We discussed the transition to more environmentally friendly refrigerants, such as natural refrigerants and hydrofluoroolefins (HFOs), as well as the industry’s efforts to comply with regulatory measures and promote sustainability.

The HVAC industry is continuously evolving, with advancements in technology and regulations driving the adoption of eco-friendly refrigerants and the development of more energy-efficient systems. This transition requires collaboration among manufacturers, distributors, contractors, policymakers, and educated HVAC professionals.

As we strive to create a greener and more sustainable future, the responsible use of refrigerants should be a top priority. By selecting environmentally friendly refrigerants with low ozone depletion potential and global warming potential, we can significantly reduce the environmental impact of HVAC systems while achieving optimal system performance and maintaining indoor comfort.

In conclusion, refrigerants in HVAC systems have a significant impact on energy efficiency, environmental sustainability, and human comfort. By staying informed about the latest advancements in refrigerants and embracing the transition to more eco-friendly options, we can contribute to a greener future while enjoying the benefits of efficient and effective HVAC systems.

Frequently Asked Questions about What Refrigerant Is Used In HVAC

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Refrigerant Is Used In HVAC”