Articles

What Is a PWM Fan

Modified: January 18, 2024

Discover the benefits and uses of PWM fans in our informative articles. Learn how PWM technology enhances fan control and maximizes cooling efficiency.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A PWM fan, also known as a Pulse Width Modulation fan, is a type of cooling fan commonly used in electronic devices and computer systems to regulate temperature and dissipate heat. PWM fans have become increasingly popular due to their efficient and precise control of fan speed, providing better cooling performance and quieter operation compared to traditional DC fans.

In this article, we will explore the basics of PWM fans, how they work, their advantages over DC fans, different methods of PWM fan control, and their applications. By understanding the fundamentals of PWM fans, you can make informed decisions when selecting and optimizing cooling solutions for your electronic devices.

Key Takeaways:

- PWM fans, with their Pulse Width Modulation technology, provide precise speed control, improved energy efficiency, and reduced noise levels, making them the preferred choice for cooling electronic devices and systems.

- PWM fans offer flexibility, compatibility, and longevity, ensuring reliable performance and cost-effective cooling solutions. Their diverse applications across industries highlight their essential role in maintaining optimal operating temperatures.

Read also: 12 Best Pwm Fan for 2024

PWM Fans: Definition and Basics

PWM fans are a type of cooling fan that utilize Pulse Width Modulation technology to control the rotation speed and airflow. Unlike traditional DC fans, which operate at a fixed speed, PWM fans can dynamically adjust their speed based on the temperature needs of the system.

The core component of a PWM fan is a brushless DC motor, which consists of a stator and a rotor with permanent magnets. The stator contains coils that generate a rotating magnetic field, while the rotor contains the magnets that interact with the magnetic field to produce motion.

The key feature of PWM fans is the ability to control the time duration or duty cycle of the power supply voltage. The duty cycle defines the percentage of time that the voltage is applied to the motor. By varying the duty cycle, the fan speed can be adjusted accordingly.

PWM fans typically have a 4-pin connector, with the additional pin reserved for the PWM signal. This signal is sent from the motherboard or fan controller to regulate the fan speed. The fan controller adjusts the duty cycle of the PWM signal to increase or decrease the fan speed. This precise control allows the fan to operate at different speeds, ranging from very low RPM for silent operation to maximum RPM for maximum cooling performance.

It is important to note that PWM fans are compatible with both PWM and DC fan headers. When connected to a DC fan header, the fan operates at maximum speed since there is no control over the voltage. However, when connected to a PWM fan header, the fan speed can be adjusted using PWM control signals.

In summary, PWM fans provide dynamic control over fan speed by varying the duty cycle of the power supply voltage. This offers significant advantages in terms of cooling efficiency, noise reduction, and flexibility in different temperature conditions.

How PWM Fans Work

PWM fans operate using a relatively simple but effective principle. The fan receives a PWM signal from the motherboard or fan controller, which determines the fan’s speed. The PWM signal consists of a series of pulses that vary in width, hence the name “Pulse Width Modulation”.

When the PWM signal is at its minimum width, the fan receives very little power and operates at its lowest speed. As the width of the pulses increases, the fan receives more power, causing it to spin faster and increase airflow. The fan’s speed can be adjusted by increasing or decreasing the width of the pulses in the PWM signal.

Inside the fan, a PWM controller interprets the PWM signal and adjusts the voltage supplied to the motor accordingly. The controller regulates the power supplied to the motor by rapidly turning the power on and off. This rapid switching of power allows for precise control over the fan’s speed.

The PWM controller uses a feedback mechanism to maintain the desired fan speed. It constantly monitors the fan’s current speed and compares it to the desired speed indicated by the PWM signal. If there is a difference between the two, the controller adjusts the power supplied to the motor to bring the fan’s speed in line with the desired speed.

Some PWM fans may also include additional features such as automatic fan speed control based on temperature. These fans have built-in temperature sensors that monitor the temperature of the system or component being cooled. The fan’s speed is then adjusted automatically based on the temperature readings, ensuring optimal cooling performance.

Overall, PWM fans provide precise speed control by adjusting the width of the pulses in the PWM signal. This allows for dynamic control over fan speed and optimal cooling efficiency.

Advantages of PWM Fans

PWM fans offer several advantages over traditional DC fans, making them the preferred choice in many cooling applications. Here are a few key advantages of PWM fans:

- Precise Speed Control: PWM fans allow for precise control over fan speed by adjusting the width of the PWM signal pulses. This level of control enables users to find the perfect balance between cooling performance and noise generation. The ability to dynamically adjust fan speed based on temperature needs ensures optimal cooling efficiency.

- Improved Energy Efficiency: PWM fans operate at varying speeds, consuming only the power necessary to cool the system effectively. Unlike traditional DC fans that constantly operate at a fixed speed, PWM fans can reduce power consumption during times when maximum cooling is not required. This energy efficiency can lead to lower electricity costs and a more environmentally friendly cooling solution.

- Reduced Noise Levels: By adjusting the fan speed based on temperature, PWM fans can operate at lower speeds when cooling demands are minimal. This results in reduced noise levels, making PWM fans ideal for noise-sensitive environments such as offices, bedrooms, or recording studios. The ability to maintain a quiet cooling operation enhances user comfort and productivity.

- Enhanced Longevity: The dynamic speed control of PWM fans helps reduce wear and tear on the fan motor. By avoiding continuous high-speed operation, PWM fans experience less mechanical stress, thereby extending their overall lifespan. This increased durability translates into long-term cost savings as fans require less frequent replacement.

- Flexibility and Compatibility: PWM fans are compatible with both PWM and DC fan headers, providing flexibility when selecting cooling components. They can be seamlessly integrated into various systems and easily controlled using PWM-compatible motherboards, fan controllers, or software applications. This compatibility ensures easy installation and compatibility with a wide range of devices and cooling setups.

Overall, PWM fans offer precise speed control, improved energy efficiency, reduced noise levels, enhanced longevity, and compatibility, making them the preferred choice for many cooling applications. Whether you are building a gaming rig, a home server, or a high-performance workstation, PWM fans provide the performance and versatility needed to keep your system cool and quiet.

When using a PWM fan, make sure to connect it to a 4-pin fan header on the motherboard to take advantage of its variable speed control. This allows the fan to adjust its speed based on the system’s temperature, providing efficient cooling and reducing noise.

PWM Fan Control Methods

There are various methods available to control PWM fans, allowing users to adjust fan speed and optimize cooling performance based on their specific needs. Here are some common PWM fan control methods:

- Motherboard BIOS: Many modern motherboards come with built-in BIOS settings that allow users to control fan speed. Through the BIOS interface, users can adjust fan curves, define temperature thresholds, and set the desired fan speed for different temperature ranges. This method offers a straightforward and integrated approach to PWM fan control.

- Fan Control Software: Several software applications provide comprehensive fan control capabilities, giving users full control over fan speed and performance. These software applications often come with intuitive interfaces that allow users to set custom fan curves, monitor temperatures, and adjust fan speeds in real-time. Fan control software is especially useful for enthusiasts who want advanced control and monitoring features.

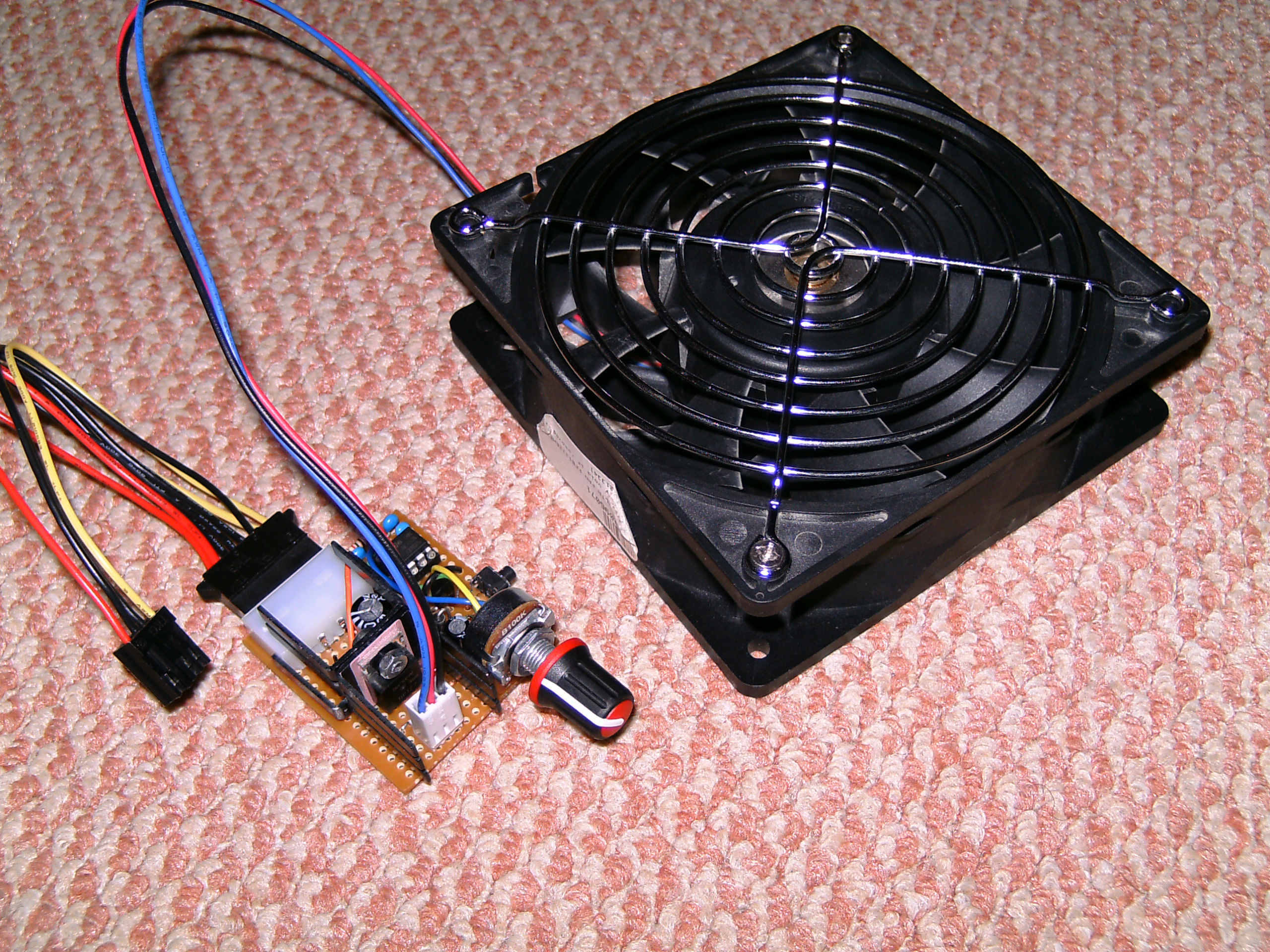

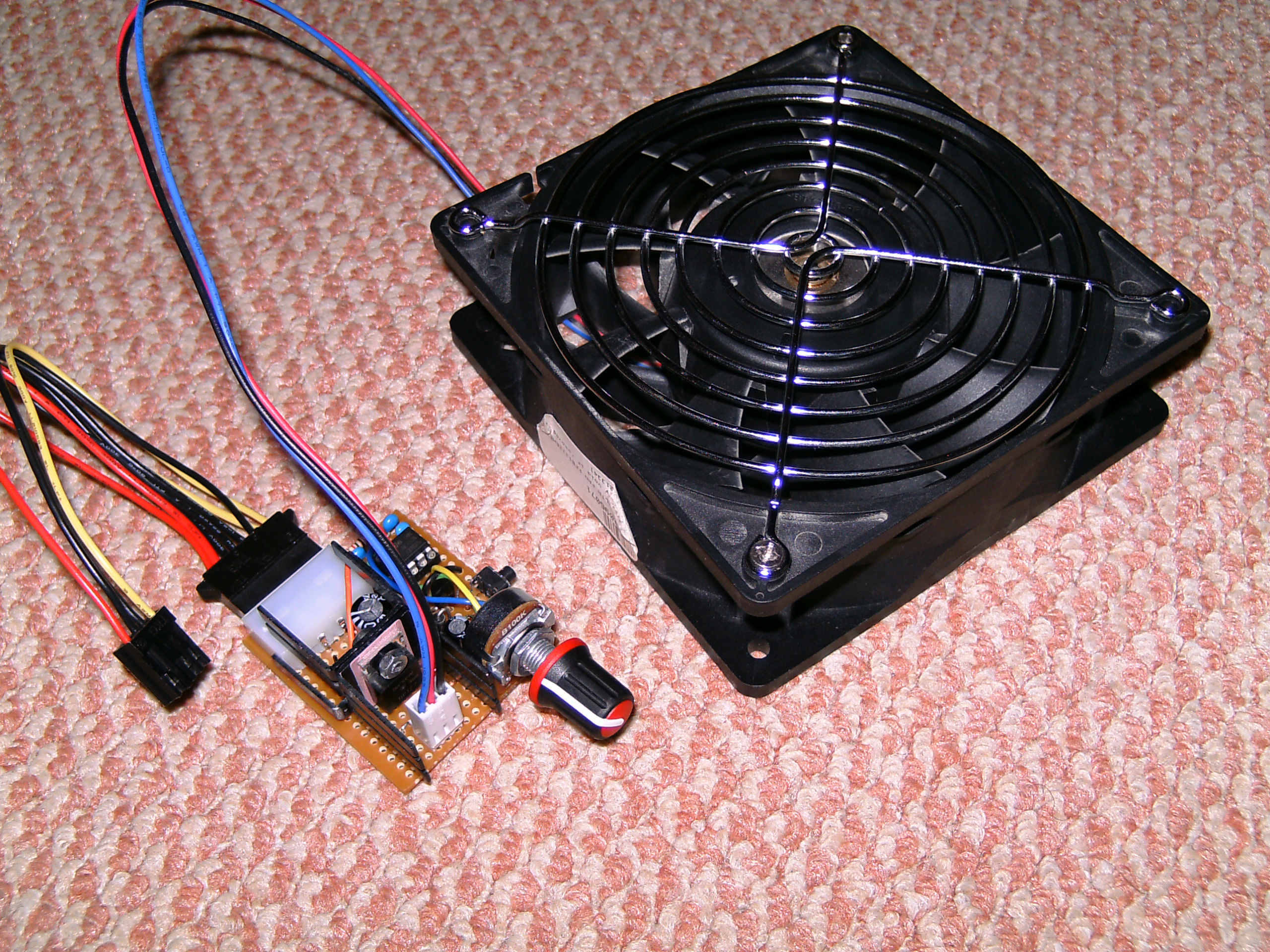

- Hardware Fan Controllers: Dedicated hardware fan controllers offer precise control over PWM fans without relying solely on motherboard capabilities. These controllers connect to the motherboard via USB or internal connectors and provide multiple channels to control multiple fans individually. Hardware fan controllers often feature manual control knobs or digital interfaces for adjusting fan speed. They are ideal for users who prefer physical controls and need to manage a large number of fans simultaneously.

- Temperature Sensors: Some PWM fans include built-in temperature sensors that allow for automatic fan speed control. These sensors monitor the temperature of the system or specific components and adjust the fan speed accordingly. This method ensures that the fan speed dynamically responds to the changing temperature conditions, providing efficient and effective cooling.

- Third-Party Software: Various third-party software applications are available that specialize in fan control and offer advanced features beyond what is provided by the motherboard or fan manufacturer. These software solutions often provide more granular control over fan speeds, customizable fan curves, and the ability to synchronize fan speeds with other system components.

It is important to note that the availability and functionality of PWM fan control methods may vary depending on the specific hardware and software configuration. It is recommended to consult the motherboard or fan manufacturer’s documentation and explore the available options to find the most suitable control method for your requirements.

Read also: 11 Best Pwm Fan Splitter for 2024

PWM Fan Applications

PWM fans have a wide range of applications across various industries and sectors. Their precise speed control and efficient cooling capabilities make them a preferred choice in many scenarios. Here are some common applications of PWM fans:

- Computers and Servers: PWM fans are extensively used in computers, gaming rigs, and servers to maintain optimal operating temperatures. They provide efficient cooling while minimizing noise levels, making them ideal for high-performance systems that require effective heat dissipation.

- Electronics: Many electronic devices generate heat during operation. PWM fans are used to cool down components such as processors, graphics cards, power supplies, and hard drives in devices like laptops, gaming consoles, and home theater systems. The ability to adjust fan speed based on temperature ensures that these devices operate within safe temperature ranges.

- Industrial Equipment: In industrial settings, PWM fans are commonly used in machinery, control panels, and cabinets to dissipate heat generated by equipment. The precise control over fan speed allows for efficient cooling in harsh environments, ensuring the longevity and optimal performance of industrial equipment.

- Automotive Cooling: PWM fans are utilized in automotive cooling systems to regulate engine temperature. They help maintain consistent cooling performance while minimizing power consumption. PWM fans in vehicles can adjust their speeds based on engine temperature, contributing to fuel efficiency and overall engine health.

- Home Appliances: PWM fans are also used in various home appliances such as refrigerators, air conditioners, and air purifiers. They assist in maintaining appropriate temperatures and airflow for efficient operation and improved user comfort.

- Energy-efficient HVAC Systems: PWM fans play a crucial role in energy-efficient heating, ventilation, and air conditioning (HVAC) systems. By adjusting the fan speed based on the cooling or heating demands, these systems can optimize energy usage and maintain a comfortable indoor environment.

These are just a few examples of the diverse applications of PWM fans. Their ability to deliver efficient and precise cooling makes them essential components in a wide range of electronic devices and industrial systems. By utilizing PWM fans, users can ensure reliable performance, extended lifespan, and enhanced energy efficiency in their cooling solutions.

PWM Fan vs. DC Fan

PWM fans and DC fans are two common types of cooling fans used in electronic devices. While both serve the purpose of cooling, they have distinct differences in terms of control methods and performance. Here’s a comparison between PWM fans and DC fans:

- Control Method: The primary difference between PWM fans and DC fans lies in the control method. PWM fans utilize Pulse Width Modulation technology to control fan speed by varying the width of the voltage pulses. On the other hand, DC fans operate at a fixed voltage, resulting in a fixed fan speed. PWM fans provide more precise control over fan speed, allowing for dynamic adjustments based on temperature needs, while DC fans have a constant speed with no adjustment flexibility.

- Speed Control: PWM fans offer a wider range of speed control compared to DC fans. PWM fans can operate at different speeds, including very low speeds, which is ideal for silent operation. DC fans, being fixed-speed fans, operate at a constant speed determined by the voltage supplied to them. PWM fans are better suited for situations where precise speed control is required, such as in temperature-sensitive environments or for balancing cooling performance with noise level concerns.

- Noise Level: PWM fans generally tend to be quieter compared to DC fans. The ability to adjust the fan speed based on temperature requirements allows PWM fans to operate at lower speeds when cooling demands are minimal. This reduction in speed results in lower noise levels. In contrast, DC fans operate at a fixed speed which may produce more noise, especially at higher speeds. PWM fans are a preferred choice for applications that prioritize silent operation.

- Power Consumption: PWM fans are generally more energy-efficient than DC fans. Since PWM fans can adjust their speed based on cooling needs, they consume only the necessary power to maintain optimal cooling performance. In contrast, DC fans operate at a fixed speed regardless of the actual cooling demands, potentially leading to higher power consumption. PWM fans are ideal for environments or applications that prioritize energy efficiency and lower power consumption.

- Compatibility: PWM fans are compatible with both PWM and DC fan headers, providing more flexibility in terms of system compatibility. They can be easily controlled using PWM-compatible motherboards, fan controllers, or software applications. DC fans, however, are compatible only with DC fan headers and lack the flexibility of PWM control. PWM fans offer more versatility and compatibility in terms of controlling fan speed.

Overall, PWM fans offer more precise speed control, lower noise levels, improved energy efficiency, and enhanced compatibility compared to DC fans. They are the preferred choice for applications that require advanced control, quiet operation, and optimized cooling performance. However, DC fans still have their place in simpler cooling setups where fixed-speed operation is sufficient and precise control is not necessary.

Conclusion

PWM fans, with their Pulse Width Modulation technology, have revolutionized cooling solutions in electronic devices and computer systems. By providing precise control of fan speed, PWM fans offer several key advantages over traditional DC fans.

The ability to adjust fan speed based on temperature needs allows PWM fans to optimize cooling performance while minimizing noise levels. This makes them ideal for environments that require efficient cooling with minimal disturbance. The flexibility and versatility of PWM fans make them a preferred choice in various applications, including computers, electronics, industrial equipment, automotive cooling, and HVAC systems.

PWM fans excel in energy efficiency by consuming only the power needed to maintain optimal cooling, reducing electricity costs and environmental impact. Additionally, their precise speed control extends their lifespan and ensures reliable performance for extended periods. This makes them a cost-effective solution in the long run.

When it comes to PWM fan control, users have a range of options, including motherboard BIOS settings, fan control software, hardware fan controllers, temperature sensors, and third-party software. These options provide users with the flexibility to select the most suitable control method based on their specific requirements and preferences.

In contrast, DC fans have a fixed speed and lack the precise control and efficiency of PWM fans. While they still have their place in simpler cooling setups, PWM fans have clearly emerged as the superior choice for those seeking advanced control, reduced noise, improved energy efficiency, and compatibility.

In conclusion, PWM fans have transformed cooling technology by offering precise speed control, improved energy efficiency, and reduced noise levels. With their versatility and outstanding performance, PWM fans are an essential component in various industries and applications, ensuring efficient cooling and optimal performance in electronic devices and systems.

Frequently Asked Questions about What Is A PWM Fan

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is a PWM Fan”