Articles

What Is The Electrical Box Called

Modified: January 19, 2024

The article explains what the electrical box is called and its importance in electrical installations. Discover the different types and their functions.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to electrical systems, safety and organization are of utmost importance. Electrical boxes play a crucial role in ensuring the proper and secure installation of electrical components. These boxes, also known as junction boxes or electrical enclosures, provide a protective housing for electrical connections, wiring, and devices. From residential homes to commercial buildings, electrical boxes are essential for maintaining a reliable and efficient electrical system.

In this article, we will explore the world of electrical boxes, their different types, materials used, installation methods, and safety considerations. Whether you are a homeowner or a professional electrician, understanding electrical boxes is essential for maintaining a safe and functional electrical system.

So, what exactly is an electrical box? Let’s delve into the definition.

Key Takeaways:

- Proper selection and installation of electrical boxes, along with adherence to safety considerations and local electrical codes, are crucial for maintaining a safe, efficient, and reliable electrical system in residential, commercial, and industrial settings.

- Understanding the different types of electrical boxes, materials used, and best practices for wiring and installation is essential for homeowners and professional electricians to ensure the longevity and functionality of electrical installations.

Read more: What Is The Main Electrical Box Called

Definition of an Electrical Box

An electrical box, also known as a junction box or electrical enclosure, is a container that houses electrical connections, devices, and wiring. It provides a secure and organized space for electrical components, helping to protect them from damage and ensuring the safety of individuals interacting with the electrical system.

Electrical boxes are typically made of durable materials such as plastic, metal, or fiberglass. They come in various sizes and designs to accommodate different types of electrical installations.

The primary function of an electrical box is to contain and control electrical connections. It acts as a central point for joining wires together or connecting devices such as switches, outlets, and light fixtures. By providing a confined space for these connections, electrical boxes prevent accidental contact with live wires, minimize the risk of short circuits, and facilitate easier troubleshooting and maintenance.

Furthermore, electrical boxes serve as a protective barrier against moisture, dust, and other environmental factors that can potentially damage electrical connections. They help contain any sparks, heat, or energy generated within the electrical system, preventing them from igniting nearby combustible materials.

Overall, electrical boxes are essential components of a safe and efficient electrical system. They ensure proper wiring connections, protect electrical components, and minimize the risk of electrical hazards.

Types of Electrical Boxes

Electrical boxes come in various types, each designed to serve a specific purpose and accommodate different electrical components. Understanding the different types of electrical boxes will help you choose the right one for your specific installation needs. Let’s explore some common types:

- Junction Box: A junction box is the most basic type of electrical box. Its main purpose is to house wire connections. Junction boxes typically have multiple entry points for electrical cables and are used to join or extend wiring within a circuit.

- Outlet Box: An outlet box, as the name suggests, is used to house electrical outlets. It provides a stable and secure mounting point for power receptacles, allowing for convenient access to electrical power for various devices and appliances.

- Switch Box: Switch boxes are specifically designed to house electrical switches. These boxes provide a protective enclosure for switch mechanisms and allow for secure mounting on walls or other surfaces.

- Device Box: Device boxes are used to house electrical devices such as dimmers, timers, or thermostats. They are similar to switch boxes in terms of design and function but are specifically intended for non-switch devices.

These are just a few examples of electrical boxes, but there are many other specialized types available for specific applications. Some examples include fan-rated boxes for ceiling fans, recessed light boxes for recessed lighting fixtures, and outdoor weatherproof boxes for exterior electrical installations.

It’s important to choose the right type of electrical box for your specific wiring needs. Consider factors such as the size of the wires and connectors, the number of connections, and the specific electrical component you’re installing. Consulting a professional electrician can help you determine the most suitable type of electrical box for your project.

Junction Box

A junction box is one of the most fundamental types of electrical boxes used in electrical installations. Its primary purpose is to provide a secure enclosure for electrical wire connections, allowing for easy access and protection.

Junction boxes come in various sizes and shapes, depending on the specific application and the number of wires or connections that need to be housed. They are typically made of durable materials such as plastic, metal, or fiberglass.

The key function of a junction box is to join or extend electrical wiring within a circuit. It serves as a central point where wires are connected together, providing a clean and organized solution for cable management. This helps to prevent loose or tangled wires, making troubleshooting and maintenance much easier.

When installing a junction box, it is important to consider factors such as wire size, the number of connections, and the load on the circuit. It is crucial to adhere to electrical codes and regulations to ensure the safety and reliability of the electrical system.

Here are a few key features and considerations when dealing with junction boxes:

- Wire Capacity: Junction boxes have specific wire capacity ratings, indicating the maximum number and size of wires they can accommodate. It is important not to exceed these ratings to prevent overcrowding and overheating within the box.

- Access: Junction boxes should be easily accessible for future maintenance or repairs. It is important to ensure that they are not obstructed by walls, ceilings, or other structures.

- Cover Securement: Junction boxes require a cover to protect the connections and prevent accidental contact. The cover should be securely fastened to the box to ensure it stays in place.

- Grounding: Junction boxes should be properly grounded to provide safety against electrical faults and ensure the integrity of the grounding system.

- Waterproofing: In certain applications, such as outdoor or wet environments, waterproof or weatherproof junction boxes are necessary to protect the electrical connections from moisture and water damage.

By using junction boxes, you can ensure that electrical connections are secure, organized, and protected. They are a vital component in any electrical system, contributing to its safety, functionality, and longevity.

Outlet Box

An outlet box, also known as a receptacle box, is a type of electrical box specifically designed to house electrical outlets or receptacles. Outlet boxes provide a secure and organized enclosure for power connections, allowing for convenient access to electrical power throughout a building.

Outlet boxes are available in different sizes and configurations to accommodate various types of outlets, including standard 120-volt outlets, GFCI (Ground Fault Circuit Interrupter) outlets, and specialized outlets for appliances or devices.

The main function of an outlet box is to provide a stable and safe mounting point for electrical outlets. These boxes are typically installed within walls or mounted to electrical conduit to secure the outlets in place. Outlet boxes are made of durable materials such as plastic or metal to protect the electrical connections and prevent damage to the wiring.

When installing an outlet box, there are a few considerations to keep in mind:

- Size and Capacity: Outlet boxes come in different depths and sizes to accommodate the number of wires and connectors required for the specific outlet. It is crucial to choose the appropriate size to ensure that there is enough space for the wiring connections.

- Location: Outlet boxes should be strategically placed to provide convenient access to power. They are commonly installed at a comfortable height, following local electrical codes and regulations.

- Mounting: Outlet boxes should be securely mounted to the building structure to ensure stability. This can be achieved by attaching them to wall studs or using mounting brackets.

- Grounding: It is important to ensure that outlet boxes are properly grounded to prevent electrical shocks and ensure the safe operation of the outlets.

Outlet boxes are an essential component in residential, commercial, and industrial electrical systems. They allow for the safe and reliable distribution of electrical power through electrical outlets, making them a fundamental part of our everyday lives.

Whether you are installing a new outlet or replacing an existing one, using the appropriate outlet box is crucial for the proper installation and functionality of electrical outlets.

Switch Box

A switch box, also known as a switch enclosure, is a specific type of electrical box designed to house electrical switches. Switch boxes provide a secure and protective enclosure for switch mechanisms, allowing for the control and operation of electrical devices and lighting fixtures.

Switch boxes come in various sizes and configurations to accommodate different types of switches, such as toggle switches, rocker switches, and dimmer switches. They are typically made of durable materials like plastic or metal to withstand the mechanical stress of switch operation.

The primary function of a switch box is to provide a safe mounting point for switches and facilitate the connection of electrical wires to control devices or lighting circuits. When installing a switch box, there are several considerations to keep in mind:

- Size and Mounting: Switch boxes come in different sizes, depths, and mounting options to accommodate the specific switch and installation requirements. It is important to choose the appropriate size of the switch box to accommodate the switch mechanism and provide enough space for wiring connections.

- Number of Switches: Depending on the application, switch boxes can accommodate a single switch or multiple switches. In cases where multiple switches are used in a single box, it is essential to ensure sufficient room for wire connections without overcrowding the box.

- Grounding and Wiring: Switch boxes should be properly grounded to ensure electrical safety. Additionally, proper wiring techniques should be followed, such as using wire connectors or terminal screws, to secure the electrical connections.

- Cover Plate: Once the switches are installed in the switch box, a cover plate is used to conceal the wiring and provide a finished look. The cover plate should be securely fastened to the switch box to ensure it remains in place.

Switch boxes are commonly found in residential, commercial, and industrial applications, allowing for easy control of lighting fixtures, fans, and other electrical devices. They provide a central location for switches, making it convenient to operate and control various electrical circuits.

Proper installation of switch boxes is crucial for the safe and reliable operation of electrical switches. Following local electrical codes and regulations is important to ensure the proper installation and functionality of switch boxes in your electrical system.

Device Box

A device box, also known as a device enclosure, is a specific type of electrical box designed to house electrical devices such as dimmers, timers, thermostats, or other non-switch devices. Device boxes provide a secure and organized enclosure for these devices, ensuring their proper installation and protection.

Device boxes are available in various sizes, shapes, and configurations to accommodate different types of devices. They can be made of materials such as plastic or metal, depending on the specific application and local electrical codes.

The main purpose of a device box is to provide a stable and safe mounting point for non-switch electrical devices. These devices often require a controlled environment and secure installation to operate effectively. Device boxes provide the necessary protection for the devices and the electrical connections.

When installing a device box, there are several considerations that need to be taken into account:

- Size and Configuration: Device boxes come in different sizes to accommodate various devices. It is important to choose the appropriate size and configuration to ensure a proper fit and allow for easy installation of the device.

- Mounting and Installation: Device boxes should be securely mounted to the wall or other surfaces to provide stability and support for the device. Mounting brackets or screws may be used to achieve a secure installation.

- Wiring: Proper wiring techniques should be followed when connecting devices in the device box. This includes using wire connectors, following color-coding standards, and ensuring secure connections.

- Cover Plate: Once the device is installed in the device box, a cover plate is used to provide a finished appearance and protect the device and wiring. The cover plate should be securely fastened to ensure it remains in place.

Device boxes are commonly used in residential, commercial, and industrial applications for a wide range of devices, including dimmers, thermostats, occupancy sensors, and more. They provide a secure and organized housing for these devices, allowing for convenient access and operation.

Proper installation of device boxes is essential for the safe and reliable operation of non-switch devices. Following local electrical codes and regulations is important to ensure the correct installation and functionality of device boxes in your electrical system.

The electrical box is commonly referred to as a junction box or an electrical enclosure. It is used to protect and contain electrical connections and wiring.

Materials Used for Electrical Boxes

Electrical boxes are made from a variety of materials, each offering specific properties and benefits. The choice of material for an electrical box depends on factors such as the intended application, environmental conditions, and local electrical codes. Let’s explore some common materials used for electrical boxes:

1. Plastic: Plastic is a popular choice for electrical boxes due to its affordability, versatility, and ease of installation. Plastic boxes are lightweight, non-conductive, and resistant to corrosion, making them suitable for both interior and exterior applications. PVC (polyvinyl chloride) and ABS (acrylonitrile butadiene styrene) are commonly used plastics for electrical boxes.

2. Metal: Metal boxes are known for their durability, strength, and fire resistance. Steel and aluminum are the most common metals used for electrical boxes. Steel boxes provide excellent protection against impact and are commonly used in commercial and industrial settings. Aluminum boxes are lightweight and corrosion-resistant, making them suitable for outdoor applications.

3. Fiberglass: Fiberglass boxes offer superior resistance to chemicals, moisture, and extreme temperatures. They are commonly used in harsh environments where durability and protection against corrosion are essential. Fiberglass boxes are also non-conductive, offering an added layer of safety.

4. Non-metallic: Non-metallic, or NM, boxes are typically made from a combination of plastic and fiberglass materials. They are designed specifically for use with non-metallic sheathed cables (Romex). NM boxes are easy to install, lightweight, and resistant to corrosion.

5. Weatherproof: For outdoor applications, weatherproof electrical boxes are used to protect electrical connections from moisture, dust, and other environmental factors. These boxes are typically made of heavy-duty plastic or metal and feature gaskets or seals to create a watertight enclosure.

The material chosen for an electrical box should be compatible with the wiring method and the specific electrical components being installed. It is important to adhere to local electrical codes and regulations when selecting the appropriate material for an electrical box.

Ultimately, the choice of material for an electrical box depends on the specific requirements of the application, including safety, durability, and environmental conditions. By choosing the right material, you can ensure the longevity and functionality of your electrical system.

Installation of Electrical Boxes

The proper installation of electrical boxes is essential for ensuring the safety, functionality, and longevity of an electrical system. Whether you are a homeowner or a professional electrician, following the correct installation procedures is crucial. Here are the key steps to consider when installing electrical boxes:

- Plan and Prepare: Before beginning the installation, plan the location and layout of the electrical boxes based on the specific requirements of the wiring and devices. Identify the appropriate box type, size, and material for the application.

- Turn Off the Power: Always turn off the power supply to the area where the electrical box will be installed. This can be done by switching off the circuit breaker or removing the appropriate fuse.

- Mark the Location: Use a pencil or marker to mark the location where the box will be installed. Ensure that the location complies with local electrical codes and regulations.

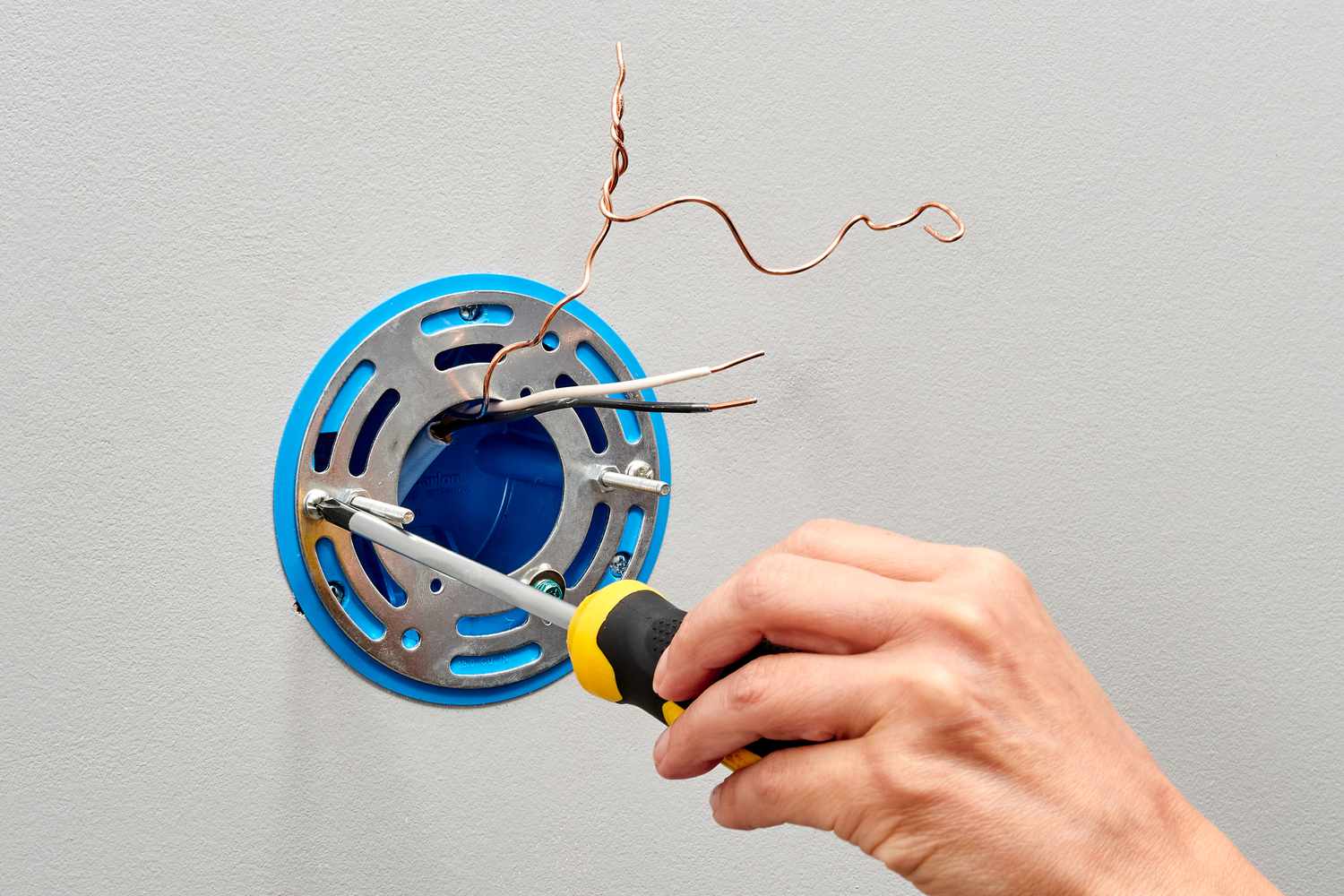

- Prepare the Wall or Ceiling: If necessary, cut a hole in the wall or ceiling using a keyhole saw or a drywall saw. Take care to avoid cutting any existing wires or damaging adjacent structures.

- Mounting the Box: Securely mount the electrical box to the wall or ceiling using appropriate installation methods. This may include attaching the box to a stud, using mounting brackets, or utilizing adjustable mounting bars for ceiling boxes.

- Connect the Wiring: Carefully run the electrical wiring into the box through the appropriate knockouts or cable clamps. Strip the wire insulation and make the necessary connections, following proper wiring techniques and using wire connectors or terminal screws.

- Secure the Wiring: Neatly organize and secure the wiring within the box using cable clamps or wire connectors to prevent strain, interference, or damage to the wires. Avoid overcrowding the box and ensure that there is enough space for proper connections and future maintenance.

- Install the Cover: Once the wiring connections are made, install an appropriate cover on the electrical box. Ensure that the cover is securely fastened to the box and that it provides ample protection for the wiring and electrical connections.

- Restore Power and Test: Once the installation is complete, restore power to the circuit and test the electrical box to ensure proper operation. Use a voltage tester to verify that the power is off before touching any wiring or devices.

It is important to follow local electrical codes, regulations, and best practices when installing electrical boxes. If you are unsure about any aspect of the installation process, consult a qualified electrician to ensure the proper and safe installation of your electrical boxes.

Remember, proper installation not only ensures the safety of the electrical system but also allows for easier maintenance and troubleshooting in the future.

Read more: What Is The End Of An Electrical Cord Called

Wiring in Electrical Boxes

Wiring within electrical boxes is a critical aspect of any electrical installation. Proper wiring techniques ensure the safe and efficient operation of the electrical system. Whether you are wiring a junction box, outlet box, switch box, or device box, here are some key considerations:

- Plan and Prepare: Before wiring, carefully plan the layout of the wiring within the electrical box. Identify the correct wires for the specific application and determine the appropriate wire size based on the electrical load and local codes.

- Turn Off the Power: Always turn off the power supply to the electrical circuit before working on the wiring inside the box. This can be done by switching off the circuit breaker or removing the appropriate fuse.

- Choose the Correct Wiring Method: Select the appropriate wiring method for your specific installation. Common types of wiring include non-metallic sheathed cable (Romex), armored cable (AC or BX), and conduit wiring (rigid or flexible).

- Strip the Wire Insulation: Carefully strip the insulation from the ends of the wires using wire strippers. Ensure that the correct length of insulation is removed to make proper connections within the box.

- Make Connections: Follow proper wiring techniques to make connections within the electrical box. This may include twisting wires together with wire connectors, using terminal screws, or using push-in connectors, depending on the specific wiring method and device being connected.

- Secure and Organize Wiring: Neatly organize the wires within the box and secure them using cable clamps or wire connectors. Arrange the wires in a way that allows for easy identification and prevents strain or interference between wires.

- Avoid Overcrowding: Avoid overcrowding the electrical box with excessive wires or connections. Ensure that there is enough space to make proper connections and allow for future maintenance and troubleshooting.

- Grounding: Properly ground the wiring within the electrical box to provide safety against electrical faults. Connect ground wires to grounding screws or terminals within the box and ensure proper bonding with the grounding system.

- Test Connections: Once the wiring connections are made, carefully inspect and test the connections before restoring power to the circuit. Use a voltage tester to ensure that the wiring is properly connected and that there are no exposed or faulty wires.

It is important to familiarize yourself with local electrical codes and regulations to ensure compliance with proper wiring practices. If you are unsure about any aspect of the wiring process, consult a qualified electrician for guidance.

Remember, a well-executed wiring job within electrical boxes ensures the safety, reliability, and functionality of your electrical system. Take the time to follow proper techniques and guidelines to achieve a successful wiring installation.

Electrical Box Covers and Accessories

Electrical box covers and accessories play an important role in providing protection, organization, and functionality to electrical installations. These components complete the installation of electrical boxes and ensure the safety and reliability of the electrical system. Here are some common electrical box covers and accessories:

- Cover Plates: Cover plates, also known as faceplates, are used to cover the opening of electrical boxes. They provide a protective barrier for the wiring and connections and also provide a finished appearance. Cover plates come in various sizes, shapes, and designs to accommodate different types of electrical devices, such as switches, outlets, and dimmers.

- Gaskets and Seals: Gaskets and seals are used to create a watertight or weatherproof seal between the electrical box and the cover plate. They help to prevent moisture, dust, and other debris from entering the electrical box, ensuring the integrity and longevity of the electrical connections.

- Extension Rings: Extension rings are used to increase the depth or capacity of electrical boxes. They provide additional space for wiring connections, making it easier to accommodate large bundles of wires or devices with bulky wiring connections.

- Cable Clamps: Cable clamps, also known as strain relief connectors, are used to secure and protect the incoming and outgoing wiring within the electrical box. They help to prevent strain, tension, or damage to the wires, ensuring a secure and organized wiring installation.

- Grounding Screws and Clips: Grounding screws or clips are used to provide a secure grounding connection within the electrical box. They are used to connect the grounding wire to the box, ensuring electrical safety and compliance with local codes and regulations.

- Wire Connectors: Wire connectors, also known as wire nuts or twist-on connectors, are used to join or splice wires together within the electrical box. They provide a secure connection, preventing accidental wire disconnection and reducing the risk of electrical hazards.

- Mounting Brackets: Mounting brackets are used to securely attach electrical boxes to wall studs or other surfaces. They provide stability to the box and ensure a durable installation, allowing for secure mounting of devices and cover plates.

- Labeling and Identification: Labeling and identification accessories, such as adhesive labels or markers, are used to identify circuits, devices, and wiring connections within the electrical box. This helps with troubleshooting, maintenance, and future modifications.

These are just a few examples of electrical box covers and accessories available in the market. It is important to select the appropriate cover plates and accessories based on the specific type of electrical box and the devices being installed.

Remember to follow local electrical codes and regulations when choosing and installing electrical box covers and accessories. By using the right covers and accessories, you can ensure a safe, organized, and functional electrical installation.

Safety Considerations for Electrical Boxes

When working with electrical boxes, it is important to prioritize safety to prevent accidents, electrical hazards, and damage to the electrical system. Here are some essential safety considerations to keep in mind:

- Turn off the Power: Always turn off the power supply to the electrical circuit before working on or inside electrical boxes. This can be done by switching off the circuit breaker or removing the appropriate fuse. Use a voltage tester to double-check that the power is off before starting any work.

- Follow Electrical Codes: Adhere to local electrical codes and regulations when installing electrical boxes. These codes provide guidelines for proper installation, appropriate wire sizes, and grounding requirements. Following these codes ensures the safety and reliability of the electrical system.

- Proper Box Selection: Choose the correct type, size, and material of electrical box for your specific application. Ensure that the box provides sufficient space for wire connections without overcrowding. Using an undersized or inappropriate box can lead to overheating, wire damage, or electrical malfunction.

- Secure Wiring Connections: Make sure all wiring connections within the electrical box are properly secured. Use appropriate wire connectors, terminal screws, or push-in connectors to create secure and reliable connections. Loose or improper connections can lead to electrical problems, including shorts, overheating, or electrical shock hazards.

- Avoid Overloading: Do not overload electrical boxes with excessive wires, devices, or connections. Overloading can cause overheating and can potentially lead to circuit failures or fire hazards. Use larger boxes or additional junction boxes if needed to accommodate the wiring connections appropriately.

- Protective Covers: Install suitable covers on electrical boxes to protect the wiring and connections. Ensure that the covers are securely fastened and provide ample protection against accidental contact or environmental hazards. Use gaskets or seals to create a weatherproof or watertight seal for outdoor or wet locations.

- Grounding: Properly ground the electrical boxes and devices to ensure electrical safety. Follow local codes and regulations for grounding requirements and connect the grounding wires to the grounding screws or terminals within the box. A solid grounding system reduces the risk of electrical shock and protects against electrical faults.

- Regular Inspection and Maintenance: Regularly inspect electrical boxes for any signs of damage, such as cracks, loose connections, or dislodged covers. Perform routine maintenance to ensure that the wiring and connections remain secure and in good condition. If any issues are identified, they should be promptly addressed and corrected.

When in doubt or faced with complex electrical installations, it is always advisable to seek the assistance of a qualified electrician. They have the expertise and knowledge to ensure that electrical boxes are installed safely and in compliance with electrical codes.

Remember, prioritizing safety is crucial when working with electrical boxes. By following the proper safety precautions, you can create a secure and reliable electrical system that minimizes the risk of accidents and electrical hazards.

Conclusion

Electrical boxes are an essential component of any electrical system, providing a safe and organized housing for electrical connections, devices, and wiring. From junction boxes to outlet boxes, switch boxes, and device boxes, each type serves a specific purpose in maintaining a reliable and efficient electrical installation.

Choosing the right type and size of electrical box, along with proper installation techniques, is crucial for a safe and functional electrical system. The selection of materials, such as plastic, metal, or fiberglass, should be based on the specific application and environmental conditions.

When installing electrical boxes, it is important to adhere to local electrical codes and regulations. This ensures that wiring connections are secure, covers and accessories are properly installed, and safety measures are followed at all times.

Safety should always be a top priority when working with electrical boxes. Turning off the power, making secure wiring connections, avoiding overloading, and using protective covers are all key considerations for a safe electrical installation.

Regular inspection and maintenance of electrical boxes are vital to ensure proper functionality and to address any potential issues promptly. Working with a qualified electrician can ensure that installations meet professional standards and comply with electrical codes.

In conclusion, understanding and implementing best practices for electrical box installations play a vital role in maintaining a safe, efficient, and reliable electrical system. By following the guidelines and safety considerations outlined in this article, you can ensure the proper installation, functionality, and longevity of your electrical boxes.

Frequently Asked Questions about What Is The Electrical Box Called

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Electrical Box Called”