Articles

What Type Of Electrical Wire Is Used In Homes

Modified: September 2, 2024

Looking for information on the different types of electrical wire used in homes? Check out our comprehensive articles on this topic.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electrical wire plays a crucial role in every home, serving as the lifeline of our electrical systems. Without it, we would be left in the dark, quite literally. From powering our lights and appliances to providing the necessary connections for communication and entertainment devices, electrical wire ensures the smooth operation of our daily lives. But have you ever wondered what type of electrical wire is used in homes?

In this article, we will explore the different types of electrical wire commonly found in homes, their characteristics, and the factors to consider when choosing the appropriate wire for your electrical needs. Whether you are a homeowner looking to understand the wiring in your house or a DIY enthusiast interested in electrical installations, this article will provide valuable insights.

The importance of using the correct electrical wire cannot be overstated. Using improper or substandard wire can lead to electrical hazards, fire hazards, or damage to your electrical devices. It is crucial to have a sound understanding of the various types of electrical wire available and their appropriate applications.

Now, let’s dive into the world of electrical wire and discover the different types commonly used in homes.

Key Takeaways:

- Choosing the right electrical wire is crucial for safety and efficiency in homes. Consider factors like wire gauge, insulation, and voltage rating to ensure proper installation and longevity of the electrical system.

- Prioritize safety when working with electrical wire. Turn off power, use proper PPE, inspect for damage, and avoid overloading circuits. Seek professional help if unsure to create a secure and reliable electrical system.

The Importance of Electrical Wire in Homes

Electrical wire is the backbone of any residential electrical system. It serves as the conduit through which electricity flows, connecting various devices and appliances to the power source. The use of proper electrical wire is essential for the safe and efficient functioning of your home’s electrical system. Here are key reasons why electrical wire is of paramount importance in homes:

- Safe Transmission of Electricity: Electrical wire is designed to safely carry the flow of electric current from the power source to the connected devices. It is crucial to use the appropriate wire size and type to ensure that the wire can handle the electrical load without overheating or causing a short circuit.

- Prevention of Electrical Hazards: Using the wrong wire or faulty wiring can lead to electrical hazards, such as electrical shocks, fires, or damage to electrical devices. High-quality electrical wire with proper insulation helps prevent these hazards by providing a secure and reliable electrical connection.

- Reliable Power Supply: The use of high-quality electrical wire ensures a steady and uninterrupted power supply throughout your home. It prevents voltage drops, interference, and electrical disturbances that can affect the performance of your appliances and devices.

- Longevity of Electrical System: Properly installed and maintained electrical wire can significantly extend the lifespan of your electrical system. By using durable and reliable wire, you reduce the risk of electrical failures and the need for frequent repairs or replacements.

- Compliance with Electrical Codes: Electrical wire must meet specific safety standards and electrical codes set by local authorities. Using approved and certified wire ensures compliance with these codes, promoting the safety and legality of your electrical system.

- Flexibility for Future Upgrades: Choosing the right electrical wire allows for flexibility when it comes to future upgrades or renovations. Wiring that can accommodate higher amperages or increased electrical loads allows for the addition of new appliances or the expansion of the electrical system without the need for rewiring.

Overall, electrical wire is a critical component of homes that should never be overlooked. It ensures the safe and uninterrupted flow of electricity, protecting your home and its occupants from electrical hazards and providing a reliable power supply. By investing in high-quality electrical wire and following proper installation practices, you can ensure the efficient performance and longevity of your home’s electrical system.

Common Types of Electrical Wire Used in Homes

There are several different types of electrical wire that are commonly used in residential homes. Each type has its own unique characteristics and is designed for specific applications. Here are some of the most common types of electrical wire used in homes:

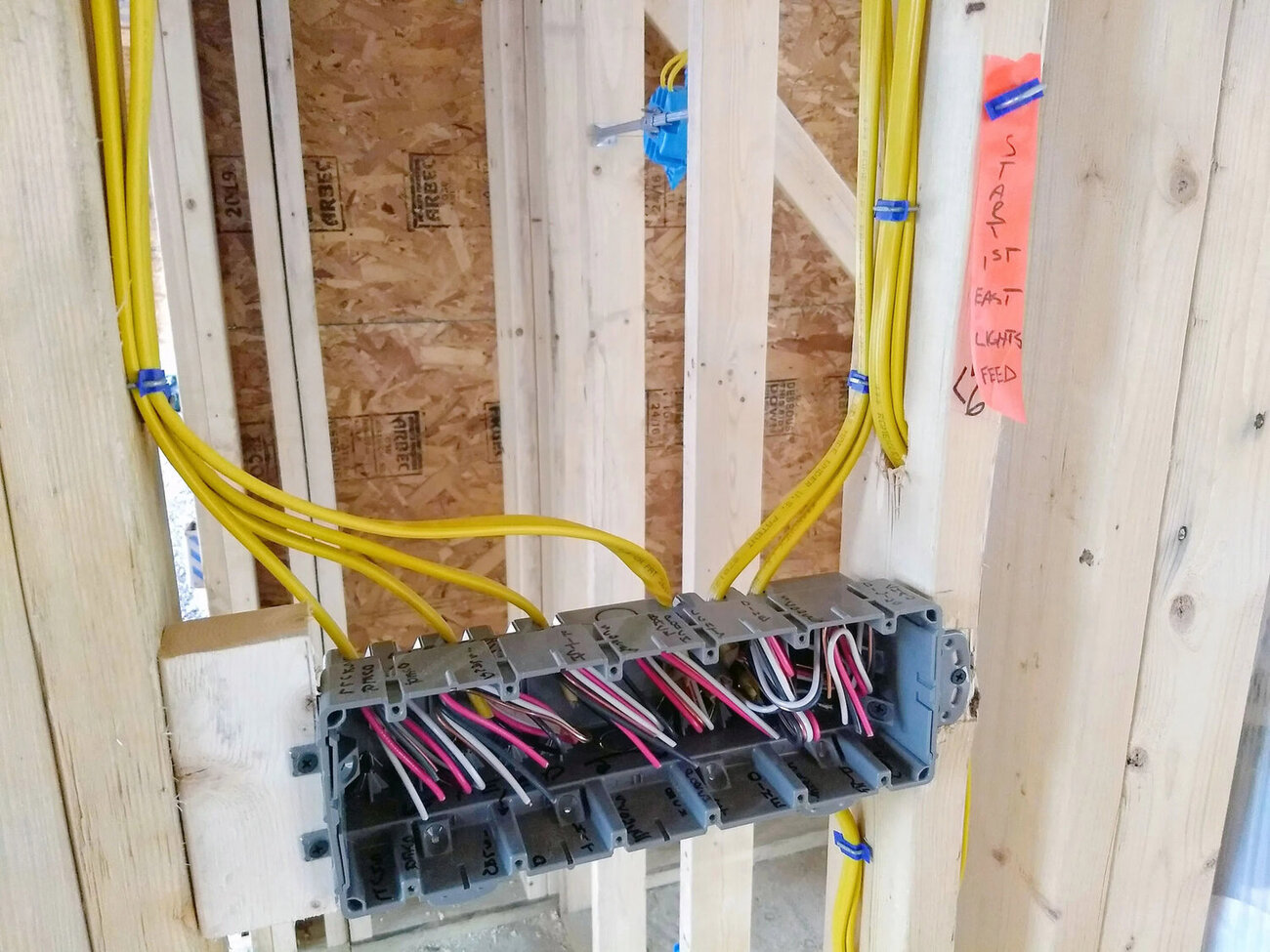

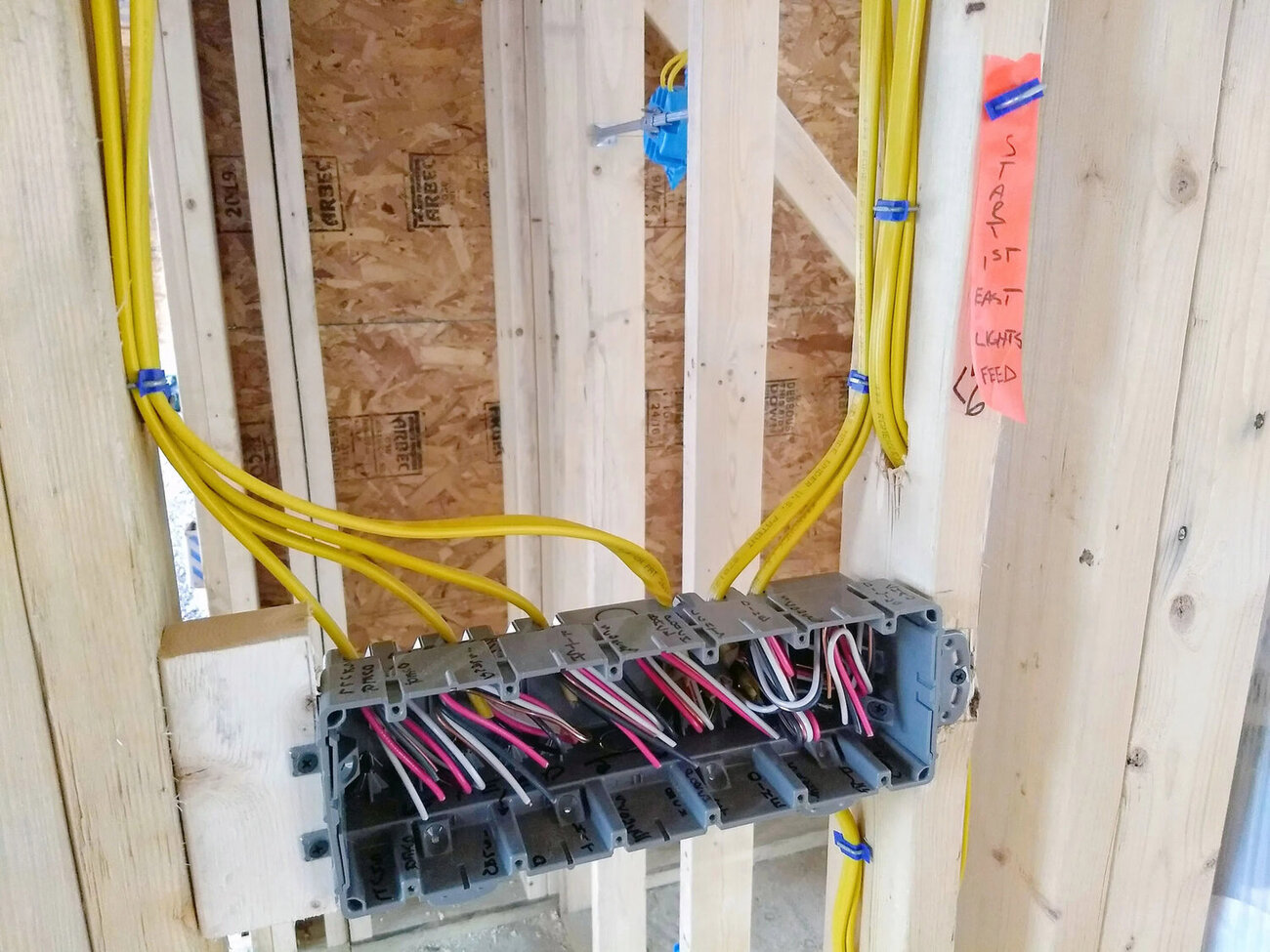

1. Non-Metallic (NM) or Romex Wire

Non-metallic wire, also known as Romex wire, is one of the most widely used types of electrical wire in homes. It consists of two or more insulated conductors, typically color-coded, and a bare copper ground wire. This type of wire is commonly used for general wiring purposes, such as lighting fixtures, outlets, and switches.

2. BX Cable

BX cable, also referred to as armored cable, is a type of electrical wire that has a metallic sheath surrounding the insulated conductors. The sheath provides protection against physical damage and acts as a grounding conductor. BX cable is often used in areas where additional protection is required, such as garages, basements, and outdoor locations.

3. Underground Feeder (UF) Cable

Underground Feeder (UF) cable is specifically designed for buried applications. It is moisture-resistant and has a tough exterior jacket to protect against damage from direct burial. UF cable is commonly used for outdoor lighting, underground electrical connections, and other applications where the wire will be exposed to moisture or buried underground.

4. Armored Cable (AC)

Armored cable, also known as AC cable or “Greenfield,” is a type of electrical wire that consists of individually insulated conductors wrapped in a flexible metal armor. The armor provides protection against physical damage, making it ideal for locations where the wire may be exposed to potential hazards. AC cable is commonly used for wiring in commercial buildings, garages, and outdoor applications.

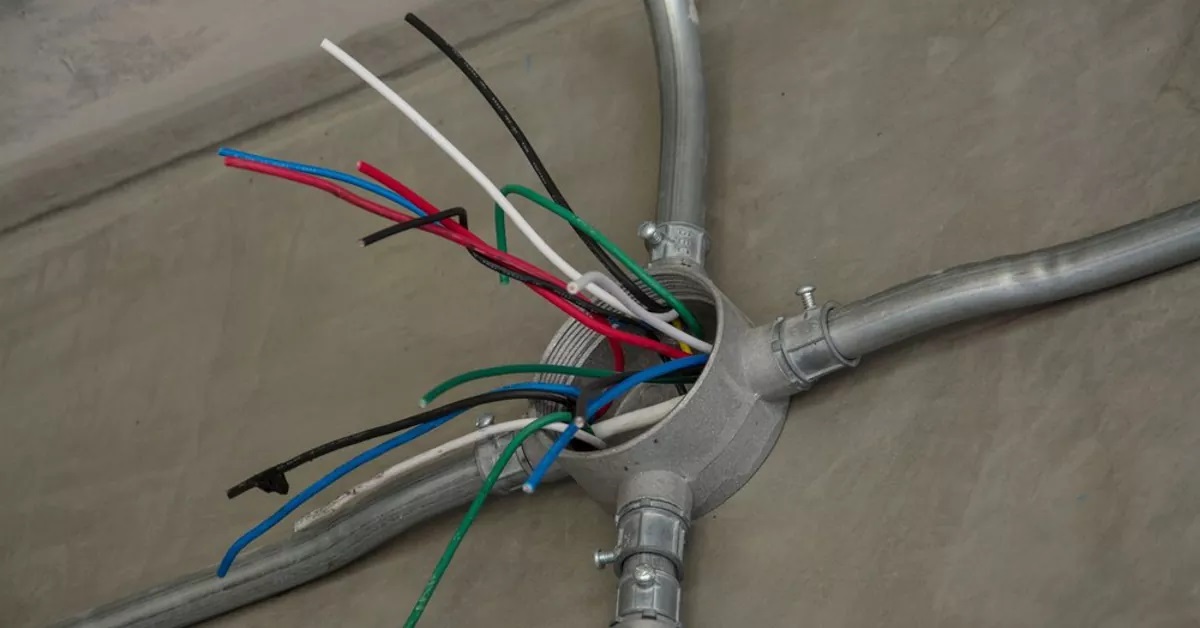

5. Flexible Metal Conduit (FMC)

Flexible Metal Conduit (FMC), also known as “Greenfield,” is a flexible type of conduit that is used to protect electrical wires. It is typically made of interlocking metal strips and has a plastic coating for added protection. FMC is commonly used in areas where flexibility is required, such as in tight spaces or where there may be frequent movement or vibrations.

6. Electrical Metallic Tubing (EMT)

Electrical Metallic Tubing (EMT) is a type of rigid metal conduit that is commonly used for exposed electrical wiring. It is lightweight and easy to install, making it a popular choice for residential electrical applications. EMT is often used in indoor settings, such as basements, garages, and commercial buildings.

When choosing the appropriate type of electrical wire for your home, it is important to consider factors such as the application, location, and specific electrical requirements. Consulting a professional electrician or referencing local electrical codes can ensure that you select the right wire for your specific needs.

Common Types of Electrical Wire Used in Homes

1. Non-Metallic (NM) or Romex Wire

Non-Metallic (NM) or Romex wire is one of the most commonly used types of electrical wire in residential homes. It consists of two or more insulated conductors, typically color-coded for identification, and a bare copper ground wire. The conductors are made of copper or aluminum, both known for their excellent conductivity.

One of the primary advantages of NM wire is its ease of use. It is flexible and can be easily manipulated during installation, making it a convenient choice for electricians and DIY enthusiasts alike. The wire is typically sold in rolls or coils for easy handling and installation.

Romex wire is most commonly used for general-purpose wiring within the home, such as for lighting fixtures, outlets, and switches. Due to its versatility and affordability, it is often the go-to option for residential wiring projects.

When installing NM wire, it is important to follow the guidelines set forth by the National Electrical Code (NEC) and local electrical codes. The wire must be protected by appropriate conduit or installed in areas where it will not be subject to physical damage. Additionally, the wire must be properly sized to handle the electrical load it will carry to ensure optimal performance and safety.

It is essential to note that NM wire is intended for use in dry locations only. If you need to wire areas exposed to moisture or outdoor environments, you must use approved wire types specifically designed for those applications.

Overall, Non-Metallic (NM) or Romex wire is a popular choice for residential electrical installations. Its ease of use, affordability, and versatility make it a go-to option for general-purpose wiring needs within the home. However, it is crucial to follow proper installation procedures and adhere to electrical codes to ensure the safety and efficiency of your electrical system.

Common Types of Electrical Wire Used in Homes

2. BX Cable

BX cable, also known as armored cable, is a type of electrical wire that provides both electrical conductivity and physical protection. It consists of insulated conductors encased in a flexible metallic sheath, typically made of aluminum or steel. The sheath serves as a grounding conductor and provides protection against damage from external factors such as moisture, impact, or abrasion.

One of the primary advantages of BX cable is its durability and resistance to physical damage. The metallic sheath provides an extra layer of protection, making it suitable for use in areas where wires may be exposed to potential hazards. It is commonly used in garages, basements, and outdoor locations where additional protection is required.

Another benefit of BX cable is its versatility in installation. It can be used in both exposed or concealed locations, allowing for flexibility in wiring applications. However, it is important to note that BX cable typically requires special tools for cutting and stripping the armored sheath.

When installing BX cable, it is crucial to follow electrical codes and best practices. The cable must be properly secured and supported to prevent strain on the conductors and maintain the integrity of the installation. Additionally, proper grounding techniques should be employed to ensure the safety and reliable operation of the electrical system.

It is important to consider the specific requirements of your project and consult with a professional electrician to determine if BX cable is the appropriate choice. Factors such as environmental conditions, electrical load, and local regulations should be taken into account when selecting the type of wire for your installation.

In summary, BX cable, or armored cable, is a type of electrical wire that provides both electrical conductivity and physical protection. Its durability, versatility, and resistance to damage make it a popular choice for areas where wires may be exposed to potential hazards. However, proper installation techniques and adherence to electrical codes are essential to ensure a safe and reliable electrical system.

Common Types of Electrical Wire Used in Homes

3. Underground Feeder (UF) Cable

Underground Feeder (UF) cable is a specialized type of electrical wire designed specifically for underground applications. It is commonly used to supply power to outdoor lighting, pumps, and other electrical components in locations where the wire will be buried underground.

One of the key features of UF cable is its resistance to moisture and direct burial. It is constructed with insulation and jacketing materials that provide protection against water and moisture ingress. This ensures that the cable remains functional and safe, even when continuously exposed to damp or wet environments.

UF cable typically consists of solid or stranded copper conductors, insulated with either thermoplastic or thermoset materials. The insulation and jacketing materials used in UF cable are rated for direct burial and are resistant to damage from sunlight, oil, and other environmental factors.

When installing UF cable, it is essential to follow local electrical codes and regulations. The cable should be buried at a sufficient depth to protect it from damage, usually determined by local building codes. It is also important to use appropriate conduit or protective tubing when transitioning from underground to above-ground installations.

UF cable is an excellent choice for outdoor landscaping projects, such as lighting systems, irrigation systems, or underground circuits for outbuildings. Its ability to withstand moisture and direct burial makes it ideal for these types of applications.

It is crucial to emphasize that only licensed electricians or experienced individuals should install UF cable. The expertise of a professional ensures proper installation methods, compliance with local regulations, and adherence to the necessary safety precautions.

In summary, Underground Feeder (UF) cable is specifically designed for underground applications, providing protection against moisture and direct burial. It is commonly used for outdoor electrical projects and is ideal for supplying power to devices and fixtures in buried locations. Proper installation techniques and knowledge of local electrical codes are essential when working with UF cable to ensure a safe and reliable electrical system.

Common Types of Electrical Wire Used in Homes

4. Armored Cable (AC)

Armored Cable (AC), also known as “Greenfield,” is a type of electrical wire that combines electrical conductivity with physical protection. It consists of insulated conductors enclosed in a flexible metal armor, typically made of aluminum or steel.

The primary advantage of AC cable is its robust construction, providing excellent protection against physical damage and mechanical stress. The metallic armor acts as a shielding layer, safeguarding the conductors from impact, compression, and other external forces. This makes AC cable especially suitable for areas where the wire may be exposed to potential hazards or require additional durability.

AC cable is commonly used in applications where flexibility and versatility are required. It can be used for both exposed and concealed installations, making it a popular choice for residential wiring projects. It is often found in garages, workshops, outdoor environments, and in commercial or industrial settings where wiring may be subject to rough handling or potential damage.

When installing AC cable, it is essential to follow proper installation practices and adhere to local electrical codes. The cable must be properly secured and supported to prevent strain on the conductors and maintain the integrity of the electrical installation. Additionally, the metal armor of AC cable is typically used as a grounding path and must be bonded to the grounding system.

It is important to note that AC cable may require special tools for cutting and stripping the metal armor. This should be taken into consideration before undertaking any installation involving AC cable.

Consulting a professional electrician or referring to local electrical codes is recommended to ensure the appropriate use of AC cable in your specific application. They can provide guidance on selecting the correct size and type of AC cable, as well as ensuring compliance with safety regulations and best practices.

In summary, Armored Cable (AC) provides both electrical conductivity and physical protection. Its robust construction makes it an ideal choice for areas where the wire may be exposed to potential hazards or require additional durability. AC cable offers versatility during installation and is commonly used in various residential, commercial, and industrial applications with proper installation techniques and adherence to electrical codes.

Common Types of Electrical Wire Used in Homes

5. Flexible Metal Conduit (FMC)

Flexible Metal Conduit (FMC), also known as Greenfield, is a type of electrical conduit that provides both protection and flexibility for electrical wires. It is made of a series of interlocking metal strips, typically made of steel or aluminum, with a plastic coating for additional protection.

The primary advantage of FMC is its flexibility, making it an excellent choice for installations that require bending or maneuvering around obstacles. The flexible nature of FMC allows for easy routing within confined spaces, such as walls, ceilings, or areas with tight corners.

FMC is commonly used for electrical wiring in both residential and commercial settings. It is often utilized in applications such as lighting fixtures, outlets, and switches, where flexibility is necessary. FMC is also suitable for wiring in areas where there may be structural movement or vibrations.

When installing FMC, it is essential to follow proper installation guidelines and adhere to local electrical codes. The conduit must be securely fastened and properly supported to prevent strain on the wires and maintain the integrity of the electrical system.

It is important to note that FMC is not intended for use in wet or outdoor environments unless it is specifically rated for such applications. Moisture can potentially damage the plastic coating and compromise the safety of the electrical system.

It is advisable to consult a professional electrician or refer to local electrical codes when considering the use of FMC in your wiring project. They can provide guidance on the appropriate size, installation techniques, and specific requirements for your application.

In summary, Flexible Metal Conduit (FMC) provides both protection and flexibility for electrical wires. Its ability to bend and maneuver in tight spaces makes it a preferred choice for installations that require flexibility. However, it is important to ensure proper installation and adherence to electrical codes for optimal performance and safety.

Common Types of Electrical Wire Used in Homes

6. Electrical Metallic Tubing (EMT)

Electrical Metallic Tubing (EMT) is a type of rigid metal conduit commonly used in residential and industrial electrical installations. It is made of galvanized steel or aluminum and provides strong mechanical protection for electrical wires.

One of the key advantages of EMT is its durability and strength. The rigid construction of EMT ensures the protection of wiring in areas where it may be subject to impact or damage. It is resistant to crushing and bending, making it a reliable choice for long-term electrical installations.

EMT is often used for exposed indoor installations, such as basements, garages, and commercial buildings. It is commonly seen in lighting systems, power distribution, and branch circuit wiring applications.

Another advantage of EMT is its ease of installation. The tubing is lightweight, making it easier to handle and maneuver during installation compared to other types of rigid conduit. Additionally, EMT is compatible with a wide range of fittings, allowing for flexibility and adaptability in various wiring configurations.

When installing EMT, it is important to adhere to the appropriate installation techniques and follow local electrical codes. The conduit must be properly secured and supported using appropriate hangers or straps to prevent strain on the wiring and maintain the integrity of the electrical system.

It is worth noting that EMT does not provide the same level of physical protection as armored or flexible conduit types. Therefore, it may not be suitable for installations in areas with potential hazards or where increased protection is required.

Consulting a professional electrician or referencing local electrical codes is recommended when considering the use of EMT in your electrical installation. They can provide guidance on the appropriate size, installation methods, and specific requirements for your application.

In summary, Electrical Metallic Tubing (EMT) is a rigid metal conduit that provides strong mechanical protection for electrical wires. Its durable construction and ease of installation make it a popular choice for exposed indoor electrical installations. However, it is important to consider specific requirements and consult with professionals to ensure appropriate use and compliance with electrical codes.

Read more: What Is Blue Electrical Wire Used For

Factors to Consider When Choosing Electrical Wire for Homes

When it comes to choosing the right electrical wire for your home, several factors need to be taken into consideration. Each factor plays a crucial role in determining the suitability and safety of the wire for a specific application. Here are some key factors to consider when selecting electrical wire for homes:

1. Wire Gauge

Wire gauge refers to the thickness or diameter of the wire. The gauge determines the wire’s current-carrying capacity, with lower gauge numbers indicating thicker wires capable of handling higher electrical loads. It is essential to choose the appropriate wire gauge based on the expected electrical load and the type of circuit it will be used for. Using a wire with an inadequate gauge can lead to overheating and potential fire hazards.

2. Ampacity Rating

Ampacity rating represents the maximum amount of current that a wire can safely carry without overheating. It is crucial to select a wire with an ampacity rating that matches or exceeds the expected electrical load. Exceeding the ampacity rating can result in overheating and increased risk of electrical hazards. Ampacity ratings can be found in electrical code tables or provided by manufacturers.

3. Insulation Material

The insulation material of the electrical wire is essential for both electrical and mechanical protection. Common insulation materials include thermoplastic, thermoset, or rubber. The insulation material must be suitable for the environment and conditions in which the wire will be installed. It should provide resistance to heat, moisture, chemicals, and abrasion, ensuring safe operation and longevity of the wire.

4. Voltage Rating

The voltage rating refers to the maximum voltage that the wire can withstand safely. It is crucial to select a wire with a voltage rating that matches or exceeds the voltage of the electrical system it will be installed in. Using a wire with an inappropriate voltage rating can lead to electrical breakdown, insulation failure, and potential safety risks.

5. Environmental Factors

Consider the specific environmental factors that the wire will be exposed to. For instance, if the wire will be installed outdoors or in areas with high moisture levels, it is important to choose wire with appropriate moisture resistance and protection against UV rays. Environmental factors can significantly impact the performance and longevity of the wire.

6. Compliance with Electrical Codes

Always ensure that the selected electrical wire complies with the relevant electrical codes and safety standards. Following electrical codes is crucial to ensure the safety and legality of your electrical installation. It is advisable to consult with a professional electrician or refer to local electrical codes to ensure compliance.

By considering these factors when selecting electrical wire for your home, you can ensure a safe and reliable electrical system that meets the specific requirements of your installation. Consulting with professionals and adhering to electrical codes will further ensure the optimal performance and longevity of your electrical wiring.

Read more: What Is Blue Electrical Wire Used For

Factors to Consider When Choosing Electrical Wire for Homes

1. Wire Gauge

Wire gauge refers to the size or thickness of the wire. It is an essential factor to consider when choosing electrical wire for your home. The wire gauge determines the wire’s current-carrying capacity and is crucial for preventing overheating and electrical hazards.

Wire gauge is measured using a numerical system, with lower gauge numbers indicating thicker wires capable of carrying higher electrical currents. The most common wire gauges for residential applications range from 14 gauge to 10 gauge.

When selecting the appropriate wire gauge, consider the electrical load the wire will be carrying. Each circuit and electrical device has its own specific ampere rating, which determines the amount of current it requires. Choose a wire gauge that can safely handle the expected current load without exceeding its maximum ampacity.

Using a wire with an inadequate gauge can lead to several issues. If the wire is too thin for the electrical load, it will increase resistance and cause the wire to heat up. This can result in overheating, insulation degradation, and even electrical fires.

On the other hand, using a wire with excessive gauge (thicker wire than necessary) may seem like a safe choice, but it can be economically impractical and difficult to work with due to its stiffness and increased cost.

Consulting an electrician or referring to electrical code regulations can help determine the appropriate wire gauge for your specific application. Factors such as the length of the wire run, the type of circuit, and the maximum current expected should be taken into consideration.

It is important to note that certain appliances or circuits may require specific wire gauges due to their power requirements. For example, high-power appliances such as electric stoves or hot water heaters typically require thicker wire gauges to handle the increased electrical load.

By selecting the correct wire gauge, you can ensure a safe and efficient electrical system in your home. Proper consideration of wire gauge prevents unnecessary risks associated with overheating and helps maintain the integrity of your electrical circuits.

Read more: What Is Blue Electrical Wire Used For

Factors to Consider When Choosing Electrical Wire for Homes

2. Ampacity Rating

The ampacity rating is an essential factor to consider when choosing electrical wire for your home. It refers to the maximum current-carrying capacity of the wire and ensures that it can safely handle the electrical load without overheating.

Every wire has a specific ampacity rating, which is determined by factors such as the wire gauge, insulation type, and ambient temperature. The ampacity rating indicates the maximum amount of current that the wire can carry without exceeding its temperature rating.

Exceeding the ampacity rating can cause the wire to overheat, leading to a potential fire hazard and damage to the wire’s insulation. Therefore, it is crucial to select a wire with an ampacity rating that matches or exceeds the expected electrical load.

To determine the appropriate ampacity rating, refer to electrical code regulations or consult with a professional electrician. The ampacity rating of different wire sizes and types can be found in electrical code tables.

Keep in mind that the ampacity rating depends on various factors, including the wire insulation material and the installation conditions. Wires installed in areas with high ambient temperatures, such as attics or near heat sources, may have a reduced ampacity rating.

It is important to calculate the expected electrical load for each circuit and choose a wire with an ampacity rating that meets or exceeds that load. This will ensure proper and safe operation of your electrical system.

Additional considerations may include future expansion or upgrades to the electrical system. It is wise to select wire with a greater ampacity rating than the current needs to accommodate potential future increases in electrical load.

Remember that the total ampacity of a wire should not exceed the rating of the circuit breaker protecting it. The circuit breaker is designed to trip and disconnect the circuit if the current exceeds its rating, preventing overheating and potential hazards.

In summary, selecting wire with the appropriate ampacity rating is crucial to ensure the safe and efficient operation of your electrical system. Adhering to the ampacity rating guidelines helps prevent overheating and reduces the risk of electrical hazards. Consulting an electrician or referencing electrical code regulations can provide further guidance in selecting wire with the correct ampacity rating for your specific application.

Read more: What Is Blue Electrical Wire Used For

Factors to Consider When Choosing Electrical Wire for Homes

3. Insulation Material

The insulation material of electrical wire is an important factor to consider when choosing the right wire for your home. The insulation serves as a protective barrier that prevents electrical leakage, provides mechanical support, and ensures the safety and longevity of the wire.

There are various insulation materials used in electrical wire, and each has its own unique properties and suitability for different applications. Common insulation materials include thermoplastic (such as PVC), thermoset (such as cross-linked polyethylene), and rubber.

When selecting the insulation material, consider the environment and conditions in which the wire will be installed. The insulation should provide resistance to heat, moisture, chemicals, and abrasion, depending on the specific needs of the electrical installation.

Here are some commonly used insulation materials and their characteristics:

- Polyvinyl Chloride (PVC): PVC insulation is widely used in electrical wire due to its affordability, versatility, and excellent moisture resistance. It is resistant to most oils, chemicals, and sunlight exposure. PVC insulation is commonly found in general-purpose electrical wiring applications.

- Cross-linked Polyethylene (XLPE): XLPE insulation offers better thermal properties and resistance to high temperatures compared to PVC. It is commonly used in wiring for higher voltage applications. XLPE insulation provides excellent moisture resistance and is suitable for both indoor and outdoor installations.

- Rubber: Rubber insulation offers excellent flexibility, durability, and resistance to high temperatures. It is commonly used in portable cords, appliance wiring, and wiring in industrial environments where flexibility is crucial.

When selecting wire insulation material, consider factors such as the location of the wire, the presence of moisture or chemicals, and the expected temperature variations. It is important to choose insulation that is suitable for the specific environmental conditions in which the wire will be installed.

It is crucial to ensure that the chosen insulation material meets the relevant safety standards and electrical codes. Always select wire from reputable manufacturers that comply with industry regulations and have been tested for safety and performance.

Consulting with a professional electrician can provide valuable insights and recommendations on the appropriate insulation material for your specific electrical application. They can assess the specific requirements and environmental factors to help you choose wire with the most suitable insulation material.

In summary, selecting the proper insulation material is vital for the safe and reliable operation of electrical wire in your home. The insulation should provide protection against electrical leakage, mechanical support, and resistance to environmental factors. Consider the specific installation conditions and consult with professionals to ensure the right insulation material for your electrical needs.

Read more: What Is Blue Electrical Wire Used For

Factors to Consider When Choosing Electrical Wire for Homes

4. Voltage Rating

The voltage rating is a critical factor to consider when choosing electrical wire for your home. It refers to the maximum voltage at which the wire can safely operate without the risk of electrical breakdown or insulation failure.

Electrical systems in homes typically operate at standard voltages such as 120 volts or 240 volts in the United States. It is crucial to select wire with a voltage rating that matches or exceeds the voltage of the electrical system in which it will be installed.

Using wire with an inappropriate voltage rating can result in serious safety hazards. If the voltage exceeds the wire’s rating, it can cause the wire to fail, leading to electrical hazards, insulation breakdown, and even fires.

The voltage rating should be specified on the wire’s labeling or packaging. It is important to check the voltage rating and ensure it meets the requirements of your electrical system.

Understanding the voltage rating is particularly important in situations where different voltage levels are present, such as in commercial or industrial settings. In such cases, it is essential to use wire with the appropriate voltage rating for each specific circuit or application.

When selecting wire for your home, it is advisable to consult with a professional electrician or refer to local electrical codes for guidance. They can help determine the correct voltage rating based on the electrical system’s specifications and the specific application of the wire.

Another consideration is future electrical upgrades or renovations. If you anticipate potential changes in your electrical system that involve higher voltage levels, it may be wise to select wire with a higher voltage rating to accommodate those future upgrades.

Remember, using wire with the correct voltage rating is crucial for maintaining the safety and integrity of your electrical system. Adhering to proper voltage ratings ensures that the wire can handle the electrical load and voltage levels without risking electrical failures or hazards.

In summary, verify the voltage rating of the wire to ensure it matches or exceeds the voltage requirements of your electrical system. Proper voltage ratings safeguard against insulation failures, minimize the risk of electrical hazards, and maintain the safety and reliability of your home’s electrical wiring.

Safety Precautions When Working with Electrical Wire

Working with electrical wire can potentially be hazardous if proper safety precautions are not followed. Whether you are a professional electrician or a DIY enthusiast, it is crucial to prioritize safety to prevent accidents and ensure a secure working environment. Here are some key safety precautions to keep in mind when working with electrical wire:

Read more: What Is 4 Wire Electrical Wire

1. Turn off the Power

Before beginning any electrical work, always turn off the power at the circuit breaker or fuse box. This ensures that you are not working on live wires, reducing the risk of electrical shock or injury. Additionally, use a voltage tester to confirm that the power is truly off before proceeding with any electrical work.

2. Use Proper Personal Protective Equipment (PPE)

Wearing the appropriate personal protective equipment (PPE) is essential for your safety. PPE may include insulated gloves, safety goggles, work boots, and clothing made from non-conductive materials. The use of PPE protects you from potential electrical shocks, burns, and other injuries.

3. Inspect the Wire for Damage

Prior to installation or handling, thoroughly inspect the electrical wire for any signs of damage, such as cuts, frays, or exposed wiring. Using damaged wire can lead to electrical hazards, so replace any damaged wire before proceeding. Never attempt to repair damaged wire; it is safer to replace it entirely.

4. Use the Right Tools

Always use the proper tools for cutting, stripping, and connecting electrical wire. Using the wrong tools can damage the wire, compromise the integrity of the connection, or risk personal injury. Invest in quality tools specifically designed for working with electrical wire and use them according to the manufacturer’s instructions.

Read more: What Type Of Bone Is Used In Home Decor

5. Avoid Overloading Circuits

Ensure that the electrical load does not exceed the capacity of the wire or circuit. Overloading a circuit can cause overheating, which can damage the wire insulation and increase the risk of electrical fires. Refer to the wire’s ampacity rating and follow electrical code regulations to ensure appropriate wire and circuit selection.

6. Secure and Protect the Wire

Properly secure and protect electrical wires to prevent damage and reduce the risk of accidents. Use approved conduits, tubing, or wire channels to protect the wire from physical harm and exposure to moisture or chemicals. Avoid running wires through areas prone to excessive heat or where they may be subjected to sharp objects or unnecessary stress.

7. Seek Professional Help if Unsure

If you are uncertain about any aspect of the electrical work, do not hesitate to seek professional help. Electricians have the expertise and experience to handle complex electrical installations safely. It is better to enlist their help rather than put yourself or others at risk.

By following these safety precautions, you can ensure a safer working environment and reduce the likelihood of accidents when working with electrical wire. Never compromise safety and always prioritize caution to protect yourself and those around you when handling electrical wire.

Conclusion

Choosing the right electrical wire is crucial for the safe and efficient functioning of your home’s electrical system. Understanding the different types of wire available and considering various factors when making your selection will help ensure the proper installation and longevity of your electrical system.

We explored common types of electrical wire used in homes, including Non-Metallic (NM) or Romex Wire, BX Cable, Underground Feeder (UF) Cable, Armored Cable (AC), Flexible Metal Conduit (FMC), and Electrical Metallic Tubing (EMT). Each type has its own unique characteristics and applications, so it is essential to choose the appropriate wire for your specific needs.

When selecting electrical wire, consider factors such as wire gauge, ampacity rating, insulation material, voltage rating, and compliance with electrical codes. These factors play crucial roles in ensuring proper electrical load handling, resistance to environmental conditions, and compliance with safety standards.

It is equally important to prioritize safety when working with electrical wire. Follow safety precautions such as turning off the power, using proper personal protective equipment, inspecting the wire for damage, using the right tools, and avoiding overloading circuits. Remember to seek professional help if you are unsure about any aspect of the electrical work.

By making informed decisions and taking the necessary precautions, you can create a safe and reliable electrical system in your home. Consulting with professionals and adhering to electrical codes will further ensure the optimal performance and longevity of your electrical wiring.

Remember, electrical work can be complex and potentially hazardous. When in doubt, always consult with a professional electrician who can provide expert advice and assistance. Prioritizing safety and following best practices will help you create a secure and efficient electrical system in your home.

Frequently Asked Questions about What Type Of Electrical Wire Is Used In Homes

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Type Of Electrical Wire Is Used In Homes”