Articles

What Is SOOW Electrical Wire

Modified: December 7, 2023

Learn all about SOOW electrical wire in this comprehensive article. Discover its uses, specifications, and benefits for various applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to electrical installations, using the right wire is crucial for safety and functionality. One popular type of electrical wire that is widely used in various applications is SOOW wire. If you’re not familiar with SOOW wire, don’t worry – in this article, we will provide you with a comprehensive overview of what SOOW electrical wire is all about. From its definition and construction to its features and applications, we’ll cover everything you need to know about SOOW wire.

SOOW electrical wire is a type of portable cord commonly used for temporary power applications. The acronym SOOW stands for Service, Oil-resistant outer jacket, Weather-resistant outer jacket. This type of wire is designed to withstand demanding environments, making it ideal for a wide range of indoor and outdoor applications. Whether you need to power up construction equipment, portable lights, or industrial machinery, SOOW wire is a reliable and durable choice.

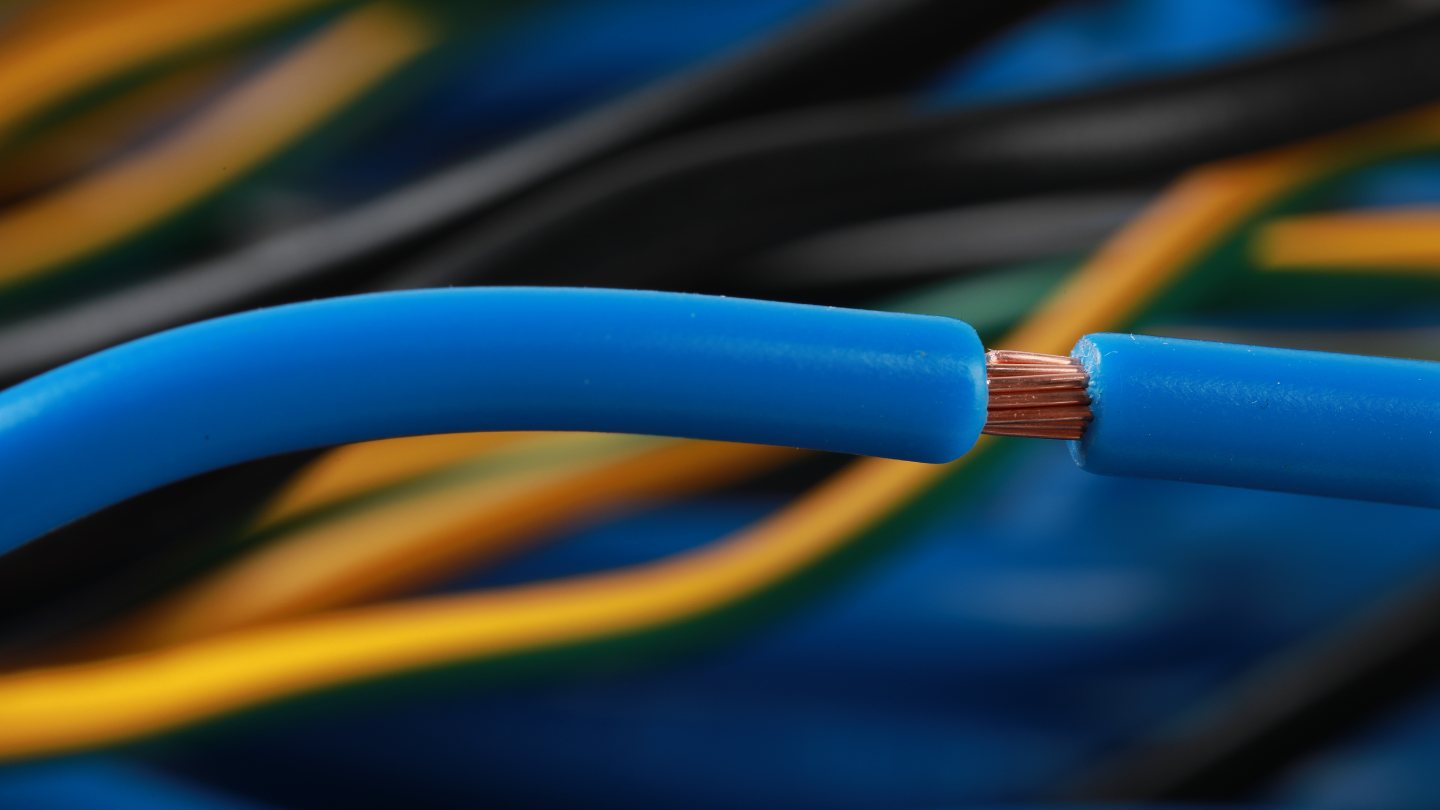

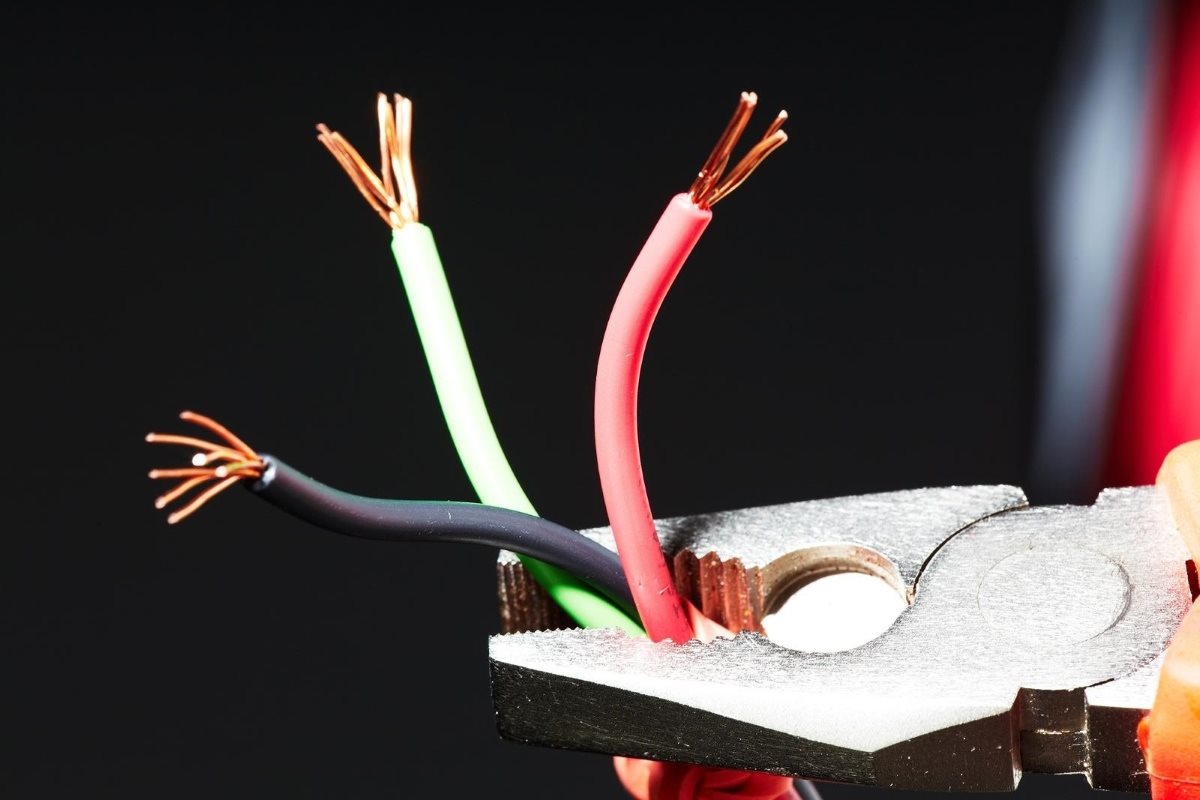

The construction of SOOW electrical wire consists of several important components. The conductors, usually made of copper or tinned copper, are responsible for carrying the electrical current. These conductors are stranded, which means they are made up of multiple smaller wires twisted together. The stranding allows for flexibility and makes the wire easier to handle and install.

To protect the conductors, insulation layers are applied. The insulation materials used in SOOW wire are typically made of ethylene propylene diene monomer (EPDM) rubber. EPDM rubber offers excellent resistance to heat, chemicals, and oils, making it well-suited for industrial environments. On top of the insulation layer, the wire is covered with a durable jacket that provides additional protection against abrasion, moisture, and sunlight exposure.

SOOW electrical wire comes with a range of features and benefits. Firstly, its oil-resistant and weather-resistant properties make it suitable for use in both indoor and outdoor applications. Whether the wire is exposed to extreme temperatures or harsh weather conditions, it will continue to function reliably. Additionally, the flexibility of SOOW wire allows for easy installation and maneuverability, ensuring convenience in various settings.

In terms of applications, SOOW electrical wire is commonly found in construction sites, industrial facilities, entertainment venues, and temporary power setups. It can be used to provide power to equipment such as generators, power tools, pumps, and lighting systems. The rugged construction of SOOW wire makes it a reliable choice for demanding environments where durability is paramount.

Key Takeaways:

- SOOW electrical wire is a durable and flexible solution for temporary power needs, with oil and weather-resistant properties, making it ideal for construction, industrial, and entertainment applications.

- When working with SOOW wire, prioritize safety by ensuring proper installation, regular maintenance, and adherence to safety standards, promoting secure and efficient electrical systems.

Read more: What Is 4 Wire Electrical Wire

Definition of SOOW Electrical Wire

SOOW electrical wire is a type of portable cord that is widely used in various electrical applications. The acronym SOOW stands for Service, Oil-resistant outer jacket, Weather-resistant outer jacket, which reflects the key characteristics of this type of wire. SOOW wire is designed to provide a reliable and flexible power solution in both indoor and outdoor settings.

The primary purpose of SOOW wire is to carry electrical current from a power source to electrical equipment. It is commonly used in applications that require temporary power connections or frequent movement of equipment. The wire is designed to withstand harsh environments, making it suitable for use in construction sites, industrial settings, and entertainment venues.

One of the distinguishing features of SOOW wire is its oil-resistant outer jacket. This means that the wire can resist damage and perform effectively even in the presence of oil or other petroleum-based substances. This property is particularly important in industrial settings where oil and other chemicals are commonly used. The oil-resistant jacket ensures that the wire remains durable and reliable in these challenging conditions.

In addition to being oil-resistant, SOOW wire also features a weather-resistant outer jacket. This means that it is able to withstand exposure to various weather conditions, including extreme temperatures, sunlight, moisture, and even some chemicals. The weather-resistant properties of SOOW wire make it suitable for both indoor and outdoor applications, without compromising its performance or durability.

SOOW wire is available in various sizes and conductor configurations to accommodate different power requirements. The conductors in SOOW wire are typically made of copper or tinned copper, which offer excellent electrical conductivity. The wire is also constructed with stranded conductors, where multiple smaller wires are twisted together. This stranding not only enhances the flexibility of the wire but also increases its current-carrying capacity.

Overall, the definition of SOOW electrical wire can be summarized as a durable and flexible portable cord with an oil-resistant and weather-resistant jacket. Its primary purpose is to provide a reliable power connection in temporary or frequently changing electrical setups. Whether it’s used in construction projects, industrial applications, or entertainment events, SOOW wire ensures that power is delivered safely and efficiently.

Construction and Components of SOOW Electrical Wire

Understanding the construction and components of SOOW electrical wire is important for ensuring its performance and durability in various applications. SOOW wire is designed with specific materials and construction techniques to withstand demanding environments and provide reliable power connections.

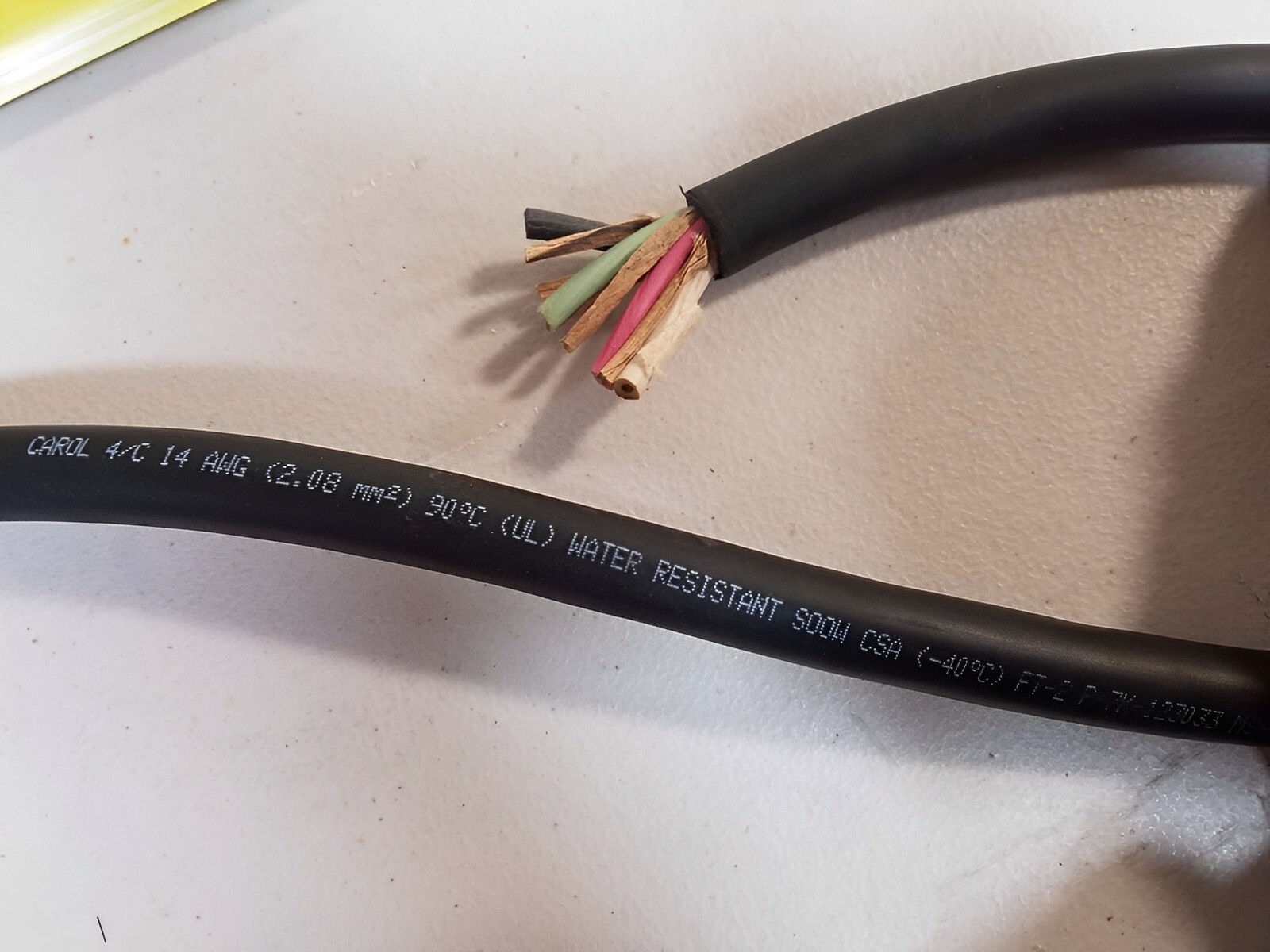

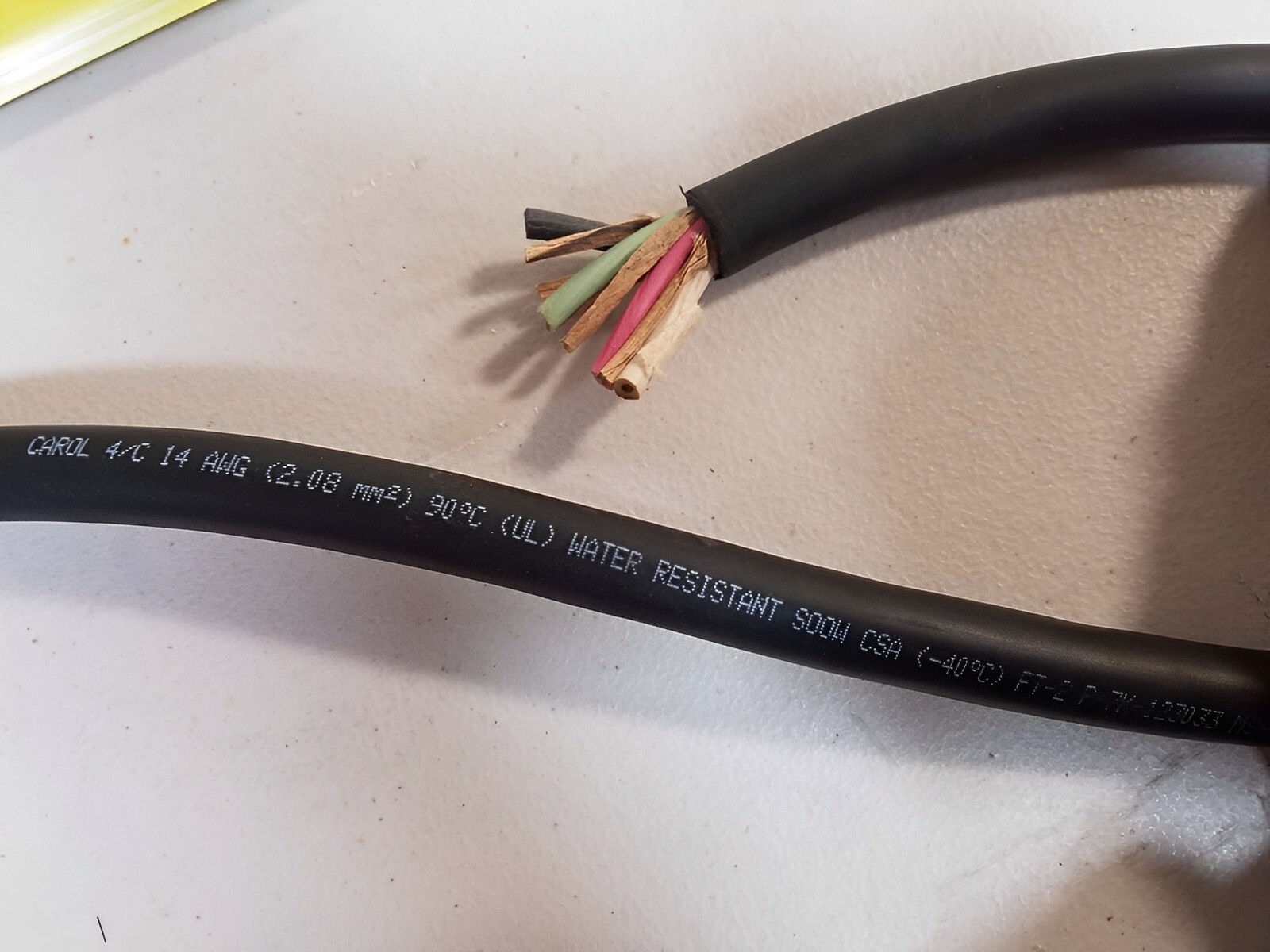

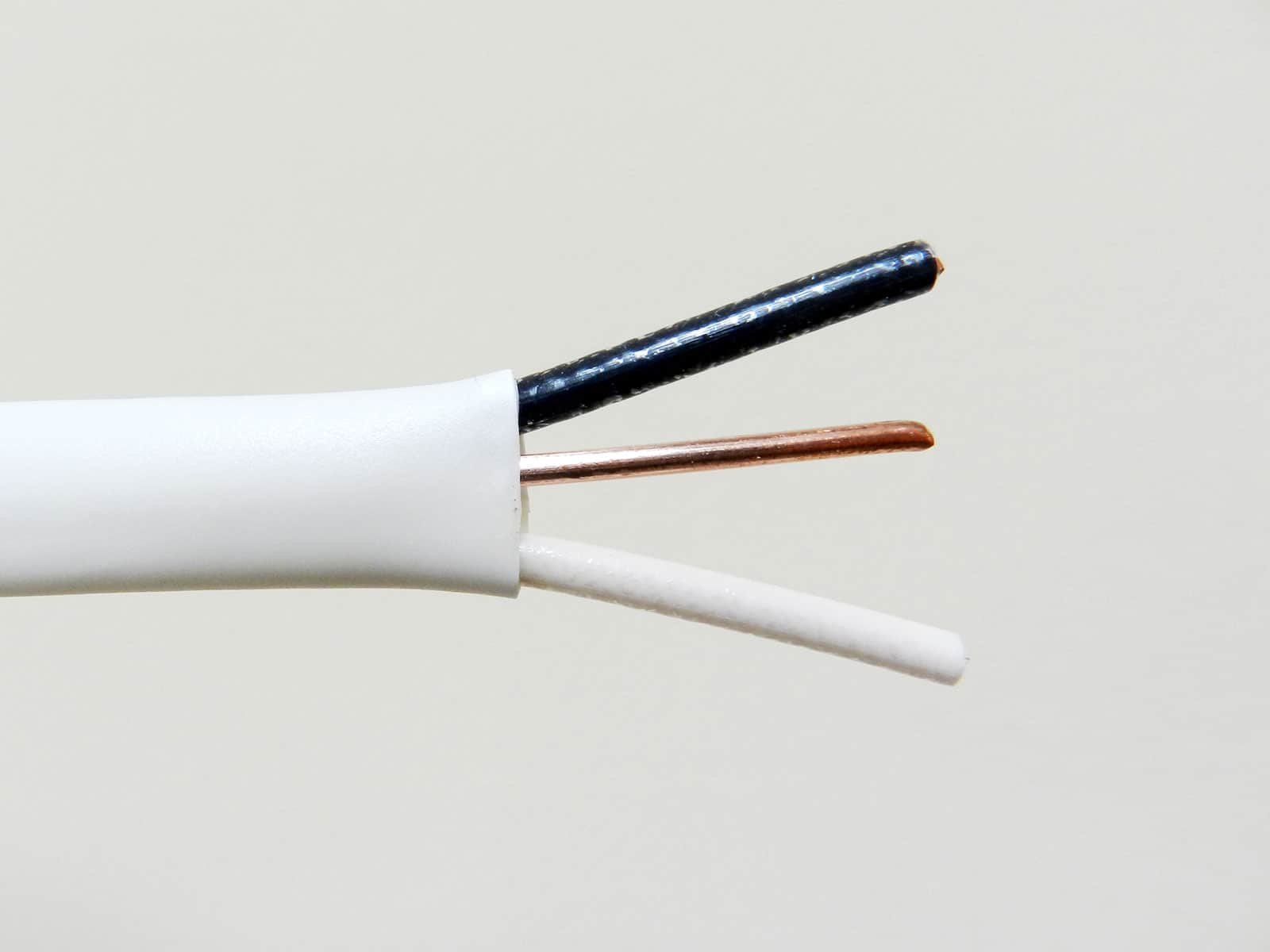

The construction of SOOW electrical wire consists of several key components. At its core, SOOW wire features stranded conductors, insulation layers, and a protective jacket. Let’s take a closer look at each of these components.

1. Stranded Conductors: SOOW wire is typically composed of multiple strands of copper or tinned copper conductors. Stranding the conductors provides flexibility and makes the wire easier to handle and install. The stranding also increases the wire’s current-carrying capacity, allowing it to handle high-powered equipment and applications.

2. Insulation Layers: The conductors in SOOW wire are insulated with layers of ethylene propylene diene monomer (EPDM) rubber. EPDM rubber is known for its excellent heat, chemical, and oil resistance. This insulation protects the conductors from damage and ensures optimal electrical performance, even in demanding environments. The insulation layers are crucial for preventing short circuits and maintaining the integrity of the wire.

3. Protective Jacket: The outermost layer of SOOW wire is the protective jacket, which provides durability and resistance to external factors. This jacket is typically made of thermoplastic elastomer (TPE) or neoprene, adding flexibility and toughness to the wire. The jacket protects the wire from abrasion, moisture, sunlight exposure, and other physical damage that could compromise its performance. It also contributes to the wire’s overall resistance to oils and chemicals.

The combination of these components ensures that SOOW wire is capable of withstanding various challenging conditions. The stranded conductors offer flexibility, allowing the wire to be easily routed and maneuvered in tight spaces. The EPDM rubber insulation provides exceptional protection against heat, chemicals, and oils, making the wire suitable for use in industrial environments. The protective jacket adds an extra layer of durability, safeguarding the wire from external elements.

It is important to note that the construction and components of SOOW electrical wire meet specific standards and regulations, such as the UL (Underwriters Laboratories) and CSA (Canadian Standards Association) standards. These certifications ensure that the wire is manufactured to high-quality standards and meets safety requirements.

Overall, the construction and components of SOOW electrical wire are carefully designed to withstand harsh conditions and provide reliable power connections. The stranded conductors, insulation layers, and protective jacket work together to ensure the wire’s durability, flexibility, and resistance to oils, chemicals, abrasion, moisture, and sunlight. This construction ensures that SOOW wire can be used in a wide range of applications, from construction sites to industrial facilities, with confidence and peace of mind.

Features and Benefits of SOOW Electrical Wire

SOOW electrical wire offers a range of features and benefits that make it a popular choice for various applications. Whether you’re working in construction, industrial settings, or entertainment venues, understanding the features and benefits of SOOW wire can help you make an informed decision for your electrical projects.

1. Oil-Resistance: One of the key features of SOOW wire is its oil-resistant outer jacket. This means that the wire can withstand exposure to oils and other petroleum-based substances without compromising its performance. In industrial settings where oil and chemicals are commonly present, the oil-resistant feature ensures that the wire remains durable and reliable over time.

2. Weather-Resistance: SOOW wire is also designed with a weather-resistant outer jacket. This means that it can withstand exposure to extreme temperatures, sunlight, moisture, and certain chemicals. Whether the wire is used indoors or outdoors, in hot or cold climates, it will continue to perform reliably without degrading or becoming damaged due to weather conditions.

3. Flexibility: SOOW wire is made with stranded conductors, which provide flexibility and ease of installation. The stranding allows the wire to bend and maneuver in tight spaces, making it ideal for applications where flexibility is required. This feature ensures that you can easily route the wire around obstacles and connect electrical equipment with ease.

4. Durability: The combination of stranded conductors, insulation layers, and a protective jacket makes SOOW wire highly durable. It is designed to withstand harsh environments, including abrasion, physical impact, and exposure to chemicals. This durability ensures that the wire can handle the demands of various industrial and construction applications, providing a reliable and long-lasting power solution.

5. Versatility: SOOW wire is highly versatile and can be used in a wide range of applications. Whether you need to power up construction equipment, industrial machinery, lighting systems, or temporary power setups, SOOW wire can accommodate diverse needs. Its flexibility, durability, and resistance to oil and weather conditions make it a reliable choice for both indoor and outdoor applications.

6. Ease of Maintenance: Another benefit of SOOW wire is its ease of maintenance. The oil-resistant and weather-resistant properties of the wire minimize the need for frequent cleaning or repairs. Additionally, the wire’s durability ensures that it can withstand the rigors of regular use, reducing the frequency of replacements or repairs.

7. Compliance with Safety Standards: SOOW wire is manufactured in compliance with safety standards, such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association). This ensures that the wire meets stringent quality and safety requirements, providing peace of mind and assurance when using it for electrical installations.

In summary, the features and benefits of SOOW electrical wire include oil-resistance, weather-resistance, flexibility, durability, versatility, ease of maintenance, and compliance with safety standards. These features make SOOW wire a reliable and trusted choice for a wide range of applications, where a flexible and durable power solution is required.

Common Applications of SOOW Electrical Wire

SOOW electrical wire is widely used in various industries and applications that require portable and flexible power solutions. Its durability, oil-resistant and weather-resistant properties, and versatility make it suitable for a range of indoor and outdoor projects. Here are some of the common applications where SOOW wire is commonly used:

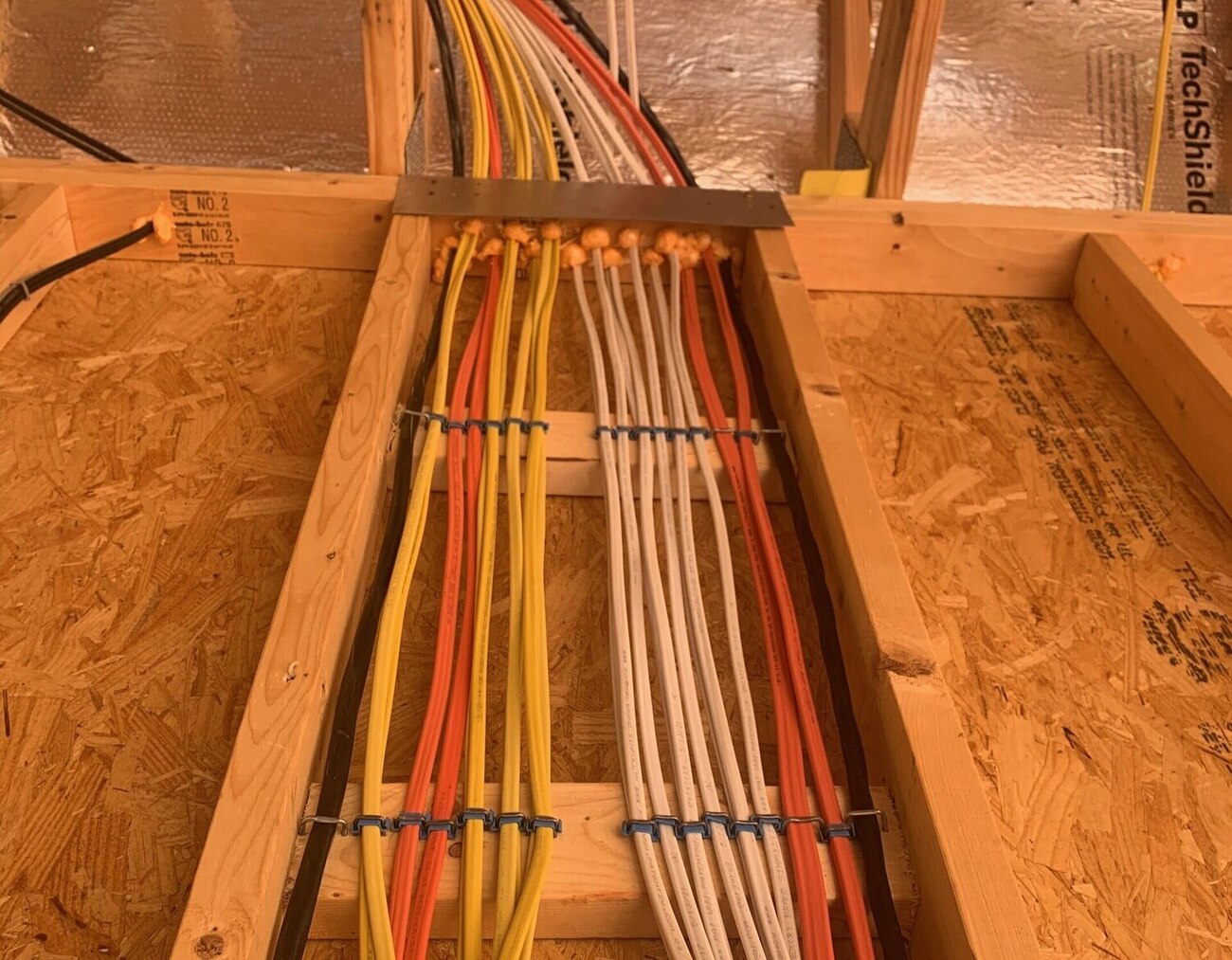

1. Construction Sites: SOOW wire is a popular choice for construction sites, where temporary power connections are needed. It can be used to power tools, equipment, and lighting systems, allowing for efficient and safe operation on the job site. The rugged construction of SOOW wire ensures that it can withstand the demanding conditions and constant movement that is common in construction projects.

2. Industrial Facilities: In industrial settings, where machinery and equipment are often relocated or require temporary power, SOOW wire is an ideal solution. It can supply power to motors, pumps, conveyor systems, and other industrial equipment. The oil-resistant and weather-resistant properties of SOOW wire make it suitable for use in environments where oils, chemicals, and harsh weather conditions may be present.

3. Entertainment Venues: SOOW wire is commonly used in the entertainment industry, such as in theaters, concerts, and outdoor events. It can provide power to stage lighting systems, sound equipment, and other audiovisual devices. The flexibility of SOOW wire allows for easy installation and maneuverability, which is crucial in dynamic entertainment setups where equipment and cables need to be frequently moved or adjusted.

4. Portable Power Solutions: SOOW wire is also used for portable power solutions, such as generators and temporary power setups. It can be used to connect the generator to electrical panels or distribute power to different areas. The durability and flexibility of SOOW wire make it well-suited for such applications, as it can withstand the rigors of outdoor use and frequent setup and breakdown.

5. Marine Applications: Given its resistance to moisture and harsh weather conditions, SOOW wire is also used in marine environments. It can be used for boat wiring, powering marine equipment, and providing electrical connections on docks and piers. The weather-resistant properties of SOOW wire ensure that it can withstand exposure to saltwater and other marine elements, making it a reliable choice for marine applications.

6. Mining and Quarrying: In mining and quarrying operations, SOOW wire is commonly used to power heavy machinery, conveyors, pumps, and other equipment. The oil-resistant properties of SOOW wire make it suitable for use in environments where oils and lubricants are present. The wire’s durability ensures that it can withstand the tough conditions and constant movement associated with mining and quarrying operations.

7. Temporary Installations: SOOW wire is often used for temporary installations, such as for events, exhibitions, or construction projects. It can provide temporary power connections for lighting, sound systems, and other equipment. The versatility and flexibility of SOOW wire make it easy to deploy and remove, allowing for efficient setups and teardowns in various temporary installations.

These are just a few examples of the common applications of SOOW electrical wire. Its reliability, flexibility, durability, and resistance to oil and weather conditions make it a trusted choice for many industries and projects that require portable and safe power solutions.

When working with SOOW electrical wire, always make sure to check the voltage and temperature ratings to ensure it is suitable for your specific application. This type of wire is commonly used in industrial settings and outdoor environments due to its resistance to oil, water, and abrasion.

Read more: What Is An Electrical Wire

Choosing the Right SOOW Wire for Your Needs

When selecting the right SOOW electrical wire for your specific needs, there are several important factors to consider. By taking these factors into account, you can ensure that you choose a wire that meets the requirements of your project and provides reliable and safe power connections. Here are some key considerations when choosing the right SOOW wire:

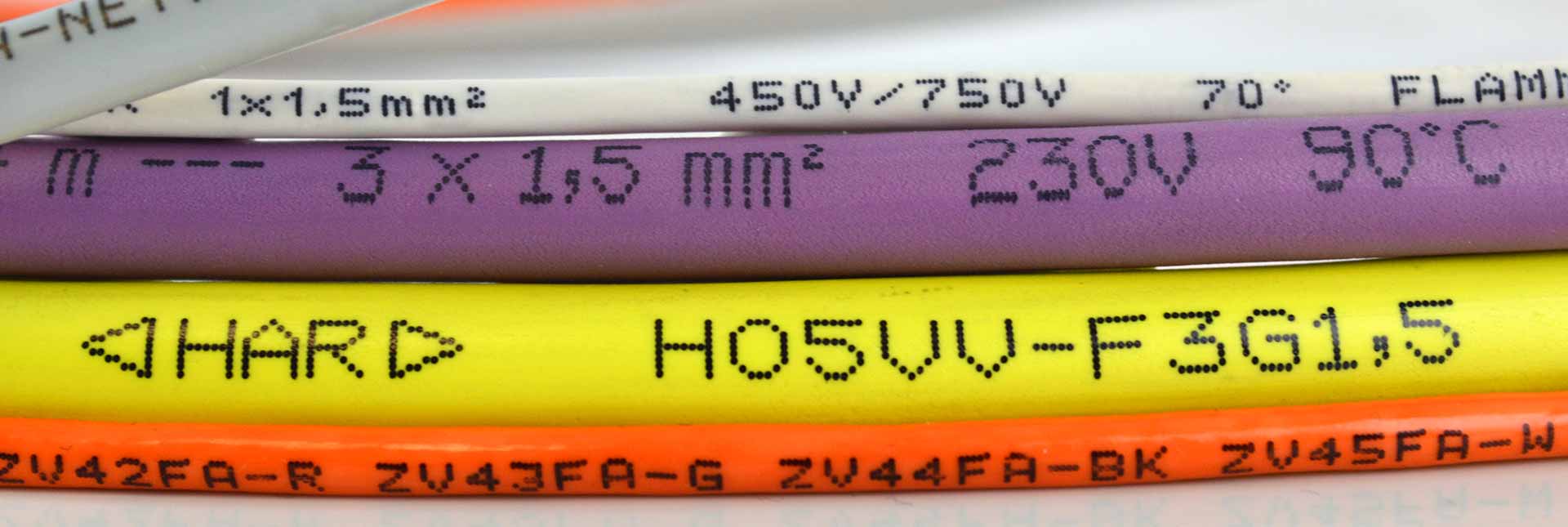

1. Gauge Size: The gauge size of the wire refers to its diameter and determines its current-carrying capacity. Consider the power requirements of your equipment and the maximum current that will flow through the wire. Choose a gauge size that can handle the current load without overheating. It is important to consult the wire gauge chart to match the gauge size to the maximum current rating of the wire.

2. Length: Determine the length of the wire that you will need for your project. It is important to have the appropriate length to ensure that the wire can reach from the power source to the equipment without being stretched or strained. Measure the distance accurately to avoid wastage or insufficient reach.

3. Voltage Rating: SOOW wire comes with different voltage ratings, such as 300V and 600V. Be sure to check the voltage requirements of your equipment and choose a wire with the appropriate voltage rating. Using a wire with a higher voltage rating than required is acceptable, but using a wire with a lower voltage rating can lead to safety hazards.

4. Temperature Rating: Consider the temperature range of the environment in which the wire will be installed. SOOW wire typically has a temperature rating that indicates the maximum temperature at which it can operate safely. Ensure that the temperature rating of the wire matches the conditions it will be exposed to, such as extreme heat or cold.

5. Insulation Material: SOOW wire is insulated with materials like ethylene propylene diene monomer (EPDM) rubber, which offers excellent resistance to heat, oil, and chemicals. Consider the specific environmental conditions in which the wire will be used and choose a wire with insulation material that provides the necessary resistance.

6. Safety Certifications: Look for SOOW wire that meets safety standards and certifications, such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association). These certifications ensure that the wire has been tested and meets specific safety and performance standards. Using certified wire provides assurance that it has been manufactured to high-quality standards.

7. Supplier Reputation: Select a reputable supplier or manufacturer when purchasing SOOW wire. Research the company’s reputation and customer reviews to ensure they provide reliable and high-quality products. A trustworthy supplier will offer support and assistance in selecting the right wire for your needs.

By considering these factors, you can choose the right SOOW wire that meets your project’s requirements. Keep in mind that it is always recommended to consult with a qualified electrician or professional to ensure that you select the most appropriate wire for your specific application.

Safety Considerations for Working with SOOW Electrical Wire

When working with SOOW electrical wire, it is important to prioritize safety to prevent accidents and ensure the proper functioning of your electrical system. Here are some key safety considerations to keep in mind when working with SOOW wire:

1. Proper Installation: Ensure that the SOOW wire is properly installed according to applicable electrical codes and guidelines. Improper installation can lead to electrical faults, short circuits, and other hazardous situations. If you are unsure about the correct installation procedures, consult a qualified electrician or refer to professional resources.

2. Insulation Integrity: Regularly inspect the insulation of the SOOW wire for any signs of damage or wear. Damaged insulation can result in exposed live wires, increasing the risk of electric shocks and short circuits. If you notice any frayed or damaged insulation, replace the wire immediately to maintain safety.

3. Proper Grounding: Ensure that the electrical system connected to the SOOW wire is properly grounded. Grounding helps protect against electrical shock in the event of a fault. Consult the applicable electrical codes and guidelines to ensure that proper grounding practices are followed.

4. Overloading: Avoid overloading the SOOW wire beyond its maximum current-carrying capacity. Excessive current flow can cause overheating and damage to the wire, potentially leading to electrical fires or equipment failures. Always check the wire’s ampacity rating and make sure it is not exceeded.

5. Protection from Mechanical Damage: Take precautions to protect the SOOW wire from mechanical damage. Avoid running the wire in areas where it could be stepped on, crushed, or exposed to sharp objects. Additionally, use suitable cable protectors or conduit when necessary to safeguard the wire from physical impact.

6. Proper Storage: Store the SOOW wire in a clean and dry area away from excessive heat or cold. Improper storage can lead to degradation of the wire’s insulation and reduce its overall performance and safety. Keep the wire rolled or coiled neatly to prevent tangling or kinks that can cause damage.

7. Equipment Compatibility: Ensure that the electrical equipment or devices used in conjunction with the SOOW wire are compatible and meet safety standards. Using non-compliant or faulty equipment can pose serious risks to both the wire and the individuals working with it. Always use certified and properly maintained equipment.

8. Risk Assessment: Before working with SOOW wire, conduct a thorough risk assessment of the work environment. Identify potential hazards, such as exposure to chemicals, extreme temperatures, or moisture, and take appropriate precautions to mitigate these risks. This may include using additional protective measures or selecting specialized SOOW wire designed for specific environmental conditions.

Remember, if you are not experienced or knowledgeable in working with electrical wires, it is always best to seek assistance from a qualified electrician or professional. They can provide expert guidance, ensure compliance with safety standards, and prevent potential hazards.

By following these safety considerations, you can work with SOOW electrical wire safely and effectively, minimizing the risk of accidents and promoting a secure electrical system.

Maintenance and Care of SOOW Electrical Wire

Proper maintenance and care of SOOW electrical wire are essential for maximizing its lifespan, ensuring optimal performance, and maintaining a safe working environment. Here are some important maintenance and care guidelines to follow when working with SOOW wire:

1. Regular Inspections: Conduct regular inspections of the SOOW wire to check for any signs of damage, wear, or degradation. Look for frayed or cracked insulation, exposed conductors, or any other visible issues. Address any problems immediately by repairing or replacing the wire as needed.

2. Cleanliness: Keep the SOOW wire clean to prevent the accumulation of dirt, dust, or other contaminants. Wipe down the wire periodically with a clean, dry cloth to remove any surface debris. Avoid using harsh cleaning agents or abrasive materials that could damage the wire’s insulation or protective jacket.

3. Protection from Chemicals: If the SOOW wire is exposed to chemicals or oils, take measures to protect it. Depending on the specific chemical or oil, you may need to use additional protective coverings or choose a wire with enhanced chemical resistance properties. Consult the wire manufacturer or supplier for suitable recommendations.

4. Proper Storage: When not in use, store the SOOW wire in a clean, dry, and well-ventilated area. Protect it from exposure to extreme temperatures, direct sunlight, moisture, or excessive humidity. Coil or roll the wire neatly to avoid tangling or kinking. Keep it away from sharp objects or potential sources of physical damage.

5. Avoid Overloading: Ensure that the electrical load placed on the SOOW wire does not exceed its maximum capacity. Overloading the wire can lead to overheating, insulation damage, and potential electrical hazards. Refer to the wire’s ampacity rating and follow electrical codes and guidelines to determine the appropriate load for your specific application.

6. Proper Installation: Properly install the SOOW wire, following electrical codes and guidelines. Make sure all connections are secure and tightened, and that the wire is routed and protected correctly. Use suitable cable protectors or conduit when necessary to minimize the risk of physical damage. Consult a qualified electrician if you are unsure about the proper installation procedures.

7. Safety Training: Ensure that anyone working with or handling the SOOW wire is properly trained in electrical safety. They should be familiar with safe work practices, such as proper grounding techniques, using personal protective equipment (PPE), and following proper lockout/tagout procedures. Regularly provide safety training updates to employees or individuals working with the wire.

8. Compliance with Standards: Use SOOW wire that meets industry safety standards, such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association). Using certified wire ensures that it has been tested and manufactured to meet specific safety requirements. Additionally, comply with any applicable local or national electrical codes and regulations.

By following these maintenance and care guidelines, you can ensure the longevity and safety of your SOOW electrical wire. Regular inspections, cleanliness, protection from chemicals, proper storage, avoiding overloading, correct installation, safety training, and adherence to standards all contribute to maintaining the optimal performance and safety of the wire in various applications.

Conclusion

SOOW electrical wire is a versatile and reliable solution for a wide range of applications that require portable and flexible power connections. With its oil-resistant and weather-resistant properties, durability, flexibility, and ease of installation, SOOW wire has become a popular choice in industries such as construction, industrial facilities, entertainment venues, and temporary power setups.

Understanding the definition, construction, features, and common applications of SOOW wire is crucial for making informed decisions when selecting the right wire for your specific needs. By considering factors such as gauge size, length, voltage rating, temperature rating, insulation material, and safety certifications, you can ensure that you choose the most suitable wire for your project.

Safety should always be a top priority when working with electrical wires, including SOOW wire. Proper installation, insulation integrity checks, grounding, and protection from mechanical damage are essential for preventing accidents, electrical faults, and equipment failures. Regular maintenance, cleanliness, proper storage, and adherence to electrical codes and guidelines further contribute to the longevity and safe operation of SOOW wire.

In conclusion, SOOW electrical wire offers durability, versatility, and reliability for temporary power connections and portable installations. Whether you’re working on a construction site, industrial facility, entertainment venue, or any project that requires flexibility and resistance to harsh environments, SOOW wire provides a secure and efficient power solution. By following the recommended safety practices and guidelines for maintenance and care, you can ensure the optimal performance and safety of your SOOW electrical wire, making it a dependable choice for your electrical needs.

Frequently Asked Questions about What Is SOOW Electrical Wire

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is SOOW Electrical Wire”