Articles

Why Are Non CTL Breakers So Expensive

Modified: March 24, 2024

Discover why non Ctl breakers are so expensive in these informative articles. Gain insights into the factors that drive up their prices and make informed decisions for your electrical needs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Non CTL breakers, also known as circuit breakers, are a crucial component in electrical systems. They play a vital role in protecting electrical circuits from overloads and short circuits, preventing damage to equipment and ensuring safety. However, one common question that arises is why non CTL breakers tend to be more expensive compared to other types of breakers.

Understanding the factors that contribute to the cost of non CTL breakers can help shed light on this issue. In this article, we will explore the various factors affecting the price of non CTL breakers, including design and construction quality, brand reputation, market demand and supply, material and manufacturing costs, and additional features and technology.

By gaining insight into these factors, readers will be able to make informed decisions when purchasing non CTL breakers and better understand the pricing discrepancies in the market.

Key Takeaways:

- Non CTL breakers are more expensive due to factors like high-quality design, brand reputation, market demand, material costs, and advanced features. Buyers should balance price and quality for optimal performance and safety.

- Investing in reputable brands and high-quality construction can provide long-term benefits and peace of mind. Consider the necessity of advanced features and weigh the benefits when purchasing non CTL breakers.

Read more: Why Are Pillows So Expensive

Understanding Non CTL Breakers

Non CTL breakers are electrical devices designed to interrupt the flow of electrical current when an overload or short circuit occurs. They consist of a switch mechanism that opens or closes the circuit in response to abnormal electrical conditions. Non CTL breakers are commonly used in residential, commercial, and industrial applications to ensure the safety and reliability of electrical systems.

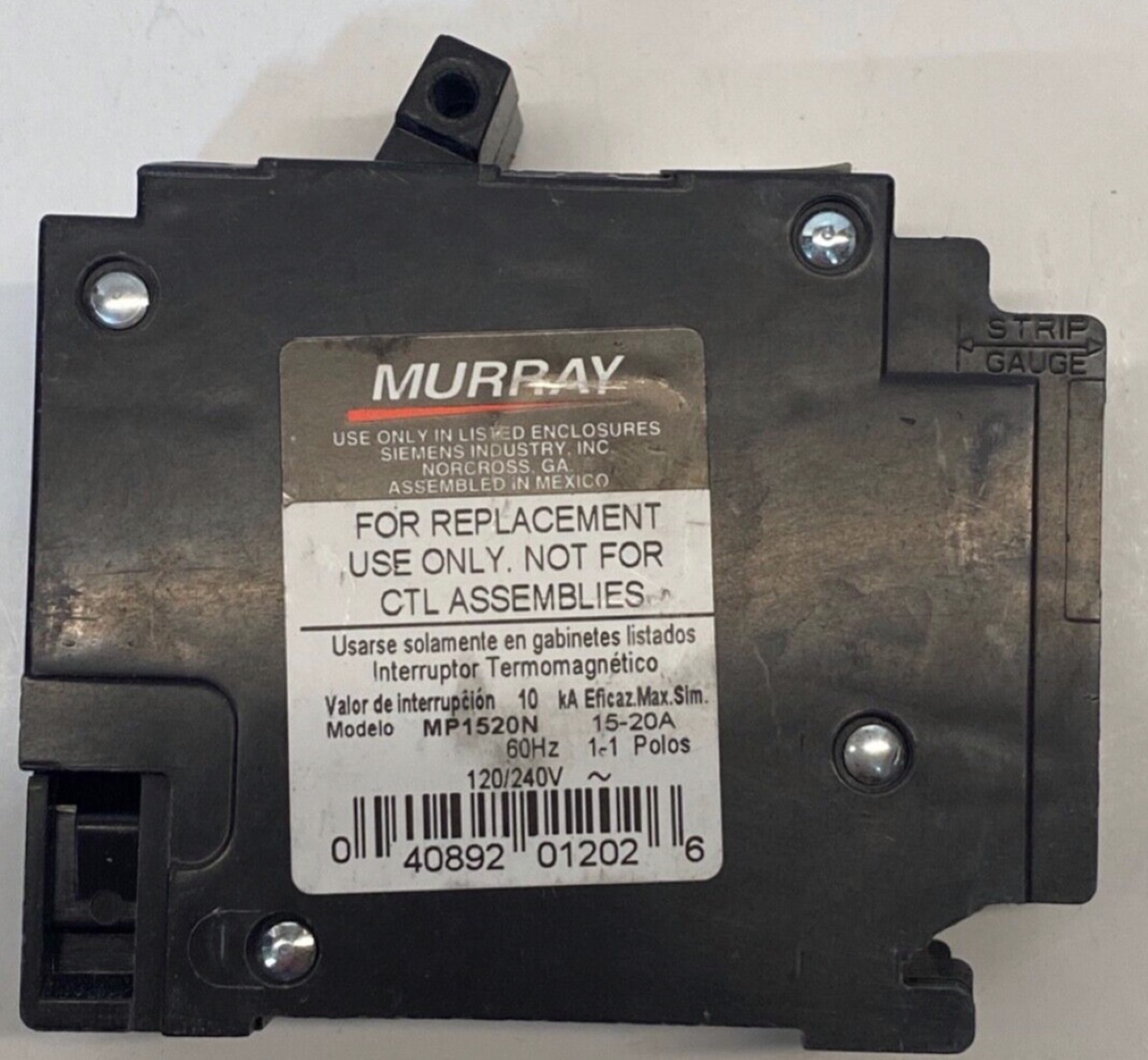

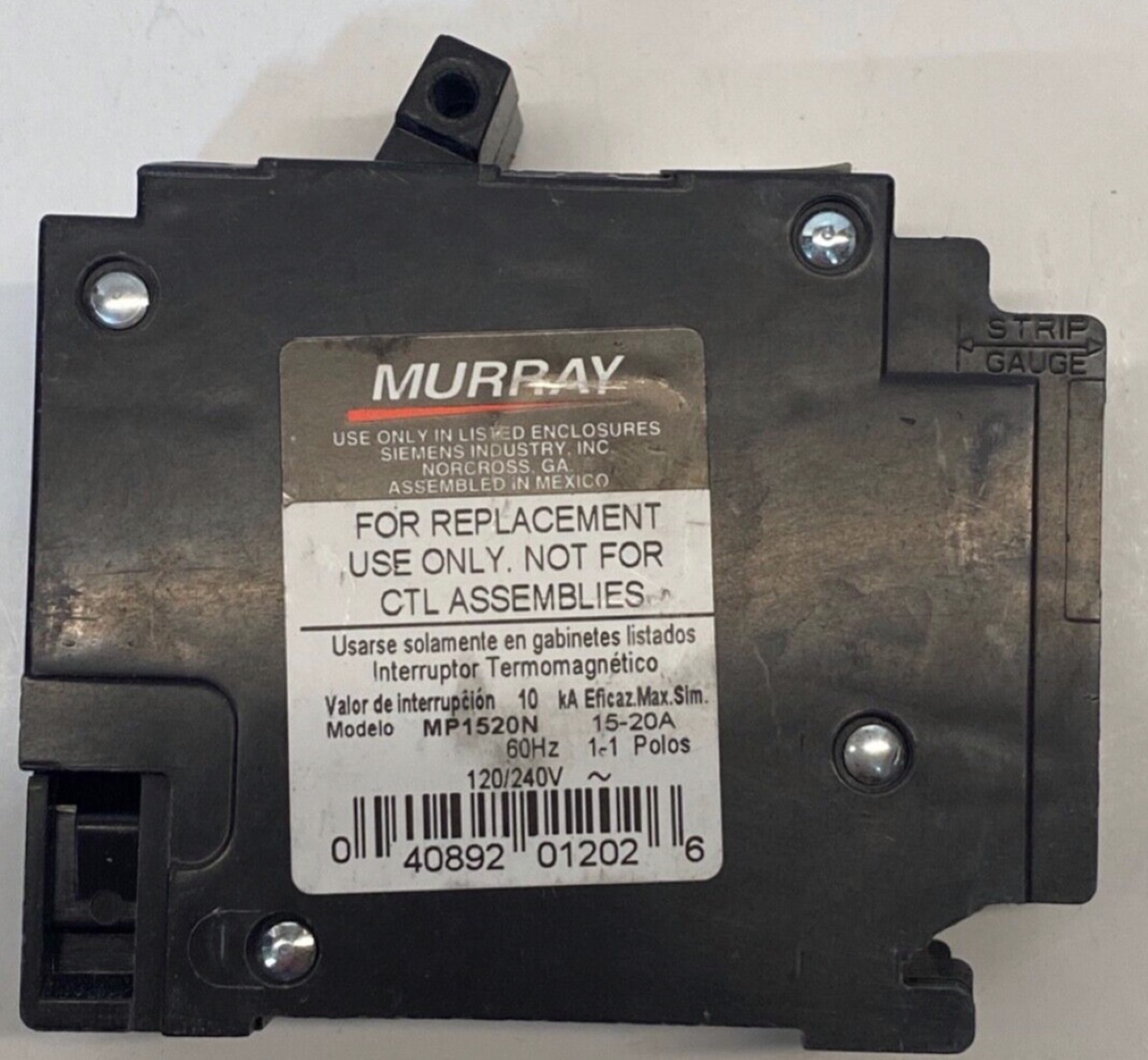

These breakers differ from CTL (Circuit Total Limit) breakers, which have specific limitations on the number of circuits that can be installed in a electrical panel. Non CTL breakers, on the other hand, do not have such limitations, allowing for more flexibility in circuit configurations.

Non CTL breakers come in different sizes and current ratings to accommodate various electrical loads. They are categorized based on their trip characteristics, including standard, delayed, instant, and combination types. Each type is designed to respond differently to overloads or short circuits, providing specific protection for different applications.

Non CTL breakers are available in different formats, including plug-in breakers that are directly inserted into an electrical panel, as well as bolt-on breakers that are mounted using screws or bolts. The choice between these formats depends on the specific requirements of the electrical system and the availability of space in the panel.

It is important to note that non CTL breakers should be installed and maintained by qualified professionals following electrical codes and regulations to ensure proper functionality and safety. Regular inspections and testing are recommended to identify any potential issues and prevent accidents or damage to electrical equipment.

Now that we have a basic understanding of non CTL breakers, let’s explore the factors that contribute to their pricing.

Factors Affecting the Price of Non CTL Breakers

There are several key factors that can influence the price of non CTL breakers. Let’s take a closer look at each of these factors:

- Design and Construction Quality: Non CTL breakers that are built with high-quality materials and durable construction will generally have a higher price. These breakers are designed to withstand the demands of electrical systems and provide long-lasting performance.

- Brand Reputation: Well-established brands in the electrical industry often command higher prices due to their reputation for delivering reliable and safe products. Customers may be willing to pay a premium for breakers from trusted brands that have a proven track record of quality and customer satisfaction.

- Market Demand and Supply: The market demand for non CTL breakers can impact their pricing. If the demand is high and the supply is limited, prices may increase due to higher competition among buyers. Conversely, if the demand is low and the supply is abundant, prices may be lower as manufacturers try to attract customers.

- Material and Manufacturing Costs: The cost of materials used in the production of non CTL breakers, such as copper, aluminum, and various components, can impact the overall price. Additionally, the manufacturing processes involved, including assembly, testing, and quality control, contribute to the final cost.

- Additional Features and Technology: Non CTL breakers that offer advanced features and technological advancements, such as built-in surge protection, diagnostic capabilities, or remote monitoring, will generally have a higher price tag. These added features enhance the functionality and performance of the breaker, providing added value to the customer.

It’s important to note that while price is an important consideration when purchasing non CTL breakers, it should not be the sole determining factor. The reliability, safety features, and compatibility with the electrical system should also be taken into account to ensure optimal performance and protection.

By understanding these factors, consumers can make informed decisions when choosing non CTL breakers and find the right balance between price and quality.

Design and Construction Quality

The design and construction quality of non CTL breakers play a significant role in their pricing. Breakers that are built with high-quality materials and robust construction are generally more expensive than those with lower-quality components.

High-quality materials, such as strong and durable alloys, are used to ensure the breaker can withstand the demands of electrical systems and provide reliable performance for an extended period. These materials contribute to the overall cost of manufacturing the breaker, thus increasing the final price.

In addition to materials, the design of the breaker also affects its cost. Manufacturers invest in research and development to create innovative designs that improve the breaker’s performance, efficiency, and safety. Breakers with advanced designs may incorporate features such as improved arc fault detection, shorter response times, and enhanced thermal stability.

The construction quality of a non CTL breaker refers to the precision and care taken during the manufacturing process. High-quality breakers undergo rigorous testing and quality control protocols to ensure that they meet the industry standards and requirements. These stringent processes add to the manufacturing costs, contributing to the higher price of the breakers.

When it comes to design and construction quality, it is important to remember that cheaper alternatives may compromise on material quality or construction standards. While these breakers may have a lower upfront price, they may not provide the same level of reliability and safety as their higher-priced counterparts.

Investing in breakers with superior design and construction quality can offer peace of mind knowing that the electrical system is protected by a reliable and well-built component. It is a worthwhile investment that can help prevent costly damages and ensure the safety of both the electrical system and the people in the vicinity.

When comparing options, buyers should consider the overall build quality and durability of the breaker, as well as any certifications or standards that it meets. Investing in a reputable brand known for its rigorous quality control measures can help ensure that the non CTL breaker will perform reliably for years to come.

Brand Reputation

The reputation of the brand manufacturing non CTL breakers is another significant factor that can influence their pricing. Well-established and reputable brands in the electrical industry often command higher prices due to the trust and confidence they have built with customers over the years.

Brands that have a strong reputation are known for delivering high-quality products that meet or exceed industry standards. They invest in research and development to continually improve their breakers and ensure they are reliable, efficient, and safe to use. These brands have a track record of providing durable and long-lasting products, which contributes to their higher price points.

Customers may be willing to pay a premium for non CTL breakers from trusted brands because they have confidence in the brand’s commitment to quality and customer satisfaction. They know that these brands have a reputation to uphold and are less likely to compromise on the performance and safety of their products.

Reputable brands also invest in customer support, providing technical assistance and warranties to address any concerns or issues that may arise during the installation or usage of their breakers. This level of customer service adds value to the overall product offering and justifies the higher price.

While non CTL breakers from reputable brands may have higher initial costs, they can offer long-term benefits that outweigh the price difference. These benefits include reliable performance, extended lifespan, and enhanced safety features.

However, it is important to note that brand reputation alone should not be the sole determining factor when purchasing non CTL breakers. Buyers should also consider other aspects, such as the specific requirements of their electrical system, compatibility with existing components, and the warranty and support offered by the brand.

In some cases, lesser-known or emerging brands may offer non CTL breakers at lower prices to compete with established brands. While these options may be more affordable, buyers should exercise caution and thoroughly research the brand’s reputation, customer reviews, and certifications to ensure that the breakers meet their quality and safety requirements.

Ultimately, the brand reputation of non CTL breakers can influence their pricing, but buyers should consider a range of factors to make an informed decision and find the right balance between brand reputation and affordability.

Non-CTL breakers are more expensive because they are designed to handle higher electrical loads and are built to higher safety standards. This makes them more durable and reliable, but also increases their cost.

Read more: Why Are Mirrors So Expensive

Market Demand and Supply

The dynamics of market demand and supply play a significant role in determining the pricing of non CTL breakers. The relationship between the demand for these breakers and the availability of supply can directly impact their prices.

When the demand for non CTL breakers is high and exceeds the available supply, prices are likely to increase. This can happen due to various factors, such as an increased demand for electrical installations in residential and commercial buildings, or a surge in industrial projects requiring advanced electrical systems.

In situations where the demand outpaces the supply, manufacturers may have limited capacity to produce enough breakers to meet the market needs. As a result, they may increase the prices to balance the demand and maximize profitability.

On the other hand, when the demand for non CTL breakers is low and there is an excess supply in the market, prices tend to be more competitive. Manufacturers may lower their prices in order to attract customers and increase sales. This scenario can occur when there is a slowdown in the construction industry or a more competitive landscape with many manufacturers offering similar products.

It’s important to note that the market demand for non CTL breakers can be influenced by factors such as technological advancements, changes in building codes and regulations, and industry trends. For instance, the growing emphasis on energy efficiency and sustainability in construction projects may increase the demand for breakers with specific energy-saving features, influencing their market prices.

Buyers should be aware of these market dynamics and consider the current demand and supply conditions when purchasing non CTL breakers. It may be beneficial to research and monitor the market to identify any pricing fluctuations or promotional offers that can provide cost-saving opportunities.

Additionally, it is advisable to assess the specific needs of the electrical system and select non CTL breakers that meet the required specifications and safety standards, rather than solely focusing on market prices. Prioritizing the reliability and functionality of the breakers over short-term cost savings can contribute to long-term satisfaction and peace of mind.

In summary, market demand and supply dynamics can have an impact on the pricing of non CTL breakers. Understanding these dynamics and considering them alongside other factors can help buyers make informed decisions and find the right balance between price and quality.

Material and Manufacturing Costs

The cost of materials and the manufacturing processes involved in producing non CTL breakers can significantly influence their pricing. The quality and type of materials used, as well as the complexity of the manufacturing process, contribute to the overall cost of the breakers.

Non CTL breakers are constructed using various materials, including metals such as copper and aluminum for conductive components, and durable alloys for housing and internal parts. These materials have associated costs, with copper being more expensive than aluminum due to its superior electrical conductivity.

The manufacturing process for non CTL breakers involves several steps, including the fabrication of components, assembly, testing, and quality control. Each step requires skilled labor and specialized equipment. The costs associated with these processes, such as wages, machinery maintenance, and quality assurance measures, are factored into the final price of the breakers.

In addition to materials and manufacturing processes, other factors that can impact the cost include overhead expenses, such as facility rent or lease, administrative costs, and research and development investments made by the manufacturer. These costs are spread across the production volume, further influencing the pricing of non CTL breakers.

Furthermore, fluctuations in the costs of raw materials and other inputs, such as energy or transportation, can also impact the overall manufacturing costs. If the prices of these inputs increase, manufacturers may adjust the prices of the breakers to maintain profitability.

It’s important to note that while material and manufacturing costs contribute to the pricing of non CTL breakers, they are not the sole determinants. Lower-priced options may use cheaper materials or employ less stringent manufacturing processes, compromising the quality and reliability of the breakers.

When considering the material and manufacturing costs, buyers should strike a balance between budget constraints and the need for high-quality and reliable breakers. It is prudent to research and compare different products, ensuring that the chosen breaker meets the required safety standards and provides the necessary protection for the electrical system.

By understanding and considering the material and manufacturing costs, buyers can make informed decisions when purchasing non CTL breakers, weighing the price against the quality and reliability of the product.

Additional Features and Technology

The presence of additional features and advanced technology in non CTL breakers can significantly impact their pricing. Breakers that offer innovative features and enhanced functionality often come at a higher price point compared to basic models.

Manufacturers are constantly striving to improve the performance and safety of non CTL breakers by incorporating new technologies and features. These advancements can include built-in surge protection, enhanced diagnostic capabilities, communication capabilities for remote monitoring, and compatibility with smart home automation systems.

The integration of these additional features requires additional research and development investments, as well as the use of specialized components and technologies. This contributes to the increased production costs and, subsequently, the higher price of the breakers.

Advanced technology in non CTL breakers can provide significant benefits to users. For example, built-in surge protection can safeguard electrical devices from power surges, extending their lifespan and minimizing the risk of damage. Diagnostic capabilities can help identify issues in the electrical system, enabling timely repairs and reducing downtime.

Moreover, non CTL breakers with communication capabilities and compatibility with smart home automation systems offer convenience and control. Users can remotely monitor and control their electrical system, receive alerts about potential issues, and even automate certain functions for increased efficiency and energy savings.

While these additional features can enhance the functionality and convenience of non CTL breakers, it’s important to evaluate their necessity for the specific application. Buyers should consider the requirements of their electrical system and how the additional features align with their needs and preferences.

For some buyers, investing in non CTL breakers with advanced features may offer long-term benefits, such as improved protection, energy efficiency, and ease of monitoring and control. However, for those with simpler electrical systems and no need for advanced features, basic non CTL breakers may suffice at a lower cost.

Ultimately, the presence of additional features and technology in non CTL breakers contributes to their pricing. Buyers should carefully evaluate their requirements and consider the added value that these features bring to their electrical system when making a purchasing decision.

Conclusion

Non CTL breakers are an essential component in electrical systems, providing protection against overloads and short circuits. However, their pricing can often be higher compared to other types of breakers due to various factors.

In this article, we explored the factors that affect the price of non CTL breakers, including design and construction quality, brand reputation, market demand and supply, material and manufacturing costs, and additional features and technology.

The design and construction quality of non CTL breakers play a significant role in their pricing. Breakers built with high-quality materials and robust construction offer enhanced reliability and safety, leading to higher costs.

Brand reputation also influences pricing, with well-established brands commanding higher prices due to their track record of delivering reliable and high-quality products. Customers often value the trust and confidence associated with reputable brands.

Market demand and supply dynamics impact non CTL breaker prices. When demand exceeds supply, prices tend to increase, while excess supply can lead to more competitive pricing.

Material and manufacturing costs, including the use of high-quality materials and complex manufacturing processes, contribute to the overall pricing of non CTL breakers. These costs, along with overhead expenses, research and development investments, and fluctuating raw material prices, influence the final price.

Finally, the presence of additional features and advanced technology in non CTL breakers can contribute to higher prices. These features offer enhanced functionality, convenience, and improved safety, but buyers should consider their necessity for their specific applications.

In conclusion, when purchasing non CTL breakers, it is essential to strike a balance between price and quality. Consider the specific requirements of the electrical system, evaluate different brands, and weigh the benefits of additional features to make an informed decision.

Investing in high-quality, reputable brands and considering long-term benefits can provide peace of mind and ensure the optimal performance and safety of the electrical system. Ultimately, finding the right non CTL breaker at the right price will contribute to a reliable and efficient electrical system for years to come.

Frequently Asked Questions about Why Are Non CTL Breakers So Expensive

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Are Non CTL Breakers So Expensive”