Home>Articles>Why Won’t My Electric Pressure Cooker Build Up Pressure

Articles

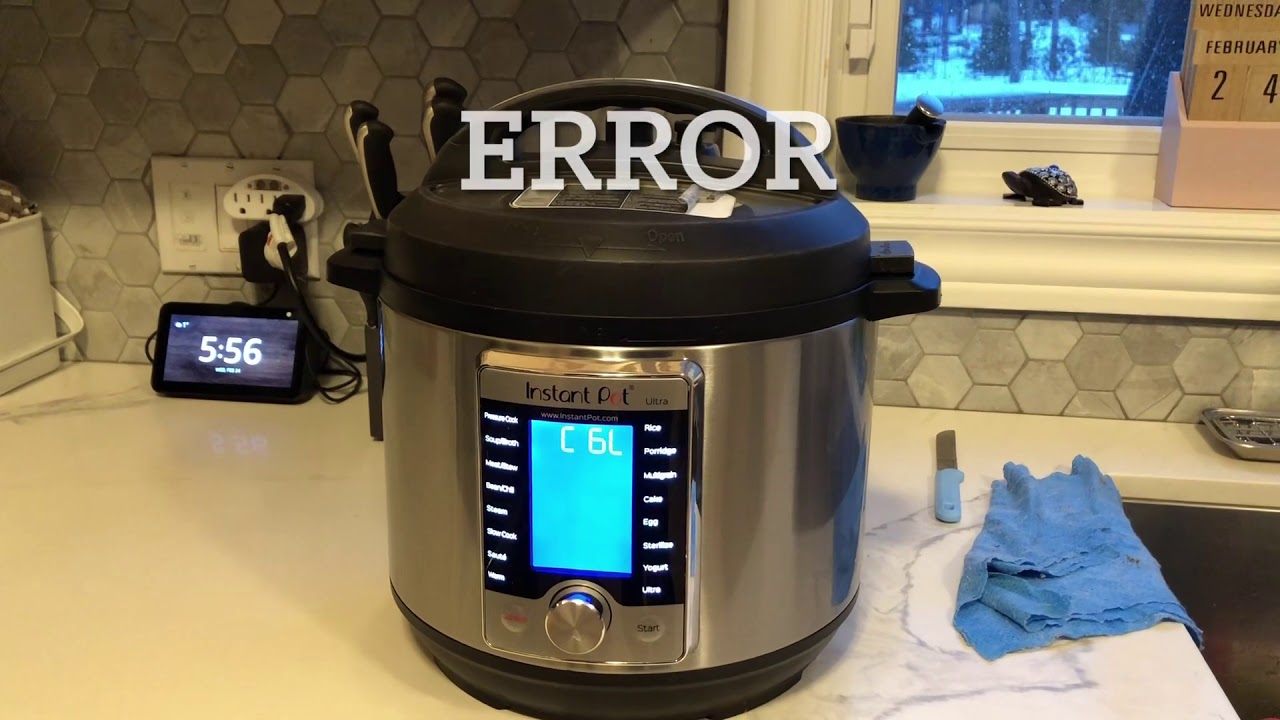

Why Won’t My Electric Pressure Cooker Build Up Pressure

Modified: January 6, 2024

Discover articles on why your electric pressure cooker is not building up pressure and learn how to troubleshoot the issue effectively.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of electric pressure cookers, where cooking delicious meals becomes a breeze. These innovative appliances are designed to save time, energy, and effort in the kitchen, making them a popular choice for home cooks and busy individuals. But what do you do when your electric pressure cooker fails to build up pressure?

In this article, we will explore the possible reasons behind this issue and provide you with troubleshooting tips to get your electric pressure cooker back in working order.

Before we dive into the solutions, it’s important to note that electric pressure cookers work by creating a sealed cooking environment, where the increase in pressure raises the boiling point of water and allows food to cook faster. If your pressure cooker fails to build up pressure, it can result in longer cooking times and potentially under-cooked dishes.

So, let’s get to the bottom of why your electric pressure cooker is not building up pressure and find ways to resolve the issue.

Key Takeaways:

- Proper sealing, sufficient liquid, and regular maintenance are crucial for an electric pressure cooker to build up pressure. By addressing these factors, you can ensure efficient cooking and delicious results.

- User errors, power supply issues, and faulty components can hinder pressure build-up in electric pressure cookers. Following troubleshooting tips and manufacturer guidelines is essential for resolving these issues and restoring the cooker’s functionality.

Read more: Why Wont My Toilet Fill Up With Water

Possible Reasons for Lack of Pressure Build-Up

There can be several factors contributing to the lack of pressure build-up in your electric pressure cooker. Let’s take a closer look at some of the most common reasons:

- Inadequate Seal: A proper seal is crucial for the pressure cooker to build up pressure. If the lid isn’t positioned correctly or the sealing ring is damaged, air can escape, preventing pressure from building up.

- Insufficient Liquid: Pressure cookers require an adequate amount of liquid to generate steam and build pressure. If there isn’t enough liquid in the cooker, it may not be able to reach the desired pressure.

- Faulty Pressure Release Valve: The pressure release valve controls the release of steam from the cooker. If it’s stuck or not functioning properly, it can hinder the pressure build-up.

- Blocked Vent Pipe: The vent pipe allows excess steam to escape during the cooking process. If it’s clogged with debris or food particles, the pressure may not be able to build up effectively.

- Faulty Gasket: The gasket is a rubber or silicone ring that creates an airtight seal between the lid and the pot. If the gasket is worn out or damaged, it can lead to air leakage and prevent pressure build-up.

- Overfilled Cooker: Overfilling the pressure cooker can impede its ability to build up pressure. The cooker needs sufficient space for the steam to circulate and create pressure.

- Incorrect Pressure Setting: Electric pressure cookers often come with different pressure settings, such as high or low pressure. If the cooker is set to the wrong pressure level, it may not be able to build up the desired pressure.

- Defective Heating Element: The heating element is responsible for generating heat in the pressure cooker. If it’s faulty or not functioning correctly, it can affect the cooker’s ability to build pressure.

- Power Supply Issues: In some cases, power supply problems can hinder the pressure cooker’s performance. Ensure that the cooker is properly plugged in and receiving adequate power.

- User Error: Lastly, user error can also contribute to the lack of pressure build-up. It’s essential to follow the instructions and guidelines provided by the manufacturer to ensure proper usage and optimal pressure build-up.

Now that we have identified some possible reasons for the lack of pressure build-up, let’s move on to troubleshooting tips that can help you resolve the issue and get your electric pressure cooker back on track.

Inadequate Seal

An inadequate seal is one of the most common reasons why an electric pressure cooker fails to build up pressure. The seal is essential for creating a closed cooking environment, allowing pressure to build and food to cook efficiently. If there is air leakage, pressure cannot be maintained inside the cooker, resulting in longer cooking times and potentially undercooked dishes.

To ensure a proper seal, you need to pay attention to two key components: the lid and the sealing ring.

Lid: Make sure the lid is positioned correctly on the pressure cooker. It should fit snugly and securely, with no gaps or misalignment. If the lid is not properly placed, it can lead to air leakage and prevent pressure build-up.

Sealing Ring: The sealing ring, also known as the gasket, is a rubber or silicone ring that creates an airtight seal between the lid and the pot. Over time, the sealing ring can wear out, become loose, or get damaged. Inspect the sealing ring regularly for any signs of wear or damage, such as cracks or tears. If you notice any issues, replace the sealing ring with a new one to ensure a proper seal.

In addition to checking the lid and sealing ring, it’s essential to clean them thoroughly before each use. Food particles or debris can prevent a tight seal and compromise the pressure build-up. Clean the lid and sealing ring with warm soapy water and dry them properly before using the pressure cooker.

Remember, a proper seal is crucial for the efficient operation of an electric pressure cooker. Take the time to ensure that the lid is positioned correctly and the sealing ring is in good condition. By doing so, you’ll eliminate one potential cause of a lack of pressure build-up and improve the overall performance of your electric pressure cooker.

Insufficient Liquid

Insufficient liquid is another common reason why an electric pressure cooker may fail to build up pressure. Adequate liquid is necessary for the production of steam, which creates the pressure needed for efficient cooking. Without enough liquid, the pressure cooker won’t be able to reach the desired pressure, resulting in longer cooking times and potentially undercooked food.

To ensure that you have sufficient liquid in your electric pressure cooker, follow the manufacturer’s guidelines regarding the minimum required amount. Typically, most pressure cooker recipes recommend a minimum of 1 to 1.5 cups of liquid. This liquid can be water, broth, or any other cooking liquid specified in the recipe.

It’s important not to exceed the maximum fill line indicated inside the pressure cooker. Overfilling the cooker can also impede pressure build-up and affect the cooking process. Leave enough space for the steam to circulate and create pressure.

In cases where you find that you have insufficient liquid in the pressure cooker, you can add more liquid to rectify the issue. Release the pressure inside the cooker by using the quick release function or letting it natural release, depending on the recipe requirements. Once the pressure is released, open the cooker, and add the desired amount of liquid. Ensure that the liquid is evenly distributed and covers the ingredients to facilitate the pressure build-up process.

Remember to always consult the recipe instructions and guidelines provided by the manufacturer of your electric pressure cooker. Following these guidelines will help ensure that you have the proper amount of liquid in your cooker, allowing it to build up pressure efficiently and produce delicious, well-cooked meals.

Faulty Pressure Release Valve

The pressure release valve is a critical component of an electric pressure cooker. It is responsible for regulating the release of steam during the cooking process. If the pressure release valve is faulty or not functioning properly, it can hinder the pressure build-up inside the cooker.

There are a few potential issues that can arise with the pressure release valve:

- Stuck Valve: Sometimes, the pressure release valve can get stuck due to food particles or debris. This can prevent the steam from escaping properly, resulting in a lack of pressure build-up. In such cases, it’s important to clean the pressure release valve thoroughly. Refer to the manufacturer’s instructions on how to disassemble and clean the valve properly.

- Improper Placement: The pressure release valve needs to be in the proper position for the pressure cooker to build up pressure. Make sure the valve is set to the sealing position during cooking. If it’s set to the venting position, steam will continuously escape, and pressure won’t be able to build up.

- Worn or Damaged Valve: Over time, the pressure release valve may wear out or get damaged. This can cause it to malfunction and hinder the pressure build-up. If you notice any signs of damage or if the valve is not working correctly, it may need to be replaced. Contact the manufacturer for assistance or consult the instruction manual for information on obtaining a new valve.

Regular maintenance and inspection of the pressure release valve are important to ensure its proper functioning. Clean the valve regularly to remove any debris or food particles that may hinder its operation. Also, pay attention to any signs of wear or damage and address them promptly to maintain the optimal performance of your electric pressure cooker.

Remember to always follow the manufacturer’s guidelines and recommendations when dealing with the pressure release valve. This will help ensure the safe and efficient operation of your electric pressure cooker.

Read more: Why Wont My Washer Turn On

Blocked Vent Pipe

The vent pipe is a crucial component in an electric pressure cooker that allows excess steam to escape during the cooking process. If the vent pipe becomes blocked or obstructed, it can impair the pressure build-up and affect the cooker’s performance.

There are a few reasons why the vent pipe may become blocked:

- Food Debris: Food particles, sauces, or liquids can sometimes find their way into the vent pipe, causing a blockage. It’s important to ensure that the vent pipe remains clear of any food debris.

- Mineral Deposits: Over time, mineral deposits from hard water can accumulate in the vent pipe and cause a blockage. This is especially true if the pressure cooker is used frequently without regular cleaning.

To clear a blocked vent pipe, follow these steps:

- Turn Off the Pressure Cooker: Ensure that the pressure cooker is turned off and all pressure has been released.

- Clean the Vent Pipe: Use a small brush or pipe cleaner to gently remove any food debris or mineral deposits from the vent pipe. Be careful not to damage the pipe or cause any further blockages.

- Wash and Rinse: After removing the blockage, wash the vent pipe with warm soapy water and rinse thoroughly. This will help remove any remaining debris or residue.

- Inspect Regularly: Regularly inspect the vent pipe to ensure that it remains clear and unobstructed. Clean it as needed to maintain optimal performance.

By keeping the vent pipe clear of blockages, you can ensure that excess steam can escape properly, allowing the pressure cooker to build up and maintain the desired pressure. This will contribute to efficient and successful cooking results.

Remember, always refer to the manufacturer’s instructions for specific guidance on cleaning and maintenance of the vent pipe. Following their recommendations will help you keep your electric pressure cooker in optimal working condition.

Faulty Gasket

The gasket, also known as the sealing ring, is a crucial component of an electric pressure cooker. It creates an airtight seal between the lid and the pot, allowing pressure to build up inside the cooker. However, if the gasket is faulty or damaged, it can lead to air leakage and prevent the pressure cooker from building up pressure effectively.

Here are a few indicators that your gasket may be faulty:

- Visible Damage: Inspect the gasket for any signs of wear and tear. Cracks, tears, or splits in the gasket can compromise its ability to form a proper seal and hinder pressure build-up.

- Loose Fit: If the gasket feels loose and doesn’t fit tightly around the rim of the pot, it may need to be replaced. A loose gasket will allow air to escape and prevent pressure from building up.

- Absence of Elasticity: Over time, the elasticity of the gasket can break down, causing it to lose its ability to form a tight seal. If the gasket feels stiff and lacks flexibility, it may no longer be effective and should be replaced.

If you suspect that your gasket is faulty, it’s important to replace it to ensure proper pressure build-up in your electric pressure cooker.

To replace the gasket:

- Obtain the Correct Replacement Gasket: Contact the manufacturer or refer to the instruction manual to find the appropriate replacement gasket for your specific pressure cooker model.

- Remove the Old Gasket: Carefully remove the old gasket from the lid of the pressure cooker. Clean the lid and pot thoroughly to remove any residue or debris.

- Install the New Gasket: Place the new gasket into the groove on the lid. Ensure it fits securely and evenly around the rim.

- Ensure Proper Positioning: Make sure the gasket is properly aligned and seated in the correct position. Smooth out any wrinkles or gaps to ensure a tight seal.

By replacing the faulty gasket, you can restore the proper sealing function of your electric pressure cooker and allow pressure to build up effectively. This will ensure efficient cooking and better results.

Remember to consult the manufacturer’s guidelines and instructions for specific details on replacing the gasket. Following their recommendations will help you maintain the optimal performance of your electric pressure cooker.

Check the sealing ring and ensure it is properly seated. Also, make sure the pressure release valve is closed and the sealing vent is clear of any debris.

Overfilled Cooker

Overfilling the electric pressure cooker is a common mistake that can hinder the pressure build-up process. When the cooker is filled beyond its recommended capacity, there isn’t enough space for the steam to circulate and build pressure effectively.

To avoid overfilling your pressure cooker, it is essential to follow the manufacturer’s guidelines regarding the maximum fill line. Typically, pressure cooker recipes recommend filling the cooker only up to two-thirds of its capacity. This allows enough room for the ingredients and liquid to expand during cooking and for pressure to build up properly.

When adding ingredients to the cooker, keep in mind that certain foods, such as grains and legumes, tend to expand during cooking. Leave enough space to accommodate this expansion and prevent any potential blockage that can hinder the pressure build-up.

If you have filled your pressure cooker beyond the recommended maximum fill line, you will need to remove some of the ingredients or liquid to rectify the situation. Release the pressure inside the cooker, either by using the quick release function or letting it natural release, depending on the recipe requirements. Once the pressure is released, carefully open the cooker and remove excess ingredients or liquid. Be mindful not to exceed the maximum fill line.

By ensuring that you do not overfill your electric pressure cooker, you allow sufficient space for the steam to circulate, facilitating efficient pressure build-up. This will lead to better cooking results and prevent any potential issues that may arise from overfilled cookers.

Remember to refer to the manufacturer’s guidelines and instructions for the specific capacity and maximum fill line of your electric pressure cooker. Following their recommendations will help you avoid overfilling and optimize the performance of your pressure cooker.

Incorrect Pressure Setting

Electric pressure cookers often come with multiple pressure settings, such as high or low pressure. Each setting corresponds to a specific level of pressure and cooking time. Using the incorrect pressure setting can prevent the pressure cooker from building up the desired pressure.

When selecting the pressure setting for your recipe, it’s essential to follow the instructions provided in the recipe or by the manufacturer of your electric pressure cooker. Using the wrong pressure setting can lead to undercooked or overcooked food.

If you’re unsure about the correct pressure setting for a particular recipe, refer to the cooking time guidelines provided for different pressure settings in the instruction manual. This will help you determine the appropriate pressure level for your desired cooking outcome.

Additionally, make sure that you have properly set the pressure selector according to the desired pressure level before starting the cooking process. Most electric pressure cookers have a knob or button that allows you to adjust and lock the pressure setting.

If you believe that you have chosen the incorrect pressure setting for your recipe, you can release the pressure and start again. Use the appropriate method to release the pressure, whether it’s the quick release function or natural release, and adjust the pressure setting accordingly. Reset the pressure cooker and restart the cooking process, making sure that the pressure selector is set to the correct pressure level.

By utilizing the correct pressure setting for your electric pressure cooker, you can ensure the optimal pressure build-up and achieve precise cooking results. Following the recipe instructions and manufacturer’s guidelines will help you make the most of your pressure cooker’s capabilities.

Read more: Why Wont My Fan Turn On

Defective Heating Element

The heating element is a crucial component of an electric pressure cooker. It is responsible for generating the heat necessary to cook the food and build pressure inside the cooker. If the heating element is defective or not functioning properly, it can prevent the pressure cooker from reaching the desired temperature and building up pressure.

Here are some signs that your heating element may be defective:

- Inconsistent Heating: If you notice that the cooker takes longer than usual to heat up or doesn’t maintain a consistent temperature, it could be an indication of a faulty heating element.

- Lack of Pressure Build-Up: A defective heating element may not be able to generate enough heat to create the necessary steam and pressure inside the cooker. This can result in longer cooking times and a failure to reach the desired pressure.

- Visible Damage: Inspect the heating element for any visible signs of damage, such as burns or breaks. If you notice any physical damage, it’s likely that the heating element needs to be replaced.

If you suspect that the heating element in your electric pressure cooker is defective, it is recommended to contact the manufacturer for assistance or consult the instruction manual for troubleshooting steps.

In some cases, the heating element may be replaceable, allowing you to purchase a new one and install it yourself. However, it is important to follow the manufacturer’s guidelines and recommendations for replacing the heating element to ensure safety and proper functionality.

If the electric pressure cooker is still under warranty, it is advisable to reach out to the manufacturer for repair or replacement options. They will be able to guide you through the process and provide the necessary support.

By addressing a defective heating element, you can restore the proper functioning of your electric pressure cooker and ensure that it can reach and maintain the desired temperature and pressure for successful cooking results.

Remember, always prioritize safety when dealing with any electrical components. If you’re unsure or uncomfortable with replacing the heating element yourself, seek professional assistance to avoid any potential risks or accidents.

Power Supply Issues

Power supply issues can also contribute to a lack of pressure build-up in an electric pressure cooker. If the cooker is not receiving adequate power, it may struggle to generate the heat needed for pressure cooking.

Here are a few power supply-related problems to consider:

- Inadequate Power Source: Ensure that your electric pressure cooker is plugged into a dedicated electrical outlet that can provide the necessary power. Avoid using extension cords or power strips, as they may not be able to handle the electrical load required for the cooker.

- Inconsistent Voltage: Fluctuations in voltage supply can impact the performance of the pressure cooker. If you experience voltage irregularities or power surges in your area, consider using a voltage stabilizer or surge protector to safeguard your cooker and maintain stable power supply.

- Faulty Power Cord: Inspect the power cord of your electric pressure cooker for any signs of fraying, damage, or wear. A faulty power cord may prevent the cooker from receiving power efficiently. If you notice any issues, discontinue use and contact the manufacturer for a replacement cord.

- Circuit Breaker Tripped: Check your home’s circuit breaker to ensure that the circuit supplying power to the pressure cooker has not tripped. Reset the circuit breaker if necessary.

- Power Outage: If you experience a sudden power outage while using your electric pressure cooker, it can interrupt the cooking process and the pressure build-up. Wait for the power to be restored, and then resume cooking from where you left off, following proper safety precautions.

It’s important to ensure that your electric pressure cooker has a stable and consistent power supply for optimal performance. Consulting the user manual for specific power requirements and following proper electrical guidelines will help you avoid power-related issues.

If you’ve ruled out power supply issues and your pressure cooker still fails to build up pressure, it’s advisable to contact the manufacturer for technical support or consult a qualified electrician to diagnose and resolve any potential electrical problems.

By addressing power supply issues, you can ensure that your electric pressure cooker receives the necessary power to function properly and build pressure efficiently.

User Error

User error is a common factor that can contribute to a lack of pressure build-up in an electric pressure cooker. It’s important to understand how to properly operate and use the cooker to achieve the desired results.

Here are a few user errors to be aware of:

- Incorrect Assembly: Improperly assembling the pressure cooker can prevent it from building pressure. Make sure that all components, such as the lid, gasket, and pressure release valve, are securely in place before starting the cooking process.

- Failure to Seal Properly: Failing to ensure a proper seal between the lid and the pot can lead to air leakage and a lack of pressure build-up. Double-check that the lid is aligned correctly, and the sealing ring/gasket is clean and properly positioned.

- Not Enough Cooking Time: Electric pressure cookers require sufficient cooking time to build up pressure and cook the food thoroughly. Make sure to follow the recipe instructions and set the appropriate cooking time for the ingredients being used. Rushing the cooking process may result in undercooked food.

- Disturbing the Cooker During Operation: Opening the pressure cooker lid or attempting to adjust or move it while it is building up pressure can disrupt the process and prevent pressure from being maintained. It’s important to be patient and allow the cooker to complete its cycle before making any adjustments.

- Not Following the Recommended Liquid Levels: Insufficient liquid can hinder pressure build-up. It’s important to follow the recipe instructions and the manufacturer’s guidelines regarding the minimum required amount of liquid to ensure proper pressure cooking.

To avoid user errors, familiarize yourself with the instruction manual provided by the manufacturer. Understand the specific functionalities of your electric pressure cooker and the proper operating procedures.

Take the time to read and follow recipe instructions carefully, ensuring that you adhere to recommended cooking times, liquid measurements, and pressure settings.

By avoiding user errors and using the electric pressure cooker correctly, you can achieve successful pressure cooking results and ensure optimal pressure build-up.

Troubleshooting Tips for Electric Pressure Cookers

If you’re experiencing a lack of pressure build-up in your electric pressure cooker, don’t worry. Here are some troubleshooting tips to help you address the issue and get your cooker back on track:

- Check the Seal: Ensure that the lid is positioned correctly and the sealing ring/gasket is in good condition. A proper seal is essential for pressure build-up.

- Verify the Liquid Levels: Make sure you have the recommended amount of liquid in the cooker to generate steam and build pressure.

- Inspect the Pressure Release Valve: Clean and ensure that the pressure release valve is not blocked or malfunctioning.

- Clean the Vent Pipe: Remove any debris or food particles that may be blocking the vent pipe and hindering pressure build-up.

- Check the Gasket: Inspect the sealing ring/gasket for any signs of damage or wear. Replace if necessary.

- Avoid Overfilling: Fill the pressure cooker only up to the recommended maximum fill line to allow space for steam and pressure build-up.

- Double-Check the Pressure Setting: Ensure that you have selected the correct pressure setting for your recipe.

- Inspect the Heating Element: Check for any signs of damage or malfunctioning in the heating element. Replace if needed.

- Address Power Supply Issues: Verify that the cooker is plugged into a dedicated outlet and that there are no power supply problems in your area.

- Avoid User Errors: Ensure that you properly assemble the cooker, seal it correctly, follow cooking times, and avoid disturbing the cooker during operation.

If you’ve tried these troubleshooting tips and are still experiencing issues with pressure build-up, it’s recommended to consult the manufacturer’s customer support or seek professional assistance. They can provide further guidance specific to your electric pressure cooker model.

Remember, safety is paramount when troubleshooting your electric pressure cooker. Always follow the manufacturer’s instructions, exercise caution, and ensure that the cooker is not under pressure when attempting to address any issues.

By following these troubleshooting tips and taking the necessary steps to resolve the problem, you can enjoy the benefits of efficient pressure cooking and delicious meals once again!

Read more: Why Wont My Toilet Unclog

Conclusion

Electric pressure cookers are fantastic appliances that can drastically reduce cooking time and produce delicious meals. However, when these cookers fail to build up pressure, it can be frustrating and hinder your cooking experience. Fortunately, there are various potential solutions to address this issue.

In this article, we explored the possible reasons for a lack of pressure build-up in electric pressure cookers, including inadequate seals, insufficient liquid, faulty pressure release valves, blocked vent pipes, faulty gaskets, overfilled cookers, incorrect pressure settings, defective heating elements, power supply issues, and user errors.

We provided troubleshooting tips for each of these potential issues, helping you identify and resolve the problem. Checking the seal, ensuring sufficient liquid, cleaning the vent pipe, inspecting the gasket, avoiding overfilling, selecting the correct pressure setting, maintaining the heating element, addressing power supply issues, and avoiding user errors are important steps to take in troubleshooting your electric pressure cooker.

Remember to consult the manufacturer’s guidelines and instructions specific to your cooker for the most accurate troubleshooting advice. Additionally, prioritize safety when dealing with any electrical components and consider reaching out to the manufacturer’s customer support or seeking professional help if necessary.

By applying these troubleshooting tips and addressing any potential issues, you can get your electric pressure cooker back in working order and enjoy the convenience and efficiency it provides. Whether you’re cooking tender meats, flavorful stews, or time-saving one-pot meals, a properly functioning electric pressure cooker will help you achieve amazing results in the kitchen.

So, don’t let a lack of pressure build-up discourage you. Dive into the world of electric pressure cooking with confidence, knowing that you have the knowledge and tools to troubleshoot and overcome any challenges that may arise.

Frequently Asked Questions about Why Won't My Electric Pressure Cooker Build Up Pressure

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Won’t My Electric Pressure Cooker Build Up Pressure”