Home>diy>Building & Construction>What Is OSB In Construction

Building & Construction

What Is OSB In Construction

Modified: January 8, 2024

Learn what OSB is in construction and its role in building-construction. Find out how OSB is used and its benefits.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the world of building construction, there are numerous materials and components that are essential for creating sturdy and durable structures. One such material that has gained significant popularity in recent years is OSB, which stands for Oriented Strand Board. OSB is a type of engineered wood product that has become widely used in the construction industry due to its versatility, strength, and cost-effectiveness.

Understanding the basics of OSB and its applications is crucial for anyone involved in the construction process, whether they are architects, builders, or homeowners. This article will explore what OSB is, its history in construction, its composition, properties and benefits, common uses, comparison with plywood, advantages and disadvantages, environmental impact, and tips for working with OSB.

By the end of this article, you will have a comprehensive understanding of OSB and how it can be utilized effectively in construction projects. Let’s dive in!

Key Takeaways:

- OSB, or Oriented Strand Board, is a cost-effective, versatile, and environmentally friendly construction material made of wood strands, adhesives, and wax. Its strength, durability, and moisture resistance make it ideal for various applications in building construction.

- When working with OSB, proper storage, handling, cutting, fastening, and sealing techniques are crucial for optimal performance. Following manufacturer recommendations, considering ventilation, and allowing for acclimation can ensure successful installation and long-term effectiveness.

Read more: What Thickness OSB For Roof

What is OSB?

OSB, or Oriented Strand Board, is an engineered wood product that is widely used in the construction industry. It is made by compressing layers of wood strands, also known as flakes or chips, together with an adhesive under high pressure and heat. The strands are oriented in specific directions to maximize the panel’s strength and stability.

OSB is similar to plywood in terms of its structural properties but is manufactured using a different process. While plywood is made by gluing together thin layers of wood veneers, OSB uses larger wood strands that are bonded together in a crisscross pattern. This results in a panel that is strong, durable, and resistant to warping or splitting.

The thickness of OSB panels can vary depending on the intended application, ranging from 6mm to 25mm or more. They come in standard sizes of 4 feet by 8 feet, but larger panels are also available for specific construction projects.

OSB is often categorized into different grades based on its intended use. There are three main grades:

– OSB/1: Suitable for interior use, including furniture and packaging.

– OSB/2: Suitable for structural applications in dry conditions, such as wall and roof sheathing.

– OSB/3: Suitable for structural applications in humid conditions, such as flooring and wall sheathing in bathrooms or kitchens.

Overall, OSB is a cost-effective alternative to plywood and other construction materials. Its affordability, strength, and versatility make it a popular choice for various applications in the construction industry.

History of OSB in Construction

The history of OSB in construction dates back to the 1930s when it was first developed in Europe as a replacement for plywood. It gained traction in North America in the 1980s as a cost-effective alternative to traditional wood panel products.

The concept of oriented strand board originated from the desire to find a more efficient and economical way to utilize wood resources. Unlike plywood, which requires large and high-quality logs, OSB can be produced using smaller logs, low-grade timber, or even wood waste materials. This resulted in a more sustainable and environmentally friendly product.

Initially, OSB panels were primarily used as sheathing material for roofs and walls. Their structural strength and moisture resistance made them ideal for these applications. Over time, as technology advanced and manufacturing processes improved, OSB began to be utilized in a wide range of construction applications.

Throughout the years, the quality and performance of OSB have continuously improved, making it a staple in the construction industry. Advancements in bonding agents, pressing techniques, and quality control measures have made OSB panels more consistent, stable, and reliable.

Today, OSB is widely accepted as a standard construction material, especially in residential and commercial buildings. Its popularity can be attributed to its affordability, durability, and ease of use.

As the demand for sustainable and eco-friendly building materials continues to grow, OSB has also gained attention for its environmental benefits. Utilizing small-diameter logs and wood waste materials reduces the strain on forests, making it a more sustainable alternative to traditional wood products.

The history of OSB in construction is a testament to its evolution and widespread adoption. From humble beginnings as a plywood substitute, it has become an integral part of modern construction practices, providing builders and contractors with a reliable and cost-effective solution.

Composition of OSB

OSB, or Oriented Strand Board, is made up of three main components: wood strands, adhesives, and wax. Each component plays a crucial role in the composition and performance of OSB panels.

The wood strands used in OSB are typically made from small-diameter logs or wood waste materials. These strands are obtained by debarking the logs and then shaving or flaking them into thin pieces. The strands are randomly oriented and come in various lengths, typically ranging from 1 inch to 6 inches.

Adhesives are a vital component of OSB as they bind the wood strands together. The most commonly used adhesive is phenol-formaldehyde resin, which provides excellent bonding strength and durability. Additionally, melamine-urea-formaldehyde, isocyanate, and polyurethane adhesives are sometimes used to improve specific properties, such as water resistance.

Wax is added to the mixture to enhance the moisture resistance of OSB panels. The wax is usually paraffin-based and acts as a water repellent, preventing the wood fibers from absorbing moisture and expanding or warping. This feature makes OSB suitable for applications in humid and moisture-prone environments.

The manufacturing process of OSB involves several steps. First, the wood strands are dried to a specific moisture content to ensure stability. Then, the strands are blended with the adhesive mixture, which evenly coats each strand. The coated strands are then placed in layers on a forming line, where they are oriented in specific directions. This alignment of strands maximizes the strength of the final panel.

The layers of oriented strands are then pressed together under high pressure and heat. This process activates the adhesive, causing it to cure and bond the strands together. The panels are then trimmed to the desired dimensions and undergo quality checks to ensure they meet the required specifications.

It is important to note that OSB panels are typically made up of an odd number of layers to maintain stability and prevent warping. The density and thickness of the panel can vary depending on its intended application.

The composition of OSB, with its mixture of wood strands, adhesives, and wax, results in a durable, versatile, and environmentally friendly construction material. The combination of these components ensures that OSB panels have excellent strength, dimensional stability, and resistance to moisture and other external factors.

Properties and Benefits of OSB

OSB, or Oriented Strand Board, possesses a range of properties and benefits that make it a popular choice in the construction industry. Here are some of the key properties and benefits of using OSB:

Read more: How To Install OSB On Interior Walls

1. Strength and Durability:

OSB is renowned for its exceptional strength and durability. The orientation of wood strands and the adhesive bonding process contribute to its high structural integrity. It can withstand heavy loads and resist bending or warping, making it suitable for demanding construction applications.

2. Moisture Resistance:

OSB panels are engineered to have excellent moisture resistance. The wax coating applied during manufacturing helps repel water and prevent swelling or warping of the boards. This feature makes OSB ideal for use in humid environments, such as bathrooms, kitchens, and areas prone to moisture exposure.

3. Versatility:

OSB is a versatile construction material that can be used for various applications. It is commonly used for roof and wall sheathing, flooring, subfloors, and as a base for exterior finishes. OSB can also be easily cut, shaped, and installed, making it adaptable to different construction needs.

4. Cost-Effectiveness:

Compared to traditional wood products, such as plywood, OSB is more cost-effective. Its manufacturing process allows for the use of smaller logs and wood waste materials, reducing production costs. As a result, OSB panels are generally more affordable while still offering comparable strength and performance.

Read more: How To Treat Osb For Outdoor Use

5. Sustainability:

OSB is considered a sustainable building material. It utilizes smaller logs and wood waste, reducing the demand for larger, high-quality trees. This helps preserve forests and promotes responsible forestry practices. Additionally, the manufacturing process of OSB produces less waste and emissions compared to other construction materials.

6. Fire Resistance:

OSB exhibits good fire resistance properties. It is not easily ignited and can withstand fire for a longer period compared to traditional wood products. Fire-rated OSB panels are also available, providing an added layer of protection for buildings in areas with strict fire safety regulations.

In summary, the properties and benefits of OSB make it an attractive choice in the construction industry. Its strength, moisture resistance, versatility, cost-effectiveness, sustainability, and fire resistance make it a reliable and practical option for a wide range of applications. Whether used in residential, commercial, or industrial projects, OSB offers durability and performance without compromising on affordability or environmental impact.

Common Uses of OSB in Construction

OSB, also known as Oriented Strand Board, has gained widespread popularity in the construction industry due to its versatility and durability. It is used in various applications across residential, commercial, and industrial projects. Here are some of the common uses of OSB:

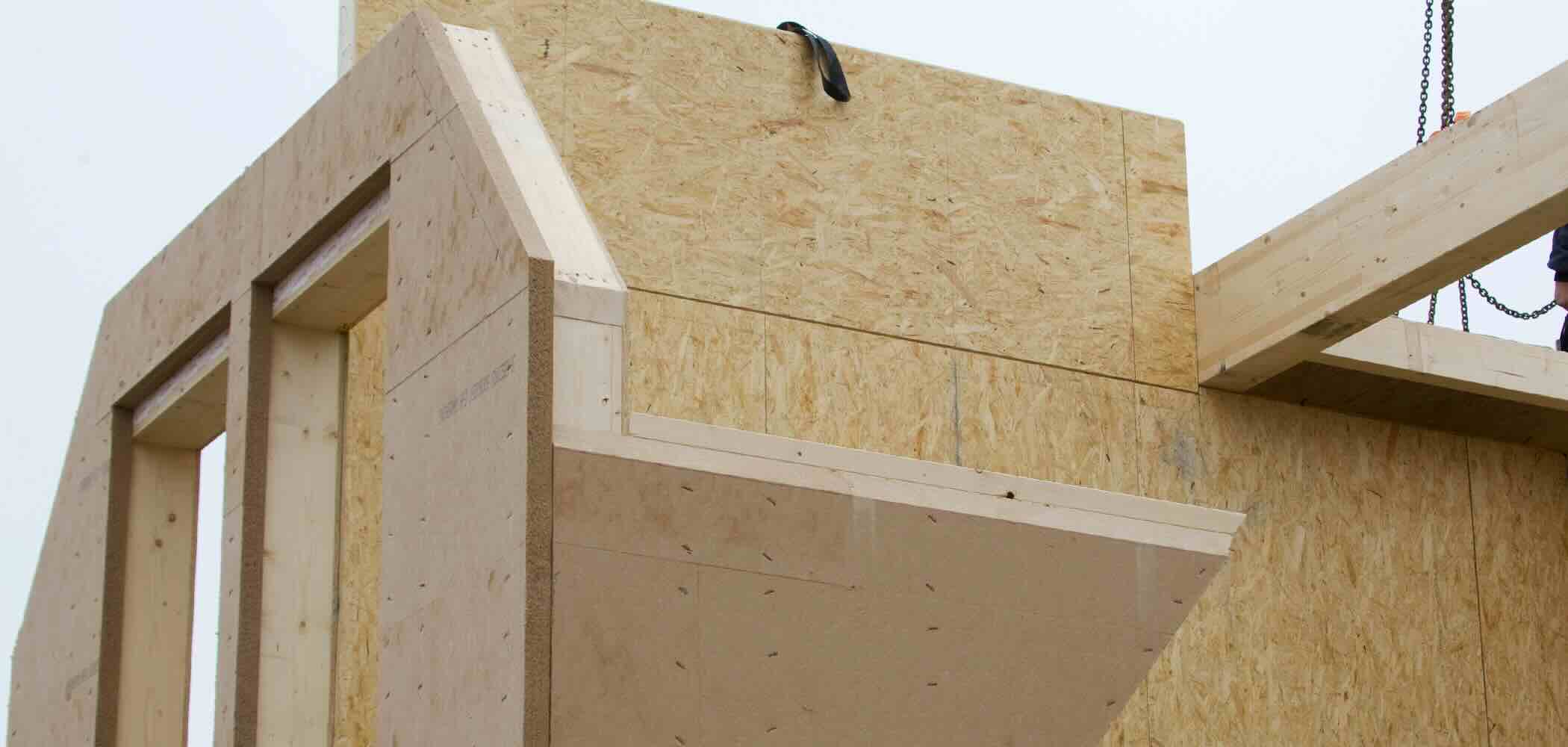

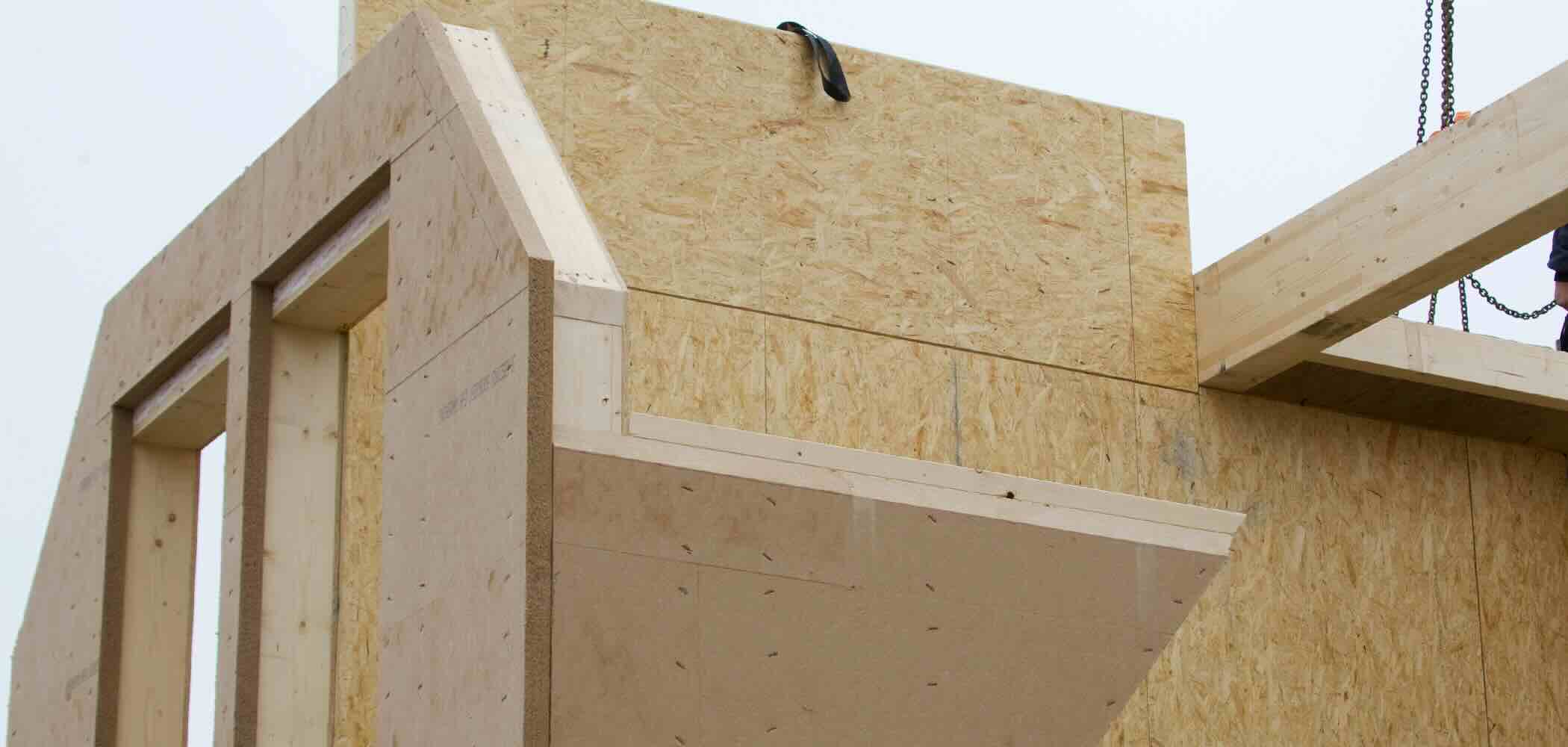

1. Roof and Wall Sheathing:

OSB is commonly used as roof and wall sheathing in residential and commercial buildings. Its high strength and moisture resistance make it an ideal choice for providing structural support and protection against the elements. OSB panels are typically installed over the framing to create a solid and stable surface for the roof covering or exterior cladding.

Read more: What Is Pre-Construction In Construction

2. Flooring and Subfloors:

OSB is an excellent material for flooring and subfloors. Its strength and rigidity allow it to withstand heavy loads and provide a stable base for various floor coverings, such as hardwood, laminate, or tile. OSB subfloors also help reduce noise transmission and provide thermal insulation.

3. Shear Walls and Bracing:

OSB is frequently used in shear walls and bracing systems to provide lateral stability to buildings. These components help resist forces generated by wind or seismic events. The high strength and dimensional stability of OSB make it an effective material for reinforcing the structural integrity of a building.

4. Exterior Siding:

In some construction projects, OSB panels can be used as an exterior siding material. The panels can be finished with various coatings or applied with a layer of exterior-grade paint to enhance their appearance and protect them from weathering.

5. Cabinetry and Furniture:

Due to its strength and affordability, OSB has found its way into the world of cabinetry and furniture. It can be used as a cost-effective alternative to plywood or solid wood to create shelves, cabinets, and other furniture pieces. OSB can be finished with veneers or laminates to achieve a polished and attractive look.

Read more: What Is Construction

6. Packaging and Shipping:

OSB panels are also used for packaging and shipping purposes. The durability and strength of OSB make it an ideal material for creating crates, pallets, and protective packaging. Its dimensional stability ensures that the packaged items remain secure during transit.

These are just a few examples of the common uses of OSB in construction. Its versatility and wide range of applications have made it a preferred choice for builders, architects, and homeowners alike. Whether it’s providing structural support, creating stable surfaces, or enhancing the aesthetic appeal of a space, OSB continues to prove its value in the construction industry.

Comparison between OSB and Plywood

When it comes to choosing the right material for construction projects, two popular options are OSB (Oriented Strand Board) and plywood. While both are engineered wood products and have similar applications, there are several key differences between the two. Let’s compare OSB and plywood based on various factors:

1. Composition:

OSB is made by compressing and bonding wood strands together with adhesives, while plywood is made by gluing together multiple thin layers of wood veneers. This fundamental difference in composition leads to variations in their structural characteristics.

2. Strength and Durability:

Both OSB and plywood are known for their strength and durability. However, OSB often exhibits greater uniformity in strength due to the way the wood strands are oriented and compressed. Plywood, on the other hand, may have slight variations in strength between layers. Both materials have good load-bearing capacity, but OSB is less prone to warping or sagging.

Read more: OSB vs Plywood: Choosing The Better Wood

3. Moisture Resistance:

When it comes to moisture resistance, plywood has an advantage over OSB. The multiple layers of veneers in plywood provide better resistance to moisture penetration, making it more suitable for applications in high humidity or wet environments. OSB, although engineered to be moisture resistant with the addition of wax, is still more susceptible to swelling and damage if exposed to prolonged moisture.

4. Cost:

In terms of cost, OSB tends to be more affordable than plywood. The manufacturing process of OSB allows for the use of smaller logs and wood waste materials, making it a cost-effective option. Plywood, on the other hand, requires larger and higher-quality logs, which increases the production cost and, consequently, the price of the finished product.

5. Availability and Sizes:

Both OSB and plywood are widely available and come in a variety of sizes. However, OSB panels are commonly available in larger dimensions, making them suitable for larger construction projects where fewer seams are desired. Plywood panels are available in smaller standard sizes but can be custom-cut to fit specific requirements.

6. Environmental Impact:

In terms of sustainability, OSB is considered more environmentally friendly than plywood. OSB utilizes smaller logs and wood waste materials, reducing the demand for larger trees and promoting responsible forestry practices. Additionally, the manufacturing process of OSB produces less waste and emissions compared to plywood production.

Ultimately, the choice between OSB and plywood depends on the specific project requirements, budget, and environmental considerations. While both materials have their strengths and weaknesses, OSB is often favored for its cost-effectiveness and uniform strength, while plywood is preferred for applications requiring higher moisture resistance. Consulting with a construction professional can help determine the most suitable option based on project-specific needs and priorities.

Read more: What Is A Construction Painter

Advantages and Disadvantages of OSB

OSB, or Oriented Strand Board, is a popular construction material that offers several advantages in terms of cost, strength, and versatility. However, like any building material, OSB also has its disadvantages. Let’s explore the advantages and disadvantages of using OSB in construction:

Advantages of OSB:

1. Cost-Effective:

OSB is generally more affordable than plywood and other traditional wood products. Its manufacturing process allows for the use of smaller logs and wood waste materials, reducing production costs. This makes OSB a cost-effective option for various construction applications.

2. High Strength and Durability:

OSB is engineered to be strong and durable. The orientation of wood strands and the adhesive bonding process result in a panel with excellent load-bearing capacity. It can withstand heavy loads and resist bending or warping, making it ideal for structural applications.

3. Versatility:

OSB is a versatile material that can be used in various construction applications. It is commonly used for roof and wall sheathing, flooring, subfloors, and as a base for exterior finishes. OSB can be easily cut, shaped, and installed, making it adaptable to different design and construction needs.

4. Moisture Resistance:

OSB panels are engineered to be moisture resistant. They are coated with wax during the manufacturing process, which helps repel water and prevent swelling or warping of the boards. This feature makes OSB suitable for use in humid and moisture-prone environments.

5. Environmental Sustainability:

OSB is considered a more environmentally friendly option compared to plywood. It utilizes smaller logs and wood waste materials, reducing the demand for larger, high-quality trees. Additionally, the manufacturing process of OSB produces less waste and emissions compared to other wood products.

Disadvantages of OSB:

1. Susceptible to Moisture Damage:

While OSB is engineered to be moisture resistant, it is still more susceptible to moisture damage compared to other materials like plywood. Prolonged exposure to moisture can cause OSB to swell, warp, or even delaminate, impacting its structural integrity. Proper installation and moisture management are crucial to mitigate this risk.

2. Limited Exterior Use:

OSB is not ideally suited for prolonged exposure to the elements. While it can be used as exterior sheathing or siding with proper treatment and finishing, it may not offer the same level of moisture resistance or long-term durability as other materials like plywood or fiber cement boards.

3. Formaldehyde Emissions:

Traditionally, OSB was known to emit formaldehyde, a volatile organic compound, due to the adhesives used in its manufacturing process. However, advancements in technology have led to the development of low-emitting or formaldehyde-free OSB alternatives, reducing this concern.

4. Limited Aesthetic Options:

Compared to plywood, OSB has limited aesthetic options. It typically has a rough texture and appearance, making it less suitable for applications where a smooth or finished look is desired. However, OSB can be covered with veneers or laminates to enhance its aesthetic appeal.

Understanding the advantages and disadvantages of OSB is essential in making informed decisions about its suitability for specific construction projects. While OSB offers numerous benefits, it is important to consider its limitations and address any potential challenges to ensure the success and longevity of the construction project.

Environmental Impact of OSB

As sustainability and environmental concerns continue to grow, it is crucial to evaluate the environmental impact of construction materials. When it comes to OSB (Oriented Strand Board), there are several aspects to consider:

Read more: What Is A Superintendent In Construction

1. Resource Utilization:

One of the significant environmental benefits of OSB is its efficient use of wood resources. OSB can be manufactured using smaller logs and wood waste materials, including chips and flakes. This reduces the demand for larger, high-quality trees and promotes responsible forestry practices. By utilizing these smaller logs and waste materials, OSB helps to decrease the strain on forests and contribute to sustainable wood sourcing.

2. Manufacturing Process:

The manufacturing process of OSB has also evolved to reduce its environmental impact. Advanced technologies and production methods have been developed to minimize waste and emissions. Additionally, the use of adhesives with low formaldehyde emissions has become more common, further reducing potential harm to human health and the environment.

3. Energy and Water Consumption:

The production of OSB requires less energy and water compared to some other construction materials. The manufacturing process involves pressing and bonding wood strands together using heat and pressure. This process consumes less energy compared to other materials that require extensive processing or extraction. Additionally, water usage is generally lower in OSB production, contributing to overall reduced environmental impact.

4. Recyclability and Reusability:

OSB can be recycled or repurposed at the end of its useful life. While it may not be as widely recognized as other materials like metal or concrete for recycling, OSB can still be reprocessed into wood-based products or used for energy generation. This reduces waste and extends the lifespan of the material, minimizing its environmental impact.

Read more: What Is An RFQ In Construction

5. Carbon Footprint:

OSB has a relatively low carbon footprint compared to some other construction materials. The engineered wood panels are carbon-neutral or even carbon-negative in some cases. This means that the carbon stored in the wood strands used to produce OSB exceeds the emissions generated during manufacturing, resulting in a net reduction of carbon dioxide in the atmosphere.

6. Environmental Certifications:

Various environmental certifications, such as the Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI), can validate the responsible sourcing and manufacturing practices of OSB products. These certifications ensure that the wood used in the production of OSB comes from sustainably managed forests and adheres to stringent environmental standards.

It is important to note that while OSB offers several environmental benefits, it is essential to consider its specific application and suitability for a given project. Proper installation, maintenance, and consideration of the lifespan of the material are crucial in maximizing its environmental benefits.

Overall, OSB’s efficient resource utilization, lower energy and water consumption, recyclability, and lower carbon footprint make it a favorable choice for those seeking sustainable construction materials. By integrating OSB into construction projects, it is possible to reduce environmental impact while constructing durable and structurally sound buildings.

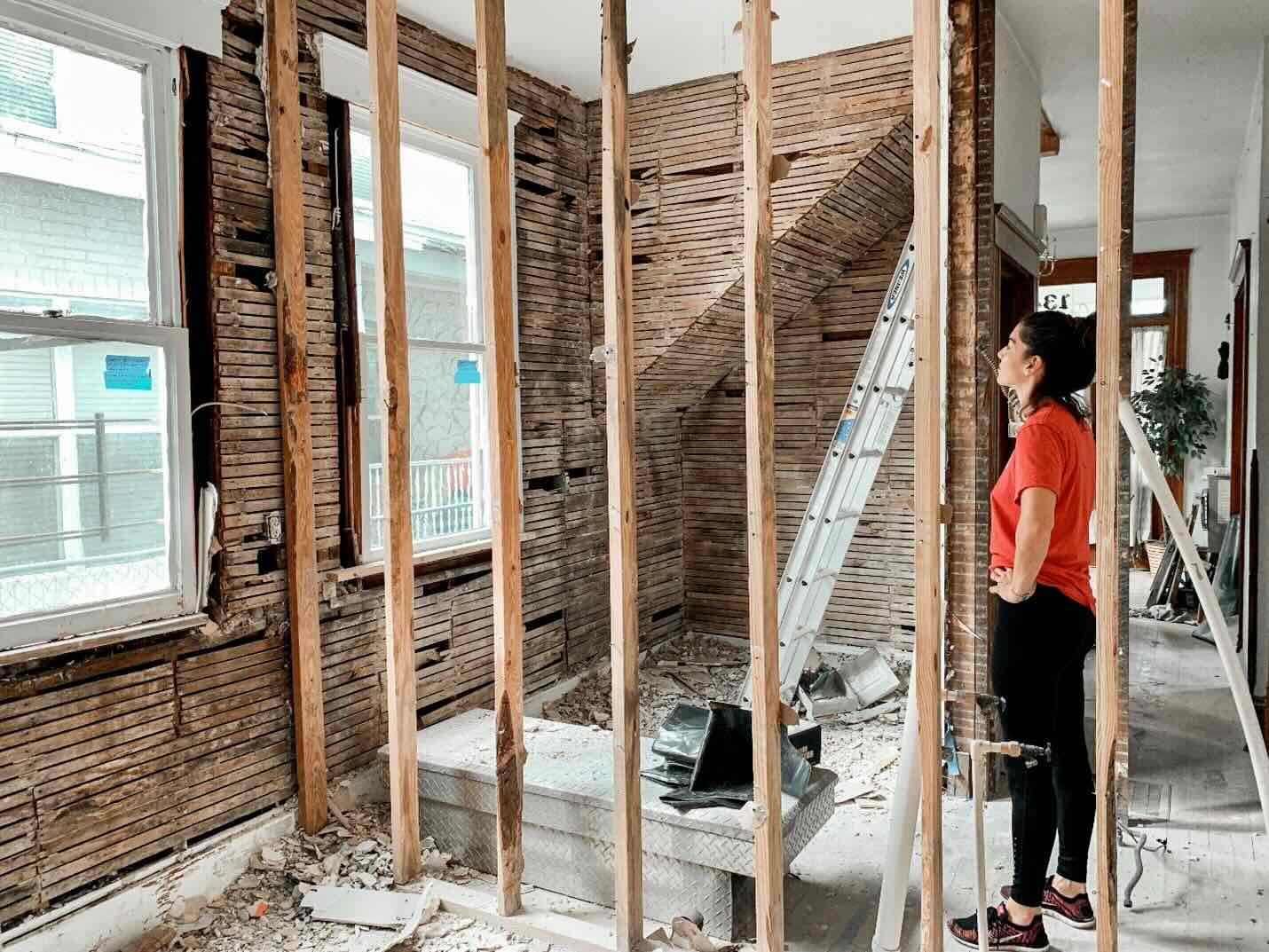

Tips for Working with OSB in Construction

Working with OSB (Oriented Strand Board) in construction requires careful consideration and proper techniques to ensure successful installation and optimal performance. Here are some useful tips to keep in mind when working with OSB:

1. Storage and Acclimation:

Store OSB panels in a well-ventilated area to prevent moisture absorption and potential warping. Allow the panels to acclimate to the job site conditions by keeping them flat and off the ground for a few days before installation. This helps minimize any dimensional changes that may occur due to moisture content variations.

Read more: What Is A Wattle In Construction

2. Proper Handling and Cutting:

When handling OSB panels, carry them in a horizontal position to minimize sagging or bending. Use caution to avoid dropping or dragging the panels, as it can result in surface damage. When cutting OSB, use a circular saw or a jigsaw with a fine-toothed blade to ensure clean and precise cuts. Measure and mark the panels carefully before cutting to achieve accurate dimensions.

3. Fastening and Installation:

Use appropriate fasteners, such as nails or screws, that are specifically designed for OSB. Ensure that the fasteners penetrate the OSB panels adequately and securely attach them to the framing members. Follow the recommended nailing or screwing pattern provided by the manufacturer for proper installation and maximum structural integrity.

4. Maintain Proper Gaps and Spacing:

Allow for expansion and contraction by leaving a small gap, usually 1/8 inch, between adjacent OSB panels during installation. This allows the panels to adjust to temperature and moisture changes without causing warping or buckling. Additionally, leave adequate spacing around edges and corners to accommodate any potential movement.

5. Properly Seal and Protect Edges:

Seal the exposed edges of OSB panels with an appropriate sealant to enhance their moisture resistance and prevent water penetration. Pay special attention to areas with potential water exposure, such as exterior applications. Applying a coat of paint or primer on the exposed surfaces can also help protect the panels from weathering.

Read more: What Is WIP In Construction

6. Consider Proper Ventilation:

In applications where OSB is used as roof or wall sheathing, ensure proper ventilation to prevent moisture buildup. Proper ventilation allows air to circulate and reduces the risk of condensation, which can lead to mold or decay. Follow building codes and industry guidelines regarding ventilation requirements in specific applications.

7. Follow Manufacturer’s Recommendations:

Each manufacturer may have specific guidelines and recommendations for working with their OSB products. It is essential to carefully read and follow these instructions to ensure proper installation and to maintain any warranties associated with the product.

By following these tips, you can optimize the performance and durability of OSB in your construction projects. Proper handling, cutting, fastening, installation techniques, and adherence to manufacturer guidelines will help you achieve a successful outcome and ensure the long-term effectiveness of OSB as a building material.

Conclusion

OSB, or Oriented Strand Board, has emerged as a versatile and cost-effective material in the world of building construction. Its strength, durability, and affordability make it a preferred choice for structural components and various applications across residential, commercial, and industrial projects.

Throughout this article, we have explored the key aspects of OSB, including its composition, properties, uses, and comparisons with other materials like plywood. We have learned that OSB is made up of wood strands, adhesives, and wax, giving it excellent strength, moisture resistance, and versatility. It can be used for roof and wall sheathing, flooring, subfloors, and even cabinetry and furniture.

OSB offers several advantages, such as its cost-effectiveness, high strength, and durability. It is also environmentally friendly, utilizing smaller logs and wood waste materials, while its manufacturing process consumes less energy and water compared to other materials. However, it is essential to consider its limitations, such as its susceptibility to moisture damage and limited exterior use.

Working with OSB requires proper handling, cutting, and installation techniques. Following guidelines for storage, acclimation, fastening, and sealing will maximize its performance and longevity. It is also important to consider proper ventilation and follow manufacturer recommendations for specific applications.

In conclusion, OSB offers an attractive combination of affordability, strength, and versatility. It is an excellent choice for various construction projects, providing reliable structural support and withstanding demanding environmental conditions. By understanding the properties, benefits, and limitations of OSB, construction professionals and homeowners can confidently incorporate it into their projects and create durable and sustainable structures.

Frequently Asked Questions about What Is OSB In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is OSB In Construction”