Home>Furniture & Design>Interior Design Trends>How Does Tempered Glass Break

Interior Design Trends

How Does Tempered Glass Break

Modified: October 19, 2024

Learn why tempered glass breaks and how it impacts interior design trends. Explore the factors that contribute to the breakage of tempered glass.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

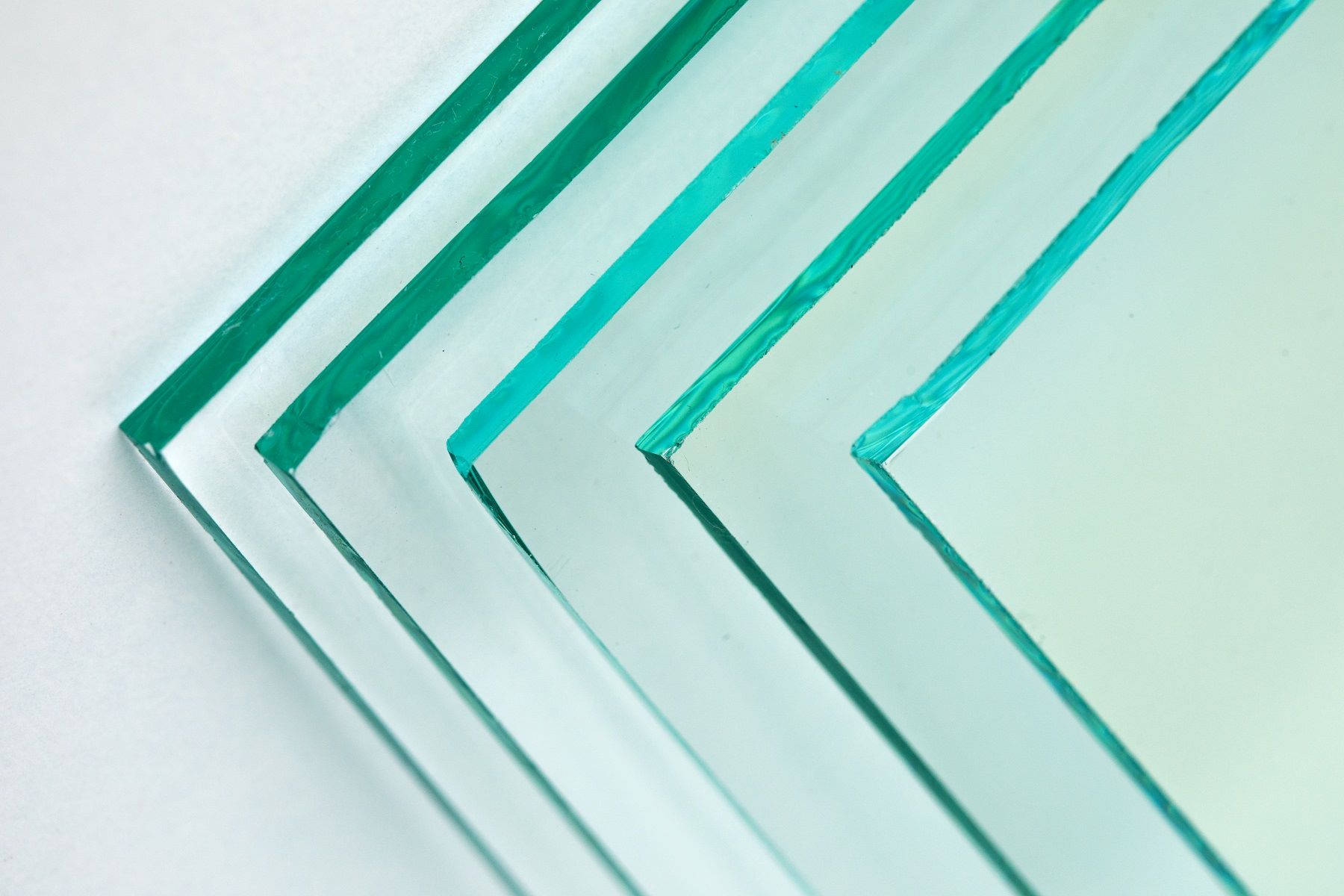

Tempered glass is a ubiquitous material in modern architecture and interior design, renowned for its strength, safety, and versatility. From sleek glass balustrades to elegant shower enclosures, tempered glass is a popular choice for a wide range of applications. However, despite its durability, tempered glass is not impervious to breakage. Understanding the factors that contribute to the breakage of tempered glass is crucial for ensuring its safe and effective use in various settings.

In this comprehensive guide, we will delve into the intricacies of tempered glass, exploring its composition, manufacturing process, and the common causes of breakage. By gaining insight into the inner workings of tempered glass, you will be better equipped to make informed decisions regarding its selection, maintenance, and safety measures.

Let's embark on a fascinating journey into the world of tempered glass, unraveling the mysteries behind its remarkable strength and the circumstances that can lead to its unexpected breakage. Through this exploration, you will gain a deeper appreciation for the complexities of this remarkable material and the precautions necessary to harness its potential while mitigating the risks associated with breakage.

Key Takeaways:

- Tempered glass is strong and safe, but can still break due to flaws, improper handling, thermal stress, external impacts, and edge damage. Understanding these factors helps prevent breakage and ensure safety.

- The process of making tempered glass involves precision engineering and thermal manipulation, resulting in a material known for its strength, safety, and aesthetic appeal. However, it’s important to be aware of potential causes of breakage to maintain its longevity and safety.

Read more: Why Does Glass Break With Sound

What is Tempered Glass?

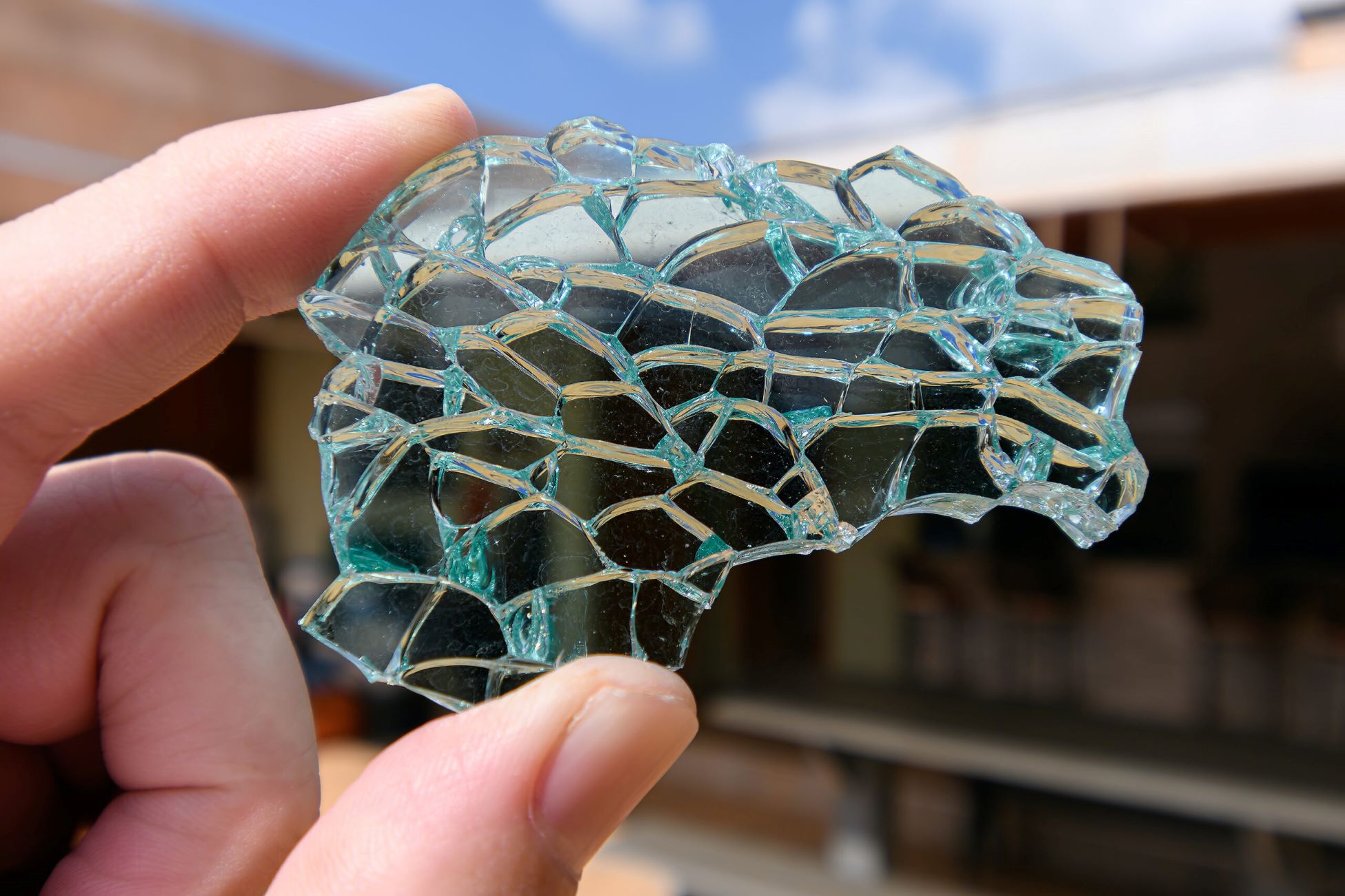

Tempered glass, also known as toughened glass, is a type of safety glass that is specially treated to enhance its strength and durability. Unlike traditional annealed glass, which is prone to shattering into sharp, jagged pieces when broken, tempered glass is designed to fragment into small, relatively harmless pieces upon impact. This unique characteristic significantly reduces the risk of injury, making tempered glass an ideal choice for various architectural and interior design applications.

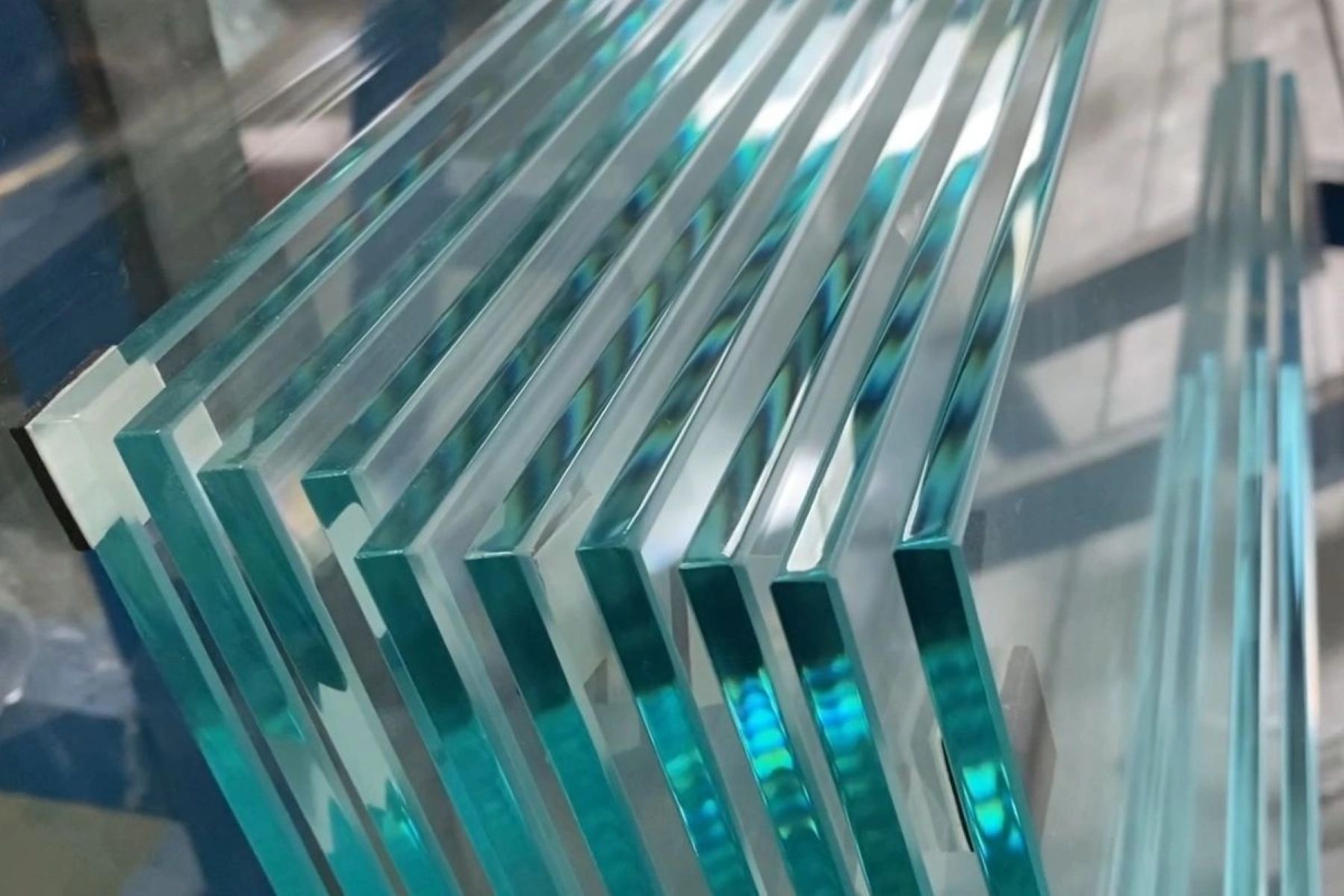

The process of tempering glass involves subjecting it to intense heat followed by rapid cooling, which induces high surface compression and internal tension within the glass. This thermal treatment alters the structural properties of the glass, resulting in increased strength and resilience. As a result, tempered glass exhibits enhanced resistance to mechanical stress, thermal fluctuations, and impact, making it a preferred option for applications where safety and durability are paramount.

One of the key features of tempered glass is its exceptional resistance to breakage. When subjected to significant force, tempered glass is designed to disintegrate into small, granular fragments rather than sharp shards, reducing the likelihood of severe injuries in the event of breakage. This property makes tempered glass an ideal choice for various architectural elements, such as glass doors, partitions, shower enclosures, and balustrades, where safety is a primary concern.

Furthermore, tempered glass offers superior thermal resistance compared to standard glass, making it well-suited for applications exposed to fluctuating temperatures, such as glass tabletops, oven doors, and fireplace screens. Its ability to withstand thermal differentials reduces the risk of thermal breakage, ensuring long-term reliability in diverse environmental conditions.

In addition to its safety and durability benefits, tempered glass also boasts optical clarity and a smooth, scratch-resistant surface, enhancing its aesthetic appeal and practicality in interior design. Its versatility and resilience make tempered glass a popular choice for modern architectural and interior design projects, where it serves as a testament to the seamless integration of safety, functionality, and visual elegance.

In summary, tempered glass represents a remarkable advancement in glass technology, offering enhanced safety, durability, and versatility for a wide range of applications. Its unique properties make it an indispensable material in contemporary design, providing both aesthetic appeal and peace of mind for architects, designers, and homeowners alike.

How is Tempered Glass Made?

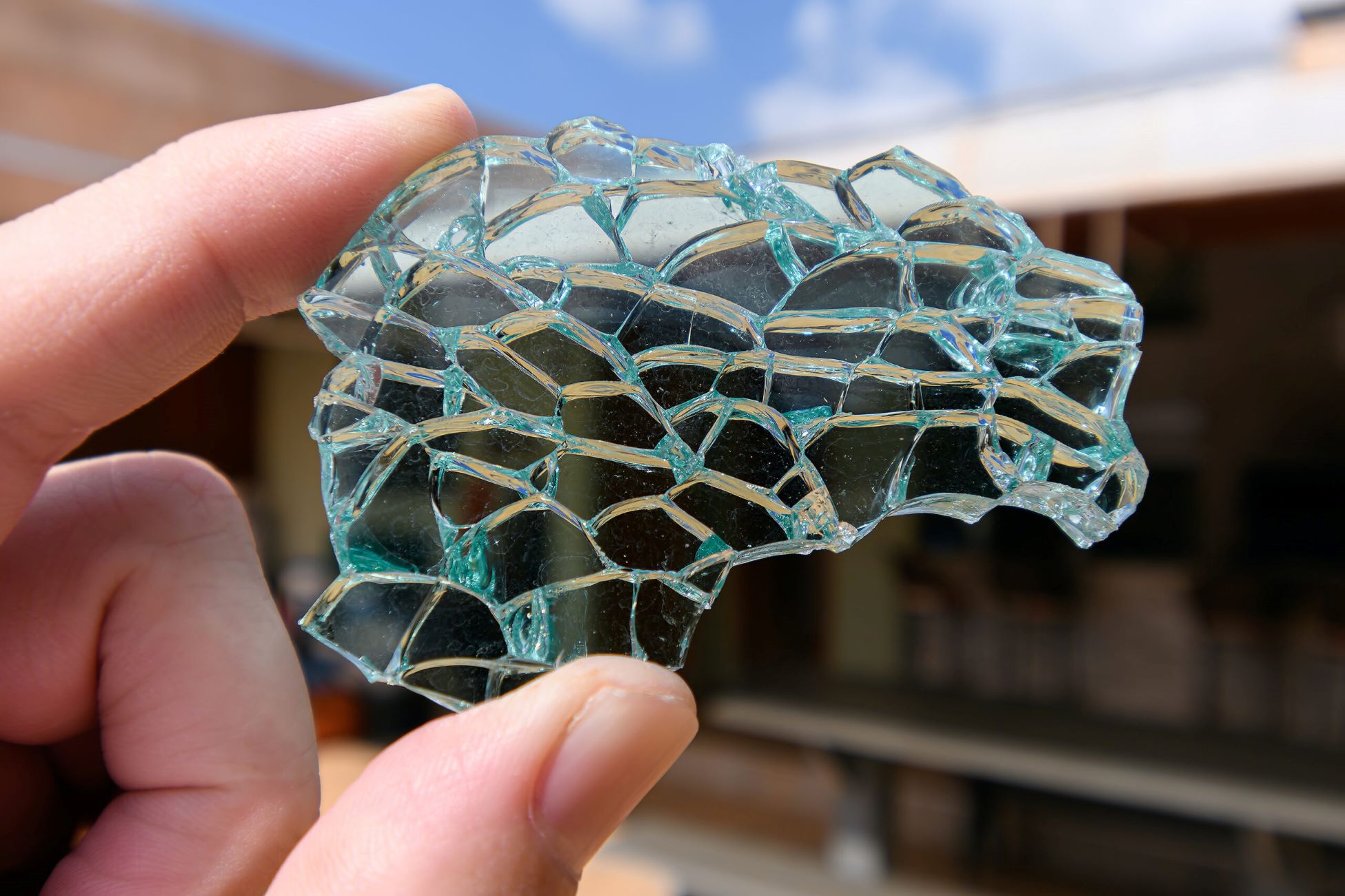

The process of manufacturing tempered glass involves a series of meticulous steps designed to enhance its strength and safety properties. The journey from raw glass to tempered glass involves precision engineering and thermal manipulation to achieve the desired structural integrity and resilience.

-

Selection of Raw Materials: The production of tempered glass begins with the careful selection of high-quality raw materials, typically soda-lime glass with uniform thickness. This initial step lays the foundation for the subsequent stages of the manufacturing process, ensuring the consistency and integrity of the glass composition.

-

Cutting and Shaping: Once the raw glass is sourced, it undergoes precision cutting and shaping to achieve the desired dimensions and configurations for specific applications. Whether destined for architectural glazing, automotive windows, or household fixtures, the glass is tailored to meet the exact specifications of the intended use.

-

Surface Polishing: Following the cutting process, the glass surfaces are meticulously polished to achieve a smooth, pristine finish. This step not only enhances the visual appeal of the glass but also prepares it for the subsequent thermal treatment.

-

Heat Treatment: The defining stage of the tempering process involves subjecting the glass to intense heat in a specialized furnace. The glass is heated to high temperatures, typically exceeding 600 degrees Celsius, to soften its molecular structure and make it pliable for the subsequent rapid cooling phase.

-

Quenching: Once the glass reaches the desired temperature, it undergoes rapid and controlled cooling, often achieved through the use of high-pressure air jets. This rapid cooling induces surface compression and internal tension within the glass, effectively altering its molecular structure and enhancing its strength and resilience.

-

Quality Inspection: After the tempering process, the glass undergoes rigorous quality control measures to ensure compliance with safety standards and structural integrity. Any imperfections or irregularities are meticulously identified and addressed to guarantee the reliability and safety of the tempered glass.

-

Final Verification: Once the tempered glass passes the stringent quality checks, it is ready for distribution and integration into various applications, ranging from architectural glazing to household fixtures. Its enhanced strength, safety features, and optical clarity make tempered glass a preferred choice for a diverse array of design and construction projects.

In summary, the production of tempered glass involves a precise and intricate sequence of steps, culminating in a material renowned for its exceptional strength, safety, and versatility. The careful orchestration of cutting-edge technology and craftsmanship results in tempered glass that not only meets stringent safety standards but also elevates the aesthetic and functional aspects of modern design and architecture.

When tempered glass breaks, it shatters into small, round pieces instead of sharp, jagged shards. This is because the glass is treated with heat and rapid cooling, creating internal tension that causes it to break into safer pieces.

Why Does Tempered Glass Break?

Tempered glass is engineered to withstand a wide array of stresses and impacts, yet it is not impervious to breakage. Understanding the underlying reasons for tempered glass breakage is essential for ensuring its safe and effective use in various applications.

One of the primary factors contributing to tempered glass breakage is the presence of pre-existing defects or damage. During the manufacturing process, microscopic imperfections or stress concentrations may be introduced to the glass, which can compromise its structural integrity over time. These inherent flaws, though not immediately apparent, can serve as potential weak points that make the glass susceptible to breakage under certain conditions.

Furthermore, the installation and handling of tempered glass play a significant role in its susceptibility to breakage. Improper installation, excessive force during handling, or structural misalignment can exert undue stress on the glass, leading to localized pressure points that may exceed its threshold for resilience. Additionally, the use of incompatible hardware or mounting systems can introduce unnecessary strain on the glass, increasing the risk of breakage over time.

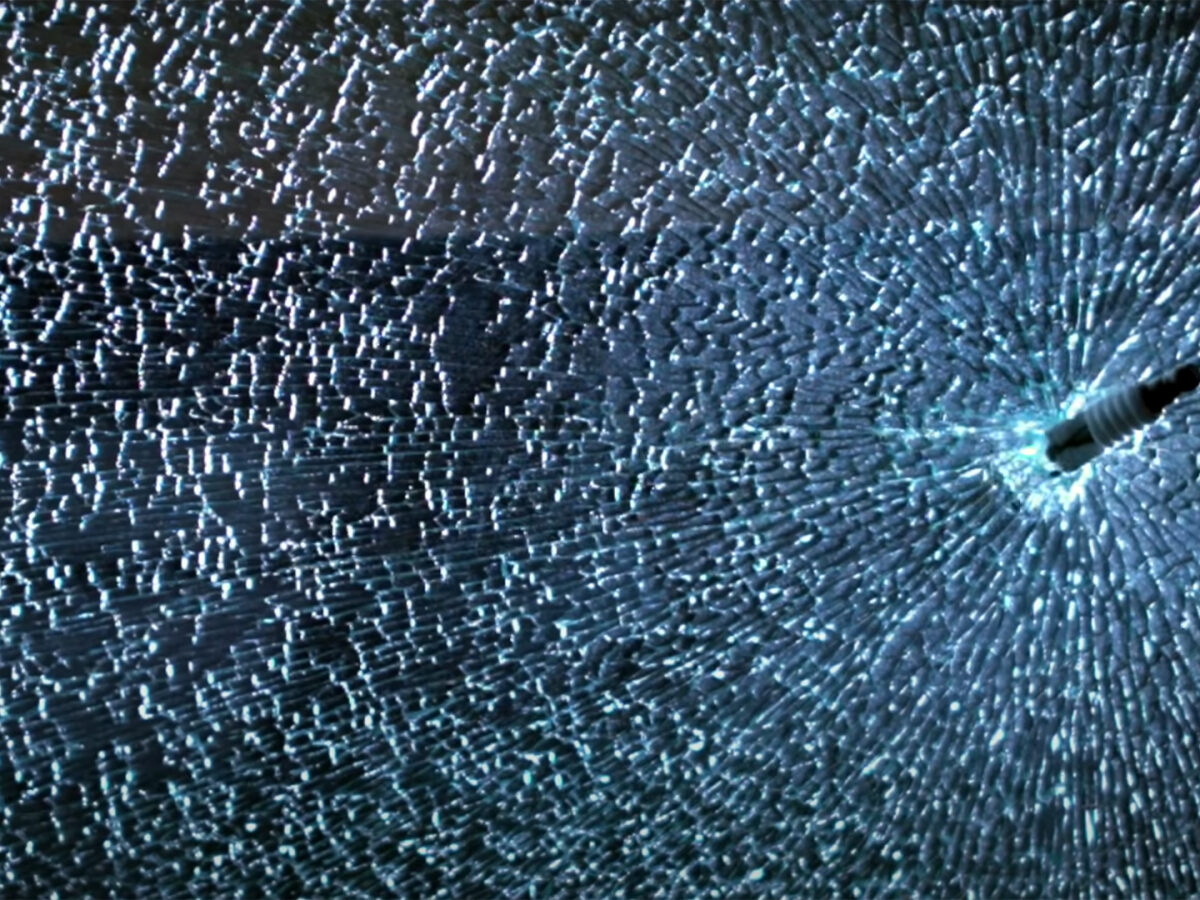

Environmental factors also contribute to the potential breakage of tempered glass. Fluctuations in temperature, particularly rapid and extreme changes, can induce thermal stress on the glass, potentially exceeding its capacity to withstand such differentials. This phenomenon, known as thermal breakage, can manifest as spontaneous fractures or cracks, especially in large expanses of tempered glass exposed to varying environmental conditions.

Moreover, external impacts and blunt force trauma can precipitate the breakage of tempered glass. While tempered glass is designed to fragment into small, relatively harmless pieces upon breakage, severe impacts or repetitive stress can surpass its resilience, causing it to shatter. Whether due to accidental collisions, deliberate vandalism, or natural disasters, such as hailstorms or earthquakes, tempered glass is susceptible to breakage when subjected to significant external forces.

In summary, the breakage of tempered glass can be attributed to a combination of intrinsic flaws, improper handling and installation, environmental stressors, and external impacts. By recognizing these contributing factors, proactive measures can be implemented to mitigate the risks associated with tempered glass breakage, ensuring its longevity and safety in diverse applications.

Common Causes of Tempered Glass Breakage

-

Inherent Flaws: Despite its enhanced strength, tempered glass may harbor microscopic imperfections or stress concentrations introduced during the manufacturing process. These inherent flaws, such as nickel sulfide inclusions or surface damage, can compromise the glass's structural integrity over time, potentially leading to spontaneous breakage.

-

Improper Handling and Installation: The mishandling and improper installation of tempered glass can create localized pressure points, exceeding its threshold for resilience. Excessive force during transportation, incorrect mounting, or the use of incompatible hardware can induce stress on the glass, increasing the likelihood of breakage.

-

Thermal Stress: Rapid and extreme fluctuations in temperature can subject tempered glass to thermal stress, potentially causing it to exceed its capacity to withstand such differentials. This phenomenon, known as thermal breakage, can manifest as spontaneous fractures, particularly in large glass panels exposed to varying environmental conditions.

-

External Impacts: Severe external impacts or blunt force trauma can surpass the resilience of tempered glass, leading to breakage. Accidental collisions, deliberate vandalism, or natural disasters, such as hailstorms or earthquakes, pose significant risks to the structural integrity of tempered glass, especially in high-traffic or vulnerable areas.

-

Edge Damage: The edges of tempered glass are particularly susceptible to breakage if not properly finished or protected. Any nicks, chips, or edge defects can compromise the glass's strength, making it more prone to breakage under stress.

-

Spontaneous Breakage: In rare cases, tempered glass may experience spontaneous breakage without any apparent external cause. This phenomenon, often attributed to the delayed expansion of nickel sulfide inclusions or other internal defects, underscores the unpredictable nature of glass breakage.

Understanding these common causes of tempered glass breakage is essential for implementing preventive measures and maintenance practices to mitigate the risks associated with breakage. By addressing these factors proactively, the longevity and safety of tempered glass installations can be significantly enhanced.

Read more: How To Tell If Glass Is Tempered

Conclusion

In conclusion, tempered glass stands as a testament to the remarkable fusion of safety, durability, and aesthetic appeal in modern design and architecture. Its unique composition and thermal treatment imbue it with exceptional strength and resilience, making it an indispensable material for a diverse array of applications. From sleek glass facades that define contemporary skyscrapers to elegant shower enclosures that adorn residential interiors, tempered glass has redefined the boundaries of safety and sophistication.

The journey from raw glass to tempered glass involves a meticulous process of precision engineering and thermal manipulation, culminating in a material renowned for its enhanced safety features and optical clarity. The careful orchestration of cutting-edge technology and craftsmanship results in tempered glass that not only meets stringent safety standards but also elevates the aesthetic and functional aspects of modern design and architecture.

Despite its robust nature, tempered glass is not immune to breakage. The presence of inherent flaws, improper handling and installation, thermal stress, external impacts, and edge damage can all contribute to the potential breakage of tempered glass. By recognizing these common causes of breakage, proactive measures can be implemented to mitigate the risks associated with tempered glass, ensuring its longevity and safety in diverse applications.

As we navigate the intricacies of tempered glass, it becomes evident that a comprehensive understanding of its properties and vulnerabilities is essential for harnessing its potential while safeguarding against unexpected breakage. By embracing a holistic approach to the selection, installation, and maintenance of tempered glass, architects, designers, and homeowners can leverage its unparalleled benefits while minimizing the inherent risks.

In the ever-evolving landscape of design and construction, tempered glass continues to reign as a symbol of innovation and reliability. Its ability to harmonize safety, functionality, and visual elegance underscores its enduring relevance in shaping the built environment. With a keen awareness of the factors influencing tempered glass breakage and a commitment to best practices, the enduring allure and resilience of tempered glass will continue to enrich architectural and interior design endeavors for generations to come.

Frequently Asked Questions about How Does Tempered Glass Break

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does Tempered Glass Break”