Home>Furniture & Design>Interior Design Trends>How To Temper Glass

Interior Design Trends

How To Temper Glass

Modified: March 2, 2024

Discover the latest interior design trends with our guide on how to temper glass. Enhance your space with this modern and stylish technique.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

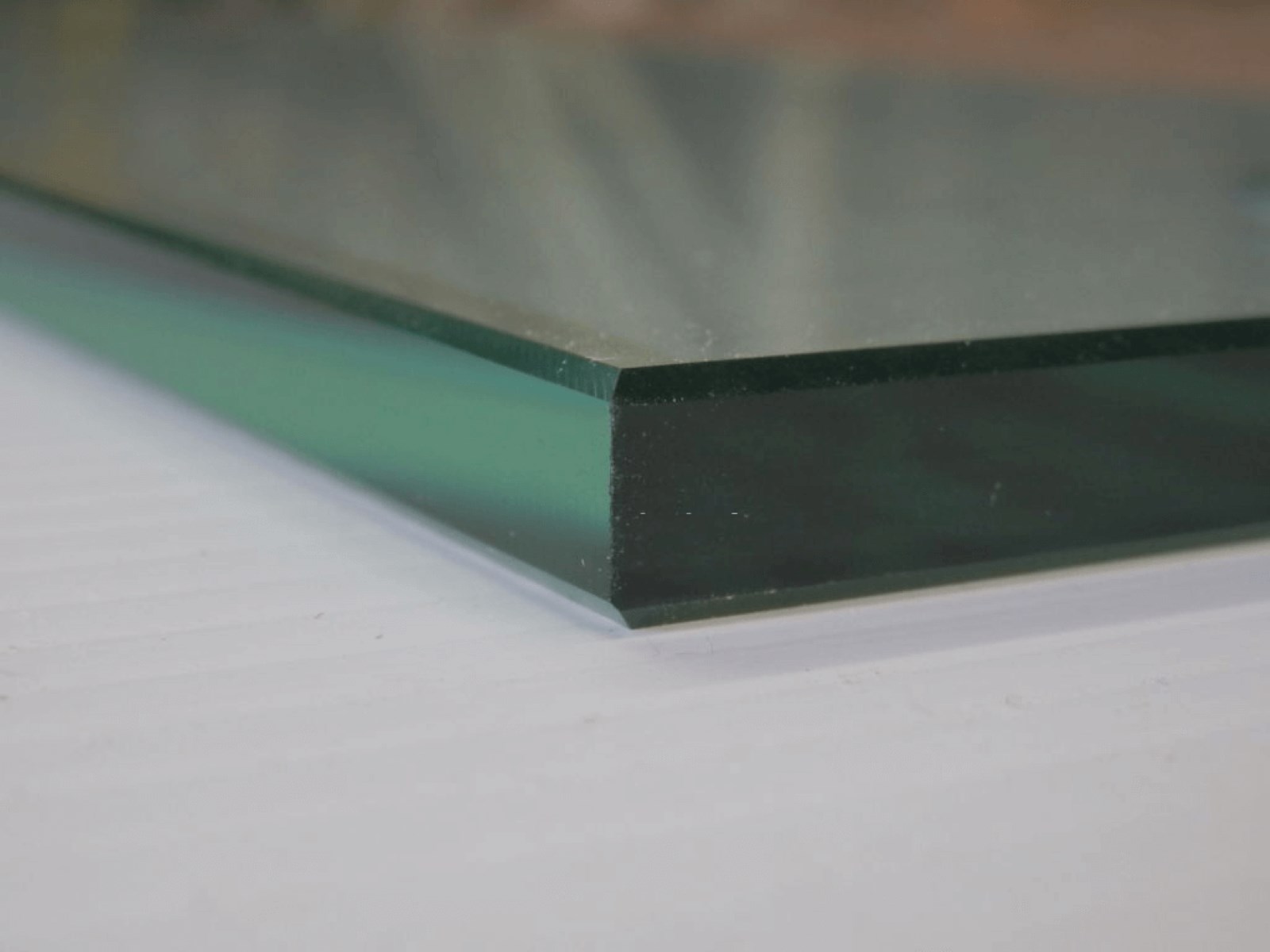

Tempered glass is a versatile material that is widely used in modern architecture and interior design. Its strength and safety features make it a popular choice for various applications, from windows and doors to furniture and shower enclosures. The process of tempering glass involves heating it to high temperatures and then rapidly cooling it, resulting in increased strength and durability. This article will guide you through the process of tempering glass, providing valuable insights and practical tips to help you achieve professional results.

Tempering glass is a fascinating and intricate process that requires precision and attention to detail. By understanding the principles behind glass tempering and following the correct procedures, you can create durable and resilient glass products that meet safety standards and aesthetic requirements. Whether you are a DIY enthusiast or a professional in the field of glasswork, mastering the art of tempering glass can open up a world of creative possibilities.

In the following sections, we will delve into the fundamentals of glass tempering, explore the essential tools and materials needed for the process, and provide a step-by-step guide to help you successfully temper glass. Additionally, we will emphasize the importance of adhering to safety precautions to ensure a secure and risk-free tempering experience. By the end of this article, you will have gained valuable knowledge and practical insights that will empower you to embark on your glass tempering journey with confidence and proficiency.

Key Takeaways:

- Glass tempering involves heating and rapidly cooling glass to make it stronger and safer. It’s important to use the right tools and follow safety precautions for successful results.

- Prioritizing safety and precision is crucial when tempering glass. Understanding the process and using the correct equipment can lead to professional-grade tempered glass for various design and construction projects.

Read more: How To Tell If Glass Is Tempered

Understanding Glass Tempering

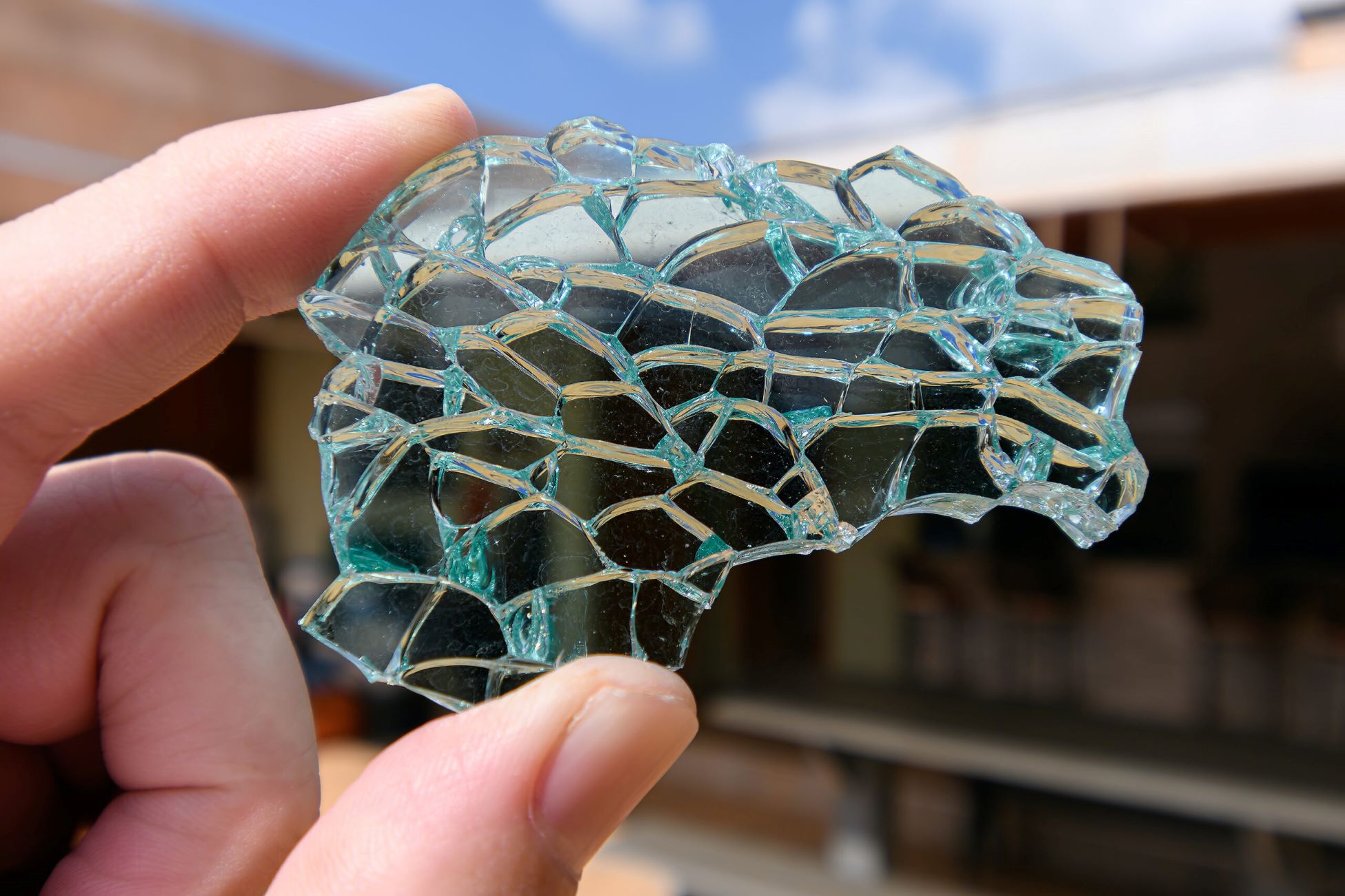

Glass tempering is a specialized process that enhances the strength and safety of glass by subjecting it to controlled heating and rapid cooling. This transformational technique alters the internal structure of the glass, resulting in increased resilience and resistance to impact and thermal stress. The tempered glass produced through this method is significantly stronger than untreated glass and is designed to fracture into small, granular pieces rather than sharp shards, reducing the risk of injury in the event of breakage.

The tempering process involves heating the glass to high temperatures, typically exceeding 600 degrees Celsius, and then rapidly cooling it using high-pressure air jets. This rapid cooling, also known as quenching, induces high surface compression and tensile stress within the glass, creating a balanced state of internal tension. As a result, tempered glass exhibits enhanced mechanical strength, making it suitable for a wide range of applications where safety and durability are paramount.

One of the key characteristics of tempered glass is its resistance to thermal stress. The tempering process creates a state of equilibrium within the glass, enabling it to withstand rapid temperature differentials without compromising its structural integrity. This property makes tempered glass an ideal choice for applications exposed to varying temperature conditions, such as building facades, automotive windows, and household cookware.

In addition to its strength and safety features, tempered glass also offers optical advantages. The tempering process minimizes optical distortion, ensuring that the glass maintains clarity and uniformity, making it suitable for architectural glazing and decorative applications.

Understanding the principles of glass tempering is essential for achieving successful results and harnessing the full potential of tempered glass in various design and construction projects. By comprehending the transformative effects of controlled heating and rapid cooling on glass, individuals can make informed decisions regarding the selection and utilization of tempered glass in their respective endeavors.

As we delve deeper into the process of glass tempering, it is important to recognize the significance of the tools and materials involved in executing this technique effectively. The next section will provide valuable insights into the essential equipment required for tempering glass, setting the stage for a comprehensive understanding of the practical aspects of this intricate process.

Tools and Materials Needed

The successful tempering of glass hinges on the utilization of specialized tools and materials that facilitate precise control over the heating, cooling, and shaping processes. These essential components are instrumental in ensuring the quality and integrity of the tempered glass produced. Here's a comprehensive overview of the tools and materials required for glass tempering:

1. Glass Cutting and Shaping Equipment

- Glass Cutter: A high-quality glass cutter equipped with a sharp cutting wheel is essential for accurately scoring and cutting the glass to the desired dimensions before the tempering process.

- Glass Grinding and Polishing Tools: These tools are utilized to refine the edges and surfaces of the glass, ensuring smoothness and uniformity, which is crucial for the tempering process.

2. Tempering Furnace

- Heating Elements: The tempering furnace is equipped with specialized heating elements capable of reaching and maintaining the high temperatures required for the tempering process.

- Control System: A precise and reliable control system is essential for regulating the temperature and duration of the heating phase, ensuring uniform heating of the glass.

Read more: What Is Tempered Glass

3. Quenching Equipment

- High-Pressure Air Nozzles: These nozzles are utilized to deliver rapid and uniform airflow to the glass surface during the quenching process, facilitating controlled cooling and the induction of surface compression.

- Quenching Chamber: A well-designed quenching chamber is essential for containing the quenching process and maintaining the required pressure and airflow conditions.

4. Inspection Tools

- Polariscope: This tool is used to analyze the stress patterns within the tempered glass, enabling the detection of any irregularities or defects that may compromise its strength and safety.

5. Safety Gear

- Protective Eyewear and Gloves: Given the high temperatures and potential hazards associated with glass tempering, the use of appropriate protective eyewear and heat-resistant gloves is imperative to ensure the safety of the personnel involved in the process.

6. Tempering Glass

- High-Quality Glass: Utilizing premium-quality glass with uniform thickness and minimal imperfections is crucial for achieving consistent and reliable results during the tempering process.

Read more: How To Break Tempered Glass

7. Cleaning and Inspection Materials

- Cleaning Solutions and Cloths: These materials are essential for maintaining the cleanliness of the glass surfaces throughout the tempering process, ensuring optimal results and minimizing the risk of imperfections.

By assembling and utilizing the aforementioned tools and materials with precision and expertise, individuals can embark on the glass tempering process with confidence, knowing that they have the necessary resources to achieve exceptional results. The next section will delve into the step-by-step procedures for tempering glass, providing valuable insights into the intricacies of this transformative technique.

Steps for Tempering Glass

-

Glass Preparation: Begin by selecting high-quality glass with uniform thickness and minimal imperfections. Clean the glass surfaces thoroughly to remove any contaminants or residues that could affect the tempering process.

-

Cutting and Shaping: Use a precision glass cutter to score and cut the glass to the desired dimensions. Ensure that the edges are smooth and free from any defects that could compromise the tempering process.

-

Loading into the Furnace: Carefully place the prepared glass into the tempering furnace, ensuring that it is positioned securely and uniformly. The furnace should be preheated to the specified temperature required for the tempering process.

-

Heating Phase: Initiate the heating phase, allowing the glass to reach the designated temperature within the furnace. The heating elements and control system play a crucial role in ensuring uniform heating and precise temperature regulation.

-

Quenching Process: Once the glass reaches the desired temperature, initiate the rapid cooling process using high-pressure air nozzles. The quenching chamber contains the glass during this phase, facilitating controlled cooling and the induction of surface compression.

-

Stress Analysis: After the quenching process, utilize a polariscope to analyze the stress patterns within the tempered glass. This step is essential for detecting any irregularities or defects that may compromise the strength and safety of the tempered glass.

-

Final Inspection and Cleaning: Thoroughly inspect the tempered glass for any imperfections or residual contaminants. Clean the glass surfaces using appropriate solutions and cloths to ensure optimal clarity and uniformity.

-

Quality Assurance: Conduct rigorous quality checks to verify the strength, resilience, and optical properties of the tempered glass. This step is crucial for ensuring that the tempered glass meets the required safety standards and performance criteria.

By meticulously following these steps and leveraging the essential tools and materials, individuals can achieve professional-grade results in the glass tempering process. It is imperative to approach each step with precision and attention to detail, ensuring that the tempered glass exhibits the desired strength, safety, and visual clarity.

Safety Precautions

Ensuring the safety of personnel and maintaining a secure working environment is paramount when undertaking the glass tempering process. The high temperatures and rapid cooling involved in glass tempering pose potential hazards that necessitate strict adherence to safety protocols. By implementing comprehensive safety precautions, individuals can mitigate risks and safeguard against accidents, promoting a secure and controlled tempering experience.

1. Personal Protective Equipment (PPE)

Prior to commencing the tempering process, all personnel involved must be equipped with appropriate personal protective equipment. This includes heat-resistant gloves, protective eyewear, and suitable attire to shield against potential heat exposure and airborne particles. The use of PPE is essential for minimizing the risk of thermal injuries and ensuring the well-being of individuals working in close proximity to the tempering equipment.

Read more: How Thick Is Tempered Glass

2. Controlled Access and Restricted Zones

Establishing controlled access areas and restricted zones around the tempering equipment is crucial for preventing unauthorized personnel from entering hazardous areas. Clear signage and physical barriers should be employed to demarcate restricted zones, ensuring that only authorized individuals with the requisite training and expertise are permitted to operate or access the tempering machinery.

3. Emergency Response Preparedness

Maintaining a comprehensive emergency response plan is imperative to address unforeseen incidents or equipment malfunctions during the tempering process. All personnel should be well-versed in emergency procedures, including evacuation protocols, first-aid measures, and the operation of emergency shutdown systems. Additionally, the presence of readily accessible firefighting equipment and emergency exits is essential to bolster the preparedness for potential contingencies.

4. Equipment Maintenance and Inspection

Regular maintenance and inspection of the tempering equipment are essential to identify and rectify potential safety hazards. This includes the periodic calibration of heating and cooling systems, inspection of electrical components, and the upkeep of safety interlocks and emergency stop mechanisms. By ensuring the operational integrity of the tempering machinery, the risk of equipment-related incidents can be significantly mitigated.

5. Training and Safety Awareness

Providing comprehensive training and safety awareness programs for personnel involved in the glass tempering process is fundamental to fostering a safety-conscious work culture. Training should encompass the proper handling of tempering equipment, adherence to safety protocols, and the recognition of potential hazards. Heightened safety awareness among personnel contributes to a proactive approach to risk mitigation and promotes a secure working environment.

Read more: Where Is Tempered Glass Required

6. Regulatory Compliance

Adhering to relevant regulatory standards and industry guidelines is non-negotiable when undertaking glass tempering activities. Compliance with safety regulations, building codes, and occupational health standards is essential to ensure that the tempering process aligns with established safety benchmarks and legal requirements. Regular audits and assessments should be conducted to verify compliance and address any identified areas of improvement.

By prioritizing safety precautions and integrating them into the fabric of the glass tempering process, individuals can cultivate a secure and controlled environment conducive to the successful execution of glass tempering activities. The conscientious implementation of safety measures not only safeguards personnel and equipment but also underscores a commitment to excellence and responsibility in the realm of glasswork.

Conclusion

In conclusion, the art of glass tempering represents a harmonious fusion of precision, innovation, and safety. The transformative process of subjecting glass to controlled heating and rapid cooling yields tempered glass with enhanced strength, resilience, and safety features, making it an indispensable material in contemporary design and construction.

By delving into the intricacies of glass tempering, individuals gain a profound understanding of the structural and optical enhancements achieved through this technique. The ability to harness the strength and safety benefits of tempered glass empowers designers, architects, and glasswork enthusiasts to explore new frontiers of creativity and functionality in their projects.

The comprehensive overview of essential tools and materials underscores the significance of equipping oneself with the necessary resources to execute the tempering process with precision and expertise. From glass cutting and shaping equipment to specialized tempering furnaces and quenching apparatus, each component plays a pivotal role in ensuring the quality and integrity of the tempered glass produced.

The step-by-step guide to tempering glass provides a roadmap for individuals to navigate the intricacies of the process with confidence and proficiency. From glass preparation and heating to quenching and stress analysis, each step demands meticulous attention to detail and adherence to best practices, culminating in the creation of professional-grade tempered glass.

Moreover, the emphasis on safety precautions underscores the paramount importance of prioritizing the well-being of personnel and maintaining a secure working environment. By integrating comprehensive safety measures, individuals can mitigate risks and foster a culture of responsibility and vigilance in the realm of glass tempering.

In essence, the journey of glass tempering transcends the realm of craftsmanship, encapsulating a commitment to excellence, innovation, and safety. As individuals embark on their glass tempering endeavors, they are poised to unlock a world of possibilities, where strength, safety, and aesthetic appeal converge to redefine the boundaries of modern design and construction.

The mastery of glass tempering is not merely a technical feat; it is a testament to the ingenuity and dedication of individuals who seek to elevate the standards of craftsmanship and design. With a profound understanding of the principles, tools, and safety considerations associated with glass tempering, individuals are primed to embark on a transformative journey, where the inherent beauty and strength of tempered glass converge to shape the landscapes of innovation and creativity.

Frequently Asked Questions about How To Temper Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Temper Glass”