Home>Furniture & Design>Interior Design Trends>How Do You Cut Tempered Glass

Interior Design Trends

How Do You Cut Tempered Glass

Modified: February 18, 2024

Learn the best techniques for cutting tempered glass and incorporating it into your interior design trends. Find expert tips and advice for working with tempered glass.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Cutting tempered glass can be a daunting task for many DIY enthusiasts and professionals alike. Tempered glass is designed to be stronger and safer than regular glass, but its durability also makes it more challenging to cut. Whether you're working on a home improvement project or need to customize glass for a specific application, understanding the process of cutting tempered glass is essential.

In this comprehensive guide, we will delve into the intricacies of cutting tempered glass, providing you with valuable insights, techniques, and safety precautions to ensure a successful outcome. From understanding the unique properties of tempered glass to the tools and materials needed, we will equip you with the knowledge and confidence to tackle this task effectively. So, let's embark on this journey to unravel the art of cutting tempered glass with precision and finesse.

Key Takeaways:

- Cutting tempered glass requires precision and the right tools. Understanding its unique properties and following safety precautions are crucial for successful and safe cutting.

- Prioritize safety, patience, and attention to detail when cutting tempered glass. Mastering this skill opens up creative possibilities for customizing glass in various applications.

Read more: How Can You Tell If Glass Is Tempered

Understanding Tempered Glass

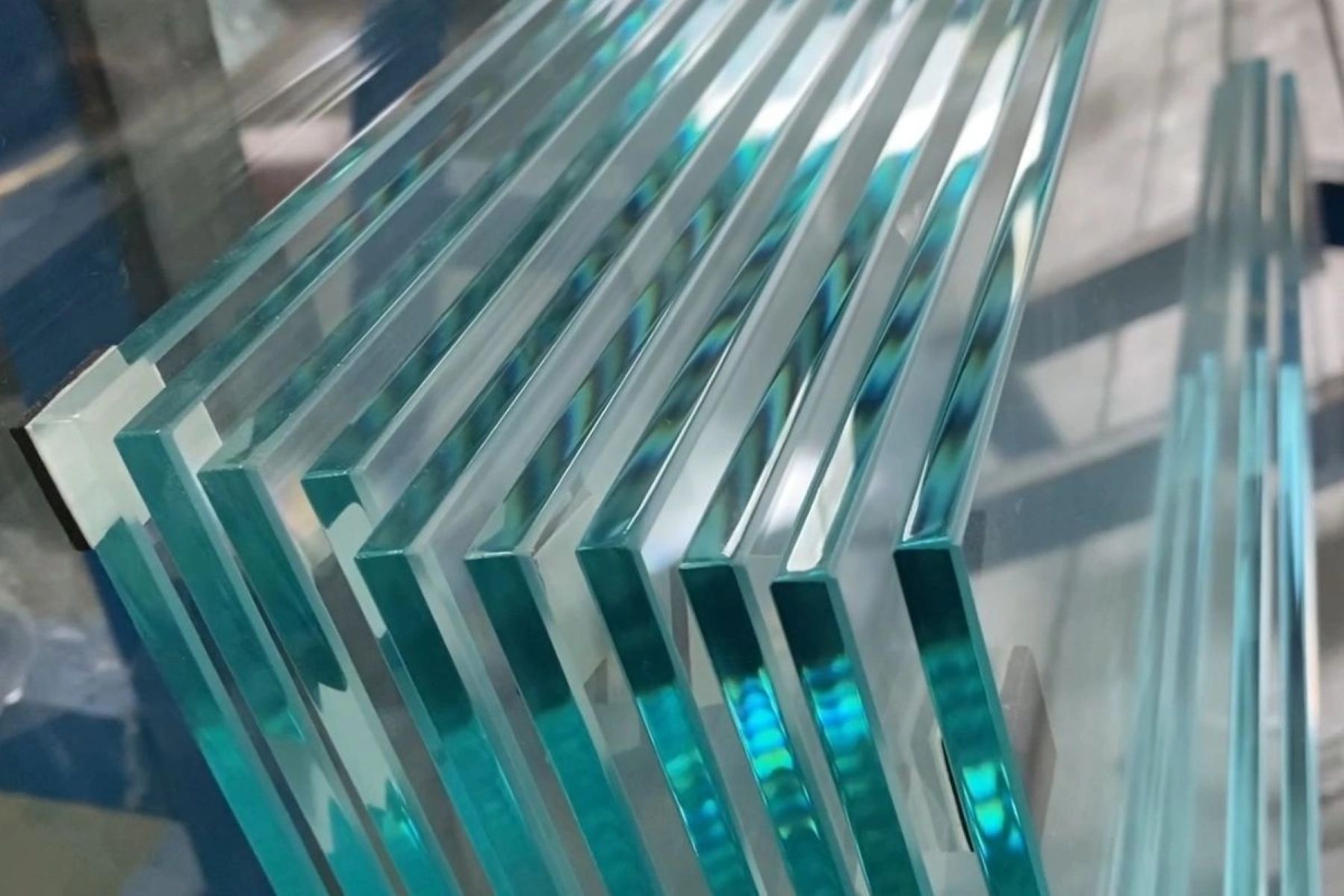

Tempered glass, also known as toughened glass, is a type of safety glass that is processed through thermal or chemical treatments to enhance its strength and durability. Unlike regular glass, tempered glass undergoes a controlled heating and rapid cooling process, which results in increased tensile strength and resistance to impact. This unique manufacturing process also influences the way tempered glass behaves when subjected to external forces.

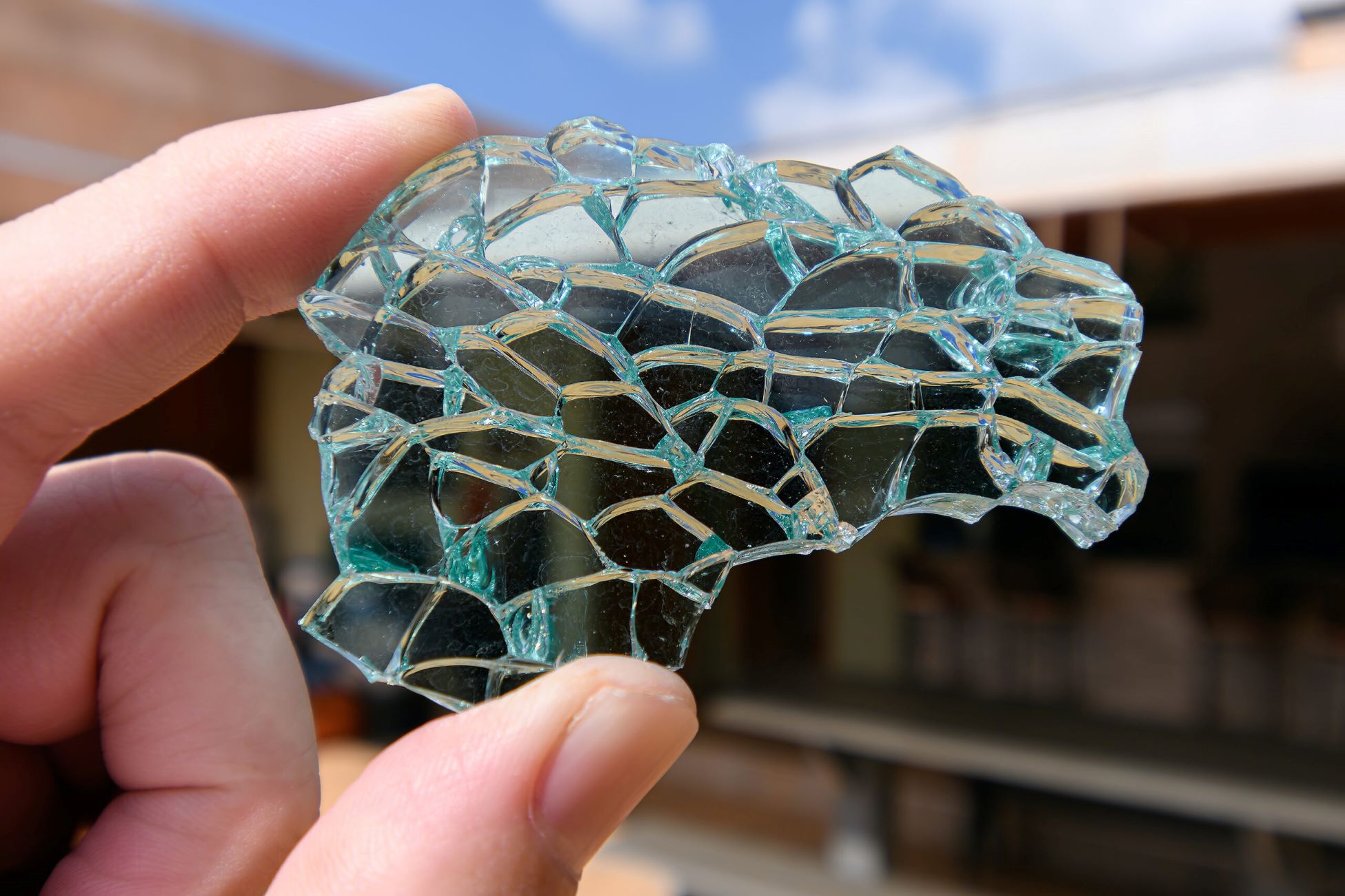

One of the key characteristics of tempered glass is its ability to shatter into small, granular pieces when broken, as opposed to sharp, jagged shards typical of regular glass. This property significantly reduces the risk of injury in the event of breakage, making tempered glass a preferred choice for various applications where safety is paramount.

In addition to its safety features, tempered glass exhibits exceptional resistance to thermal stress, making it suitable for use in environments with fluctuating temperatures. This makes it an ideal choice for applications such as shower enclosures, glass doors, tabletops, and automotive windows.

The strength and safety benefits of tempered glass stem from its internal structure. The glass is subjected to compressive stresses on its surface and tensile stresses within its core, resulting in a balanced and robust composition. This structural integrity allows tempered glass to withstand higher impact and bending forces compared to untreated glass.

It is important to note that once tempered glass is cut to size and undergoes the tempering process, it cannot be further altered. Any attempt to cut or drill the glass after tempering will result in the glass shattering into small pieces. Therefore, precise measurements and accurate cutting prior to the tempering process are crucial.

Understanding the unique properties and limitations of tempered glass is essential when embarking on any project involving this specialized material. By grasping the intricacies of tempered glass, you can approach the cutting process with the necessary knowledge and caution, ensuring a successful outcome while prioritizing safety and precision.

Tools and Materials Needed

When it comes to cutting tempered glass, having the right tools and materials is crucial for achieving precise and safe results. Here's a comprehensive list of the essential items you'll need to effectively cut tempered glass:

Tools:

-

Glass Cutter: A high-quality glass cutter with a diamond or carbide wheel is essential for scoring the glass accurately. Look for a cutter specifically designed for cutting tempered glass to ensure optimal performance.

-

Straight Edge: A sturdy straight edge, such as a metal ruler or T-square, is necessary to guide the glass cutter along straight lines. Ensure that the straight edge is longer than the glass to facilitate smooth and precise cuts.

-

Cutting Oil: Using cutting oil or glass lubricant helps reduce friction and heat during the cutting process, resulting in cleaner scores and minimizing the risk of glass breakage.

-

Pliers: A pair of running pliers or grozing pliers is essential for breaking the scored glass along the cut lines. These specialized pliers provide leverage and control to snap the glass accurately.

-

Safety Glasses and Gloves: Prioritize safety by wearing protective glasses and gloves to shield your eyes and hands from glass shards and potential injuries during the cutting and breaking process.

-

Marker or Grease Pencil: Marking the glass with a marker or grease pencil allows for clear and precise guidelines for scoring and cutting.

-

Work Surface: A flat and stable work surface, such as a workbench or table, provides a secure area for cutting and handling the glass.

Materials:

-

Tempered Glass: The glass piece to be cut should be tempered and free from any defects or damage. Ensure that the glass is clean and free of debris before initiating the cutting process.

-

Protective Film (Optional): If the tempered glass has a protective film, ensure it is intact and remove it only when ready to cut the glass.

-

Lint-Free Cloth: Use a lint-free cloth to clean the glass surface and remove any dust or particles before cutting.

-

Cardboard or Carpet: Placing a soft material, such as cardboard or carpet, on the work surface provides cushioning and prevents the glass from being scratched or damaged during handling.

By assembling these essential tools and materials, you'll be well-equipped to tackle the task of cutting tempered glass with confidence and precision. Prioritize safety at every step of the process and ensure that your work area is organized and conducive to handling glass effectively. With the right tools and materials at your disposal, you're ready to embark on the journey of cutting tempered glass with finesse and skill.

Read more: How Do You Cut Glass Bottles

Steps to Cut Tempered Glass

Cutting tempered glass requires precision, patience, and adherence to specific steps to ensure a successful outcome. Here's a detailed guide outlining the essential steps to cut tempered glass effectively:

-

Prepare the Work Area: Begin by setting up a clean and organized work area. Lay a soft material, such as cardboard or carpet, on the work surface to provide cushioning and prevent the glass from being scratched or damaged during handling.

-

Measure and Mark: Use a marker or grease pencil to mark the glass with precise guidelines for the intended cuts. Double-check the measurements to ensure accuracy before proceeding to the next step.

-

Score the Glass: With the glass cutter and a straight edge, carefully score the glass along the marked lines. Apply consistent pressure while running the cutter along the straight edge to create a clean and deep score on the surface of the glass. It's essential to score the glass in one continuous motion to achieve a uniform and precise cut.

-

Apply Cutting Oil: Apply cutting oil or glass lubricant along the scored lines to reduce friction and heat during the cutting process. This helps facilitate a smoother separation of the glass along the scored lines and minimizes the risk of breakage.

-

Use Running Pliers: Once the glass is scored and lubricated, use running pliers or grozing pliers to break the glass along the scored lines. Position the pliers at one end of the scored line and apply gentle pressure to snap the glass along the score. Repeat this process along the entire length of the scored line until the glass separates cleanly.

-

Inspect the Cut: After breaking the glass along the scored lines, carefully inspect the cut edges to ensure a clean and precise separation. Any rough or jagged edges can be smoothed using a fine-grit sandpaper or a glass file to achieve a polished finish.

-

Clean the Glass: Thoroughly clean the cut glass using a lint-free cloth to remove any debris or particles resulting from the cutting process. Ensure that the glass is free from any residues or contaminants before proceeding with its intended use.

By following these meticulous steps and exercising caution throughout the cutting process, you can effectively cut tempered glass with precision and confidence. It's important to prioritize safety by wearing protective gear and handling the glass with care at every stage. With practice and attention to detail, mastering the art of cutting tempered glass can open up a world of possibilities for customizing glass for various applications.

When cutting tempered glass, use a glass cutter with a carbide wheel and a straight edge to score the glass. Then, carefully apply pressure to the scored line to break the glass. Always wear safety goggles and gloves.

Safety Precautions

When working with tempered glass, prioritizing safety is paramount to prevent accidents and injuries. The inherent strength and unique properties of tempered glass necessitate careful handling and adherence to specific safety precautions throughout the cutting process. Here are essential safety measures to consider when cutting tempered glass:

-

Protective Gear: Before initiating the cutting process, ensure that you are equipped with the necessary protective gear. Wear safety glasses to shield your eyes from glass shards and debris. Additionally, use gloves to safeguard your hands from potential cuts and injuries during handling.

-

Stable Work Surface: Work on a stable and flat surface to minimize the risk of accidental slips or falls. A sturdy workbench or table provides a secure area for cutting and handling the glass, reducing the likelihood of mishaps.

-

Proper Tools and Equipment: Use high-quality and appropriate tools for cutting tempered glass. Ensure that the glass cutter, straight edge, and pliers are in good condition and suitable for the task at hand. Using the right tools enhances precision and minimizes the potential for accidents.

-

Caution During Cutting: Exercise caution and focus when scoring and breaking the glass. Apply consistent pressure while scoring the glass to create clean and deep cuts. When using running pliers to break the glass, apply gentle and controlled pressure to snap the glass along the scored lines.

-

Handling Glass Safely: Handle the glass with care to avoid accidental breakage or injuries. Avoid placing unnecessary pressure on the glass, and be mindful of its fragility, especially after scoring. Additionally, be cautious when transporting and maneuvering the cut glass to prevent accidental cuts or damage.

-

Clean Work Area: Keep the work area clean and organized to minimize potential hazards. Remove any unnecessary items from the work surface to create a clutter-free environment. This reduces the risk of accidents and allows for better focus during the cutting process.

-

Disposal of Glass Debris: Properly dispose of glass debris and waste generated during the cutting process. Use a designated container for collecting glass shards and dispose of them safely to prevent injuries from sharp fragments.

By adhering to these safety precautions, you can create a secure and controlled environment for cutting tempered glass. Prioritizing safety at every step of the process ensures a smooth and accident-free experience, allowing you to achieve precise and clean cuts while safeguarding your well-being and that of others in the vicinity.

Conclusion

In conclusion, mastering the art of cutting tempered glass requires a blend of precision, patience, and a deep understanding of the unique properties of this specialized material. By delving into the intricacies of tempered glass and equipping yourself with the essential tools, materials, and safety precautions, you can embark on the journey of cutting tempered glass with confidence and finesse.

Throughout this comprehensive guide, we've explored the distinctive characteristics of tempered glass, including its enhanced strength, safety features, and resistance to thermal stress. Understanding these attributes is fundamental to approaching the cutting process with the necessary knowledge and caution, ensuring that each cut is executed with precision and safety in mind.

The detailed steps outlined for cutting tempered glass provide a systematic approach to achieving clean and accurate cuts. From preparing the work area and measuring the glass to scoring, breaking, and inspecting the cut, each step is crucial for maintaining control and achieving the desired results. Additionally, the emphasis on safety precautions underscores the importance of prioritizing personal well-being and creating a secure environment for working with tempered glass.

As you venture into the realm of cutting tempered glass, remember that practice and attention to detail are key to honing your skills. Each successful cut brings you closer to mastering this craft, opening up a world of possibilities for customizing glass for various applications, be it in home improvement projects, artistic endeavors, or professional installations.

Ultimately, the ability to cut tempered glass with precision and confidence empowers you to unleash your creativity and bring your vision to life. Whether you're crafting custom glass panels, designing intricate glass art, or undertaking practical installations, the knowledge and skills acquired from this guide serve as a solid foundation for your endeavors.

With a firm grasp of the techniques and safety measures involved in cutting tempered glass, you are well-equipped to embark on future projects with a heightened sense of proficiency and assurance. Embrace the art of cutting tempered glass as a journey of exploration and mastery, and let your creativity flourish as you transform tempered glass into bespoke creations that captivate and inspire.

In the realm of interior design and beyond, the ability to work with tempered glass opens doors to endless possibilities, allowing you to infuse spaces with elegance, functionality, and a touch of artistic flair. As you continue to refine your craft, may each cut be a testament to your dedication and expertise, shaping tempered glass into exquisite manifestations of creativity and ingenuity.

Frequently Asked Questions about How Do You Cut Tempered Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Do You Cut Tempered Glass”