Home>Furniture & Design>Interior Design Trends>What Can Break Bulletproof Glass

Interior Design Trends

What Can Break Bulletproof Glass

Published: February 3, 2024

Discover the latest interior design trends and learn what can break bulletproof glass. Stay updated with the latest trends in interior design.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

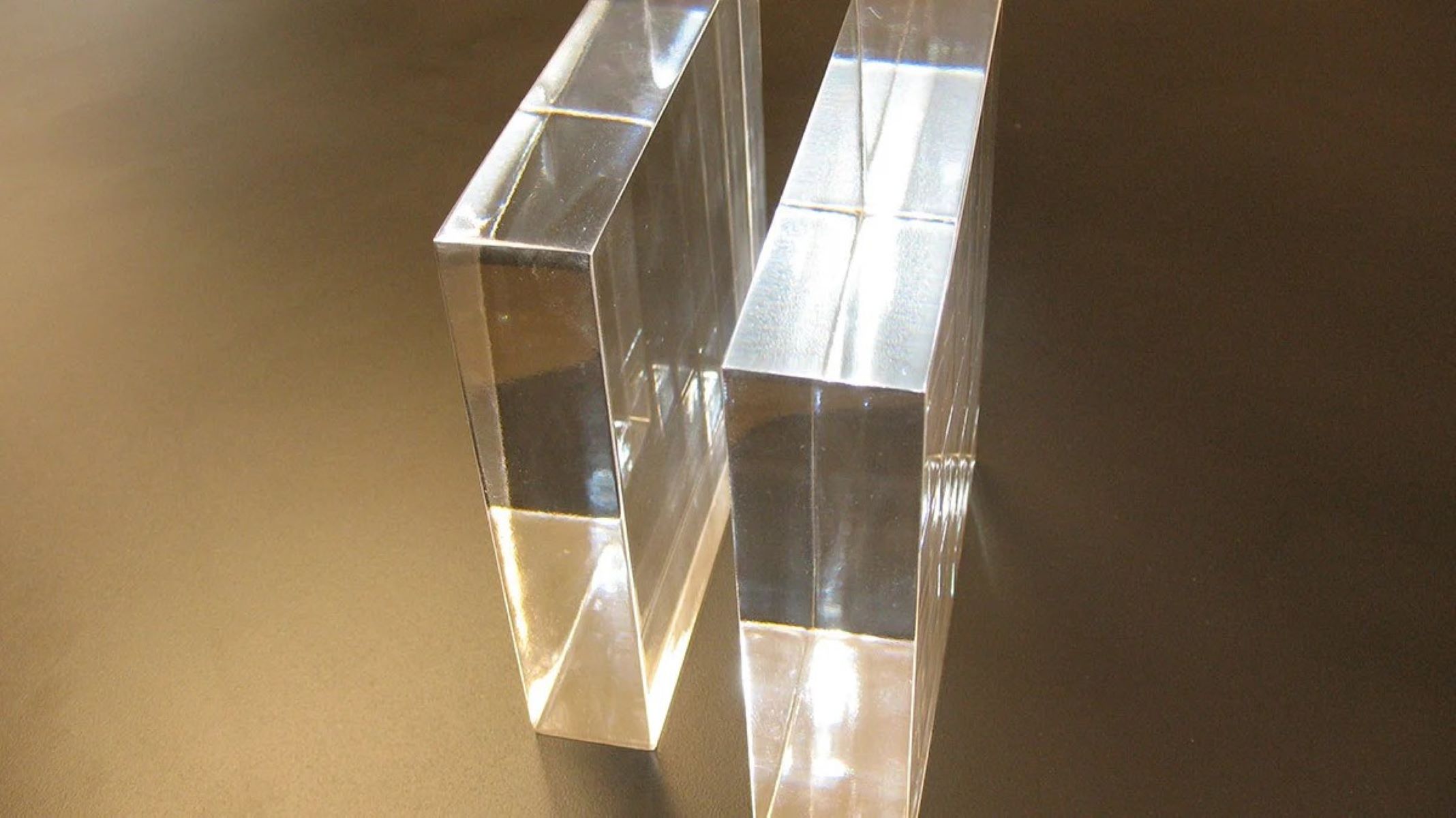

Bulletproof glass, also known as ballistic glass, transparent armor, or bullet-resistant glass, is a specialized type of glass designed to withstand various forms of impact and penetration. It is a critical component in the construction of secure facilities, including banks, government buildings, armored vehicles, and high-security installations. The development of bulletproof glass has been a significant advancement in security technology, providing protection against firearms, explosives, and other potential threats.

The creation of bulletproof glass involves a complex process that enhances the strength and resilience of traditional glass. By incorporating multiple layers of glass and synthetic materials, such as polycarbonate, into a laminated structure, manufacturers are able to produce a transparent barrier capable of withstanding high-velocity projectiles and physical force. This innovative approach has revolutionized the security industry, offering a reliable defense against armed attacks and criminal activities.

Bulletproof glass is not only a practical security solution but also a testament to human ingenuity and engineering prowess. Its ability to provide protection without sacrificing visibility has made it an indispensable asset in safeguarding valuable assets and ensuring the safety of individuals in high-risk environments. As technology continues to advance, the development of even more resilient and versatile forms of bulletproof glass is on the horizon, promising enhanced security measures for a wide range of applications.

In the following sections, we will delve into the various factors that can compromise the integrity of bulletproof glass, shedding light on the vulnerabilities that may arise in different scenarios. Understanding these potential weaknesses is crucial for maintaining the effectiveness of bulletproof glass and ensuring that security measures remain robust and reliable. Let's explore the forces and elements that can challenge the resilience of bulletproof glass, from physical impact to environmental stressors and manufacturing imperfections.

Key Takeaways:

- Bulletproof glass can be compromised by physical force, thermal stress, corrosive chemicals, manufacturing defects, and high-velocity projectiles, highlighting the need for comprehensive maintenance and proactive measures to ensure its resilience.

- Understanding the vulnerabilities of bulletproof glass to various forces and elements is crucial for maintaining its effectiveness and reliability in safeguarding valuable assets and individuals in high-risk environments.

Read more: What Breaks Bulletproof Glass

Physical Force

Physical force, in the form of blunt impact or pressure, can pose a significant threat to the integrity of bulletproof glass. While this specialized glass is engineered to withstand high-velocity projectiles and explosive forces, it is not impervious to the effects of sustained or concentrated physical pressure. The impact of heavy objects or the application of force over a prolonged period can gradually weaken the structural integrity of bulletproof glass, potentially leading to compromised security measures.

One of the primary concerns related to physical force is the potential for structural deformation. When subjected to intense pressure or impact, bulletproof glass may exhibit signs of bending, warping, or even cracking, which can undermine its ability to provide reliable protection. This vulnerability highlights the importance of maintaining a safe distance from bulletproof glass and avoiding any activities that could exert excessive force on its surface.

Furthermore, physical force can also manifest in the form of deliberate attempts to breach the glass using tools or implements. While bulletproof glass is designed to resist penetration from firearms and explosives, determined individuals may resort to using heavy-duty tools or machinery to exploit potential weaknesses in the glass. This underscores the need for comprehensive security protocols and surveillance measures to deter and respond to any attempts at forced entry.

In addition to external physical force, internal pressure differentials can also impact the performance of bulletproof glass. Fluctuations in temperature and air pressure can exert stress on the glass, potentially leading to microfractures or structural instability over time. It is essential to consider these environmental factors when implementing bulletproof glass in diverse settings, such as high-altitude locations or areas prone to extreme weather conditions.

To mitigate the risks associated with physical force, regular inspections and maintenance of bulletproof glass installations are crucial. By identifying any signs of wear, damage, or structural compromise, proactive measures can be taken to reinforce the glass and address any vulnerabilities. Additionally, educating individuals on the proper handling and care of bulletproof glass can contribute to its long-term effectiveness and resilience against physical force.

Ultimately, understanding the potential impact of physical force on bulletproof glass is essential for enhancing security protocols and ensuring the continued protection of valuable assets and individuals in high-risk environments. By addressing these concerns and implementing proactive measures, the reliability and effectiveness of bulletproof glass can be upheld, bolstering security measures and providing peace of mind in the face of potential threats.

Thermal Stress

Thermal stress poses a significant risk to the structural integrity of bulletproof glass, potentially compromising its ability to provide reliable protection in high-risk environments. This form of stress arises from fluctuations in temperature, which can exert immense pressure on the glass, leading to potential weaknesses and vulnerabilities.

The impact of thermal stress on bulletproof glass is multifaceted, encompassing both immediate and long-term effects. When exposed to rapid temperature changes, such as those experienced during fire incidents or extreme environmental conditions, bulletproof glass may undergo thermal expansion or contraction. These fluctuations can induce strain within the glass, potentially resulting in microfractures or surface imperfections that weaken its overall resilience.

Furthermore, the composition of bulletproof glass, typically consisting of multiple layers of glass and synthetic materials, makes it susceptible to differential expansion and contraction. Variations in temperature across different layers can create internal stress points, increasing the risk of structural compromise over time. This phenomenon underscores the need for meticulous design and manufacturing processes to minimize the impact of thermal stress on bulletproof glass.

In addition to direct exposure to extreme temperatures, the surrounding environment can also contribute to thermal stress. For instance, the positioning of bulletproof glass in areas exposed to direct sunlight or intense heat sources can exacerbate thermal stress, potentially accelerating the degradation of the glass's protective properties. Similarly, sudden temperature differentials caused by environmental factors can subject the glass to rapid and uneven thermal expansion, heightening the risk of structural instability.

To mitigate the risks associated with thermal stress, comprehensive design considerations and material selection are paramount. Manufacturers of bulletproof glass must carefully evaluate the thermal properties of the materials used and implement measures to minimize the impact of temperature differentials on the glass's structural integrity. Additionally, proper installation and positioning of bulletproof glass in a controlled environment can help mitigate the effects of thermal stress, ensuring that its protective capabilities remain uncompromised.

Regular assessments and maintenance of bulletproof glass installations are essential for identifying any signs of thermal stress-induced damage. By proactively addressing potential vulnerabilities and reinforcing the glass as needed, the long-term effectiveness and reliability of bulletproof glass can be upheld, bolstering security measures and providing peace of mind in the face of potential threats.

In summary, the impact of thermal stress on bulletproof glass underscores the importance of comprehensive design, meticulous manufacturing processes, and proactive maintenance to ensure its resilience in high-risk environments. By addressing the challenges posed by thermal stress, the security industry can continue to rely on bulletproof glass as a critical component in safeguarding valuable assets and individuals against potential threats.

When dealing with bulletproof glass, it’s important to remember that extreme force or impact can cause it to break. This can include high-powered firearms, explosives, or heavy objects being thrown at the glass. Regular maintenance and inspection is also crucial to ensure the glass remains in top condition.

Corrosive Chemicals

Corrosive chemicals pose a significant threat to the structural integrity and protective capabilities of bulletproof glass, presenting a unique set of challenges in high-risk environments. The corrosive nature of certain chemicals can compromise the composition of bulletproof glass, potentially leading to degradation and weakening of its defensive properties.

One of the primary concerns related to corrosive chemicals is their ability to initiate chemical reactions that can erode the surface of the glass. This erosion may manifest in the form of pitting, etching, or discoloration, all of which can diminish the transparency and structural strength of the glass. Additionally, prolonged exposure to corrosive chemicals can lead to the formation of microfractures or surface irregularities, further undermining the glass's ability to withstand impact and penetration.

The impact of corrosive chemicals on bulletproof glass extends beyond surface damage, as it can also compromise the interlayer materials that contribute to the glass's ballistic resistance. The synthetic materials, such as polycarbonate, used in the construction of bulletproof glass are susceptible to chemical degradation when exposed to corrosive substances. This degradation can weaken the bonding between glass layers and diminish the overall structural integrity of the glass, potentially rendering it less effective in providing protection against ballistic threats.

Furthermore, the presence of corrosive chemicals in the surrounding environment can accelerate the deterioration of bulletproof glass, especially in industrial or chemical processing facilities where such substances are prevalent. The combination of direct contact with corrosive chemicals and the potential for chemical fumes or vapors to permeate the glass can exacerbate the degradation process, posing a significant risk to the long-term effectiveness of the glass as a protective barrier.

Mitigating the risks associated with corrosive chemicals requires a multifaceted approach that encompasses material selection, environmental controls, and proactive maintenance. Manufacturers of bulletproof glass must carefully evaluate the chemical resistance of the materials used in its construction, ensuring that they can withstand exposure to corrosive substances without compromising their structural integrity.

Additionally, the implementation of stringent environmental controls and protective measures can help minimize the risk of exposure to corrosive chemicals, thereby preserving the effectiveness of bulletproof glass in high-risk environments. Regular inspections and maintenance protocols are essential for identifying any signs of chemical damage and taking proactive measures to reinforce the glass as needed, ensuring that its protective capabilities remain uncompromised.

In summary, the impact of corrosive chemicals on bulletproof glass underscores the need for comprehensive measures to mitigate the risks associated with chemical exposure. By addressing these challenges, the security industry can continue to rely on bulletproof glass as a critical component in safeguarding valuable assets and individuals against potential threats.

Manufacturing Defects

Manufacturing defects in bulletproof glass can significantly compromise its structural integrity and ballistic resistance, posing a substantial risk to its effectiveness in high-risk environments. These defects can manifest in various forms, ranging from inconsistencies in material composition to flaws in the lamination process, ultimately undermining the glass's ability to withstand impact and penetration.

One of the primary concerns related to manufacturing defects is the potential for air pockets or delamination within the glass layers. These imperfections can create weak points in the glass, reducing its overall strength and resilience. Additionally, variations in material thickness or density, resulting from manufacturing errors, can lead to uneven distribution of impact forces, further exacerbating the glass's vulnerability to ballistic threats.

Furthermore, inadequate bonding between glass layers or between glass and interlayer materials can compromise the cohesive integrity of bulletproof glass. This lack of bonding can result from suboptimal manufacturing processes or the use of inferior adhesives, diminishing the glass's ability to effectively absorb and dissipate the energy from ballistic impacts.

In addition to structural defects, inconsistencies in the optical clarity of bulletproof glass can also arise from manufacturing imperfections. Irregularities in the glass's transparency can not only compromise its aesthetic appeal but also indicate potential weaknesses in its composition, warranting thorough inspection and assessment.

Mitigating the risks associated with manufacturing defects requires stringent quality control measures throughout the production process. Manufacturers of bulletproof glass must adhere to precise specifications and standards, ensuring uniform material composition, proper lamination, and robust bonding between glass layers and interlayer materials. Additionally, comprehensive testing protocols are essential for identifying any manufacturing defects and verifying the glass's ballistic resistance before it is deployed in high-risk environments.

Regular inspections and quality assurance audits are crucial for detecting any signs of manufacturing defects in existing bulletproof glass installations. By proactively addressing these issues and reinforcing the glass as needed, the long-term effectiveness and reliability of bulletproof glass can be upheld, bolstering security measures and providing peace of mind in the face of potential threats.

In summary, the impact of manufacturing defects on bulletproof glass underscores the critical importance of stringent quality control measures and comprehensive testing protocols to ensure its resilience in high-risk environments. By addressing these challenges, the security industry can continue to rely on bulletproof glass as a critical component in safeguarding valuable assets and individuals against potential threats.

Read more: How To Break Bulletproof Glass

High Velocity Projectiles

High-velocity projectiles pose a formidable threat to the integrity of bulletproof glass, presenting a significant challenge in maintaining effective security measures in high-risk environments. The impact of projectiles, propelled at extreme speeds, can exert immense force on bulletproof glass, potentially compromising its ability to provide reliable protection against ballistic threats.

One of the primary concerns related to high-velocity projectiles is their capacity to induce structural deformation and penetration in bulletproof glass. When subjected to the impact of high-velocity projectiles, the glass may exhibit signs of localized stress, deformation, or, in severe cases, penetration. This vulnerability underscores the need for bulletproof glass to withstand the kinetic energy of projectiles without compromising its structural integrity.

Furthermore, the ability of bulletproof glass to effectively dissipate the energy from high-velocity projectiles is crucial in mitigating the risk of penetration. The design and composition of bulletproof glass must be optimized to absorb and distribute the kinetic energy of projectiles, minimizing the potential for structural compromise. This necessitates meticulous material selection and lamination processes to enhance the glass's ability to withstand ballistic impacts.

In addition to direct impact, the fragmentation and spalling of bulletproof glass resulting from high-velocity projectiles can pose secondary threats to individuals and assets in the vicinity. The dispersion of glass fragments and debris can create hazardous conditions, potentially causing injuries and collateral damage. Mitigating these risks requires comprehensive design considerations and material enhancements to minimize the fragmentation and spalling effects of bulletproof glass when subjected to high-velocity projectiles.

To address the challenges posed by high-velocity projectiles, rigorous testing and certification processes are essential to validate the ballistic resistance of bulletproof glass. Manufacturers must adhere to stringent standards and specifications, ensuring that the glass can withstand the impact of high-velocity projectiles without compromising its protective capabilities. Additionally, ongoing research and development efforts are crucial for advancing the resilience and effectiveness of bulletproof glass in the face of evolving ballistic threats.

In summary, the impact of high-velocity projectiles on bulletproof glass underscores the critical importance of comprehensive design, material optimization, and rigorous testing to ensure its resilience in high-risk environments. By addressing these challenges, the security industry can continue to rely on bulletproof glass as a critical component in safeguarding valuable assets and individuals against potential ballistic threats.

Frequently Asked Questions about What Can Break Bulletproof Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Can Break Bulletproof Glass”