Home>Furniture & Design>Interior Design Trends>What Is The Density Of Glass

Interior Design Trends

What Is The Density Of Glass

Modified: October 18, 2024

Discover the density of glass and its impact on interior design trends. Learn how glass density influences modern design concepts and applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Glass is a versatile and ubiquitous material that has been an integral part of human civilization for centuries. From the windows that allow natural light to filter into our homes to the sleek screens of our smartphones, glass is all around us. Understanding the density of glass is essential for various applications, from architectural design to the manufacturing of precision instruments.

The density of glass plays a crucial role in determining its strength, durability, and optical properties. By delving into the concept of glass density, we can gain valuable insights into the composition, characteristics, and practical uses of this remarkable material.

In this article, we will explore the concept of density, examine the composition of glass, and delve into the factors that influence its density. We will also discuss the methods used to measure the density of glass and provide typical density values for different types of glass. Furthermore, we will highlight the significance of understanding glass density in various applications, shedding light on its pivotal role in diverse industries.

Join us on this enlightening journey as we unravel the mysteries of glass density and discover the profound impact it has on the world around us.

Key Takeaways:

- Glass density affects its strength, transparency, and thermal behavior, impacting architectural design, electronics, and scientific research. Understanding density empowers innovation and shapes the world around us.

- Different types of glass have unique density values, influencing their properties and applications. From architectural marvels to consumer electronics, glass density drives diverse industries and fosters creativity.

Definition of Density

Density is a fundamental physical property that quantifies the mass of a substance per unit volume. In the context of glass, density refers to the compactness of the material, indicating how much mass is packed into a specific volume. It is a crucial parameter for understanding the structural and optical characteristics of glass, as well as its performance in various applications.

The density of glass is typically expressed in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). This measurement provides valuable insights into the internal arrangement of atoms and molecules within the glass structure. A higher density indicates a greater mass per unit volume, signifying a more tightly packed molecular arrangement.

From a microscopic perspective, the density of glass reflects the proximity of its constituent particles, such as silicon dioxide, sodium carbonate, calcium oxide, and other additives. These components contribute to the overall mass and volume of the glass, influencing its density and, consequently, its mechanical, thermal, and optical properties.

Understanding the density of glass is essential for engineers, architects, and material scientists, as it directly impacts the design and performance of glass-based products. For instance, in architectural applications, the density of glass affects its load-bearing capacity, thermal insulation properties, and resistance to environmental stresses. In the realm of optics and electronics, the density of glass influences its refractive index, light transmission capabilities, and suitability for precision instruments.

In summary, the density of glass serves as a critical parameter for characterizing its physical properties and performance characteristics. By quantifying the mass per unit volume, density provides valuable insights into the composition, structure, and behavior of glass, enabling engineers and designers to make informed decisions regarding its use in diverse applications.

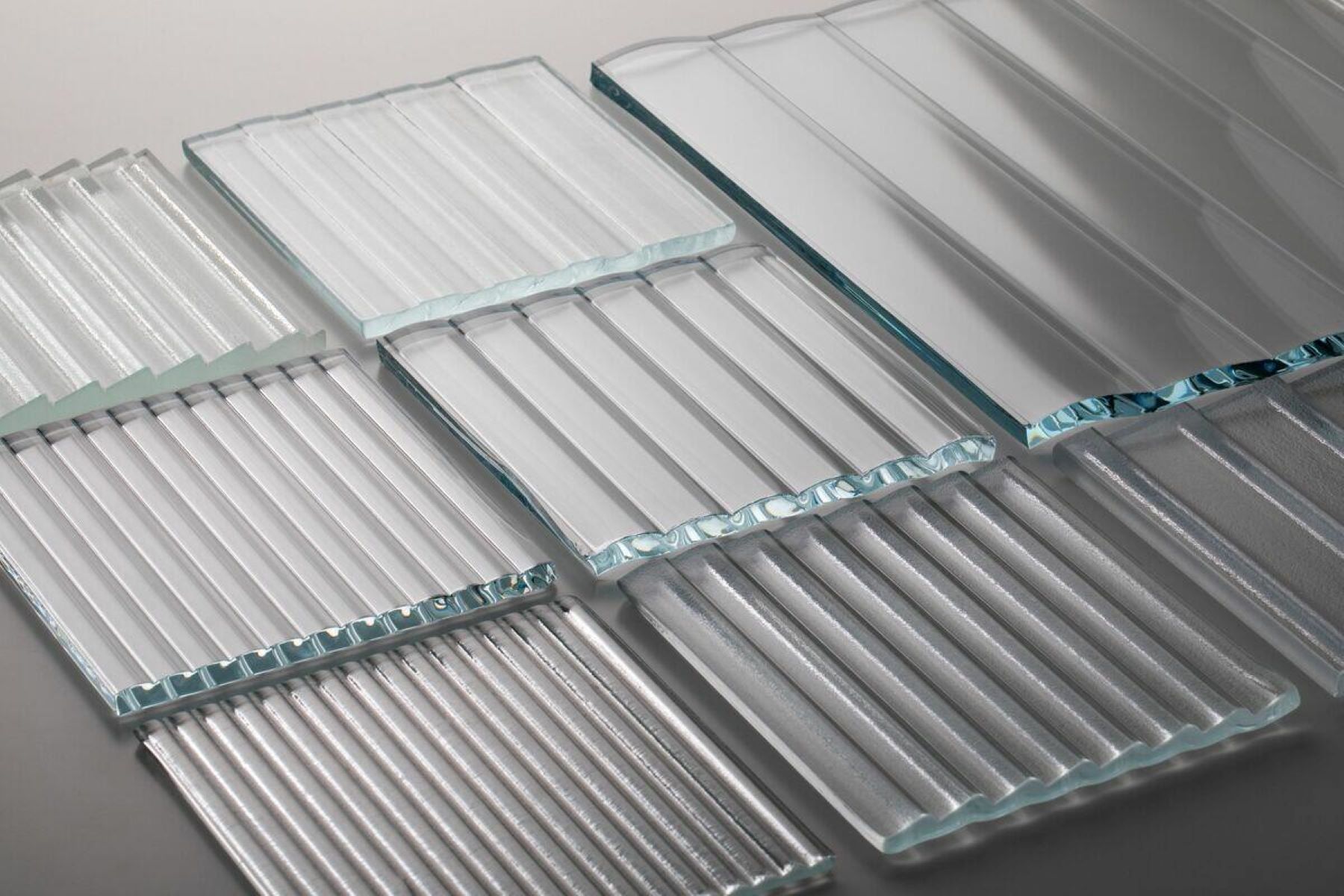

Composition of Glass

Glass is a remarkable material renowned for its transparency, durability, and versatility. Its composition is a complex interplay of various chemical elements and compounds, resulting in a unique molecular structure that defines its properties and behavior. The primary component of most types of glass is silica, or silicon dioxide (SiO2), which serves as the building block for its amorphous, non-crystalline structure. In addition to silica, glass formulations often include a diverse array of additives to impart specific properties and functionalities.

One of the most common additives in glass production is soda ash, also known as sodium carbonate (Na2CO3). This compound plays a crucial role in lowering the melting point of silica, facilitating the glass-forming process. Another essential component is limestone, or calcium carbonate (CaCO3), which serves as a flux, aiding in the fusion of the raw materials during the manufacturing process. These additives contribute to the workability and formability of the glass, allowing it to be shaped into various forms, from flat sheets to intricate sculptures.

Furthermore, glass compositions may incorporate other elements such as alumina (Al2O3), magnesia (MgO), and potassium oxide (K2O), each imparting distinct characteristics to the final product. For instance, alumina enhances the chemical resistance of glass, making it suitable for laboratory equipment and chemical storage containers. Meanwhile, the addition of lead oxide (PbO) results in leaded glass, renowned for its brilliance and optical properties, often used in fine crystalware and decorative art pieces.

The composition of glass can vary significantly depending on its intended application. For instance, borosilicate glass, known for its exceptional thermal shock resistance, contains boron oxide (B2O3) as a key component. This type of glass is commonly used in laboratory glassware, cookware, and high-performance lighting applications. On the other hand, specialty glasses used in optical lenses and fiber optics may incorporate rare earth elements and metal oxides to achieve specific optical properties and light transmission characteristics.

In summary, the composition of glass is a sophisticated blend of silica, additives, and modifiers, carefully tailored to meet the diverse requirements of modern applications. By understanding the intricate interplay of these components, scientists and engineers can develop glass formulations with tailored properties, enabling the material to thrive in a wide range of industries, from architecture and automotive engineering to healthcare and telecommunications.

Factors Affecting the Density of Glass

The density of glass, a fundamental property that influences its structural integrity and performance, is influenced by several key factors. Understanding these factors is essential for comprehending the diverse range of glass types and their applications. Here are the primary elements that affect the density of glass:

-

Chemical Composition: The chemical composition of glass is a primary determinant of its density. Different types of glass, such as soda-lime glass, borosilicate glass, and leaded glass, have distinct compositions that directly impact their densities. For example, borosilicate glass, containing boron oxide as a key component, tends to have a lower density compared to traditional soda-lime glass due to the lighter molecular structure resulting from the incorporation of boron.

-

Porosity: The presence of microscopic voids or pores within the glass structure can affect its density. Higher levels of porosity lead to reduced density as the voids displace the mass within the material. Factors such as the manufacturing process, cooling rates, and the presence of impurities can influence the porosity of glass, thereby impacting its overall density.

-

Thermal Treatment: The thermal history of glass, including the annealing and tempering processes, can influence its density. Annealed glass, which undergoes controlled cooling to relieve internal stresses, may exhibit a different density compared to tempered glass, which is subjected to rapid heating and cooling to enhance its strength. These thermal treatments can alter the molecular arrangement and density of the glass, affecting its mechanical properties.

-

Additives and Impurities: The presence of additives and impurities in glass formulations can impact its density. For instance, the incorporation of heavy metal oxides, such as lead oxide in leaded glass, can increase the overall density of the material. Conversely, the presence of air bubbles, inclusions, or foreign particles can decrease the density by introducing voids within the glass matrix.

-

Manufacturing Variations: Variations in the glass manufacturing process, including the mixing of raw materials, melting conditions, and forming techniques, can lead to differences in the density of the final glass product. Factors such as the duration of the melting process, the use of refining agents, and the presence of nucleating agents can all contribute to variations in glass density.

By considering these factors, scientists, engineers, and manufacturers can gain valuable insights into the density variations observed in different types of glass. This understanding is crucial for optimizing glass formulations, enhancing product performance, and expanding the range of applications where glass can be effectively utilized.

Methods of Measuring the Density of Glass

Accurately determining the density of glass is essential for quality control, material characterization, and research purposes. Several methods are employed to measure the density of glass, each offering unique advantages and precision. Here are the primary techniques used for this purpose:

Read more: What Is A Good Density For Memory Foam

1. Archimedes' Principle

This classic method involves immersing a glass sample in a fluid with a known density, typically a liquid such as water or a specialized immersion fluid. The buoyant force acting on the submerged sample is measured, allowing for the calculation of its volume. By dividing the mass of the sample by its volume, the density of the glass can be accurately determined. Archimedes' principle is particularly effective for irregularly shaped or porous glass samples, providing reliable results across a wide range of glass compositions.

2. Gas Pycnometry

Gas pycnometry relies on the principle of gas displacement to measure the volume of a solid material, such as glass. The sample is placed in a chamber filled with an inert gas, and the change in pressure is measured as the gas fills the voids around the sample. By comparing the pressure change to that of a reference volume, the volume of the glass sample can be determined. When combined with the sample's mass, this method yields precise density measurements, making it suitable for high-precision applications and research studies.

3. X-ray Attenuation

X-ray attenuation, commonly utilized in industrial and research settings, involves passing X-rays through a glass sample and measuring the attenuation or reduction in X-ray intensity. By analyzing the degree of X-ray attenuation, the mass thickness of the glass can be calculated, allowing for the determination of its density. This non-destructive method is particularly valuable for analyzing the density distribution within complex glass structures and identifying variations in density across a sample.

4. Ultrasound Velocity Measurement

Ultrasound velocity measurement techniques utilize the speed of sound through a material to infer its density. By transmitting ultrasonic waves through a glass sample and measuring the time taken for the waves to propagate, the density of the material can be indirectly determined. This method is non-destructive and can provide valuable insights into the density variations within a glass sample, making it suitable for research and quality control applications.

These methods, each offering unique advantages and precision, play a crucial role in accurately measuring the density of glass. By employing these techniques, researchers, engineers, and manufacturers can gain valuable insights into the physical properties of glass, enabling the development of innovative glass formulations and the optimization of glass-based products for diverse applications.

Read more: What Infill Density Should I Use

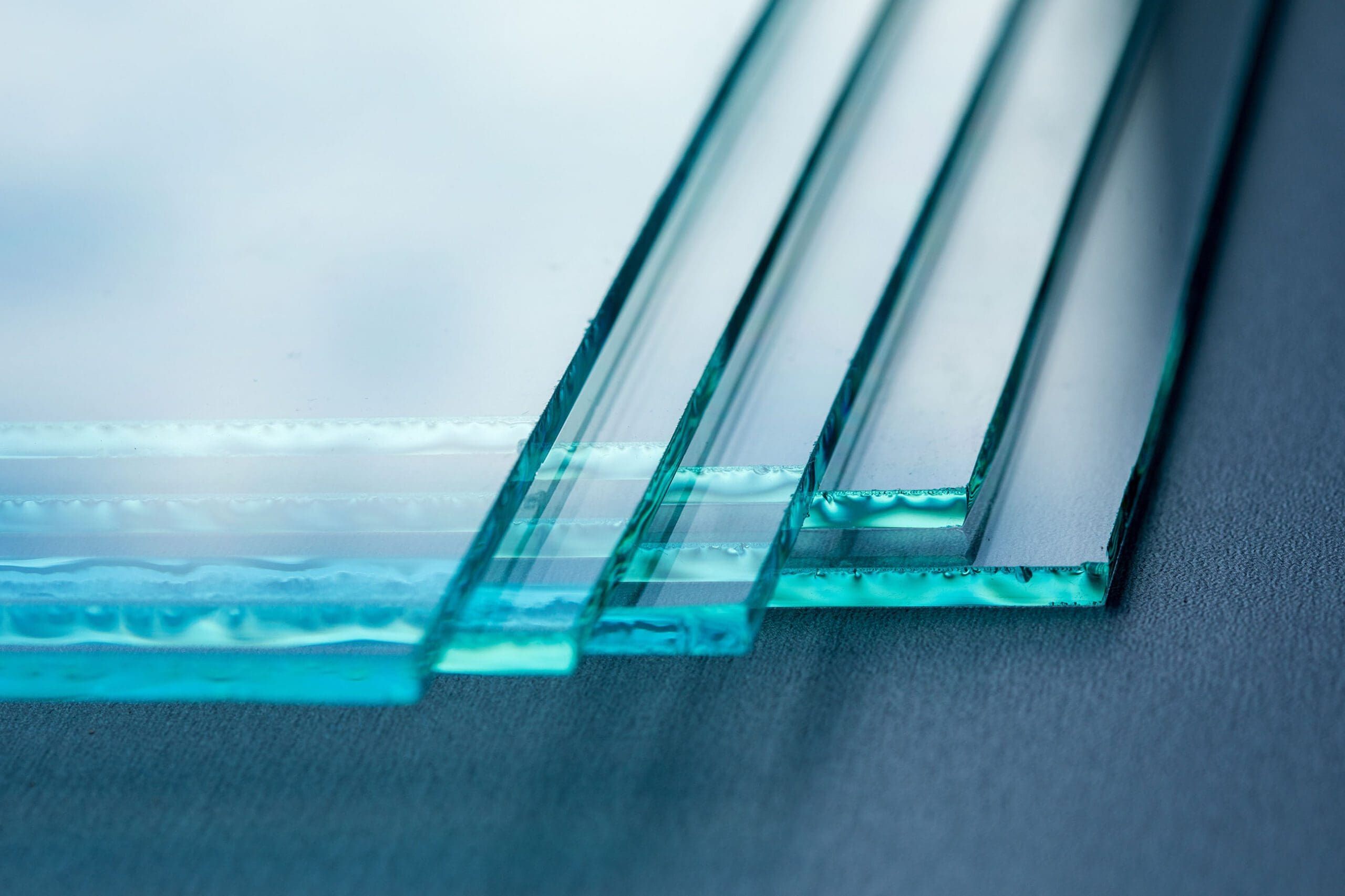

Typical Density Values for Different Types of Glass

The density of glass varies significantly depending on its composition, manufacturing process, and intended application. Different types of glass exhibit distinct density values, reflecting their unique chemical compositions and structural characteristics. Understanding the typical density values for various types of glass provides valuable insights into their properties and suitability for specific uses.

-

Soda-Lime Glass: This widely used type of glass, known for its transparency and affordability, typically exhibits a density ranging from 2.4 to 2.6 grams per cubic centimeter (g/cm³). The addition of soda ash and lime to the silica matrix contributes to its moderate density, making it suitable for applications such as windows, bottles, and household glassware.

-

Borosilicate Glass: Renowned for its exceptional thermal shock resistance and low coefficient of thermal expansion, borosilicate glass has a density in the range of 2.2 to 2.3 g/cm³. The incorporation of boron oxide into the glass composition results in a lighter molecular structure, contributing to its lower density compared to traditional soda-lime glass. This makes it ideal for laboratory glassware, cookware, and high-performance lighting applications.

-

Leaded Glass: Leaded glass, often utilized in fine crystalware and decorative art pieces, contains lead oxide as a key component, leading to a density typically ranging from 3.1 to 3.5 g/cm³. The higher density of leaded glass contributes to its brilliance and optical properties, making it a preferred choice for intricate glass art and luxury tableware.

-

Specialty Glasses: Glass formulations tailored for specific applications, such as optical lenses, fiber optics, and specialty lighting, may exhibit unique density values based on their precise compositions. For instance, high-refractive-index glasses used in precision optics may have densities exceeding 3.5 g/cm³, reflecting the incorporation of rare earth elements and heavy metal oxides to achieve specific optical properties.

By understanding the typical density values associated with different types of glass, engineers, designers, and manufacturers can make informed decisions regarding material selection for diverse applications. These values serve as crucial benchmarks for assessing the performance, durability, and suitability of glass in various industries, from architecture and automotive engineering to healthcare and telecommunications. The diverse range of density values across different types of glass underscores the versatility and adaptability of this remarkable material in meeting the evolving needs of modern technology and design.

The density of glass typically ranges from 2.2 to 2.8 grams per cubic centimeter. This can vary depending on the type of glass and its composition.

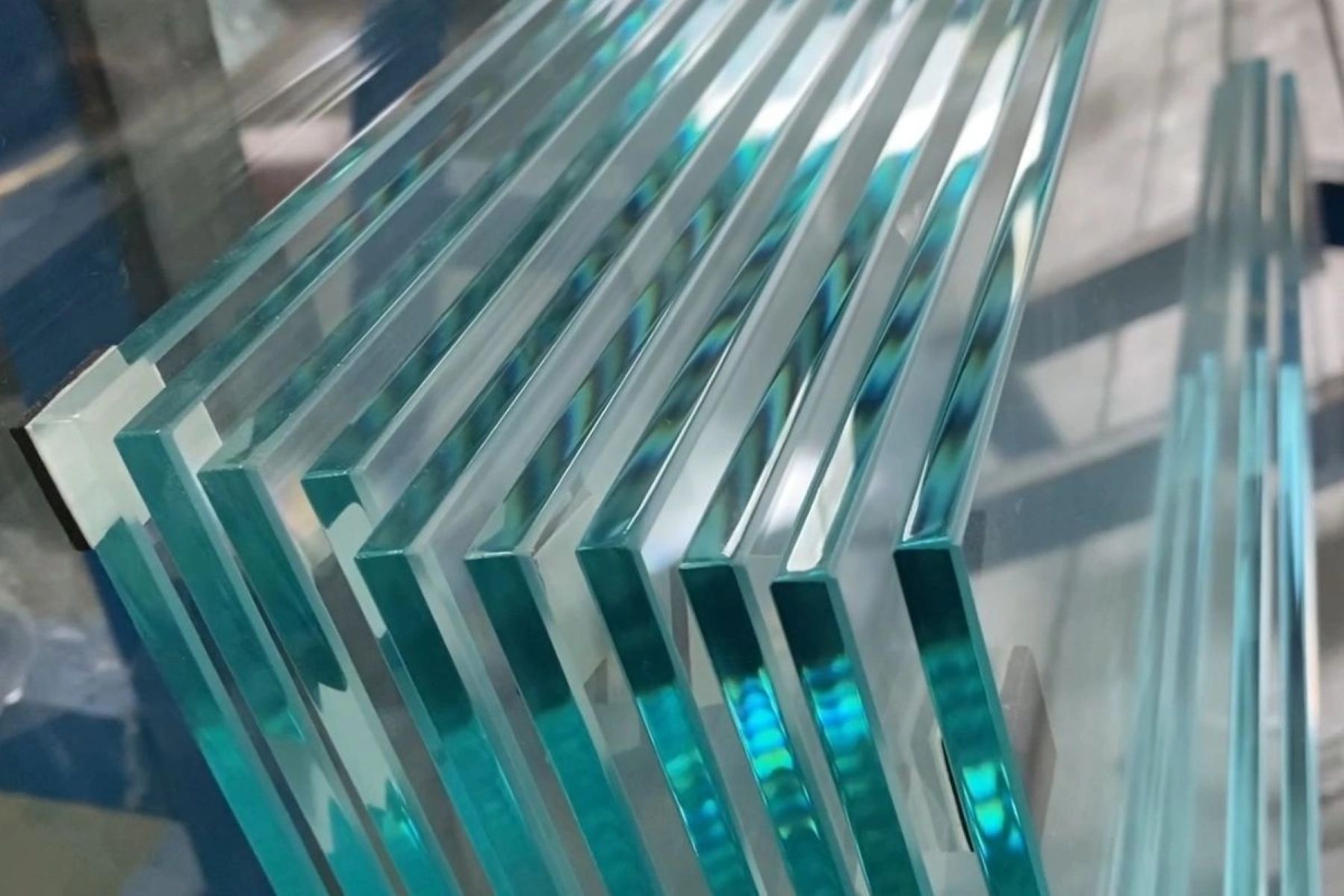

Applications of Understanding Glass Density

Understanding the density of glass holds immense significance across a myriad of industries, influencing the design, performance, and application of glass-based products. The profound insights gained from comprehending glass density find diverse applications, shaping the advancement of technology, architecture, and scientific innovation.

In the realm of architectural design and construction, the knowledge of glass density plays a pivotal role in determining the structural integrity, thermal insulation properties, and load-bearing capacity of glass components. By selecting glass types with specific density values, architects and engineers can optimize the performance of facades, windows, and skylights, ensuring their ability to withstand environmental stresses while maximizing natural light transmission. Additionally, the understanding of glass density facilitates the development of energy-efficient building designs, where the selection of low-density, high-strength glasses contributes to sustainable and visually striking architectural solutions.

In the automotive industry, the application of glass with tailored density values is instrumental in enhancing vehicle safety, comfort, and fuel efficiency. By leveraging the knowledge of glass density, manufacturers can optimize the design of windshields, sunroofs, and side windows, ensuring the desired balance of impact resistance and weight reduction. Furthermore, the use of low-density, high-strength glasses in automotive glazing contributes to improved fuel economy and overall vehicle performance, aligning with the industry's pursuit of lightweighting and sustainability.

In the field of scientific research and laboratory equipment, the understanding of glass density enables the development of specialized glassware and precision instruments tailored to specific applications. Borosilicate glass, with its lower density and exceptional thermal shock resistance, finds extensive use in laboratory settings, where accurate measurements, chemical resistance, and thermal durability are paramount. The knowledge of density variations across different glass compositions allows scientists and researchers to select the most suitable glassware for experiments, ensuring reliable and consistent results.

Moreover, in the realm of consumer electronics and display technologies, the understanding of glass density influences the design and performance of screens, touch panels, and optical components. By selecting glass types with precise density values, manufacturers can achieve optimal light transmission, touch sensitivity, and impact resistance in electronic devices, enhancing the user experience and durability of consumer products.

The applications of understanding glass density extend to diverse industries, including aerospace, telecommunications, healthcare, and art and design. By leveraging this knowledge, innovators and engineers continue to push the boundaries of glass technology, creating new possibilities for sustainable architecture, advanced materials, and cutting-edge innovations that enrich our daily lives.

In summary, the applications of understanding glass density are far-reaching and multifaceted, shaping the development of products and technologies that rely on the unique properties of glass. This knowledge serves as a cornerstone for innovation, enabling the creation of safer, more efficient, and visually captivating solutions across a wide spectrum of industries.

Conclusion

In conclusion, the density of glass serves as a fundamental parameter that underpins its diverse applications and influences its structural, optical, and thermal properties. Through our exploration of glass density, we have gained valuable insights into the intricate interplay of chemical composition, manufacturing processes, and material characteristics that define the behavior of glass in various contexts.

The understanding of glass density is essential for architects, engineers, material scientists, and manufacturers, enabling them to make informed decisions regarding material selection, product design, and performance optimization. By recognizing the impact of density on the strength, transparency, and thermal behavior of glass, professionals across industries can harness this knowledge to create innovative solutions that meet the evolving needs of modern society.

From architectural marvels adorned with high-performance glass facades to precision instruments crafted from specialized borosilicate glass, the applications of understanding glass density are far-reaching and transformative. This knowledge empowers designers to push the boundaries of creativity, sustainability, and functionality, driving the advancement of technology and the realization of visionary concepts.

As we continue to explore the frontiers of glass science and engineering, the significance of understanding glass density will remain paramount. It will fuel the development of next-generation materials, sustainable building solutions, and cutting-edge technologies that leverage the unique properties of glass to enrich our lives and shape the world around us.

In essence, the journey into the realm of glass density has unveiled the profound impact of this fundamental property on the fabric of our modern civilization. It has illuminated the path toward innovation, sustainability, and excellence, inspiring a new era of possibilities where glass, with its remarkable density, continues to captivate our imagination and redefine the boundaries of what is possible.

Frequently Asked Questions about What Is The Density Of Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Density Of Glass”