Home>Garden Essentials>What Is A Dovetail Infill Plane Used For

Garden Essentials

What Is A Dovetail Infill Plane Used For

Modified: March 7, 2024

Discover the versatility of a dovetail infill plane in your garden. Perfect for precision woodworking and creating clean, professional joints.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of woodworking, where craftsmanship meets creativity. In the realm of hand tools, there are a multitude of tools that serve specific purposes. One such tool is the dovetail infill plane.

In the art of woodworking, dovetail joints are renowned for their strength and beauty. Creating these joints requires skill, precision, and the right tools. That’s where the dovetail infill plane comes into play.

A dovetail infill plane is a specialized hand plane used primarily for cutting and shaping dovetail joints. It is an essential tool in woodworking, particularly in fine furniture making and cabinetry. With its unique design and versatility, the dovetail infill plane offers woodworkers the ability to create tight-fitting, sturdy connections between pieces of wood.

In this article, we will delve into the world of dovetail infill planes, exploring their history, characteristics, construction, different types, advantages, techniques for usage, and maintenance. By the end of this article, you’ll have a comprehensive understanding of the dovetail infill plane and its importance in woodworking.

Key Takeaways:

- The dovetail infill plane is a specialized hand tool used for creating precise and sturdy dovetail joints in woodworking, offering control, comfort, and a connection to traditional craftsmanship.

- With its metal body and wooden infill, the dovetail infill plane provides stability, strength, and versatility, making it an essential tool for achieving exceptional joinery and finely crafted woodworking projects.

Read more: What Is Infill Plane

Definition of Dovetail Infill Plane

The dovetail infill plane is a type of hand plane specifically designed for cutting and shaping dovetail joints. It is renowned for its precision and ability to create tight-fitting, interlocking joints.

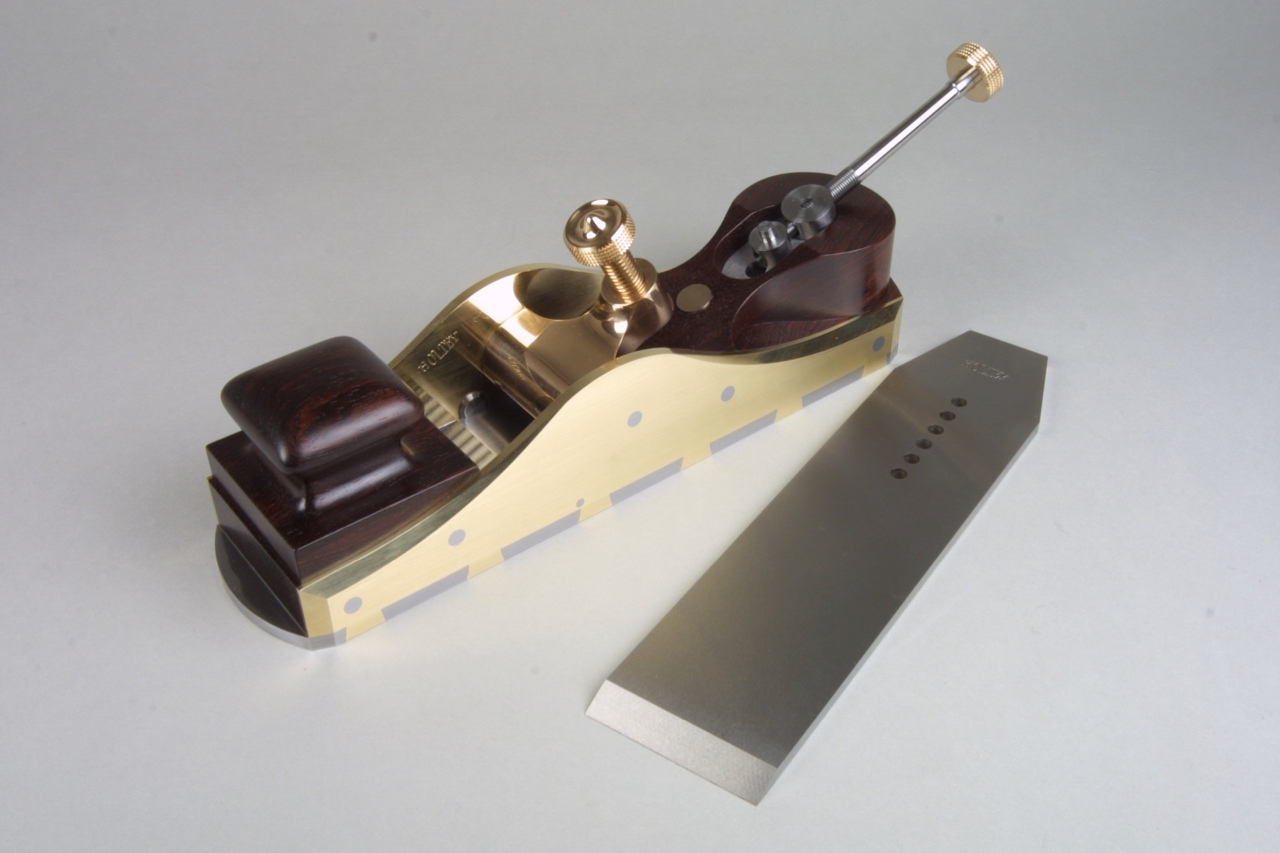

The term “infill” in dovetail infill plane refers to the construction technique employed in its design. Infill planes consist of a metal body or shell, with a wooden “infill” piece that fills the space between the metal cheeks, providing stability, comfort, and additional weight to the plane.

Unlike traditional bench planes, which have open sides, the dovetail infill plane features a closed-end design. This design allows for the chisel-like blade to be extended beyond the body of the plane, enabling woodworkers to cut dovetail joints with exceptional precision.

Dovetail infill planes are typically available in a variety of sizes, allowing woodworkers to choose the best plane for their specific project needs. They can be found in various configurations, ranging from small shoulder planes for fine detail work to larger smoothing planes for general purpose use.

One of the distinguishing features of a dovetail infill plane is the inclusion of a wooden wedge or lever cap that secures the blade in place. This ensures stability and allows for easy adjustment and replacement of the blade when necessary.

Overall, the dovetail infill plane is a specialized hand tool that plays a crucial role in the creation of precision dovetail joints. Its unique design, combined with the craftsmanship and skill of the woodworker, contributes to the creation of high-quality furniture and other woodworking projects.

History of Dovetail Infill Planes

The history of dovetail infill planes dates back to the 18th century, during the golden age of hand tool woodworking. These planes were initially developed in England and quickly gained popularity among skilled craftsmen.

The early dovetail infill planes were handcrafted by skilled blacksmiths and plane makers. They were built using a combination of metal, usually cast iron or steel, and a wooden infill. The metal body provided the necessary strength and rigidity, while the wooden infill enhanced the comfort and stability during use.

As the demand for more intricate and precise joinery increased, so did the need for specialized tools like the dovetail infill plane. Woodworkers began to recognize the benefits of using a dedicated plane for cutting dovetail joints, as opposed to modifying a standard bench plane or using handheld chisels.

During the 19th century, the production of dovetail infill planes became more industrialized. Companies like Spiers, Norris, Mathieson, and infill planes from Sheffield, England, produced a wide range of these planes, each with its own unique design and features.

In the early 20th century, with the rise of power tools and mass-produced furniture, the popularity of hand tool woodworking declined, and so did the production of dovetail infill planes. However, in recent years, there has been a resurgence of interest in traditional craftsmanship, leading to a revival of hand tool woodworking and a renewed appreciation for dovetail infill planes.

Today, there is a thriving community of enthusiasts and collectors who appreciate the beauty, craftsmanship, and functionality of these planes. Many skilled plane makers continue to produce modern interpretations of the classic infill plane design, using high-quality materials and traditional techniques.

The history of dovetail infill planes is a testament to the enduring legacy of hand tool woodworking. These planes have stood the test of time and continue to be cherished by woodworkers who value precision, aesthetics, and the connection to traditional craftsmanship.

Characteristics of Dovetail Infill Planes

Dovetail infill planes possess several distinctive characteristics that set them apart from other hand planes. These features contribute to their precision and versatility in woodworking projects. Let’s explore some of the key characteristics of dovetail infill planes:

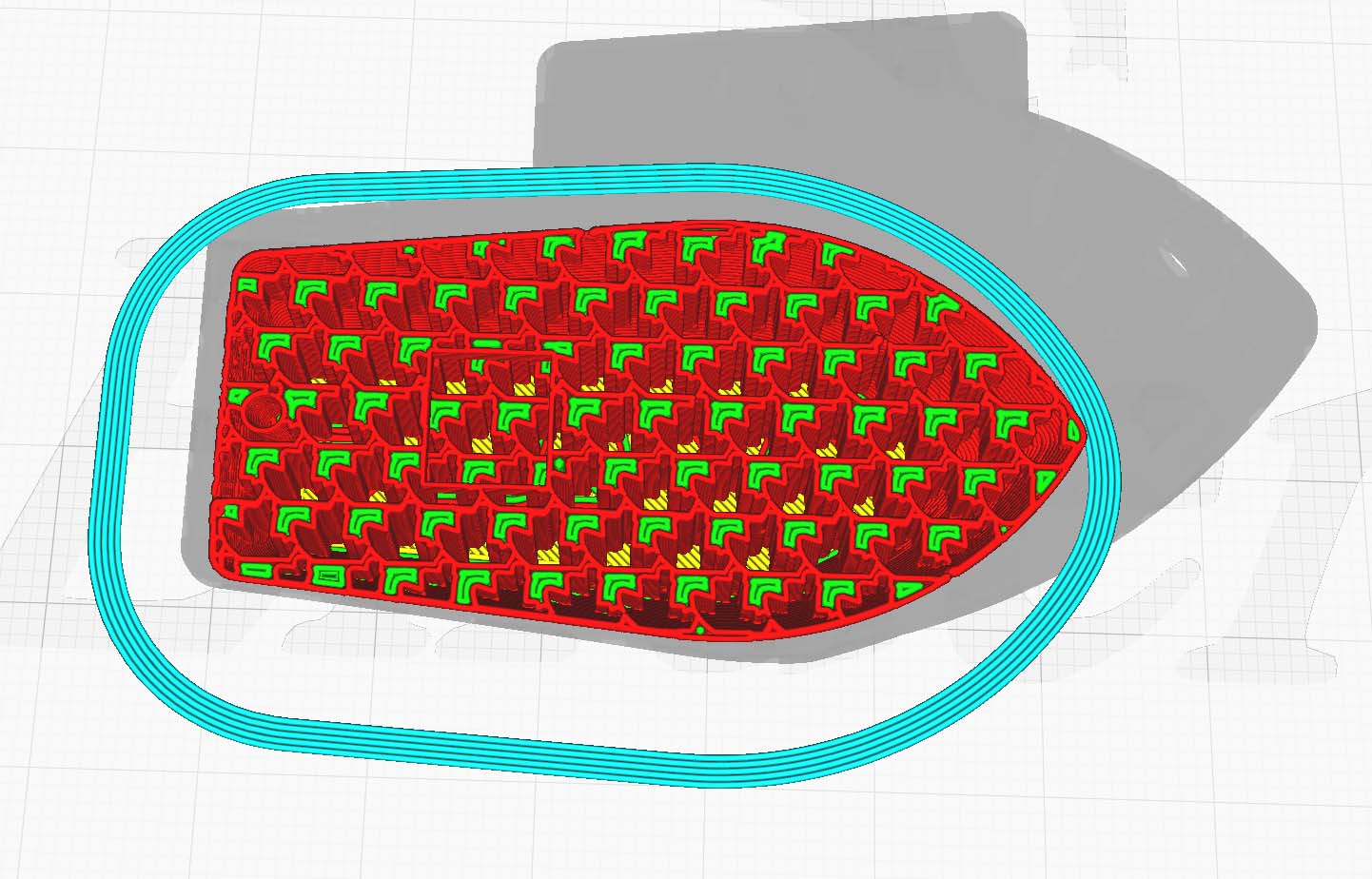

- Metal Body: Dovetail infill planes have a sturdy metal body made of cast iron or steel. This provides strength, durability, and stability during use.

- Wooden Infill: The space within the metal body is filled with a wooden infill, typically made of hardwood like rosewood, beech, or ebony. The wooden infill adds weight, absorbs vibrations, and provides a comfortable grip.

- Closed-End Design: Unlike traditional bench planes, dovetail infill planes feature a closed-end design. This allows the chisel-like blade to extend beyond the plane’s body, enabling precise cutting and shaping of dovetail joints.

- Blade Adjustment Mechanism: Dovetail infill planes often incorporate a lever cap or a wooden wedge for blade adjustment and securement. This feature allows the user to fine-tune the blade’s depth and ensure stability during usage.

- Narrow Mouth: Dovetail infill planes typically have a narrower mouth compared to other planes. This narrow opening allows for better control and prevents tear-out when working on delicate or figured wood.

- Bevel-Up Blade: Dovetail infill planes commonly feature a bevel-up blade configuration. This means that the blade’s beveled edge faces upward, allowing for a lower cutting angle. The lower angle enhances control and produces cleaner cuts.

- Compact Size: Dovetail infill planes come in various sizes, but they are generally compact, making them ideal for working in tight spaces or detailed woodworking tasks.

- Delicate Filigree Work: Dovetail infill planes are prized for their ability to perform delicate filigree work. With their precise cutting and controlled handling, they can create intricate details in dovetail joints and other fine woodworking elements.

The combination of these characteristics makes the dovetail infill plane a versatile and essential tool for woodworking enthusiasts and professionals. Its unique design and attention to detail contribute to the creation of finely crafted joinery with exceptional precision and beauty.

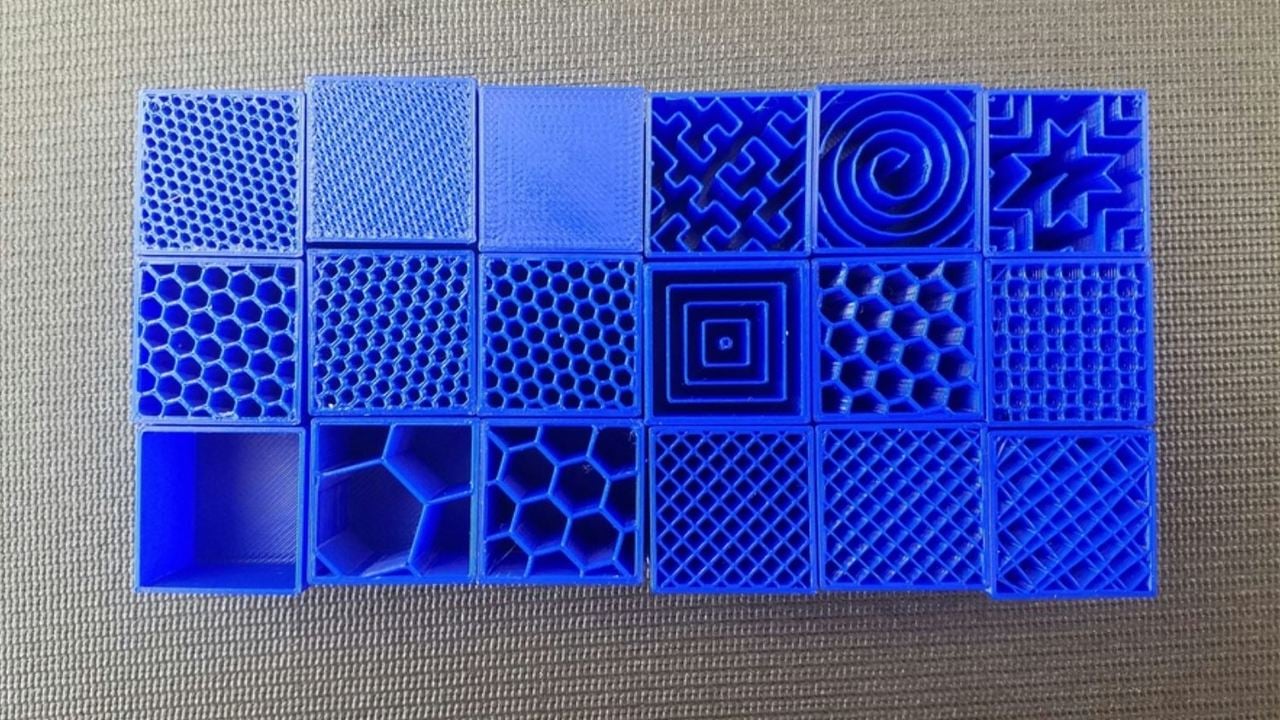

Construction of Dovetail Infill Planes

The construction of a dovetail infill plane involves a meticulous process that combines metalworking and woodworking techniques. Each component is carefully crafted to ensure precision and durability. Let’s explore the main elements involved in the construction of dovetail infill planes:

- Metal Body: The foundation of a dovetail infill plane is its metal body, typically made of cast iron or steel. The body provides strength and rigidity to the plane. The sides of the body are machined flat and square to ensure optimal performance.

- Wooden Infill: The metal body is complemented by a wooden infill, which fills the space between the metal cheeks. The wooden infill adds weight, absorbs vibrations, and provides a comfortable grip for the user. It is often made from dense hardwoods such as rosewood, beech, or ebony.

- Bedding Area: The bedding area is where the wooden infill securely fits into the metal body. This area is precisely machined to ensure a tight and stable fit, enhancing the overall performance of the plane.

- Blade and Chip Breaker: The cutting mechanism of a dovetail infill plane consists of a blade and a chip breaker. The blade is made of high-quality tool steel, hardened and sharpened to a fine cutting edge. The chip breaker sits atop the blade and helps control chip formation and prevent tear-out.

- Blade Adjustment Mechanism: Dovetail infill planes incorporate various blade adjustment mechanisms. These may include a lever cap or a wooden wedge to secure the blade in place and allow for easy depth adjustment. The adjustment mechanism ensures optimal performance and ease of use.

- Lever Cap or Wedge: A dovetail infill plane typically features a lever cap or a wedge that secures the blade in position. The lever cap is a metal component that exerts pressure on the blade, locking it in place. Alternatively, some infill planes use a wooden wedge system for blade retention.

- Handles and Tote: The handle and tote, or rear handle, provide a comfortable grip for the user. These components are commonly made from hardwood and ergonomically shaped to facilitate ease of control and reduce fatigue during extended use.

- Finish: Once all the components are properly fitted and assembled, the dovetail infill plane undergoes finishing processes. This may include sanding and applying a protective finish to the wooden infill to enhance its appearance and longevity.

The construction of a dovetail infill plane requires a high level of craftsmanship and attention to detail. Each component is carefully designed and meticulously fitted to ensure optimal performance and longevity. The combination of metal and wood in the construction creates a harmonious balance between strength, stability, and comfort for the woodworker.

A dovetail infill plane is used for precision woodworking, particularly for creating fine, detailed joinery such as dovetail joints. It provides stability and control for accurate cuts.

Read more: What Is The Walkway To A Plane Called

Types of Dovetail Infill Planes

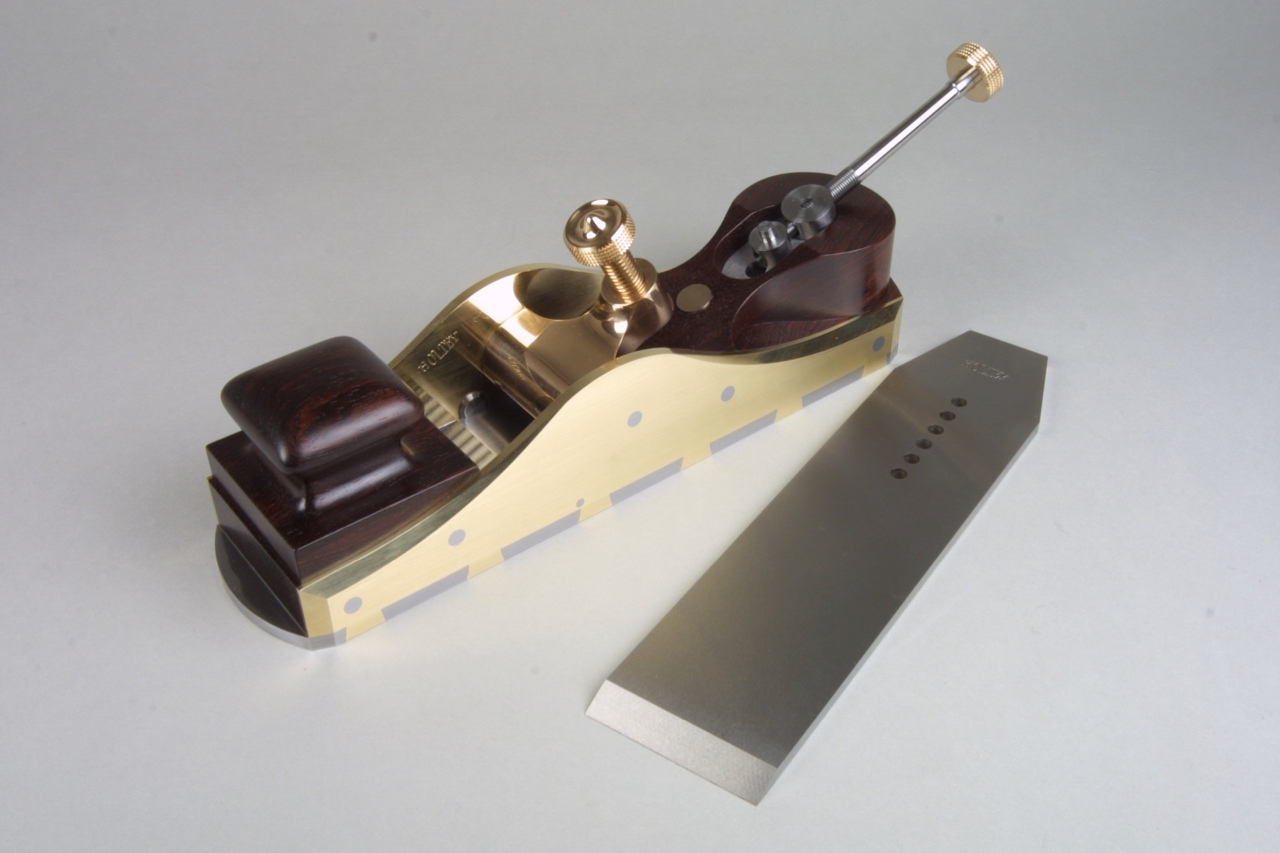

Dovetail infill planes come in various types and sizes to suit different woodworking needs and preferences. Each type has its own unique features and applications. Let’s explore some of the most common types:

- Smoothing Plane: The smoothing plane is a versatile type of dovetail infill plane used for achieving a smooth and polished finish on wood surfaces. It is typically smaller in size, allowing for easy maneuverability and precise control.

- Shoulder Plane: Shoulder planes are designed specifically for trimming and refining the shoulders of jointed surfaces, such as the cheeks of dovetail joints. They feature a wider blade and a higher sidewall, allowing for greater surface contact and control.

- Fillister Plane: Fillister planes, also known as rebate planes, are used for cutting rebates or rabbets along the edge or end grain of a piece of wood. They have a fence or guide that ensures accurate and consistent cuts.

- Chisel Plane: Chisel planes are specialty planes with a blade that extends to the edges of the plane’s body. They are primarily used for cleaning up the bottom of grooves, dados, or other recessed areas where a regular plane cannot reach.

- Mitre Plane: Mitre planes are designed specifically for trimming and fitting mitre joints, such as those found in frame and picture moldings. They have a low-angle blade that allows for precise trimming at various angles.

- Router Plane: Router planes are versatile hand planes designed for fine-tuning the depth and flatness of dadoes, grooves, and other recessed areas. They feature a narrow blade and a flat, solid base for stable and controlled cutting.

These are just a few examples of the types of dovetail infill planes available. Each type serves a specific purpose in woodworking, enabling woodworkers to achieve precise and intricate joinery. It’s important to choose the right type of infill plane based on the specific task at hand and personal preference.

Whether you are working on smoothing surfaces, fitting joinery, or creating precise cuts, having the appropriate type of dovetail infill plane in your toolbox can greatly enhance your woodworking experience and the quality of your craftsmanship.

Advantages of Using Dovetail Infill Planes

Dovetail infill planes offer numerous advantages that make them indispensable tools for woodworking enthusiasts and professionals. Here are some key benefits of using dovetail infill planes:

- Precision: Dovetail infill planes are renowned for their ability to provide precise and controlled cuts. The design allows for fine adjustments, enabling woodworkers to achieve tight-fitting dovetail joints with minimal effort.

- Strength and Stability: The metal body of dovetail infill planes provides sturdy and stable support during use. This construction ensures the longevity of the tool and enhances its performance, especially when working with hardwoods and other challenging materials.

- Comfortable Handling: The wooden infill in dovetail infill planes enhances the comfort and grip while using the tool. The ergonomic design reduces hand fatigue and allows for extended periods of use without discomfort.

- Control and Versatility: Dovetail infill planes offer a high level of control, allowing woodworkers to achieve consistent and accurate results. Whether it’s smoothing surfaces, fitting joints, or creating precise cuts, these planes are versatile and can handle a wide range of woodworking tasks.

- Reduced Tear-out: The narrow mouth and bevel-up blade configuration of dovetail infill planes help reduce tear-out, especially when working on delicate or figured wood surfaces. This results in cleaner and more polished cuts.

- Enhanced Aesthetics: Dovetail infill planes not only function exceptionally but also add an aesthetic element to woodworking. Their craftsmanship and timeless design make them a joy to use and a reflection of the woodworker’s appreciation for quality tools.

- Connection to Traditional Craftsmanship: Using a dovetail infill plane allows woodworkers to connect with woodworking traditions and techniques that have been passed down through generations. It adds a sense of authenticity and craftsmanship to the woodworking process.

The advantages of using dovetail infill planes make them a valuable tool for woodworking projects, particularly when high precision and quality joinery are desired. Whether you are a beginner or an experienced woodworker, investing in a dovetail infill plane can greatly enhance the quality, efficiency, and enjoyment of your woodworking endeavors.

Techniques for Using Dovetail Infill Planes

Using a dovetail infill plane requires a combination of technique, practice, and patience. Mastering these techniques will help you achieve precise and clean cuts. Here are some essential techniques to consider when using a dovetail infill plane:

- Setup and Adjustment: Ensure your dovetail infill plane is properly set up and adjusted before use. This includes sharpening and properly aligning the blade, adjusting the depth of cut, and ensuring the plane sits flat on the surface.

- Grain Orientation: Pay attention to the grain orientation of the wood you are working with. It’s crucial to adjust the cutting direction accordingly to prevent tear-out. For end grain, move the plane across the grain. For long grain surfaces, move the plane along the grain.

- Starting and Ending: To prevent the plane from digging into the wood at the beginning and end of a cut, hold the plane slightly above the surface, start the stroke, and gradually lower the plane onto the wood. Similarly, lift the plane slightly before reaching the end of the cut to avoid tearing the wood fibers.

- Stance and Posture: Maintain a comfortable stance and posture while using the dovetail infill plane. Keep your back straight, shoulders relaxed, and feet planted firmly on the ground. This will allow for better control and reduce fatigue during extended periods of planing.

- Smooth, Even Stroke: Execute smooth, even strokes when operating the plane. Apply consistent pressure throughout the stroke, focusing on maintaining an even depth of cut. This will help achieve a clean, polished surface and prevent uneven material removal.

- Shooting Board: Consider using a shooting board when planing end grain surfaces. A shooting board provides a stable platform and helps maintain precise 90-degree angles, allowing for accurate and straight cuts.

- Practice and Patience: Becoming proficient in using a dovetail infill plane takes practice and patience. Start with small, simple projects to build your skills and gradually move on to more complex joinery. With time and practice, you will develop the techniques and confidence required to achieve exceptional results.

Remember, mastering the techniques for using a dovetail infill plane is a journey that takes time and persistence. Don’t be discouraged if you encounter challenges along the way. Embrace the learning process and enjoy the craftsmanship that comes with using this remarkable tool.

Maintenance and Care of Dovetail Infill Planes

Proper maintenance and care of your dovetail infill plane are essential to ensure its optimal performance and longevity. By following these maintenance tips, you can keep your plane in excellent condition and enjoy its precision for years to come:

- Blade Sharpening: Regularly sharpen the blade of your dovetail infill plane to maintain its cutting efficiency. Use sharpening stones or honing guides to achieve a sharp edge. Take care to maintain the original bevel angle of the blade for best results.

- Blade Adjustment: Periodically check the blade adjustment and make any necessary adjustments to ensure it is properly aligned and secured. This will ensure accurate cuts and prevent unnecessary wear on the blade and the plane body.

- Wooden Infill Care: The wooden infill on your dovetail infill plane may require occasional maintenance. Apply a thin coat of wax or oil to keep the wood nourished and protected from drying out or cracking. Keep the infill clean and free from dust and moisture.

- Storage: Store your dovetail infill plane in a dry, clean, and well-ventilated area. Avoid exposure to excessive heat, humidity, or drastic temperature changes, as these can negatively affect the metal and wooden components of the plane.

- Lubrication: Periodically lubricate the moving parts of your dovetail infill plane to ensure smooth operation. Use a light machine oil or a specialized lubricant recommended by the manufacturer. Apply a small amount to the pivot points, adjuster mechanisms, and any other areas where friction may occur.

- Tool Cleaning: Regularly clean your dovetail infill plane to remove dust, debris, and any residue that may accumulate during use. Use a brush or compressed air to clean the plane body, blade, and wooden infill. Avoid using harsh chemicals that may damage the metal or wood.

- Periodic Inspection: Routinely inspect your dovetail infill plane for any signs of damage, wear, or loose parts. Tighten any loose screws or fixings and address any issues promptly to prevent further damage or compromise the plane’s performance.

- Professional Servicing: If necessary, consider seeking professional servicing or repairs for your dovetail infill plane. A skilled plane restorer can help with more extensive maintenance, such as truing the sole, repairing or replacing damaged components, or refinishing the plane.

By implementing these maintenance practices, you can keep your dovetail infill plane in top condition and ensure consistent performance. Remember to respect the craftsmanship and heritage of your tool by giving it the care and attention it deserves.

Read more: What Is Used As Infill For Timber Frames

Conclusion

The dovetail infill plane is a remarkable tool that has been a staple in the world of woodworking for centuries. Its precision, versatility, and timeless design make it an essential tool for woodworking enthusiasts and professionals alike.

From its origins in the 18th century to its resurgence in modern woodworking, the dovetail infill plane has stood the test of time. Its construction, combining a metal body with wooden infill, provides stability, strength, and comfort during use.

Whether you’re creating tight-fitting dovetail joints, refining surfaces, or shaping intricate details, the dovetail infill plane offers the precision and control necessary for achieving exceptional results. Its ability to navigate tight spaces and handle delicate materials makes it a go-to tool for woodworking projects of all sizes.

Maintaining and caring for your dovetail infill plane is crucial to its longevity and continued performance. Regular blade sharpening, proper adjustment, and routine cleaning and lubrication will ensure that your tool remains in excellent condition for years to come.

While power tools have their place in modern woodworking, the dovetail infill plane provides a connection to traditional craftsmanship, allowing woodworkers to appreciate the artistry of hand tool woodworking. It invites patience, practice, and a deep appreciation for the process of creating exceptional joinery and finely crafted woodworking projects.

In conclusion, the dovetail infill plane is not just a tool but a symbol of the dedication and passion of the woodworker. With its precision, versatility, and timeless design, it continues to be an indispensable tool in the art of woodworking, enabling the creation of beautiful, well-crafted pieces that stand the test of time.

Frequently Asked Questions about What Is A Dovetail Infill Plane Used For

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Dovetail Infill Plane Used For”