Home>Gardening & Outdoor>Pool & Spa Care>How To Test A Hot Tub Pump

Pool & Spa Care

How To Test A Hot Tub Pump

Modified: January 3, 2024

Learn how to properly test a hot tub pump for optimal performance and efficiency with our expert pool and spa care tips. Keep your hot tub running smoothly!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of hot tub care! Whether you're a seasoned hot tub owner or a newbie looking to maintain your spa, understanding how to test a hot tub pump is crucial for ensuring the optimal performance of your relaxation oasis. The hot tub pump is the heart of the entire system, responsible for circulating water, powering the jets, and maintaining the water's cleanliness. Regular testing of the pump is essential for identifying any issues and addressing them promptly to prevent more significant problems down the line.

In this comprehensive guide, we will walk you through the step-by-step process of testing a hot tub pump, covering visual inspections, electrical testing, flow testing, and noise testing. By the end of this article, you will feel confident in your ability to assess the health of your hot tub pump and take the necessary measures to keep it running smoothly. So, grab your testing tools and let's dive into the world of hot tub pump testing!

Key Takeaways:

- Regularly testing your hot tub pump is crucial for maintaining its performance and longevity. Visual, electrical, flow, and noise testing are essential steps to ensure a safe and serene hot tub experience.

- Prioritize safety by turning off the power, wearing protective gear, and following manufacturer guidelines. With the right tools and thorough testing, you can keep your hot tub pump running smoothly.

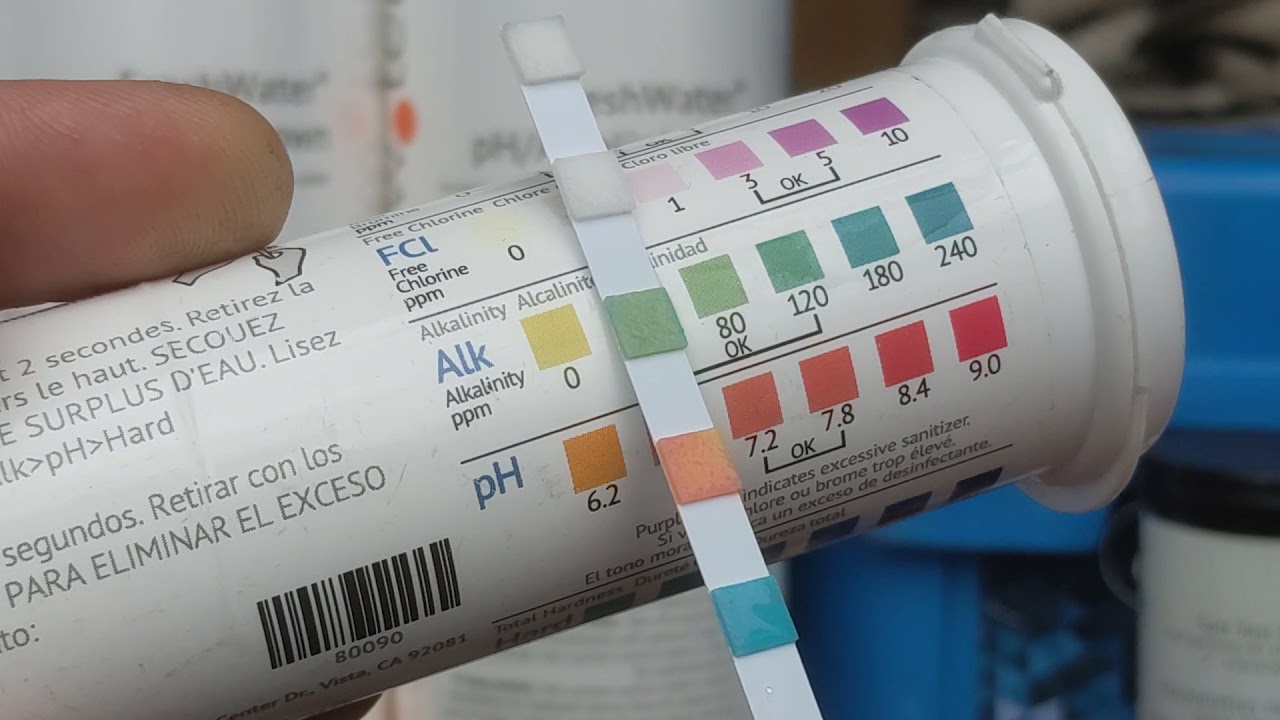

Read more: How To Test Hot Tub Water With Strips

Safety Precautions

Before embarking on any hot tub maintenance or testing procedures, it’s crucial to prioritize safety. Hot tubs involve a combination of water and electricity, making it essential to take the necessary precautions to avoid accidents and ensure a smooth testing process. Here are some vital safety measures to keep in mind:

- Power Off: Always turn off the power to the hot tub at the main circuit breaker before conducting any testing on the pump. This will prevent the risk of electrical shock or damage to the equipment.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as insulated gloves and safety goggles, when handling electrical components to protect yourself from potential hazards.

- Secure the Area: Ensure that the testing area is dry and free from any tripping hazards. Keep the testing space well-lit and organized to facilitate a safe and efficient testing process.

- Follow Manufacturer Guidelines: Refer to the hot tub manufacturer’s guidelines and recommendations for specific safety instructions related to your hot tub model. Adhering to these guidelines can help prevent accidents and maintain the warranty validity.

- Avoid Solitary Work: If possible, have someone nearby while conducting the tests. In case of an emergency, having another person present can provide assistance and ensure a prompt response if needed.

By prioritizing safety and following these precautions, you can create a secure environment for testing your hot tub pump, mitigating potential risks and ensuring a smooth and incident-free testing process.

Tools and Equipment Needed

Before diving into the hot tub pump testing process, it’s essential to gather the necessary tools and equipment to facilitate a thorough and accurate assessment. Here’s a list of the essential items you’ll need:

- Insulated Screwdriver: An insulated screwdriver is crucial for safely handling electrical components during the testing process. It helps prevent electrical shock and ensures secure manipulation of wires and connections.

- Multi-Meter: A multi-meter is a versatile tool for measuring voltage, current, and resistance. It’s indispensable for conducting electrical tests on the hot tub pump and diagnosing potential issues accurately.

- Flow Meter: A flow meter allows you to measure the flow rate of water through the hot tub pump. This is essential for assessing the pump’s performance and identifying any flow-related issues.

- Noise Meter: A noise meter, or sound level meter, is useful for evaluating the operational noise of the hot tub pump. By measuring the sound levels, you can identify any unusual or excessive noise that may indicate underlying problems.

- Flashlight: A reliable flashlight is essential for conducting visual inspections of the hot tub pump and its components. It helps illuminate hard-to-reach areas and allows for thorough scrutiny of the pump’s condition.

- Owner’s Manual: The hot tub’s owner’s manual provides valuable insights into the specific testing procedures recommended by the manufacturer. It also offers essential safety information and guidelines for maintaining the hot tub pump.

- Protective Gloves and Eyewear: Ensure you have protective gloves and eyewear to safeguard yourself from potential hazards, especially when working with electrical components and conducting visual inspections.

By having these tools and equipment at your disposal, you’ll be well-prepared to conduct a comprehensive assessment of your hot tub pump, enabling you to identify and address any issues effectively. Now that you’ve gathered the necessary tools, let’s move on to the visual inspection of the hot tub pump.

Visual Inspection

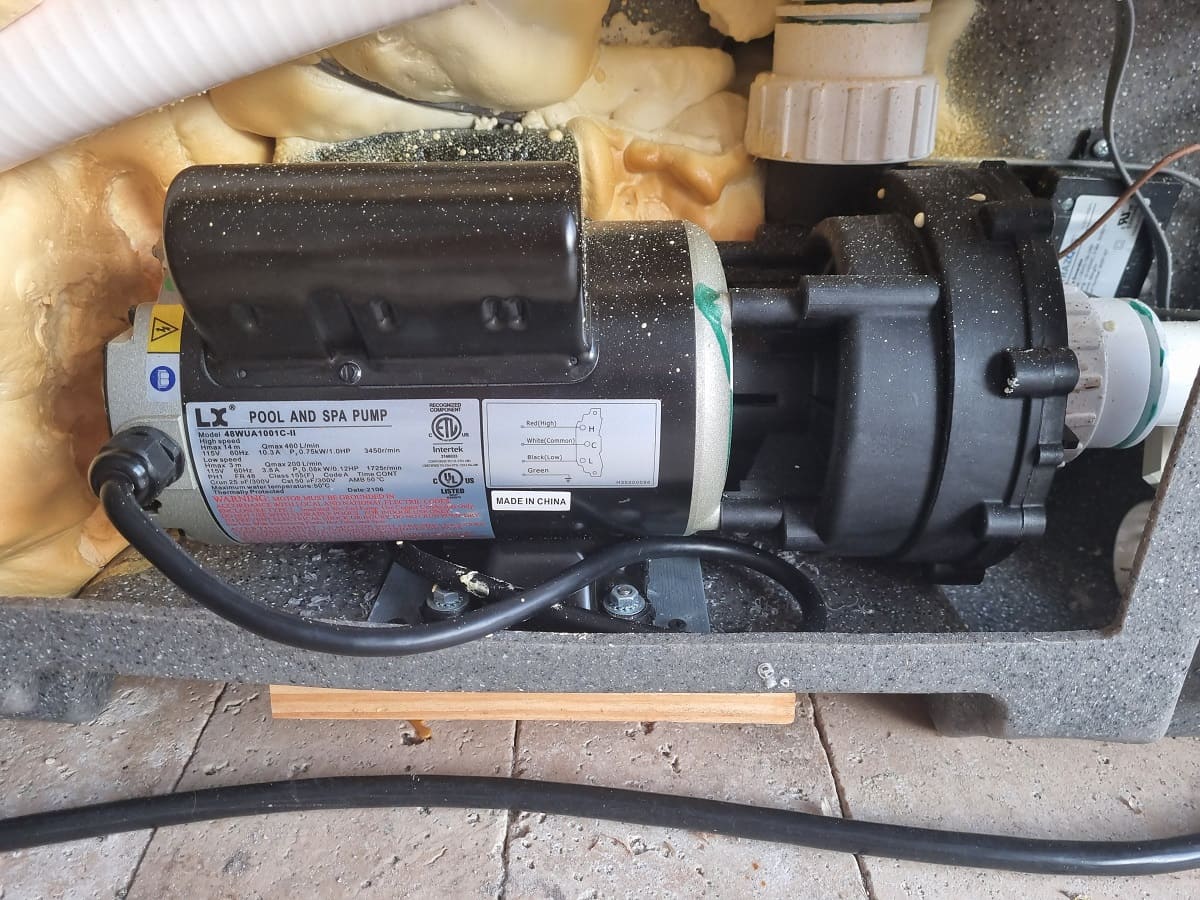

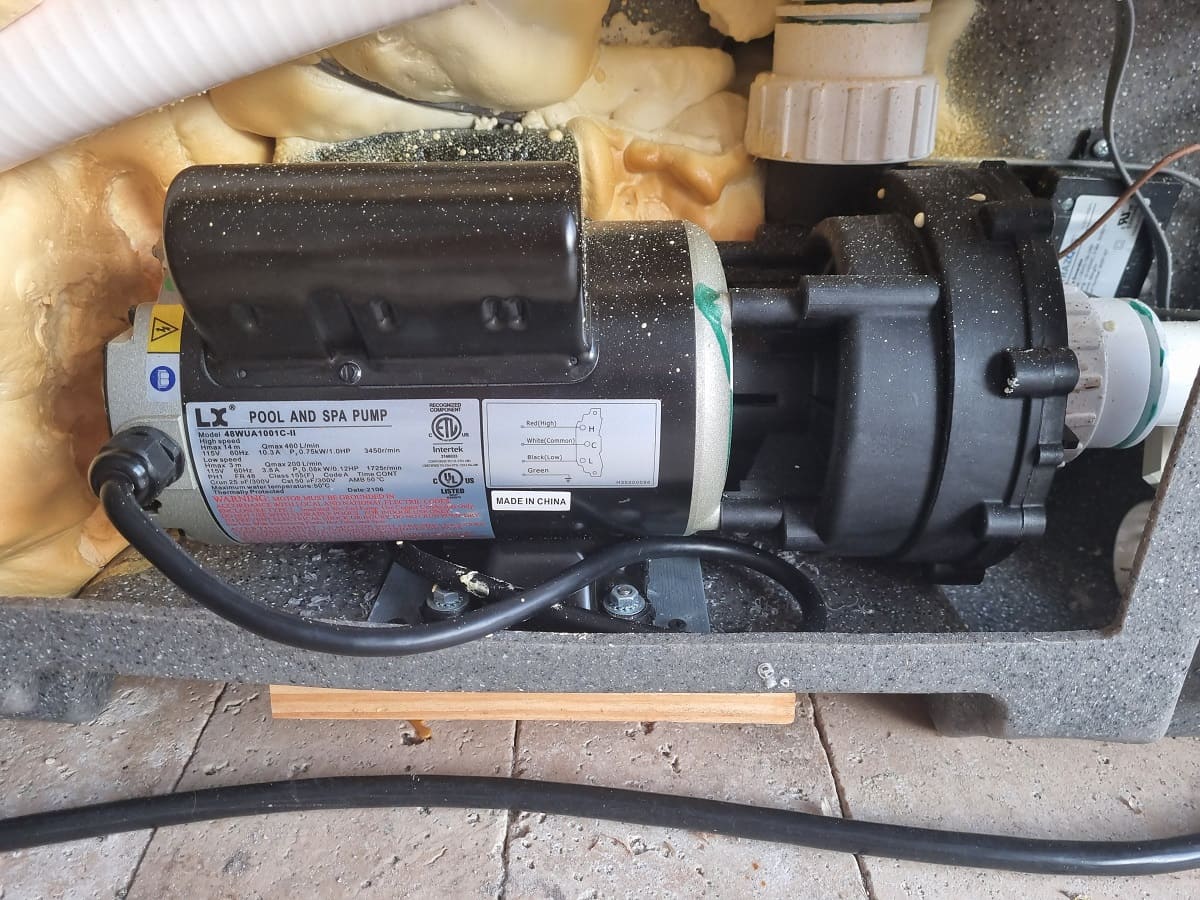

The visual inspection serves as the initial step in assessing the condition of your hot tub pump. This process allows you to visually examine the pump and its components for any visible signs of wear, damage, or irregularities. Here’s a step-by-step guide to conducting a thorough visual inspection:

- Power Off: Ensure that the power to the hot tub is turned off at the main circuit breaker before initiating the visual inspection. This prevents the risk of electrical accidents during the examination process.

- Remove the Access Panel: Access the hot tub pump by removing the appropriate access panel or cover. Use a screwdriver, if necessary, to carefully remove the panel and gain clear visibility of the pump and its surrounding components.

- Inspect for Leaks: Check for any signs of water leaks around the pump and its connections. Pooled water, dampness, or corrosion may indicate leaks that need to be addressed promptly to prevent further damage.

- Examine Wiring and Connections: Inspect the wiring and electrical connections for any signs of fraying, damage, or loose connections. Ensure that all electrical components are securely fastened and free from visible defects.

- Check for Debris: Look for any debris, such as leaves or dirt, that may have accumulated around the pump or within its housing. Clear any obstructions to maintain optimal pump performance.

- Inspect Pump Housing: Examine the pump housing for cracks, rust, or deterioration. Any structural issues with the housing can impact the pump’s functionality and should be addressed accordingly.

- Observe Motor and Impeller: Take a close look at the pump motor and impeller for any signs of wear, corrosion, or irregularities. These components play a crucial role in the pump’s operation and should be in good condition.

By conducting a meticulous visual inspection, you can identify potential issues that require further testing and maintenance. Once you’ve completed the visual inspection, the next step is to proceed with electrical testing to assess the pump’s electrical components and functionality.

Regularly check the pump for any unusual noises, leaks, or reduced water flow. This can help identify any potential issues before they become major problems.

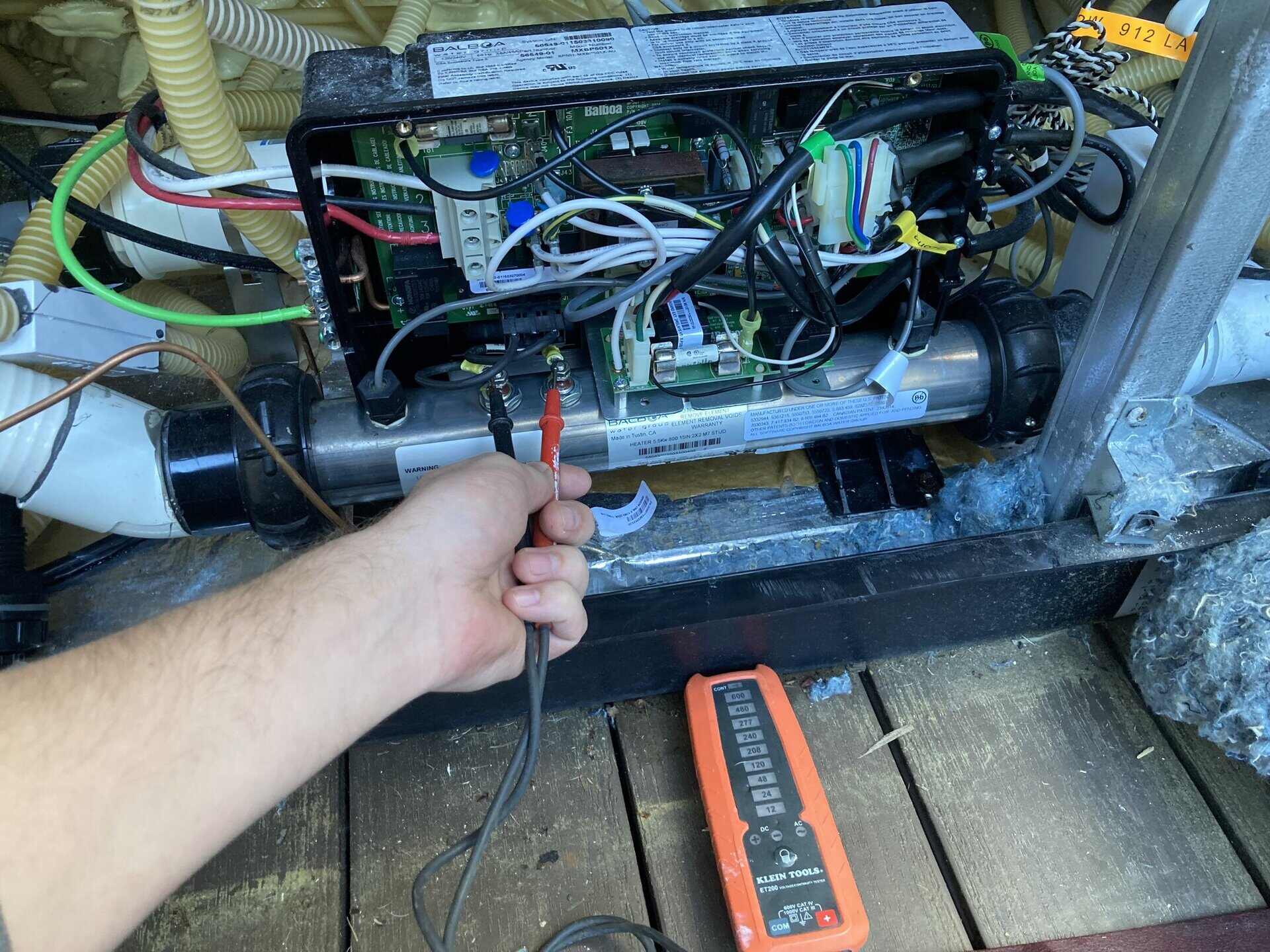

Electrical Testing

Conducting electrical testing is essential for evaluating the functionality and integrity of the hot tub pump’s electrical components. By performing a series of tests, you can assess the electrical connections, voltage, and overall performance of the pump’s motor. Here’s a comprehensive guide to conducting electrical testing on your hot tub pump:

- Use a Multi-Meter: Begin by setting the multi-meter to the voltage testing mode. Ensure that the multi-meter is functioning correctly and the probes are in good condition before proceeding with the tests.

- Test Voltage Input: With the power to the hot tub pump turned on, carefully test the voltage input to the pump motor. Place the multi-meter probes on the appropriate terminals to measure the voltage being supplied to the motor.

- Check for Consistent Voltage: Monitor the multi-meter readings to ensure that the voltage supplied to the motor remains consistent within the expected range. Fluctuations or irregularities in voltage may indicate underlying electrical issues.

- Inspect Wiring and Connections: Carefully examine the wiring and electrical connections for signs of wear, corrosion, or loose connections. Any visible damage or irregularities should be addressed promptly to maintain electrical integrity.

- Test Motor Functionality: Activate the hot tub pump and observe the motor’s performance while monitoring the voltage readings on the multi-meter. Ensure that the motor operates smoothly and that the voltage remains stable during operation.

- Measure Current Draw: If possible, use the multi-meter to measure the current draw of the pump motor during operation. Compare the readings to the manufacturer’s specifications to assess the motor’s electrical efficiency.

- Document Test Results: Record the voltage readings, observations, and any anomalies detected during the electrical testing process. This documentation can provide valuable insights for troubleshooting and future maintenance.

By meticulously conducting electrical testing, you can gain a comprehensive understanding of the hot tub pump’s electrical health and performance. The insights gathered from these tests will guide you in identifying and addressing any electrical issues that may impact the pump’s functionality. With the electrical testing complete, the next step is to proceed with flow testing to assess the pump’s water circulation capabilities.

Read more: How To Use Hot Tub Test Strips

Flow Testing

Flow testing is a critical step in evaluating the hot tub pump’s ability to circulate water effectively throughout the spa system. By assessing the flow rate and identifying potential obstructions or inefficiencies, you can ensure that the pump is operating at optimal performance. Here’s a detailed guide to conducting a thorough flow test for your hot tub pump:

- Prepare the Flow Meter: Set up the flow meter according to the manufacturer’s instructions, ensuring that it is properly calibrated and ready for accurate measurements.

- Locate the Flow Sensor: Identify the location of the flow sensor within the hot tub’s plumbing system. This sensor is typically positioned to measure the flow rate of water passing through the pump.

- Activate the Pump: Turn on the hot tub pump to initiate water circulation through the system. Allow the pump to reach its normal operating flow rate before proceeding with the measurements.

- Measure Flow Rate: Use the flow meter to measure the flow rate of water passing through the pump and the associated plumbing. Take multiple measurements at different points to ensure consistency and accuracy.

- Compare to Expected Flow: Compare the measured flow rate to the expected flow rate specified by the hot tub manufacturer. Deviations from the expected flow rate may indicate potential issues with the pump or the plumbing system.

- Inspect for Obstructions: While conducting the flow test, visually inspect the plumbing and pump inlet for any signs of obstructions, such as debris or blockages. Clear any obstructions to facilitate optimal water flow.

- Document Flow Test Results: Record the flow meter readings, observations, and any anomalies detected during the flow testing process. This documentation provides valuable insights for diagnosing and addressing flow-related issues.

By performing a comprehensive flow test, you can gain valuable insights into the hot tub pump’s water circulation capabilities and identify any potential impediments to efficient flow. The results of the flow test will guide you in addressing any flow-related issues and optimizing the pump’s performance. With the flow testing complete, the next step is to proceed with noise testing to assess the operational sound levels of the hot tub pump.

Noise Testing

Conducting noise testing is a crucial aspect of assessing the overall health and functionality of your hot tub pump. By evaluating the operational sound levels, you can identify any unusual or excessive noise that may indicate underlying issues with the pump’s components or performance. Here’s a detailed guide to conducting noise testing on your hot tub pump:

- Establish Baseline Sound Level: Begin by measuring the ambient sound level in the vicinity of the hot tub pump when it is not in operation. This baseline reading will provide a reference point for evaluating the pump’s operational noise.

- Activate the Pump: Turn on the hot tub pump to initiate water circulation and jet operation. Observe the pump’s performance while focusing on the sound levels generated during operation.

- Use a Noise Meter: Utilize a noise meter to measure the sound levels produced by the hot tub pump during operation. Position the noise meter at a consistent distance from the pump to ensure accurate and reliable measurements.

- Monitor for Unusual Noise: Listen for any unusual or excessive noise emanating from the pump, including grinding, rattling, or high-pitched sounds. Unusual noise may indicate potential issues with the pump’s motor, impeller, or bearings.

- Compare to Baseline: Compare the measured sound levels during pump operation to the baseline ambient sound level obtained earlier. Significant deviations or irregularities in sound levels warrant further investigation into the source of the noise.

- Inspect Pump Components: While conducting the noise test, visually inspect the pump components, including the motor, impeller, and housing, for any visible signs of wear, damage, or irregularities that may contribute to excessive noise.

- Document Noise Test Results: Record the noise meter readings, observations, and any unusual sounds detected during the noise testing process. This documentation will aid in diagnosing and addressing any noise-related issues with the hot tub pump.

By diligently conducting noise testing, you can gain valuable insights into the operational sound levels of the hot tub pump and identify any potential sources of excessive or unusual noise. The results of the noise test will guide you in addressing noise-related issues and ensuring a quieter and more efficient pump operation. With noise testing completed, you have gained a comprehensive understanding of your hot tub pump’s health and performance, allowing you to take any necessary maintenance or corrective actions.

Conclusion

Congratulations! You’ve successfully navigated the comprehensive process of testing your hot tub pump, gaining valuable insights into its condition and performance. By following the step-by-step procedures for visual inspection, electrical testing, flow testing, and noise testing, you’ve empowered yourself to maintain and optimize the heart of your hot tub system.

Through the visual inspection, you meticulously scrutinized the pump and its components, identifying any visible signs of wear, damage, or irregularities. This initial assessment set the stage for the subsequent testing processes, enabling you to pinpoint areas that required further evaluation and potential maintenance.

During the electrical testing phase, you delved into the intricate workings of the pump’s electrical components, measuring voltage, assessing wiring integrity, and evaluating the motor’s performance. This thorough examination provided crucial insights into the electrical health of the pump, guiding you in addressing any detected issues and ensuring safe and efficient operation.

Flow testing allowed you to gauge the pump’s water circulation capabilities, measuring the flow rate and identifying any potential obstructions or inefficiencies within the plumbing system. By conducting this test, you gained a comprehensive understanding of the pump’s ability to maintain optimal water flow, paving the way for enhanced performance and efficiency.

Lastly, the noise testing process provided valuable insights into the operational sound levels of the hot tub pump, allowing you to identify and address any unusual or excessive noise that may indicate underlying issues with the pump’s components or performance. By meticulously evaluating the pump’s noise levels, you’ve contributed to a quieter and more serene hot tub experience.

Armed with the knowledge and insights gained from these testing procedures, you are well-equipped to address any identified issues, perform routine maintenance, and ensure the continued smooth operation of your hot tub pump. Remember, regular testing and maintenance are key to preserving the longevity and performance of your hot tub pump, allowing you to enjoy countless relaxing soaks in your personal oasis of tranquility.

So, pat yourself on the back for embarking on this testing journey, and rest assured that your hot tub pump is in good hands – yours!

Frequently Asked Questions about How To Test A Hot Tub Pump

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Test A Hot Tub Pump”