Home>Home Maintenance>How Does Marine Air Conditioning Work

Home Maintenance

How Does Marine Air Conditioning Work

Modified: March 6, 2024

Learn how marine air conditioning works and the importance of home maintenance for optimal performance. Discover the benefits of regular upkeep for your marine HVAC system.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome aboard, fellow sea enthusiasts! If you’re a proud owner of a yacht or a vessel, you know that proper maintenance is crucial for a smooth and comfortable sailing experience. One essential aspect of maintaining a comfortable environment on your boat is ensuring a reliable and efficient marine air conditioning system.

Marine air conditioning plays a vital role in regulating the temperature, humidity, and air quality inside your vessel. Whether you’re cruising on a hot summer day or exploring colder waters, a well-functioning air conditioning system will keep you and your crew comfortable throughout your journey.

In this comprehensive guide, we will delve into the fascinating world of marine air conditioning. We’ll explore everything from the basics of marine air conditioning, the components of a system, its working principle, different types of systems available, and the benefits and considerations of choosing marine air conditioning for your vessel. We’ll also touch on maintenance tips and troubleshooting common issues in marine air conditioning systems.

So, sit back, relax, and let’s embark on a journey to explore the intricacies of marine air conditioning and discover how it can enhance your boating experience.

Next, let’s dive into the basics of marine air conditioning systems!

Key Takeaways:

- Marine air conditioning systems keep boats comfortable by cooling and dehumidifying the air. They have essential components like compressors, condensers, and evaporators that work together to regulate indoor temperatures.

- Self-contained and split systems are the two main types of marine air conditioning. They offer benefits like improved air quality and flexibility, but require regular maintenance to ensure optimal performance.

Read more: How Does Geothermal Air Conditioning Work

Basics of Marine Air Conditioning

Before we delve into the inner workings of marine air conditioning, let’s start with the basics. Marine air conditioning systems are designed to provide a comfortable indoor environment in boats, yachts, and other vessels. They typically consist of three main components: the compressor, the condenser, and the evaporator.

The compressor is the heart of the air conditioning system. It pressurizes and circulates the refrigerant, a substance that absorbs and releases heat, to facilitate the cooling process. The condenser, located outside the vessel, is responsible for dissipating the heat absorbed by the refrigerant. It uses fans or water flow to transfer the heat to the surrounding environment.

Inside the vessel, the evaporator plays a crucial role. It receives the cooled refrigerant from the condenser and removes heat and humidity from the indoor air. The cooled air is then blown into the living or cabin spaces, creating a comfortable and regulated temperature.

Marine air conditioning systems utilize either a direct expansion (DX) system or a chilled water system. In a DX system, the refrigerant flows directly through the evaporator, absorbing heat and cooling the air. This system is commonly used in smaller vessels and offers quick cooling with lower initial costs.

On the other hand, chilled water systems circulate chilled water through a network of pipes connected to air handling units. The chilled water absorbs heat from the air as it passes through the units, cooling the indoor space. Chilled water systems are more complex and often preferred for larger vessels as they provide better control over temperature and humidity levels.

It’s important to note that marine air conditioning systems require a power source, typically generated by the boat’s generator or shore power connection. Proper electrical connections and considerations should be made to ensure a stable power supply to the system.

Now that we have a basic understanding of marine air conditioning, let’s take a closer look at the components that make up these systems.

Components of Marine Air Conditioning Systems

A marine air conditioning system is a complex network of components working together to provide a comfortable indoor environment on boats and yachts. Understanding the key components of these systems is essential for proper maintenance and troubleshooting. Let’s explore these components in more detail.

1. Compressor: The compressor is the heart of the air conditioning system. It pressurizes the refrigerant gas, increasing its temperature and converting it into a high-pressure vapor. This compressed vapor is then sent to the condenser for further processing.

2. Condenser: The condenser is responsible for dissipating the heat absorbed by the refrigerant. It is usually located outside the vessel and uses either air or water to transfer the heat to the surrounding environment. The refrigerant, which is in vapor form at this stage, releases the heat and condenses into a high-pressure liquid.

3. Evaporator: The evaporator is located inside the vessel and plays a crucial role in cooling the indoor space. It receives the high-pressure liquid refrigerant from the condenser and allows it to expand rapidly. This expansion causes the refrigerant to absorb heat and convert into a low-pressure vapor. The evaporator contains a network of coils through which the indoor air passes, allowing the refrigerant to absorb the heat and cool the air.

4. Expansion Valve: The expansion valve, also known as the metering device, regulates the flow of refrigerant into the evaporator. It controls the pressure and temperature of the refrigerant as it enters the evaporator, ensuring optimal cooling efficiency.

5. Air Handler: The air handler is responsible for distributing the cooled air throughout the boat. It consists of a blower fan and a network of ducts or vents that carry the conditioned air to different areas of the vessel. The air handler also filters the air, removing dust, allergens, and other impurities, to improve indoor air quality.

6. Thermostat: The thermostat serves as the control interface for the marine air conditioning system. It allows users to set and maintain the desired temperature inside the boat. Modern thermostats often come with advanced features such as programmable schedules and remote control capabilities.

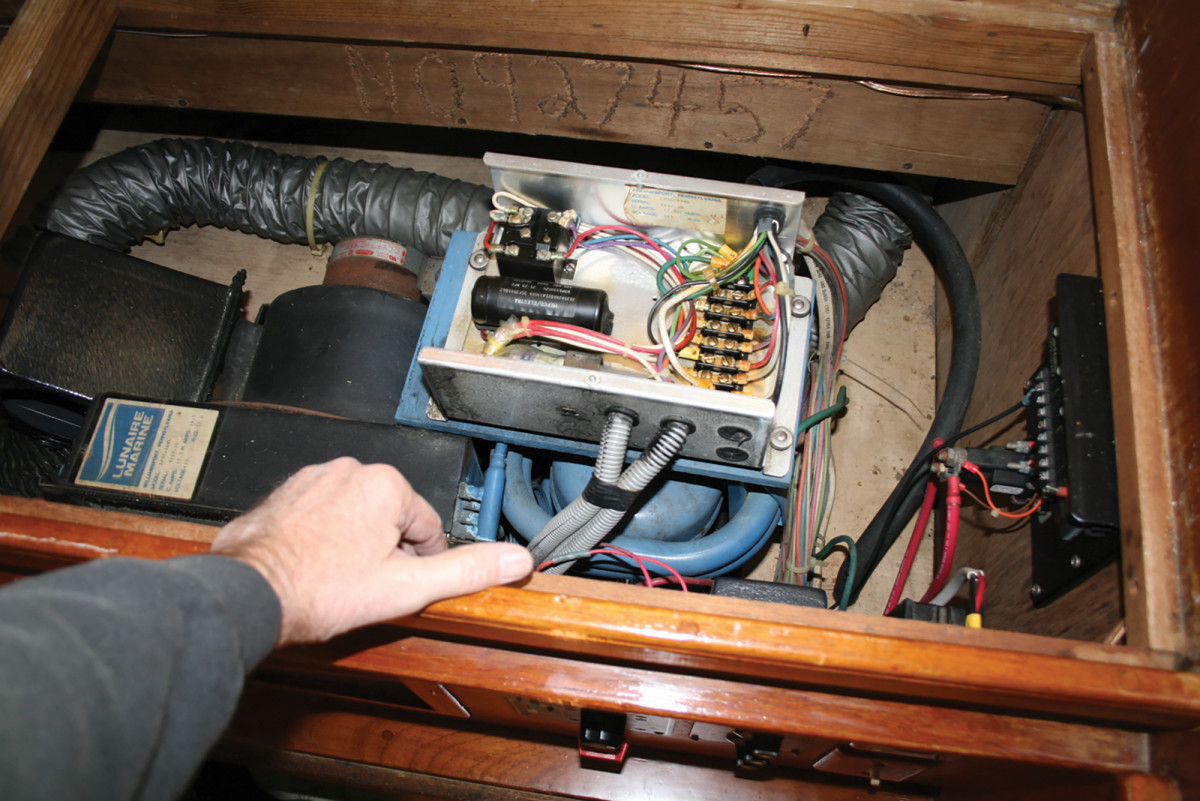

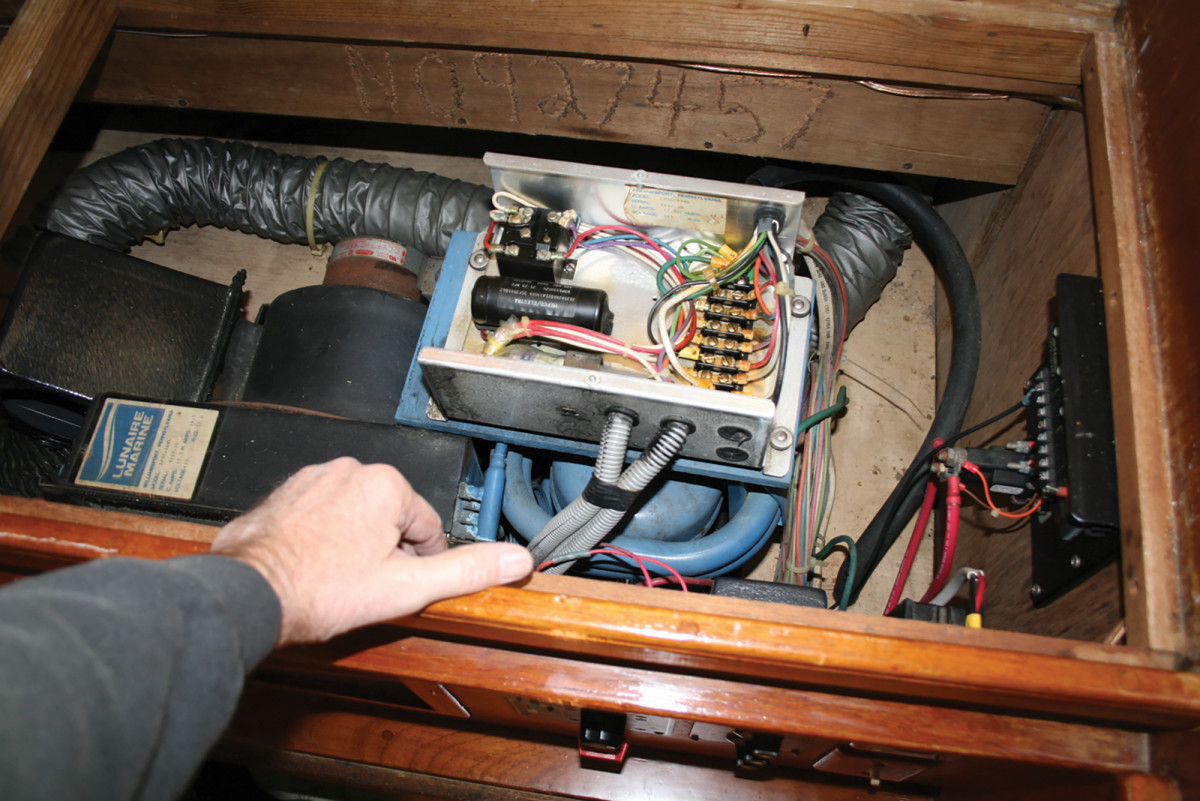

7. Electrical Controls: Marine air conditioning systems include various electrical controls to ensure safe and efficient operation. These controls include relays, capacitors, contactors, and temperature sensors, among others. They work together to regulate the power supply, monitor system performance, and protect the components from electrical faults.

These are the essential components that make up a marine air conditioning system. Understanding how each component functions and interacts with the others is crucial for proper maintenance and troubleshooting. Now that we know the components, let’s explore the working principle of marine air conditioning systems in the next section.

Working Principle of Marine Air Conditioning

Understanding the working principle of marine air conditioning systems can help boat owners and enthusiasts grasp how these systems cool the indoor environment on vessels. Let’s explore the step-by-step process of how marine air conditioning works.

1. Circulation of Refrigerant: The process begins with the circulation of the refrigerant, typically a specific type of fluid designed to absorb and release heat, such as R-410A or R-134a. The compressor pressurizes the refrigerant, transforming it into a high-pressure vapor.

2. Heat Dissipation: The high-pressure vapor is then sent to the condenser, either located on the roof or an exterior part of the vessel. The condenser utilizes either air or water to dissipate the heat extracted from the refrigerant. As the refrigerant releases heat, it undergoes a phase change and condenses into a high-pressure liquid.

3. Evaporation and Cooling: The high-pressure liquid refrigerant then flows into the evaporator, which is typically located inside the boat. Inside the evaporator, the refrigerant rapidly expands through an expansion valve or metering device, causing it to evaporate and transform into a low-pressure vapor. This evaporation process absorbs heat from the indoor air passing through the evaporator coils, thus cooling the air.

4. Condensation and Removal of Moisture: As the refrigerant absorbs heat from the indoor air, it also removes moisture or humidity from the air. This process helps in dehumidifying the cabin or living spaces, making the indoor environment more comfortable.

5. Air Distribution: The cooled and dehumidified air is then distributed throughout the boat using an air handler, which consists of a blower fan and a network of ducts or vents. The air handler blows the conditioned air into different areas, ensuring a consistent and comfortable temperature throughout the vessel.

6. Thermal Regulation: The marine air conditioning system continuously monitors the temperature inside the boat using a thermostat. The thermostat allows users to set their desired temperature, and the system adjusts the cooling operation accordingly to maintain the set temperature. This ensures a comfortable and regulated indoor environment.

This is the basic working principle of marine air conditioning systems. By understanding how these systems circulate and manipulate the refrigerant to cool and dehumidify the air, boat owners can better appreciate the functionality and importance of marine air conditioning in providing a comfortable stay on board.

Now that we’ve explored the working principle, let’s dive into the different types of marine air conditioning systems available.

Regular maintenance of marine air conditioning systems is crucial to ensure efficient and reliable operation. This includes cleaning the filters, checking for leaks, and inspecting the overall condition of the system.

Types of Marine Air Conditioning Systems

When it comes to marine air conditioning systems, there are primarily two main types: self-contained systems and split systems. Each type has its own advantages and considerations, catering to different needs and preferences of boat owners. Let’s explore these types in more detail.

1. Self-Contained Systems: Self-contained marine air conditioning systems, also known as package units, are compact and all-in-one solutions. These systems consist of a single unit that contains all the necessary components, including the compressor, condenser, evaporator, and blower fan. Self-contained systems are typically installed in a specific area or space within the vessel, such as a cabin or cockpit.

The key advantage of self-contained systems is their simplicity and ease of installation. They require minimal ductwork and are relatively straightforward to set up. Self-contained systems are often used in small to medium-sized vessels or individual compartments where cooling is required.

2. Split Systems: Split marine air conditioning systems are more complex and versatile than self-contained units. These systems consist of two main components: an evaporator unit installed inside the boat and a separate condensing unit placed outside the vessel. The two units are connected through refrigerant lines and electrical wiring.

Split systems offer greater flexibility in terms of installation, allowing boat owners to place the evaporator unit in one area and the condensing unit in a different location. This flexibility is particularly beneficial in larger vessels where cooling requirements may vary in different areas.

Split marine air conditioning systems also offer enhanced energy efficiency and quieter operation since the condensing unit, which produces more noise, is located outside the living spaces. Moreover, split systems provide the opportunity for more advanced control options, such as zoning capabilities, which allow different areas of the boat to be cooled independently.

It’s important to note that both self-contained and split systems can be further categorized based on the type of refrigerant used. Common refrigerants for marine air conditioning systems include R-410A and R-134a, which are more environmentally friendly and comply with regulations regarding ozone depletion and global warming potential.

When deciding on the type of marine air conditioning system to choose, various factors should be considered, such as the size and layout of the vessel, cooling requirements, energy efficiency, and budget constraints. Consulting with a professional marine air conditioning specialist can help in selecting the most suitable system for your specific needs.

Now that we’ve examined the types of marine air conditioning systems available, let’s explore the benefits and considerations of installing marine air conditioning on your vessel.

Read more: How Does Ducted Air Conditioning Work

Benefits and Considerations of Marine Air Conditioning

Installing a marine air conditioning system on your vessel offers numerous benefits that enhance your boating experience. However, there are also various considerations to keep in mind when choosing and utilizing marine air conditioning. Let’s explore the benefits and considerations in detail.

Benefits:

- Comfort: The primary benefit of marine air conditioning is the enhanced comfort it provides on board. Whether you’re in tropical climates or exploring colder waters, a well-functioning air conditioning system maintains a comfortable temperature and regulates humidity levels, ensuring a pleasant environment for you and your guests.

- Improved Indoor Air Quality: Marine air conditioning systems feature air filters that remove dust, allergens, and other impurities from the air, improving the overall air quality on your vessel. This is particularly beneficial for individuals with respiratory conditions or allergies.

- Protection of Interior Elements: A stable and regulated indoor environment helps protect the interior elements of your boat, such as woodwork, upholstery, and electronics. Proper temperature and humidity control prevent damage caused by excessive heat, condensation, or mold growth.

- Flexibility and Zoning: Split marine air conditioning systems offer the flexibility to cool different areas of the boat independently. This zoning capability allows you to customize the temperature settings based on individual preferences or specific needs in different compartments or cabins.

- Increased Resale Value: Having a marine air conditioning system installed can potentially increase the resale value of your vessel. Buyers often prioritize comfort and amenities, and a well-maintained air conditioning system can be a desirable feature.

Considerations:

- Power Consumption: Marine air conditioning systems require a stable power supply, typically generated by the boat’s generator or shore power connection. Considering energy consumption is important to ensure proper power capabilities and avoid overloading electrical systems.

- Maintenance: Regular maintenance is crucial for keeping marine air conditioning systems running efficiently. This includes cleaning or replacing air filters, checking refrigerant levels, inspecting and cleaning coils, and ensuring proper drainage to prevent clogs or leaks. Routine maintenance helps prolong the lifespan of the system and ensures optimal performance.

- Space and Installation: Depending on the type of system chosen, marine air conditioning units may require adequate space for installation. Planning and considering the spatial limitations of your vessel is important to ensure a proper fit and efficient airflow.

- Environmental Impact: It’s important to select marine air conditioning systems that use environmentally friendly refrigerants and comply with regulations regarding ozone depletion and global warming potential. Choosing systems with eco-friendly features helps minimize the environmental impact while enjoying the benefits of air conditioning.

- Budget and Cost: Installing and operating marine air conditioning systems can involve upfront costs as well as ongoing operational expenses. It’s essential to weigh the benefits against the associated costs and establish a budget that aligns with your financial capabilities and expectations.

Considering these factors will help you make an informed decision when selecting and utilizing marine air conditioning on your vessel. It’s always recommended to consult with experienced professionals in the marine industry for expert advice and guidance tailored to your specific needs.

Now that we’ve explored the benefits and considerations, let’s move on to maintenance and troubleshooting tips for marine air conditioning systems.

Maintenance and Troubleshooting of Marine Air Conditioning Systems

Regular maintenance and troubleshooting are essential for ensuring the optimal performance and longevity of your marine air conditioning system. By following these tips, you can prevent potential issues, identify problems early on, and keep your system running smoothly. Let’s explore some maintenance and troubleshooting practices for marine air conditioning systems.

Maintenance Tips:

- Clean and Replace Air Filters: Regularly clean or replace the air filters in your marine air conditioning system. Dirty filters can restrict airflow, reduce cooling efficiency, and lead to poor indoor air quality. Follow the manufacturer’s guidelines to determine the recommended frequency of filter cleaning or replacement.

- Inspect and Clean Coils: Inspect the evaporator and condenser coils for dust, dirt, and debris buildup. Dirty coils can impede heat transfer and reduce cooling efficiency. Gently clean the coils using a soft brush or vacuum cleaner to remove any accumulated debris. Avoid using harsh chemicals that could damage the coil’s surface.

- Check Condensate Drainage: Ensure that the condensate drainage system is clear and free from blockages. If the drain line or condensate pan becomes clogged, it can lead to water leaks and damage to your vessel. Regularly inspect and clean the condensate drainage components to prevent such issues.

- Monitor Refrigerant Levels: Low refrigerant levels can affect the performance and cooling capacity of your marine air conditioning system. Periodically check the refrigerant levels and, if necessary, consult a professional technician to recharge or top up the refrigerant as per the manufacturer’s specifications.

- Keep Vents and Registers Clear: Ensure that the vents and registers are not obstructed by furniture, curtains, or other objects. Blocked vents can restrict airflow and reduce cooling efficiency. Allow for proper air circulation by keeping the vents clear and unobstructed.

Troubleshooting Tips:

- No Power: If your marine air conditioning system is not receiving power, check the electrical connections, circuit breakers, and fuses. Ensure that the power supply to the system is stable and functioning correctly.

- Inadequate Cooling: If your system is not cooling effectively, check the thermostat settings to ensure they are correctly set. Additionally, clean or replace the air filters and inspect the evaporator and condenser coils for any dirt or debris buildup that may be impacting cooling performance.

- Water Leaks: Water leaks can occur due to clogged condensate drain lines or a malfunctioning condensate pump. Check the drain lines for any blockages and clean them if necessary. If the issue persists, consult a professional technician to inspect and repair the condensate drainage system.

- Strange Noises: Unusual noises like rattling, banging, or squealing can indicate problems with the fan motor, compressor, or other components. If you hear such noises, it’s best to contact a qualified technician to diagnose and address the issue before it worsens.

- Intermittent Operation: If your marine air conditioning system turns on and off at irregular intervals, it may be a sign of electrical or control problems. Check the electrical connections and consult a professional if the issue persists.

Remember, when performing maintenance or troubleshooting your marine air conditioning system, always follow the manufacturer’s guidelines and, if needed, consult a professional technician who specializes in marine air conditioning systems. Their expertise and experience can help identify and resolve issues effectively.

By following these maintenance and troubleshooting tips, you can ensure that your marine air conditioning system operates at its best, providing you with a comfortable and enjoyable boating experience.

Now that we’ve covered maintenance and troubleshooting, let’s conclude our guide to marine air conditioning systems.

Conclusion

As we conclude our guide to marine air conditioning systems, we hope you’ve gained a comprehensive understanding of the basics, components, working principle, types, benefits, considerations, maintenance, and troubleshooting of these systems. Whether you’re cruising in tropical waters or exploring colder climates, a well-functioning marine air conditioning system brings comfort, regulated temperatures, and enhanced indoor air quality to your vessel.

From the compressor, condenser, and evaporator to the thermostat, air handler, and electrical controls, each component plays a crucial role in maintaining a comfortable indoor environment. Understanding the different types of marine air conditioning systems, such as self-contained and split systems, allows you to choose the solution that best suits your needs and vessel size.

Installation considerations, such as power consumption, space, and environmental impact, should be weighed against the benefits of enhanced comfort, improved air quality, and protection of interior elements. Proper maintenance, including cleaning air filters, inspecting and cleaning coils, monitoring refrigerant levels, and ensuring proper condensate drainage, ensures optimal performance and longevity of your marine air conditioning system.

Should issues occur, following troubleshooting tips such as checking power supply, addressing inadequate cooling or water leaks, and identifying strange noises or intermittent operation can help in resolving the problems effectively. Consulting a professional technician specializing in marine air conditioning systems can provide further assistance in diagnosing and resolving complex issues.

By investing in a reliable and efficient marine air conditioning system and staying proactive in maintenance and troubleshooting, you can create a comfortable and enjoyable environment on your boat. Whether you’re hosting guests, spending quality time with family, or simply relaxing after a day of adventure, a well-regulated indoor climate enhances your boating experience.

Remember, the key to a successful marine air conditioning system is understanding its components, working principles, and maintenance requirements. With this knowledge, you can navigate the seas confidently, knowing that you have a comfortable retreat waiting for you onboard.

So, embrace the benefits of marine air conditioning, keep up with regular maintenance, and ensure a comfortable journey, no matter where your seafaring adventures take you.

Frequently Asked Questions about How Does Marine Air Conditioning Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.