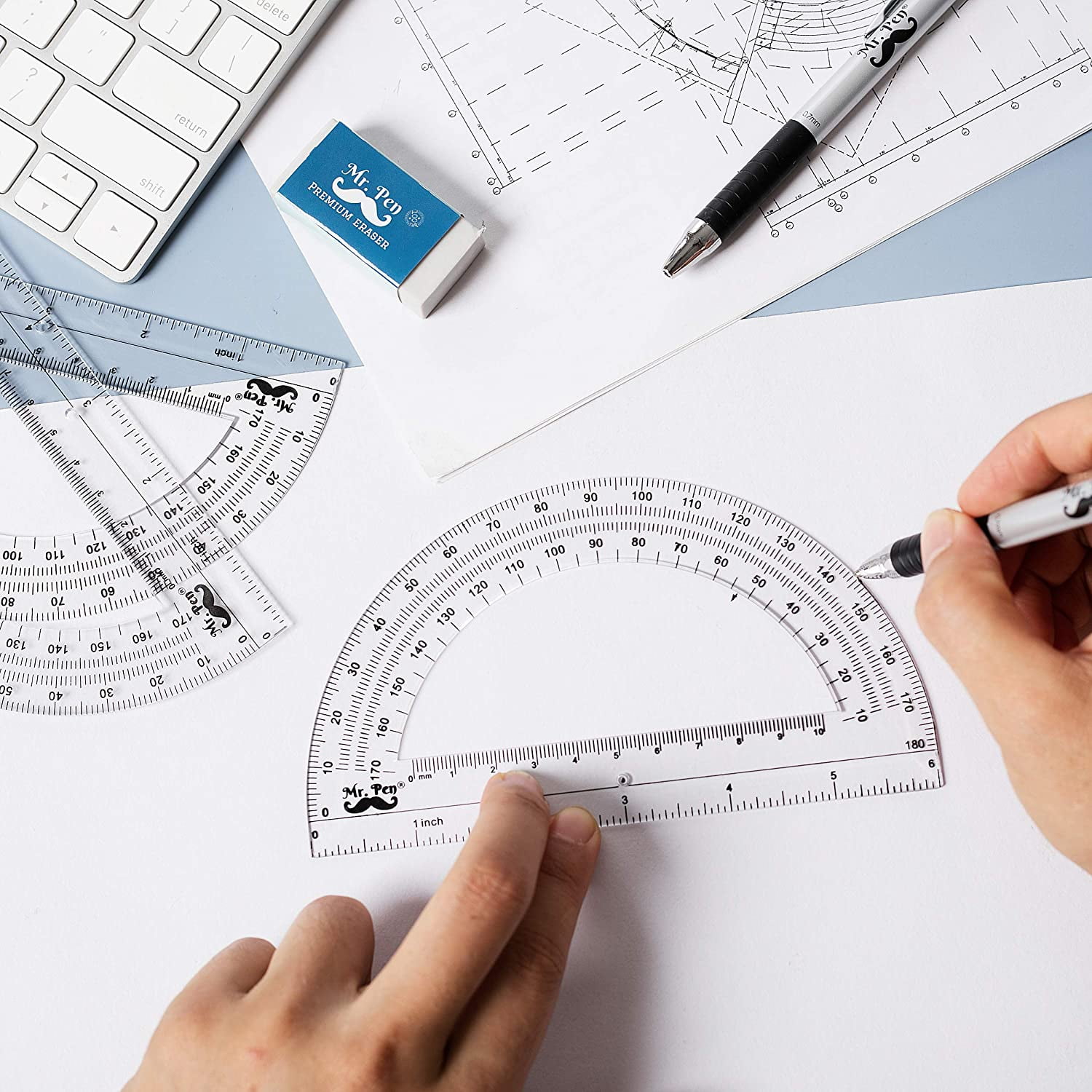

Home> Measuring Tools

Measuring Tools: Essential Guide to Accurate Precision Engineering

Explore our in-depth guide on measuring tools: from their functionalities, best practices, to choosing the right one. They’re a must for precise, reliable results.