Home>Technology>Smart Home Devices>What Printer Is Best For Stickers

Smart Home Devices

What Printer Is Best For Stickers

Modified: August 17, 2024

Looking for the best printer for stickers? Explore our top recommendations for smart home devices and find the perfect match for your needs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to printing stickers, selecting the right printer is crucial for achieving high-quality, durable results. With the rapid advancements in printing technology, consumers are presented with various options, each offering unique benefits and drawbacks. In this comprehensive guide, we will delve into the world of printers suitable for sticker printing, exploring the pros and cons of inkjet, laser, and thermal printers. By the end of this article, you will have a clear understanding of the most suitable printer for your sticker printing needs, empowering you to make an informed decision that aligns with your requirements and preferences. Let's embark on this insightful journey to discover the ideal printer for bringing your sticker designs to life.

Key Takeaways:

- Inkjet printers are great for colorful and detailed stickers, but they may smudge and consume more ink. They are affordable and compact, making them suitable for home-based sticker printing.

- Laser printers are perfect for durable and high-speed sticker production, but they may have color limitations and higher upfront costs. They offer cost-effective, professional-grade stickers for businesses.

Read more: What Printers Can Print Stickers

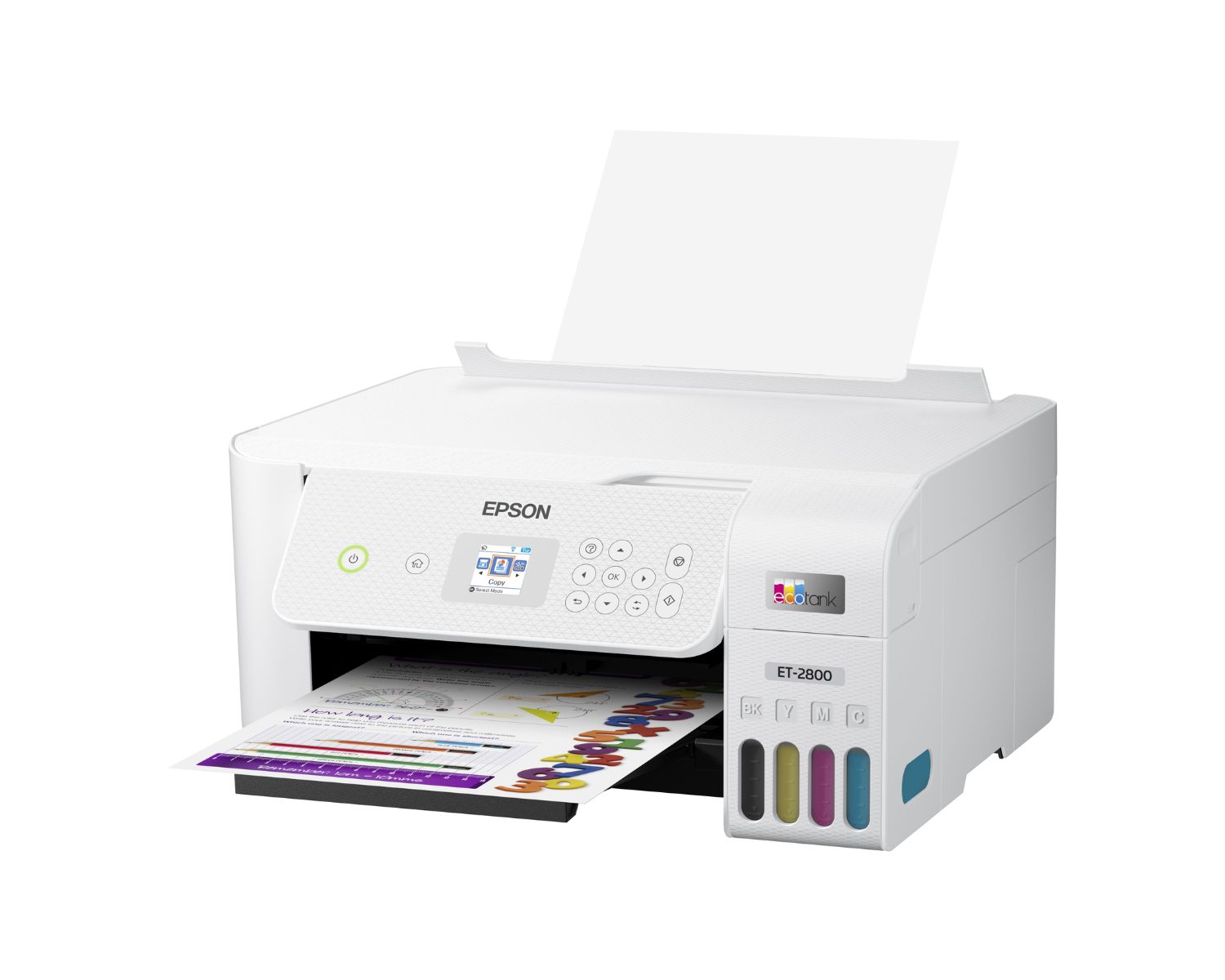

Inkjet Printers

When it comes to sticker printing, inkjet printers are a popular choice for several compelling reasons. Let’s explore the advantages and limitations of using inkjet printers for this purpose.

Pros:

- Versatility: Inkjet printers are highly versatile, capable of producing vibrant and detailed sticker designs. Whether you need to print intricate patterns or vivid images, inkjet printers can deliver impressive results.

- Affordability: Many inkjet printers are available at affordable price points, making them an accessible option for individuals and small businesses looking to create custom stickers without a substantial initial investment.

- Color Range: Inkjet printers excel in producing a wide spectrum of colors, enabling you to bring your sticker designs to life with rich, eye-catching hues.

- Photo Printing: If your sticker designs incorporate photographic elements, inkjet printers are well-suited for rendering high-quality images with exceptional clarity and detail.

- Compact Size: Inkjet printers are often compact and space-efficient, making them suitable for home-based sticker printing setups where desk space is a consideration.

Cons:

- Smudging: The ink used in inkjet printing can be prone to smudging, especially if the printed stickers come into contact with moisture. This limitation may affect the durability of the stickers, particularly in outdoor or high-contact applications.

- Ink Consumption: Inkjet printers can be relatively high consumers of ink, leading to ongoing operational costs, especially for frequent sticker printing. This aspect should be considered when evaluating the long-term affordability of inkjet printing.

- Print Speed: In comparison to laser printers, inkjet printers may have slower print speeds, which could impact productivity when handling large sticker printing volumes.

- Water Resistance: While some specialized inkjet printers offer water-resistant inks, standard inkjet prints may be susceptible to water damage, limiting the stickers' resilience in wet conditions.

Understanding the strengths and limitations of inkjet printers is essential for making an informed decision regarding their suitability for your sticker printing requirements.

Laser Printers

When considering the optimal printer for sticker production, laser printers present a compelling alternative to inkjet models. Let’s delve into the advantages and drawbacks of utilizing laser printers for sticker printing.

Pros:

- Speed and Efficiency: Laser printers are renowned for their rapid printing speeds, making them ideal for high-volume sticker production. The efficient nature of laser printing can significantly enhance productivity, particularly for businesses with substantial printing requirements.

- Durability: The toner used in laser printing results in exceptionally durable stickers. Laser-printed stickers are resistant to smudging, water damage, and fading, ensuring longevity and robustness in various environments.

- Cost-Effectiveness: While the initial investment for a laser printer may be higher than that of an inkjet model, laser printing can be more cost-effective in the long run. The lower cost per page and reduced frequency of toner replacement contribute to its economic appeal for extensive sticker printing projects.

- Sharp Text and Graphics: Laser printers excel in producing sharp, precise text and graphics, making them suitable for stickers that incorporate intricate details, fine lines, and small text.

- Consistency: Laser printing delivers consistent results, ensuring uniform quality across all printed stickers. This reliability is advantageous for maintaining brand consistency and professional aesthetics.

Cons:

- Color Limitations: While color laser printers are available, they may not offer the same color vibrancy and range as inkjet printers, potentially limiting the color palette for sticker designs.

- Upfront Cost: The initial purchase cost of a laser printer can be higher than that of an inkjet model, which may pose a barrier for individuals or small businesses with budget constraints.

- Size and Weight: Laser printers are often bulkier and heavier than inkjet counterparts, requiring ample space and sturdy furniture to accommodate their size and weight.

- Warm-Up Time: Laser printers typically require a brief warm-up period before initiating the printing process, which may impact immediate printing needs or time-sensitive projects.

By weighing the advantages and limitations of laser printers, you can make an informed decision regarding their suitability for your sticker printing endeavors.

Thermal Printers

Thermal printers offer a distinct approach to sticker printing, leveraging thermal technology to produce high-quality, durable stickers. Let’s explore the advantages and limitations of utilizing thermal printers for this purpose.

Pros:

- Speed and Efficiency: Thermal printers are renowned for their rapid printing speeds, making them ideal for on-demand sticker production. The direct thermal printing process eliminates the need for ink or toner, streamlining the printing workflow and enhancing overall efficiency.

- Durability: Thermal printed stickers exhibit exceptional durability, as they are resistant to smudging, fading, and water damage. This resilience makes them suitable for various applications, including outdoor use and product labeling.

- Low Maintenance: With no ink or toner cartridges to replace, thermal printers require minimal maintenance, contributing to their cost-effectiveness and operational convenience.

- Compact Design: Thermal printers are often compact and space-efficient, making them suitable for environments where desk space is limited. Their portability and small footprint enhance their versatility for diverse sticker printing needs.

- Quiet Operation: Thermal printers operate quietly, creating a conducive work environment without disruptive printing noises, which can be advantageous in shared or noise-sensitive spaces.

Cons:

- Monochrome Printing: Thermal printers are primarily designed for monochrome printing, limiting their suitability for color-intensive sticker designs. While some advanced models support limited color printing, the color range is typically narrower than that of inkjet or laser printers.

- Specialized Media: Thermal printers require specific thermal paper or labels for printing, which may entail higher material costs and reliance on proprietary consumables compared to traditional inkjet and laser printers.

- Environmental Factors: The durability of thermal printed stickers can be affected by exposure to extreme heat or direct sunlight, potentially leading to discoloration or degradation over time in challenging environmental conditions.

- Upfront Investment: While thermal printers offer long-term cost savings, the initial purchase cost may be higher than that of standard inkjet printers, necessitating a careful assessment of the return on investment for sticker printing requirements.

By comprehensively understanding the strengths and limitations of thermal printers, you can make an informed decision regarding their suitability for your sticker printing needs, considering factors such as color requirements, durability, and long-term cost considerations.

Conclusion

As we conclude our exploration of inkjet, laser, and thermal printers for sticker production, it’s evident that each printing technology offers unique advantages and considerations. When selecting the ideal printer for your sticker printing needs, it’s essential to consider factors such as print quality, durability, cost-effectiveness, and color requirements.

For individuals and businesses seeking versatile, affordable, and color-rich printing, inkjet printers emerge as a compelling choice. Their ability to produce vibrant, detailed designs makes them suitable for a wide range of sticker applications, from personal crafting projects to small-scale commercial endeavors. However, the susceptibility to smudging, ink consumption, and print speed should be carefully evaluated when weighing the pros and cons of inkjet printers.

On the other hand, laser printers excel in delivering durable, high-speed printing, making them ideal for businesses with extensive sticker production needs. The cost-effectiveness, sharp text and graphics, and consistent results position laser printers as a formidable option for creating resilient, professional-grade stickers. While color limitations and upfront costs are factors to consider, the long-term efficiency and durability of laser printing warrant thoughtful consideration.

Thermal printers offer a niche solution for on-demand, monochrome sticker printing, emphasizing speed, durability, and low maintenance. Their compact design and quiet operation make them suitable for specific applications, particularly in environments where space and noise considerations are paramount. However, the monochrome printing and reliance on specialized media should be weighed against the benefits of rapid, resilient sticker production.

Ultimately, the selection of the best printer for stickers hinges on aligning the unique features of each printing technology with your specific requirements, preferences, and budget. By carefully evaluating the pros and cons of inkjet, laser, and thermal printers in the context of your sticker printing needs, you can make an informed decision that optimizes print quality, durability, and cost-effectiveness for your projects.

Armed with a deeper understanding of these printing technologies, you are empowered to embark on your sticker printing journey with confidence, knowing that the chosen printer aligns seamlessly with your creative vision and practical considerations.

Frequently Asked Questions about What Printer Is Best For Stickers

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Printer Is Best For Stickers”