Home>Technology>Smart Home Devices>Which Type Of Printer Uses A Drum, Plastic Toner, And Fuser To Create A Printed Page

Smart Home Devices

Which Type Of Printer Uses A Drum, Plastic Toner, And Fuser To Create A Printed Page

Modified: February 18, 2024

Discover the smart home devices that utilize a drum, plastic toner, and fuser to produce high-quality printed pages. Explore the latest technology in printing for your smart home setup.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

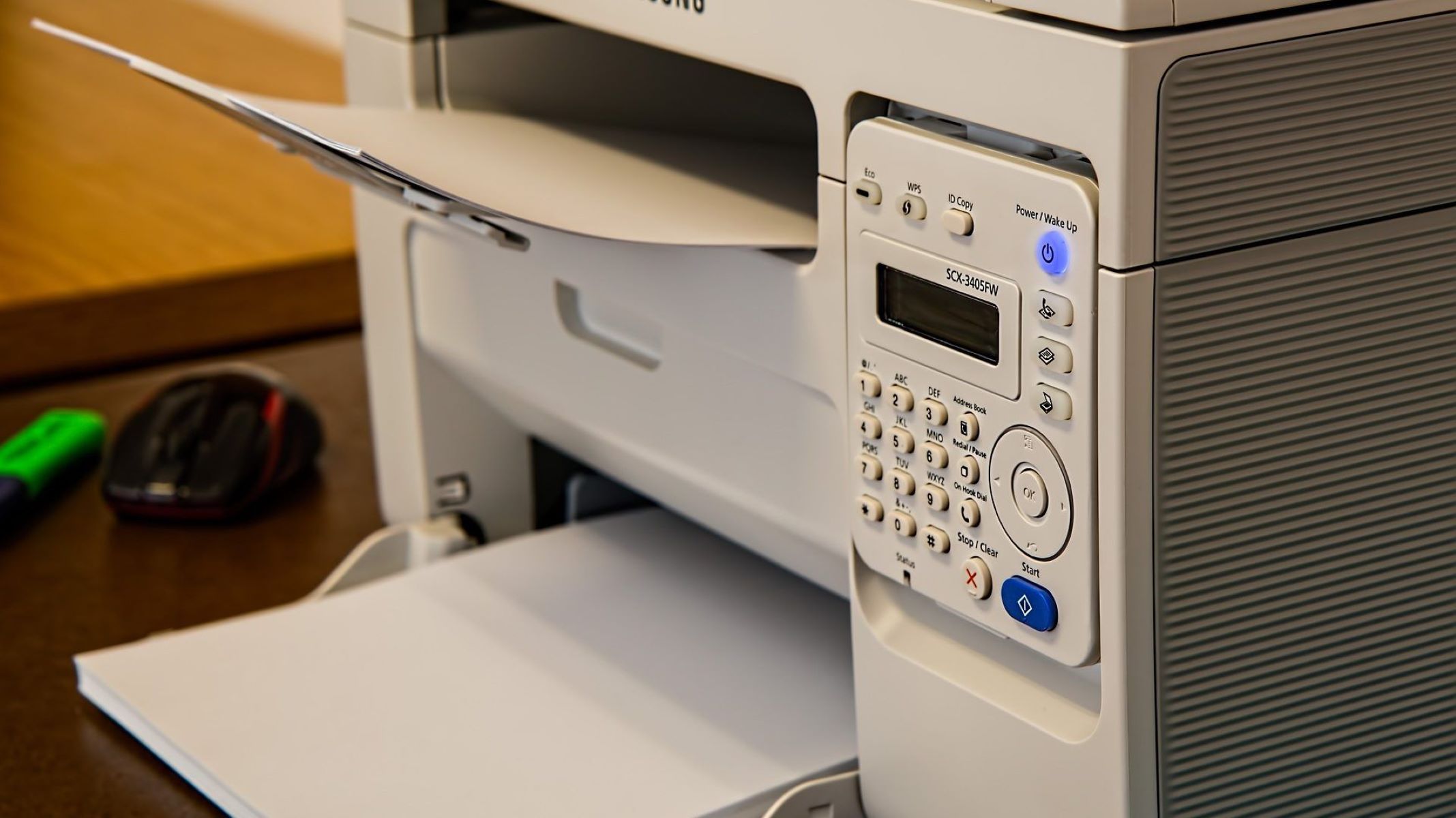

Printers have become an indispensable part of our daily lives, enabling us to effortlessly transform digital documents into tangible, hard-copy prints. Among the various types of printers available, one particular category stands out for its efficient and high-quality printing capabilities. This type of printer utilizes a drum, plastic toner, and fuser to create a printed page. In this article, we will delve into the intricate workings of this innovative printing technology, shedding light on the drum printer, plastic toner, and fuser, and how they collectively contribute to the creation of crisp and clear printed pages.

The seamless integration of these components within this type of printer results in exceptional print quality and reliability. Understanding the role of each component is crucial in comprehending the intricate process that unfolds every time a document is sent to print. So, let's embark on a fascinating journey through the inner workings of this remarkable printing technology, unraveling the magic behind the creation of every printed page.

Key Takeaways:

- Drum printers, plastic toners, and fusers work together in a special type of printer to create high-quality printed pages by faithfully replicating digital content with precision and durability.

- The drum printer forms an electrostatic image, the plastic toner adheres to it, and the fuser bonds the toner onto the paper, resulting in vivid, long-lasting prints.

Read more: Why Is Canon Printer Printing Blank Pages

Drum Printer

The drum printer is a pivotal component in the printing process, playing a central role in transferring the digital content onto the printed page. This component comprises a cylindrical drum typically made of highly durable materials such as aluminum or a specialized photoconductive material. The surface of the drum is electrostatically charged to create an image of the document to be printed.

As the printing process commences, the charged drum is exposed to the digital content, causing specific areas of the drum’s surface to become discharged, forming an electrostatic image of the document. This electrostatic image serves as the foundation for the subsequent stages of the printing process, setting the stage for the precise replication of the digital content onto the physical medium.

The drum printer’s remarkable functionality lies in its ability to faithfully replicate the intricate details and nuances of the digital content, ensuring that the printed output is an accurate representation of the original document. This level of precision is crucial in achieving high-quality prints, making the drum printer a cornerstone of this type of printing technology.

Furthermore, the drum printer’s capacity to consistently maintain the integrity of the electrostatic image throughout the printing process is a testament to its reliability and efficiency. This ensures that each printed page retains the clarity and fidelity of the original digital document, meeting the stringent demands of modern printing requirements.

In essence, the drum printer’s role in this type of printing technology is indispensable, serving as the conduit through which the digital content is meticulously transferred onto the physical medium. Its precision, reliability, and unwavering commitment to maintaining print quality make it a fundamental component in the seamless creation of printed pages.

Plastic Toner

One of the key elements in the printing process of this type of printer is the plastic toner, a vital component that contributes to the creation of vivid and durable prints. The plastic toner consists of tiny, electrostatically charged particles, typically composed of a polymer material, pigment, and other additives. These minute particles play a crucial role in translating the electrostatic image formed on the drum onto the printed page with remarkable precision and clarity.

As the printing process unfolds, the plastic toner is attracted to the charged areas of the drum, adhering to the electrostatic image to form a visible representation of the digital content. This precise deposition of the toner onto the drum’s surface ensures that every minute detail of the document is faithfully replicated, resulting in sharp and well-defined prints.

Moreover, the plastic toner’s composition is meticulously engineered to withstand the rigors of the printing process, ensuring that the prints exhibit exceptional durability and resistance to fading. This is particularly crucial in professional settings where printed documents are expected to maintain their visual appeal and legibility over extended periods.

Furthermore, the plastic toner’s versatility extends to its ability to deliver a wide spectrum of vibrant colors, catering to diverse printing requirements with unparalleled fidelity. Whether it’s producing vivid images or crisp text, the plastic toner excels in capturing the essence of the digital content, infusing the printed pages with a captivating visual impact.

Overall, the plastic toner’s remarkable attributes, including its precision, durability, and color reproduction capabilities, make it an indispensable component in this type of printing technology. Its ability to faithfully translate the electrostatic image onto the printed page with exceptional clarity and longevity underscores its significance in the seamless creation of high-quality prints.

A laser printer uses a drum, plastic toner, and fuser to create a printed page. The drum attracts the toner, which is then fused onto the paper by the fuser to create the final print.

Fuser

The fuser is a critical component in the final stages of the printing process, playing a pivotal role in transforming the latent image formed by the drum and plastic toner into a permanent, tangible print. This component is tasked with the crucial responsibility of bonding the deposited toner onto the surface of the print medium, ensuring that the printed pages emerge with impeccable quality and durability.

Upon the completion of the toner deposition on the drum, the electrostatically charged print medium, typically a sheet of paper, passes through the fuser assembly. Here, the fuser employs a combination of heat and pressure to permanently fuse the toner particles onto the paper, creating a resilient and long-lasting impression of the digital content.

The fuser’s ability to meticulously regulate the application of heat and pressure is paramount in achieving consistent and high-quality prints. This precise control ensures that the toner is uniformly fused onto the print medium, resulting in prints that boast impeccable clarity, sharpness, and resilience.

Furthermore, the fuser’s role in the printing process extends beyond mere toner fusion. It also contributes to the overall efficiency and productivity of the printing system by facilitating rapid print output. The fuser’s adeptness in swiftly and effectively bonding the toner onto the print medium enables the printer to deliver prints with impressive speed, catering to the demands of diverse printing environments.

Additionally, the fuser’s unwavering commitment to precision and reliability is evident in its capacity to accommodate various print media, ranging from standard paper to specialized substrates. This versatility ensures that the printing system can seamlessly adapt to a myriad of printing requirements, delivering exceptional results across a spectrum of applications.

In essence, the fuser’s integral role in the printing process of this type of printer is underscored by its ability to impart durability, clarity, and efficiency to the printed output. Its adeptness in seamlessly fusing the toner onto the print medium, coupled with its versatility and speed, solidifies its position as a cornerstone of the printing technology, ensuring that every printed page meets the highest standards of quality and reliability.

Conclusion

In conclusion, the seamless orchestration of the drum printer, plastic toner, and fuser within this type of printing technology embodies a harmonious synergy that culminates in the creation of exceptional printed pages. The drum printer, with its precision in faithfully replicating the electrostatic image, lays the foundation for the subsequent stages of the printing process. As the charged drum transfers the electrostatic image onto the print medium, the plastic toner steps in, meticulously adhering to the image to create vivid and durable prints. Finally, the fuser, with its adeptness in bonding the toner onto the print medium, ensures that the printed pages emerge with impeccable quality and resilience.

This intricate dance of components within the printing system not only exemplifies the remarkable advancements in printing technology but also underscores the unwavering commitment to delivering prints of exceptional clarity, durability, and efficiency. The collective prowess of the drum printer, plastic toner, and fuser is instrumental in meeting the diverse and exacting demands of modern printing requirements, catering to a myriad of applications with unparalleled fidelity and reliability.

As we witness the seamless transformation of digital content into tangible prints, it becomes evident that the intricate interplay of the drum printer, plastic toner, and fuser embodies the epitome of printing excellence. Each component, with its unique capabilities and contributions, converges to elevate the printing experience, ensuring that every printed page is a testament to precision, durability, and visual impact.

In essence, this type of printer, with its sophisticated amalgamation of cutting-edge components, stands as a testament to the remarkable strides made in the field of printing technology. As we continue to embrace the seamless creation of high-quality prints, the drum printer, plastic toner, and fuser remain steadfast in their commitment to transforming digital content into tangible, enduring impressions, enriching our lives with the enduring legacy of printed pages.

Frequently Asked Questions about Which Type Of Printer Uses A Drum, Plastic Toner, And Fuser To Create A Printed Page

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Which Type Of Printer Uses A Drum, Plastic Toner, And Fuser To Create A Printed Page”