Articles

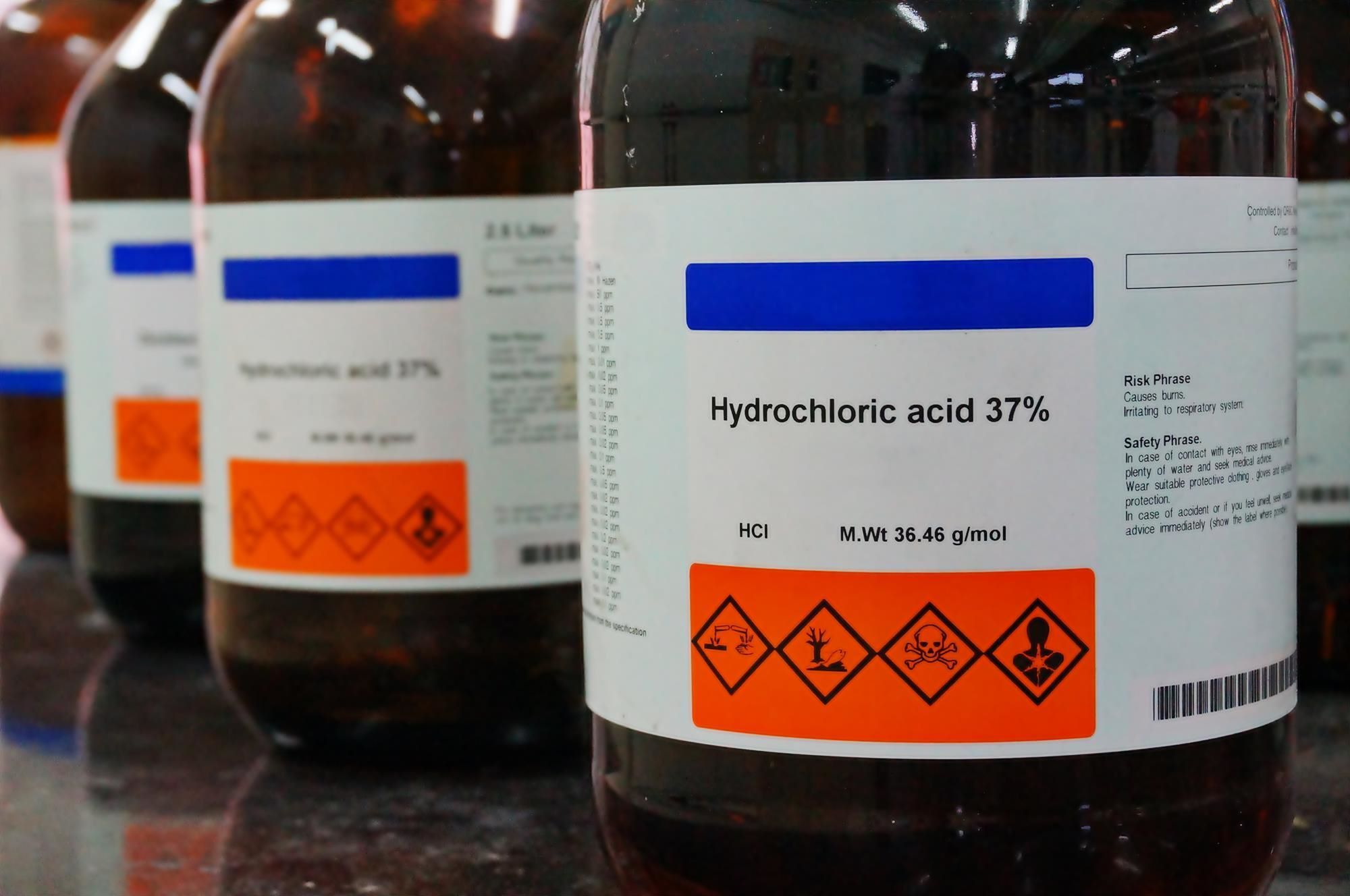

How To Store Hydrochloric Acid

Modified: December 7, 2023

Learn how to safely store hydrochloric acid and prevent any accidents or corrosive damage. Read our informative articles for expert tips and guidelines.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Hydrochloric acid, often abbreviated as HCl, is a highly corrosive and dangerous chemical commonly used in various industrial settings. It plays a crucial role in numerous processes, including production, cleaning, and water treatment. However, due to its hazardous properties, proper storage and handling are essential to ensure the safety of workers and the environment.

In this article, we will explore the best practices for storing hydrochloric acid to prevent accidents, minimize risks, and maintain its integrity. By following the guidelines outlined here, you can effectively store and handle hydrochloric acid in a safe and responsible manner.

Key Takeaways:

- Safety First!

Prioritize safety when storing hydrochloric acid by wearing protective equipment, working in well-ventilated areas, and storing it in suitable containers away from incompatible substances. Regular training and proper labeling are essential for safe handling. - Be Prepared for Emergencies

Develop a well-defined emergency response plan, including evacuation procedures, spill response protocols, and first aid procedures. Consult local regulations for proper disposal and consider professional waste disposal services to ensure compliance and safety.

Read more: How To Store Oxalic Acid Powder

Safety Precautions

When working with hydrochloric acid, it is crucial to prioritize safety and take appropriate precautions. Here are some key safety measures to follow:

- Wear protective equipment: Always use appropriate personal protective equipment (PPE) when handling hydrochloric acid. This includes safety goggles, gloves, and a lab coat or acid-resistant clothing. PPE will help protect against potential splashes, spills, or skin contact.

- Work in a well-ventilated area: Hydrochloric acid releases corrosive fumes that can be harmful if inhaled. Ensure that the storage and handling area has proper ventilation to minimize the risk of respiratory irritation or injury. If necessary, use exhaust fans or open windows to allow fresh air to circulate.

- Keep a spill kit handy: Accidental spills can happen, so it’s important to have a spill kit readily available. This kit should include absorbent materials, neutralizing agents, and proper disposal tools. Familiarize yourself with the spill response procedures and train employees on how to handle spills safely.

- Store separately from incompatible substances: Hydrochloric acid can react with various substances, such as ammonia, bleach, or oxidizing agents, resulting in hazardous reactions. Keep hydrochloric acid containers away from these materials, and store them separately to avoid potential chemical reactions.

- Label containers properly: Clearly label all containers holding hydrochloric acid with appropriate hazard warning signs. This will help ensure that everyone in the facility is aware of the contents and the associated risks. Additionally, store the acid in containers made of materials that are compatible with hydrochloric acid, such as glass or high-density polyethylene (HDPE).

- Train employees: Proper training is vital to ensuring the safe handling and storage of hydrochloric acid. Train all employees on the hazards associated with the chemical, safe operating procedures, and emergency response plans. Regular refresher training sessions should be conducted to reinforce safety protocols.

By adhering to these safety precautions, you can significantly reduce the risk of accidents and injuries when working with hydrochloric acid.

Suitable Containers for Storage

Choosing the right containers for storing hydrochloric acid is crucial to maintain its integrity and prevent leaks or spills. Here are some considerations when selecting suitable containers:

- Material compatibility: Hydrochloric acid is corrosive and can react with certain materials. It is essential to use containers made of materials that are resistant to the corrosive nature of the acid. Glass, high-density polyethylene (HDPE), or polypropylene (PP) containers are commonly used for storing hydrochloric acid. These materials provide excellent resistance to corrosion and ensure the integrity of the acid.

- Sealing capabilities: A container that can be securely sealed is important to prevent leaks and spills. Look for containers with tight-fitting lids or caps that can be securely fastened. This will help to minimize the risk of accidental exposure and maintain the quality of the acid.

- Strength and durability: Hydrochloric acid is a heavy and dense chemical, so it’s essential to select containers that are strong and durable to withstand the weight and pressure exerted by the acid. Ensure that the containers are of sufficient thickness and have the necessary structural integrity to prevent any leaks or breakages.

- Proper labeling: Clearly label all containers storing hydrochloric acid with appropriate hazard warning signs. This will ensure that everyone in the facility is aware of the contents and the associated risks. It is also advisable to include information such as the concentration of the acid and the date of storage to track its shelf life.

- Secondary containment: To further mitigate the risk of spills or leaks, consider using secondary containment measures. This can include placing the acid containers on secondary containment pallets or using secondary containment tubs or trays to capture any potential spills. This additional layer of protection is particularly important if storing large quantities of hydrochloric acid.

Remember to regularly inspect the containers for any signs of degradation or damage. If there are any concerns about the integrity of the containers, transfer the hydrochloric acid to a new, suitable container. Following these guidelines will help ensure the safe and secure storage of hydrochloric acid.

Storage Location

Choosing the right storage location for hydrochloric acid is essential to minimize risks and ensure the safety of the facility and its occupants. Here are some considerations when determining the storage location:

- Separate storage area: It is crucial to store hydrochloric acid in a separate area away from other chemicals and substances. This helps prevent any potential reactions or accidental mixing that could lead to hazardous situations. Ideally, allocate a dedicated storage room or cabinet specifically for storing the acid.

- Accessibility: The storage location should be easily accessible to authorized personnel. This ensures that the acid can be handled and accessed responsibly when needed. However, it should still be secured to prevent unauthorized access or tampering.

- Proper ventilation: Hydrochloric acid releases corrosive fumes, so it is important to ensure adequate ventilation in the storage area. Good ventilation helps to remove any fumes or gases that may accumulate, reducing the risk of inhalation and respiratory irritation.

- Temperature control: Hydrochloric acid should be stored in a cool and dry location to maintain its stability. Avoid exposing the acid to high temperatures or direct sunlight, as this can lead to increased pressure within the containers and possible degradation of the acid’s properties.

- Away from ignition sources: Keep hydrochloric acid away from potential ignition sources, such as open flames, sparks, or electrical equipment. The acid is highly reactive and can release flammable hydrogen gas when in contact with certain materials. Storing it away from potential ignition sources helps minimize the risk of fire or explosions.

- Secure storage: Ensure that the storage area is secure and meets the necessary safety requirements. This includes having sufficient fire protection systems, such as fire extinguishers or fire suppression systems, installed in the vicinity of the storage location.

It is also important to regularly inspect the storage area for any signs of leaks, spills, or damage to the containers. If any issues are identified, address them immediately and take appropriate actions to rectify the situation.

By selecting an appropriate storage location and implementing these guidelines, you can effectively store hydrochloric acid in a safe and controlled environment.

Temperature Considerations

The temperature at which hydrochloric acid is stored is critical to maintaining its stability and integrity. Here are some key temperature considerations when storing hydrochloric acid:

- Avoid extreme temperatures: Hydrochloric acid should be stored away from sources of extreme heat or cold. Excessive heat can lead to increased pressure within the containers and potential degradation of the acid. Extreme cold temperatures can also impact the acid’s properties or cause the containers to become brittle, increasing the risk of leaks or breakages.

- Recommended storage temperature: The ideal storage temperature for hydrochloric acid is typically between 15°C and 30°C (59°F-86°F). Storing the acid within this temperature range helps to maintain its stability and prevent any adverse reactions or changes in its chemical properties.

- Monitor temperature fluctuations: It’s important to monitor the storage area regularly to ensure that the temperature remains within the recommended range. Fluctuations in temperature can occur due to environmental factors or equipment malfunctions. If significant temperature variations are observed, take necessary action to stabilize the storage conditions.

- Avoid direct sunlight: Exposure to direct sunlight should be avoided when storing hydrochloric acid. Sunlight can increase the temperature in the storage area and potentially cause the acid to deteriorate. Store the acid in a cool, dark place to minimize the effects of sunlight.

- Insulation: If the storage area is subject to extreme temperatures, consider insulating the storage containers or using temperature-controlled storage units. This can help maintain a more consistent temperature and protect the acid from temperature-induced degradation.

Regularly monitoring and controlling the temperature in the storage area is crucial to maintaining the stability and quality of hydrochloric acid. By following these temperature considerations, you can ensure the optimal storage conditions for the acid and minimize any potential risks.

Store hydrochloric acid in a cool, dry, well-ventilated area away from direct sunlight and incompatible materials. Use a dedicated storage container made of acid-resistant material, such as polyethylene or glass. Keep it tightly sealed and away from any sources of ignition.

Read more: How To Store Sulfuric Acid

Ventilation Requirements

Proper ventilation is crucial when storing hydrochloric acid to prevent the accumulation of corrosive fumes and ensure a safe environment. Here are some important considerations for ventilation when handling hydrochloric acid:

- Natural ventilation: If possible, store hydrochloric acid in a well-ventilated area with access to natural airflow. This can be achieved by opening windows and doors to allow fresh air to circulate, helping to disperse any fumes and minimize their concentration.

- Mechanical ventilation: In situations where natural ventilation is insufficient, mechanical ventilation systems should be installed. These systems can effectively remove fumes and maintain a consistent airflow in the storage area. Ensure that the ventilation system is regularly inspected, cleaned, and properly maintained to ensure its efficiency.

- Avoid stagnant areas: Hydrochloric acid should not be stored in areas with poor air circulation or stagnant air. Stagnant air allows the fumes to accumulate, increasing the risk of respiratory irritation and potentially creating hazardous conditions.

- Isolation from occupied areas: The storage area should be isolated from occupied areas to protect individuals from exposure to hydrochloric acid fumes. This can be accomplished by using barriers or partitions to create a designated storage space separate from the main working or living areas.

- Exhaust systems for fume hoods: If hydrochloric acid is frequently used or handled in a laboratory, it is crucial to have fume hoods equipped with effective exhaust systems. These hoods help capture the fumes at the source and vent them safely to the outside, protecting researchers and maintaining air quality in the laboratory.

- Regular air testing: Periodic air testing should be conducted to ensure that the concentration of hydrochloric acid fumes in the storage area is within acceptable limits. This can be done using air monitoring devices, such as gas detectors, to detect any potential leaks or high levels of fumes.

Proper ventilation is essential for maintaining a safe working environment when storing hydrochloric acid. By following these ventilation requirements, you can minimize the risk of respiratory irritation and ensure the well-being of individuals in the facility.

Handling and Transport

Proper handling and transportation of hydrochloric acid are crucial to prevent accidents, spills, and exposure to the corrosive substance. Here are some key considerations when handling and transporting hydrochloric acid:

- Personal protective equipment (PPE): Always wear appropriate personal protective equipment (PPE) when handling hydrochloric acid. This includes safety goggles, gloves, and a lab coat or acid-resistant clothing. PPE provides a barrier between the acid and your skin or eyes, minimizing the risk of chemical burns or irritation.

- Handling with care: Hydrochloric acid containers should be handled with care to avoid dropping or damaging them. It is important to lift and carry the containers using proper techniques, such as using a hand truck or trolley for heavier containers, and avoiding sudden movements or rough handling that could lead to spills or breakages.

- Avoid mixing or contact with incompatible substances: Hydrochloric acid can react with various substances, such as ammonia, bleach, or oxidizing agents. It is important to avoid any mixing or contact with these substances to prevent hazardous reactions. Store hydrochloric acid away from other chemicals and ensure proper segregation during transportation.

- Secure transportation: During transport, ensure that hydrochloric acid containers are securely sealed and placed in stable positions to prevent movement or spills. Use appropriate containment measures, such as spill-proof pallets or trays, to minimize the risk of leaks or accidental releases.

- Compliance with regulations: Familiarize yourself with the applicable local, regional, and national regulations and guidelines regarding the handling and transportation of hydrochloric acid. Ensure compliance with these regulations to maintain safety standards and prevent legal or environmental issues.

- Emergency spill response: Prepare and train employees on emergency spill response procedures. Have a spill kit readily available, including absorbent materials, neutralizing agents, and proper disposal tools, to contain and clean up any accidental spills quickly and safely.

- Recordkeeping: Maintain proper records of the handling and transportation of hydrochloric acid. This includes documenting the date of receipt, storage, and transportation, as well as the quantity and concentration of the acid. These records can help track the acid’s lifecycle and ensure proper accountability.

By following these guidelines for handling and transportation, you can mitigate the risks associated with hydrochloric acid and ensure the safety of personnel and the environment.

Emergency Response Plan

Having an effective and well-defined emergency response plan is crucial when working with hydrochloric acid. This plan ensures that all employees are prepared to respond promptly and appropriately in the event of an emergency. Here are some key components to include in an emergency response plan:

- Emergency contact information: Compile a list of emergency contact numbers, including local emergency services, poison control center, and environmental agencies. Make sure this information is easily accessible to all employees in case of an emergency.

- Evacuation procedures: Establish clear and well-communicated evacuation procedures for the facility. Designate assembly points outside the building where employees can gather safely after evacuating. Regularly conduct evacuation drills to familiarize employees with the emergency exits and evacuation procedures.

- Alarm systems: Install reliable alarm systems, such as fire alarms or gas leak detectors, to quickly alert employees in the event of a spill, leak, or other emergency situations involving hydrochloric acid. Ensure that these alarm systems are regularly tested and maintained for optimal functionality.

- Spill response protocols: Develop detailed spill response protocols to guide employees on how to safely and effectively respond to hydrochloric acid spills. This should include steps for containing the spill, evacuating the area if necessary, and proper disposal of contaminated materials. Train employees on these protocols and provide them with appropriate spill response equipment and materials.

- First aid procedures: Establish procedures for providing first aid to employees who may come into contact with hydrochloric acid. Train designated employees in first aid techniques specific to chemical burns, inhalation hazards, and eye injuries caused by exposure to hydrochloric acid.

- Training and education: Regularly train employees on the emergency response plan and provide education on the hazards associated with hydrochloric acid. This should include proper handling, storage, and personal protective equipment usage. Conduct periodic refresher training sessions to reinforce knowledge and keep employees informed about any updates or changes to the plan.

- Post-incident evaluation: After an emergency, conduct a thorough post-incident evaluation to identify any shortcomings or areas for improvement in the emergency response plan. Address any identified issues and implement necessary changes to enhance future response efforts.

Regularly review and update the emergency response plan as needed to ensure its effectiveness. It is vital that all employees are familiar with the plan, and everyone understands their roles and responsibilities in specific emergency scenarios.

By having a well-prepared emergency response plan in place, the facility can effectively respond to emergencies involving hydrochloric acid, minimizing the potential for injuries, environmental damage, and property loss.

Disposal of Hydrochloric Acid

Proper disposal of hydrochloric acid is essential to protect the environment and ensure compliance with regulatory requirements. Here are some guidelines to follow when disposing of hydrochloric acid:

- Neutralization: In some cases, hydrochloric acid can be neutralized before disposal. This involves carefully adding a neutralizing agent, such as sodium bicarbonate or calcium carbonate, to the acid to bring the pH to a neutral level. It is important to follow proper procedures and safety precautions when neutralizing acid to avoid potential reactions or splashes.

- Consult local regulations: Before disposing of hydrochloric acid, it is crucial to consult and comply with local regulations regarding hazardous waste disposal. Different jurisdictions may have specific requirements and guidelines for proper disposal. Contact local government agencies or a licensed waste disposal facility to determine the appropriate disposal methods and locations.

- Professional waste disposal: It is recommended to engage the services of a professional waste disposal company to handle the proper disposal of hydrochloric acid. These companies have the expertise and equipment to safely and legally dispose of hazardous chemicals. They will ensure that the acid is handled, transported, and disposed of in compliance with regulations.

- Labeling and packaging: When preparing hydrochloric acid for disposal, clearly label the containers as hazardous waste and include any relevant information such as the acid’s concentration and volume. Use suitable packaging that is compatible with hydrochloric acid to prevent leaks or spills during transportation.

- Emergency spill response equipment: Have appropriate emergency spill response equipment, such as absorbent materials and neutralizing agents, readily available in case of any accidental spills or leaks during the disposal process. Follow the spill response protocols outlined in the facility’s emergency response plan.

- Documentation: Maintain detailed records of the disposal process, including the dates, quantities, and methods used for disposing of hydrochloric acid. Accurate documentation helps demonstrate compliance with regulations and provides an audit trail for accountability.

- Disposal alternatives: In some cases, there may be alternative disposal options available, such as recycling or recovery programs. Investigate if there are any local programs or facilities that can recycle or recover hydrochloric acid. This helps minimize environmental impact and conserve valuable resources.

Remember, improper disposal of hydrochloric acid can have serious consequences for the environment and human health. Always prioritize safe disposal methods and follow the appropriate guidelines to ensure the responsible management of hydrochloric acid waste.

Read more: How To Store Hydrofluoric Acid

Conclusion

Proper storage and handling of hydrochloric acid are essential to ensure the safety of workers, protect the environment, and comply with regulatory requirements. By following the best practices outlined in this article, you can minimize the risk of accidents, spills, and exposure to this corrosive chemical.

Remember to prioritize safety precautions such as wearing appropriate personal protective equipment (PPE), working in well-ventilated areas, and storing hydrochloric acid in suitable containers made of compatible materials. Additionally, ensure proper labeling, segregation from incompatible substances, and regular inspection of containers.

When selecting a storage location, consider factors such as accessibility, proper ventilation, temperature control, and secure storage. It is equally important to handle and transport hydrochloric acid with care, following proper lifting techniques and avoiding mixing or contact with incompatible substances.

Having a well-defined emergency response plan, including evacuation procedures, spill response protocols, and proper training, is crucial for effectively managing incidents involving hydrochloric acid. Additionally, consult local regulations for the proper disposal of hydrochloric acid, considering the use of professional waste disposal services and maintaining accurate documentation.

By implementing these guidelines and maintaining a proactive approach to safety, you can confidently store, handle, and dispose of hydrochloric acid in a responsible manner. Remember, safety should always be the top priority when working with hazardous chemicals like hydrochloric acid.

Frequently Asked Questions about How To Store Hydrochloric Acid

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Store Hydrochloric Acid”