Home>Articles>In What Area Of An Aircraft Would You Find A Carbon Monoxide Detector

Articles

In What Area Of An Aircraft Would You Find A Carbon Monoxide Detector

Modified: August 28, 2024

Find out where carbon monoxide detectors are located in aircrafts and other informative articles about aviation safety.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to aviation safety, every aspect of an aircraft’s operation needs to be meticulously monitored. One important element that often goes unnoticed is the detection of carbon monoxide (CO) in an aircraft. Carbon monoxide is a colorless, odorless, and tasteless gas that can be extremely dangerous, even fatal, if not detected in time.

In this article, we will delve into the importance of carbon monoxide detection in aircraft and explore the areas where carbon monoxide detectors are typically installed. By understanding the significance of these detectors, both pilots and passengers can ensure a safe flying experience.

So, let’s dive into the world of carbon monoxide and discover where these crucial detectors reside in an aircraft.

Key Takeaways:

- Carbon monoxide detectors are strategically placed in the cockpit, cabin, cargo area, and maintenance/storage areas of aircraft to provide comprehensive coverage and early detection of this silent and potentially deadly gas, ensuring the safety and well-being of everyone on board.

- By investing in comprehensive carbon monoxide detection systems and prioritizing maintenance and compliance with safety regulations, aircraft operators foster passenger confidence, mitigate risks of CO exposure, and ensure a safer and more secure flying experience for all.

Read more: What Is The Best Carbon Monoxide Detector

Understanding Carbon Monoxide (CO)

Carbon monoxide is a silent killer that poses a significant threat to human life. It is produced through the incomplete combustion of fossil fuels, such as gasoline, natural gas, oil, and coal. When these fuels are burned in enclosed spaces, such as the confined areas of an aircraft, carbon monoxide can build up rapidly.

Unfortunately, carbon monoxide is hazardous because it is odorless, colorless, and tasteless, making it difficult to detect without the use of specialized equipment. In high concentrations, it can quickly replace the oxygen in the blood, leading to carbon monoxide poisoning. Symptoms of carbon monoxide poisoning include headaches, dizziness, nausea, confusion, and even loss of consciousness.

Carbon monoxide can enter an aircraft through various sources, including engine exhaust fumes, faulty heating systems, exhaust leaks, and malfunctioning or poorly maintained equipment. It is crucial, therefore, to have effective carbon monoxide detection systems in place to ensure the safety of everyone on board.

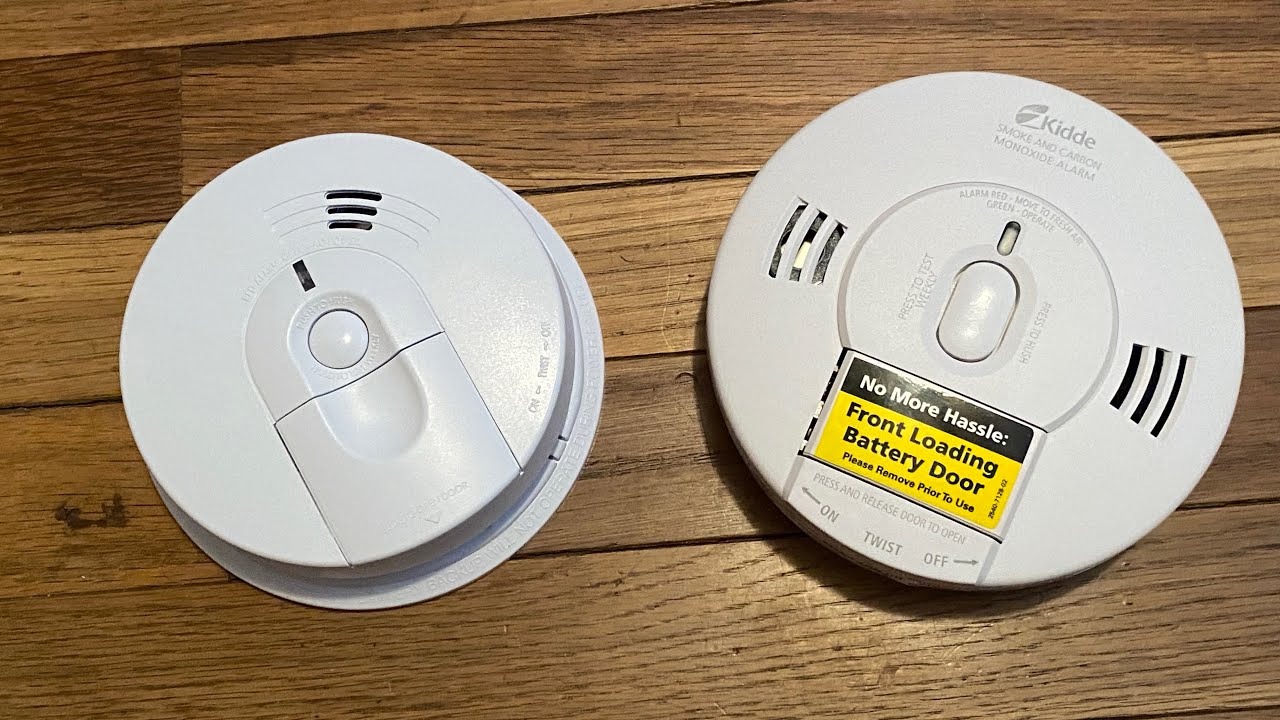

Carbon monoxide detectors are devices designed to alert occupants of the presence of this deadly gas. They work by continuously monitoring the air for the presence of carbon monoxide and triggering an alarm if dangerous levels are detected.

Now that we have a basic understanding of carbon monoxide and the risks it poses, let us explore why its detection is so essential in the aviation industry.

Importance of Carbon Monoxide Detection in Aircraft

The importance of carbon monoxide detection in aircraft cannot be overstated. It is crucial for the safety and well-being of both the flight crew and passengers on board. Here’s why:

By understanding the importance of carbon monoxide detection in aircraft, the aviation industry can prioritize the implementation and maintenance of these essential safety measures.

Installation of Carbon Monoxide Detectors in Aircraft

The installation of carbon monoxide detectors in aircraft is a critical process that ensures the early detection and mitigation of potential dangers. These detectors are strategically placed throughout the aircraft to cover all areas where carbon monoxide may accumulate. Let’s explore the installation process and considerations:

- Cockpit: A carbon monoxide detector is placed in the cockpit, close to the pilot’s seating position. This allows for immediate detection of any carbon monoxide entering the cockpit area, alerting the pilot to take necessary actions.

- Cabin: Detectors are strategically positioned throughout the cabin, considering factors such as air circulation, seating arrangements, and potential carbon monoxide sources. They are often installed near air vents and in areas where exhaust fumes or equipment malfunction might pose a risk.

- Cargo Area: It is also essential to install carbon monoxide detectors in the cargo area, where potential carbon monoxide sources, such as motorized equipment or stored hazardous materials, may pose a risk.

- Maintenance and Storage Areas: Carbon monoxide detectors should be installed in maintenance and storage areas to monitor the air quality and ensure a safe working environment for technicians.

By following these installation guidelines and adhering to industry best practices, aircraft operators can ensure effective carbon monoxide detection and provide a safe flying environment for all occupants.

Operational Areas in Aircraft for Carbon Monoxide Detectors

Carbon monoxide (CO) detectors are strategically placed in key operational areas of an aircraft to ensure comprehensive coverage and effective detection. Let’s explore the main areas where these detectors are installed:

By having carbon monoxide detectors strategically positioned in these operational areas, aircraft operators can effectively monitor potential carbon monoxide risks and take immediate action in case of detection. Regular maintenance and testing of these detectors are essential to ensure their proper functionality and reliable operation.

Ultimately, the installation of carbon monoxide detectors in these operational areas contributes to the overall safety and well-being of everyone on board the aircraft, providing reassurance and peace of mind during the flight.

You would find a carbon monoxide detector in the cabin area of an aircraft, typically near the cockpit or in the passenger cabin to monitor air quality and ensure the safety of passengers and crew.

Cockpit Area

The cockpit is the nerve center of an aircraft where the flight crew operates the controls and makes critical decisions during the flight. It is essential to maintain a safe and healthy environment in the cockpit to ensure the well-being and optimal performance of the pilots. One crucial aspect of cockpit safety is the detection of carbon monoxide (CO).

Carbon monoxide detectors in the cockpit area play a vital role in identifying the presence of this toxic gas. They are strategically installed in close proximity to the pilot’s seating position to provide immediate warning of any potential carbon monoxide buildup. These detectors continuously monitor the air quality and trigger an alarm if dangerous levels of CO are detected.

There are several reasons why installing carbon monoxide detectors in the cockpit area is of utmost importance:

It is crucial to regularly test and maintain carbon monoxide detectors in the cockpit area to ensure their proper functioning. Pilots should be familiar with the alarm signals and be trained on how to respond appropriately in the event of a carbon monoxide detection.

Overall, the installation of carbon monoxide detectors in the cockpit area enhances safety by providing pilots with an early warning system and the ability to identify and address potential risks. This enables them to maintain optimal performance and focus on their primary responsibility of safely operating the aircraft.

Cabin Area

The cabin area of an aircraft is where passengers are seated during the flight. It is crucial to prioritize the safety and well-being of passengers by ensuring a healthy and comfortable environment. Carbon monoxide (CO) detectors play a crucial role in detecting the presence of this toxic gas in the cabin area, providing an additional layer of safety. Let’s explore the significance of carbon monoxide detection in the cabin:

Regular maintenance and testing of carbon monoxide detectors in the cabin area are crucial to their effectiveness. The crew should be trained on the proper response procedures in case of a carbon monoxide detection and be familiar with the alarm signals.

By having carbon monoxide detectors strategically placed in the cabin area, airlines enhance passenger safety and provide a reassurance of a healthy environment. Passengers can fly with peace of mind, knowing that measures are in place to detect and address potential carbon monoxide risks.

Cargo Area

The cargo area of an aircraft is responsible for safely transporting goods and baggage during flights. It is essential to ensure the safety and integrity of the cargo, including monitoring the air quality for potential hazards such as carbon monoxide (CO). Carbon monoxide detectors play a critical role in this area by detecting the presence of CO and alerting operators to take necessary precautions. Let’s explore the significance of carbon monoxide detection in the cargo area:

It is important to conduct regular maintenance and testing of carbon monoxide detectors in the cargo area to ensure their proper functioning. Operators should also be trained on how to respond to carbon monoxide detections and follow established procedures to mitigate risks.

By installing carbon monoxide detectors in the cargo area, airlines and cargo operators prioritize the safety of both the cargo and the personnel involved in its transportation. This helps ensure the integrity of the transported goods and reduces the potential risks associated with carbon monoxide exposure.

Maintenance and Storage Areas

Maintenance and storage areas in an aircraft are vital operational areas where technicians work on aircraft equipment and store various items. These areas require special attention to ensure the safety and well-being of personnel. The installation of carbon monoxide (CO) detectors in these areas is essential for maintaining a safe working environment. Let’s explore the significance of carbon monoxide detection in maintenance and storage areas:

Regular maintenance, calibration, and testing of carbon monoxide detectors are necessary to ensure their reliability and accuracy. Technicians should be trained on responding to carbon monoxide alerts, understanding the alarm signals, and following established protocols in case of detection.

By installing carbon monoxide detectors in maintenance and storage areas, aircraft operators prioritize the safety and well-being of their maintenance personnel. These detectors help maintain a healthy work environment, identify potential sources of carbon monoxide emissions, and ensure adherence to safety regulations.

Read more: Why Do You Need A Carbon Monoxide Detector

Conclusion

Carbon monoxide (CO) detection in aircraft is a crucial aspect of aviation safety. The installation of carbon monoxide detectors in key operational areas, such as the cockpit, cabin, cargo area, and maintenance/storage areas, ensures comprehensive coverage and early detection of this silent and potentially deadly gas.

Understanding the risks associated with carbon monoxide exposure allows aviation professionals to prioritize the implementation of effective detection systems. Carbon monoxide detectors act as an early warning system, providing alerts to the presence of CO before it reaches dangerous levels. This allows pilots, crew members, and technicians to take immediate action, ensuring the safety and well-being of everyone on board.

The cockpit area, being the control center of the aircraft, requires carbon monoxide detectors to safeguard pilot health, prevent impaired judgment, and identify potential equipment malfunctions. In the cabin area, detectors provide passenger safety and confidence by monitoring air quality and mitigating risks associated with exhaust fumes and potential carbon monoxide sources. The cargo area benefits from detectors to protect the integrity of transported goods and ensure crew safety. Lastly, maintenance and storage areas rely on carbon monoxide detection to maintain a safe working environment for technicians.

Regular maintenance and testing of carbon monoxide detectors are essential to keep them functioning optimally. Compliance with aviation safety regulations is crucial to meet industry standards and prioritize passenger and personnel safety. By investing in comprehensive carbon monoxide detection systems, aircraft operators foster passenger confidence, mitigate risks of CO exposure, and maintain compliance with safety regulations.

In conclusion, carbon monoxide detection in aircraft is a vital component of aviation safety. Installing and maintaining carbon monoxide detectors in key operational areas helps protect the health and well-being of pilots, crew members, passengers, and maintenance technicians. By prioritizing carbon monoxide detection, the aviation industry can ensure a safer and more secure flying experience for all.

Frequently Asked Questions about In What Area Of An Aircraft Would You Find A Carbon Monoxide Detector

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “In What Area Of An Aircraft Would You Find A Carbon Monoxide Detector”