Articles

What Is A HVAC Package Unit

Modified: August 27, 2024

Learn all about package unit HVAC systems with our informative articles. Discover how they work, their benefits, and key considerations for installation and maintenance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of HVAC (Heating, Ventilation, and Air Conditioning) systems, where comfort meets efficiency. When it comes to controlling the indoor climate of a building, there are various types of HVAC systems to choose from. One popular option is a package unit HVAC system.

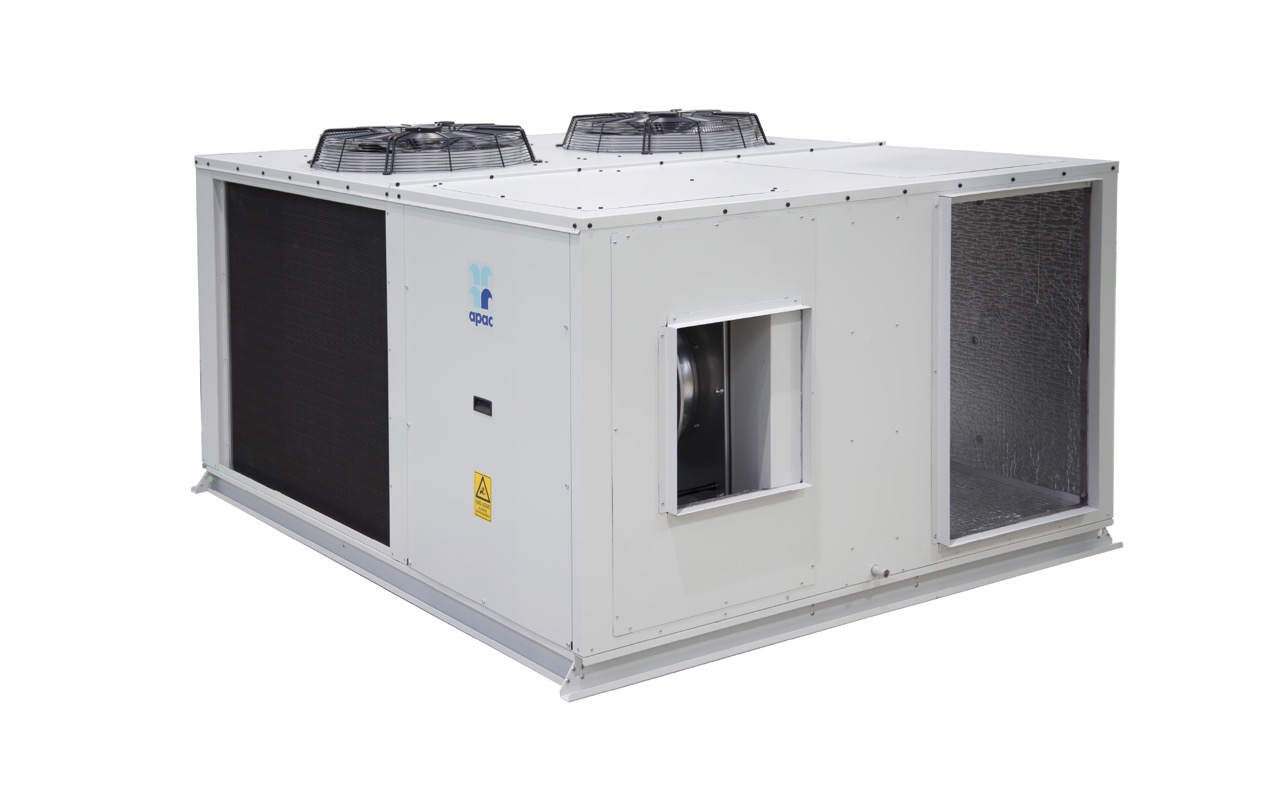

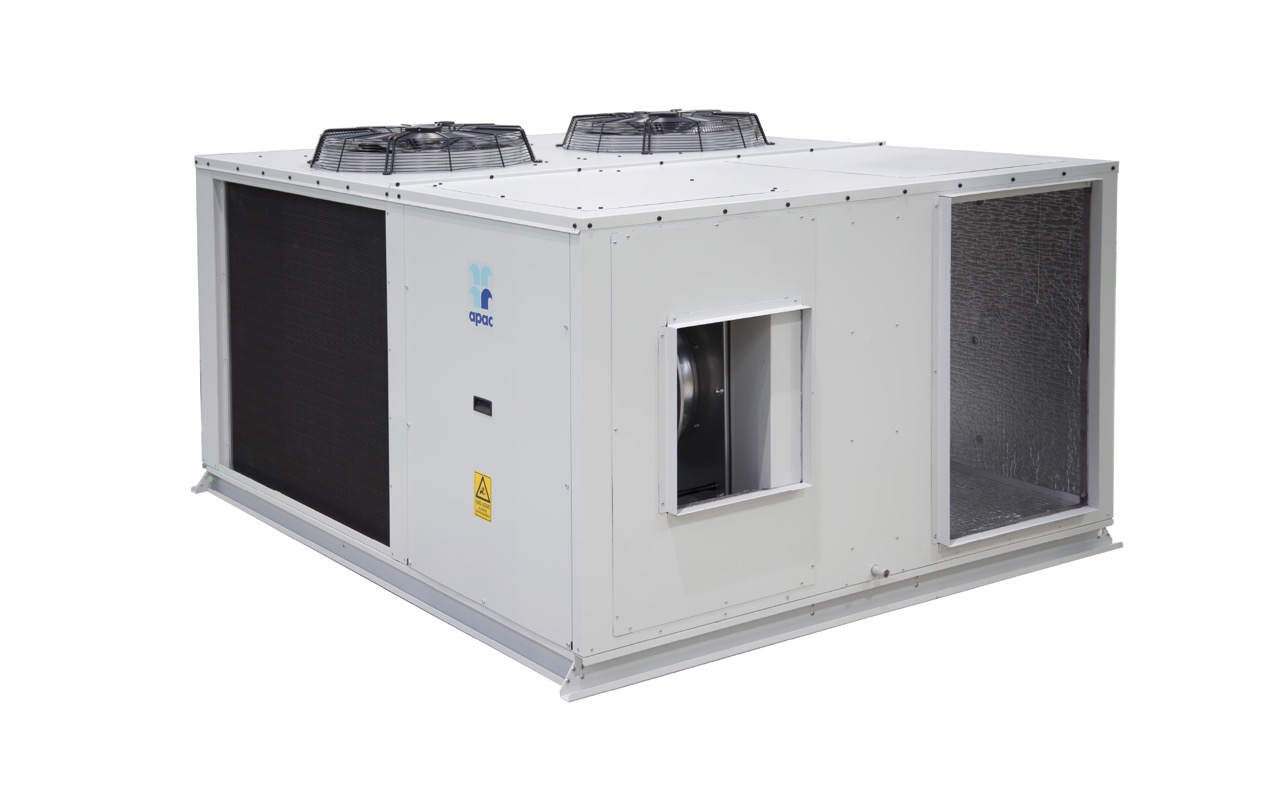

A package unit HVAC system is a self-contained heating and cooling system that is typically installed outside of a building or on the rooftop. It combines all the necessary components, including the heating, cooling, and air distribution systems, into a single unit. This makes it a convenient and space-saving solution for both residential and commercial buildings.

In this article, we will explore the definition of a package unit HVAC system, the components that make up this system, the different types available, as well as the advantages, disadvantages, installation process, maintenance requirements, and common problems associated with this type of HVAC system.

So, if you are considering a package unit HVAC system for your home or business, or simply want to expand your knowledge on HVAC systems, this article is for you. Let’s dive in!

Key Takeaways:

- Package unit HVAC systems offer a space-saving, energy-efficient solution for heating and cooling, but may require regular maintenance to prevent common issues like refrigerant leaks and electrical problems.

- Proper installation and regular maintenance are crucial for ensuring the optimal performance and longevity of package unit HVAC systems, which provide convenient and reliable heating, cooling, and ventilation for residential and commercial buildings.

Read more: How To Package Glass For Shipping

Definition of Package Unit HVAC

A package unit HVAC system, also known as a packaged unit or rooftop unit (RTU), is a self-contained heating, ventilation, and air conditioning system. It is designed to provide efficient and effective heating and cooling for residential and commercial buildings. Unlike traditional split systems, which have separate indoor and outdoor units, a package unit contains all the necessary components in a single unit that is installed outside the building or on the rooftop.

The package unit HVAC system consists of four main components: the compressor, the condenser, the evaporator, and the air handling unit. These components work together to cool or heat the air, remove moisture, and distribute it throughout the building.

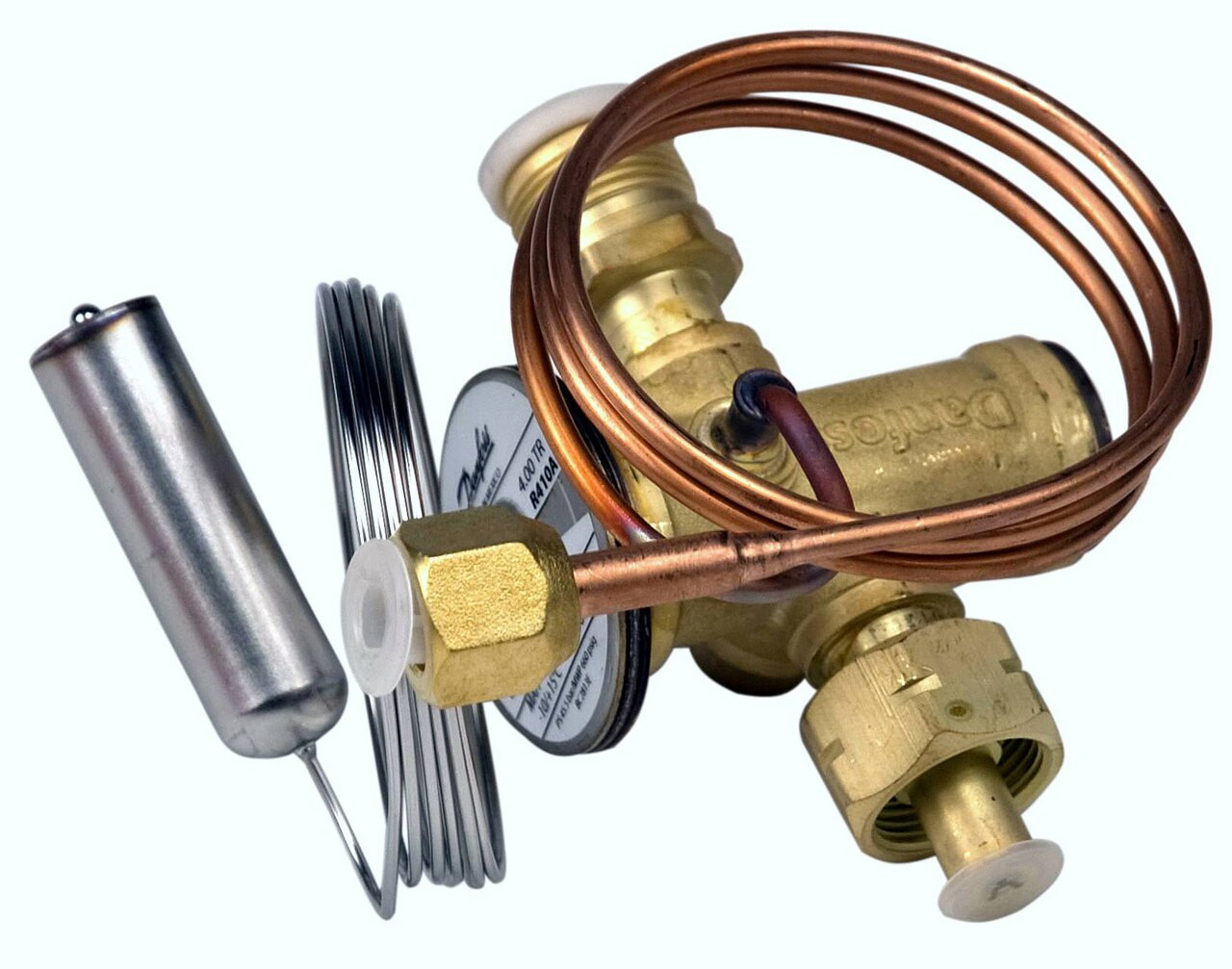

First, the compressor is responsible for compressing the refrigerant gas, which increases its temperature and pressure. This high-pressure gas then flows to the condenser, where it is cooled and condensed into a liquid by releasing heat to the surrounding air.

The liquid refrigerant then moves to the evaporator, where it expands and evaporates, absorbing heat from the indoor air. This process cools the air, and the evaporator fan blows the cooled air into the building through ductwork.

Finally, the air handling unit, which is part of the package unit, filters and distributes the conditioned air to different rooms or zones within the building. It also contains a blower fan that circulates the air and maintains proper airflow for comfort.

In addition to the heating and cooling components, a package unit HVAC system may also include additional features such as electric heating elements, air purification systems, and programmable thermostats. These added features can further enhance indoor comfort and energy efficiency.

Overall, a package unit HVAC system provides a convenient and space-saving solution for heating, cooling, and ventilating buildings, making it a popular choice for both residential and commercial applications.

Components of a Package Unit HVAC

A package unit HVAC system comprises several key components that work together to provide heating, cooling, and ventilation for a building. These components are integrated into a compact and self-contained unit, which is typically installed on the roof or outside the building. Understanding the function of each component is essential for maintaining and troubleshooting the system efficiently. Let’s take a closer look at the main components of a package unit HVAC system:

- Compressor: The compressor is the heart of the HVAC system. It is responsible for compressing the refrigerant gas and increasing its pressure and temperature before it moves to the condenser. There are different types of compressors used in package units, including reciprocating, scroll, rotary, and variable speed compressors.

- Condenser: The condenser coil is located on the outside of the package unit and is responsible for releasing heat from the refrigerant to the surrounding air. It consists of a series of fins and tubes that allow the refrigerant to cool and condense into a liquid state.

- Evaporator: The evaporator coil is located on the inside of the package unit and is responsible for absorbing heat from the indoor air. As the liquid refrigerant passes through the evaporator coil, it evaporates, generating cool air that is then circulated throughout the building.

- Air Handling Unit: The air handling unit (AHU) is a crucial component that distributes the conditioned air throughout the building. It consists of a blower fan that draws in air from the return vents and pushes it through the evaporator coil to cool or heat it. The AHU also includes filters to remove dust and pollutants from the air before it is distributed.

- Ductwork: The ductwork is a network of pipes and channels that transport the conditioned air from the air handling unit to different rooms or zones within the building. Properly designed and installed ductwork ensures efficient airflow and even distribution of air.

- Thermostat: The thermostat is the control device that allows users to set the desired temperature and control the operation of the HVAC system. It senses the temperature of the room and sends signals to the package unit to turn on or off based on the set temperature.

- Electrical Components: The package unit HVAC system also includes various electrical components like relays, capacitors, contactors, and control boards. These components help in the control and operation of the system.

- Optional Components: Depending on the specific package unit, there may be additional components such as electric heating elements, air purifiers, humidifiers, and dehumidifiers. These optional components enhance the comfort and air quality within the building.

By understanding the function and role of each component, HVAC technicians can effectively diagnose and resolve any issues that may arise with the package unit HVAC system, ensuring optimal performance, energy efficiency, and indoor comfort.

Types of Package Unit HVAC

Package unit HVAC systems come in various types to cater to different building requirements and climate conditions. Each type offers unique features and benefits. Let’s explore some of the most common types of package unit HVAC systems:

- Electric Package Unit: Electric package units utilize electricity as the main source of heating and cooling. They are commonly used in areas where natural gas or propane is not readily available. Electric package units are known for their simplicity, efficiency, and cost-effectiveness.

- Gas Package Unit: Gas package units rely on natural gas or propane to provide heating. They are a popular choice in regions with access to natural gas lines. Gas package units are highly efficient and offer significant energy savings compared to electric units.

- Heat Pump Package Unit: Heat pump package units are versatile systems that can provide both heating and cooling capabilities. They use a refrigerant cycle to transfer heat from the indoor air to the outside during cooling mode and vice versa during heating mode. Heat pump package units are energy-efficient and ideal for moderate climates.

- Hybrid Package Unit: Hybrid package units combine the efficiency of a heat pump with a backup gas or electric furnace. They automatically switch between the two heat sources based on the outdoor temperature and can provide efficient heating even in extremely cold climates.

- Single-Zone Package Unit: Single-zone package units are designed to serve a single area or zone within a building. They have a single thermostat and provide heating and cooling for that specific zone only.

- Multi-Zone Package Unit: Multi-zone package units are equipped with multiple thermostats and dampers to control temperature and airflow in different zones or rooms. They offer flexibility and individual control over each zone’s heating and cooling requirements.

- Water Source Package Unit: Water source package units use water as a heat exchange medium instead of air. They utilize a water loop system to transfer heat to or from a water source, such as a lake or well, providing efficient heating and cooling.

The choice of package unit HVAC system depends on factors such as climate, building size, energy requirements, and budget. Consulting with a professional HVAC technician can help determine the most suitable type of package unit HVAC system for a specific application.

It’s important to note that the availability of these types may vary based on location and specific manufacturers. Therefore, it is recommended to research and consult with local HVAC experts to find the most suitable package unit HVAC system for your needs.

Advantages of Package Unit HVAC

Package unit HVAC systems offer a host of advantages that make them a popular choice for both residential and commercial applications. Let’s explore some of the key advantages of using a package unit HVAC system:

- Space-Saving Design: Package unit HVAC systems are designed to be compact and self-contained. All the necessary components, including the compressor, condenser, evaporator, and air handling unit, are integrated into a single unit. This space-saving design is especially beneficial for buildings with limited space or where rooftop installation is preferred.

- Easy Installation: Package unit HVAC systems are relatively easy to install compared to traditional split systems. Since all the components are housed in one unit, there is no need for complex refrigerant line installation or indoor unit placement. This simplifies the installation process and reduces labor and material costs.

- Energy Efficiency: Package unit HVAC systems are available in various energy-efficient models. They can be equipped with high-efficiency compressors, variable speed motors, and advanced control systems that optimize energy consumption. This results in lower utility bills and reduced environmental impact.

- Flexibility: Package unit HVAC systems offer flexibility in terms of installation and location. They can be installed on the rooftop, ground level, or even hung from the side of a building. This flexibility allows for greater freedom in architectural design and placement options.

- Easy Maintenance: Since all the components are housed in a single unit, package unit HVAC systems are easier to access and maintain. Routine maintenance tasks such as filter replacements, coil cleaning, and inspection can be performed quickly and efficiently. This helps prolong the lifespan of the system and ensures optimal performance.

- Zone Control: Package unit HVAC systems can be equipped with multi-zone capabilities, allowing for individual temperature control in different areas of the building. This enhances comfort and energy efficiency by only conditioning the spaces that require heating or cooling at any given time.

- Cost-Effective: Package unit HVAC systems tend to be more cost-effective compared to other HVAC systems, especially for smaller buildings. The simplified design and installation process reduce upfront costs, while the energy-efficient operation leads to long-term savings on utility bills.

- Durability: Package unit HVAC systems are built to withstand various weather conditions as they are designed for outdoor or rooftop installation. They are constructed using durable materials that can withstand exposure to wind, rain, and extreme temperatures.

Overall, package unit HVAC systems provide a convenient and efficient solution for heating, cooling, and ventilation needs. Their space-saving design, energy efficiency, ease of installation and maintenance, and flexibility make them a popular choice for a wide range of applications.

When considering a package unit HVAC system, make sure to check the energy efficiency rating (EER) and seasonal energy efficiency ratio (SEER) to ensure you are getting a unit that will save you money on your energy bills.

Read more: What Is An AC

Disadvantages of Package Unit HVAC

While package unit HVAC systems come with numerous advantages, it’s important to consider their potential downsides as well. Understanding the disadvantages can help you make an informed decision when selecting the right HVAC system for your needs. Let’s explore some of the common disadvantages of package unit HVAC systems:

- Limited Customization: Package unit HVAC systems are pre-built with predetermined specifications, which may limit customization options. This can be a disadvantage for buildings with unique or specific heating and cooling requirements.

- Ductwork Requirements: Package unit HVAC systems require a network of ductwork to distribute conditioned air throughout the building. This means that existing buildings without ductwork may require additional modifications and installation costs to accommodate a package unit HVAC system.

- Noisy Operation: Package unit HVAC systems contain all the components in one unit, including the blower fan and compressor. The compact design and the proximity of these components can result in louder operation compared to split systems where the noisy components are placed outdoors.

- Limited Efficiency Options: While package unit HVAC systems do offer energy-efficient models, the options may be more limited compared to other types of HVAC systems. This could restrict your ability to select the most energy-efficient unit that meets your specific energy-saving goals.

- Complex Repairs: In the event of a component failure or major repair, servicing a package unit HVAC system can be more challenging and time-consuming. Due to the compact design, accessing and replacing components may require more effort and expertise.

- Less Aesthetically Pleasing: Package unit HVAC systems are typically installed on the roof or outside the building. This may impact the visual appeal of the structure, especially for residential applications, where rooftop units may be visible from the street or surrounding areas.

- Single-Point Failure: Since all the components of a package unit are housed within one unit, a single-point failure can result in complete system shutdown. In contrast, split systems usually have components that are separate from one another, so a failure in one component does not necessarily affect the others.

It’s important to note that the disadvantages may vary depending on the specific model, installation conditions, and individual preferences. Assessing these potential drawbacks in relation to your specific needs and circumstances will help you determine if a package unit HVAC system is the right choice for your building.

Ultimately, consulting with HVAC professionals and thoroughly researching different HVAC systems will help you make an informed decision that best meets your heating, cooling, and ventilation requirements.

Installation of Package Unit HVAC

The installation of a package unit HVAC system requires careful planning and adherence to industry standards. Whether it’s for a new construction or a replacement system, proper installation is crucial to ensure optimal performance, energy efficiency, and longevity of the system. Here are the key steps involved in the installation process:

- Sizing and Selection: The first step in the installation process is to determine the appropriate size and capacity of the package unit HVAC system. This is done by performing a load calculation that takes into account factors such as the size of the building, insulation levels, number of occupants, and geographical location. Proper sizing ensures that the system can effectively heat and cool the space without overworking or underperforming.

- Site Preparation: Once the sizing process is complete, the installation site needs to be prepared. This involves clearing the area where the package unit will be placed, ensuring there is sufficient space for installation and maintenance access. It’s important to comply with local building codes and regulations regarding setback requirements, noise restrictions, and safety considerations.

- Delivery and Placement: The package unit HVAC system is delivered to the installation site. The unit is positioned on a suitable and stable platform, such as a concrete pad or rooftop mounting frame. Adequate clearance is ensured around the unit to facilitate proper airflow and maintenance access.

- Connections and Wiring: The necessary electrical and refrigerant connections are made according to the manufacturer’s specifications and local building codes. This includes connecting the electrical supply, thermostat, and any optional components such as electric heating elements or air purifiers. The refrigerant lines are properly insulated and connected between the package unit and the air handling unit inside the building.

- Ductwork Installation: If ductwork is not already in place, it needs to be installed. This involves routing the ducts from the package unit to different zones or rooms within the building. The ductwork should be properly sized, insulated, and sealed to ensure efficient airflow and minimize air leakage.

- Condensate Drainage: Proper condensate drainage is essential to prevent water accumulation and potential damage to the system. A condensate drain line is installed to carry away the moisture collected from the evaporator coil. The drain line is sloped to ensure proper drainage, and a condensate pump may be required for locations where gravity drainage is not possible.

- Start-Up and Testing: Once all the connections, wiring, and ductwork are complete, the system is ready for start-up and testing. The electrical connections are energized, and the system is run to check for proper operation, airflow, and temperature control. The refrigerant levels are measured and adjusted if necessary. Any necessary adjustments or fine-tuning are made to ensure optimal performance.

- Documentation and Customer Education: Finally, documentation, including equipment manuals and warranty information, is provided to the customer. The HVAC technician should take the time to educate the customer on the operation, maintenance, and troubleshooting procedures of the package unit HVAC system. This helps the customer effectively manage and maintain their HVAC system for maximum efficiency and longevity.

It is advisable to hire a professional HVAC technician with expertise in package unit HVAC systems for the installation process. They have the knowledge, experience, and tools required to ensure a successful and compliant installation that meets all safety and performance standards.

Remember, proper installation is a crucial step in maximizing the performance and efficiency of your package unit HVAC system, so it’s worth investing in professional installation to enjoy the full benefits of your system.

Maintenance of Package Unit HVAC

Maintaining a package unit HVAC system is essential for its efficient operation, longevity, and optimal performance. Regular maintenance helps to prevent breakdowns, improve energy efficiency, and ensure good indoor air quality. Here are some important maintenance tasks to perform on a package unit HVAC system:

- Filter Replacement: One of the most critical maintenance tasks is to regularly check and replace the air filters. Dirty filters restrict airflow, reduce system efficiency, and negatively impact indoor air quality. Filters should be inspected monthly and replaced or cleaned as necessary, following the manufacturer’s guidelines.

- Coil Cleaning: The condenser coil and evaporator coil should be inspected and cleaned at least once a year. Over time, these coils can accumulate dirt, dust, and debris, reducing their efficiency. Cleaning the coils helps maintain proper heat transfer and airflow, resulting in improved system performance.

- Inspect and Clean Outdoor Unit: The outdoor unit, including the condenser and fan, should be inspected regularly for any buildup of debris, such as leaves, grass clippings, or dirt. These obstructions can restrict airflow and decrease system efficiency. Wipe the exterior of the unit and remove any debris to maintain optimal airflow.

- Check and Clear Drainage: The condensate drain line should be inspected and cleared regularly to prevent clogs and water backups. A clogged condensate drain can lead to water leakage and potential damage to the system. Ensure that the drain line is free from obstructions and functioning properly.

- Inspect and Lubricate Moving Parts: Moving parts, such as fan motors and bearings, should be inspected for wear and tear. Lubrication of these parts is crucial to reduce friction and increase their lifespan. Consult the manufacturer’s guidelines for the appropriate lubrication requirements.

- Check Electrical Connections: Regularly inspect the electrical connections and wiring to ensure they are tight and secure. Loose or faulty connections can lead to system malfunctions or electrical hazards. If any issues are detected, contact a professional HVAC technician for repairs and replacements.

- Test Thermostat and Controls: Periodically test the thermostat and controls to ensure they are functioning properly. Verify that the system turns on and off as intended and that temperature readings are accurate. Replace batteries in programmable thermostats as needed.

- Professional Maintenance: While there are several maintenance tasks you can perform yourself, it is recommended to schedule professional maintenance at least once a year. HVAC technicians have the expertise to perform thorough inspections, cleanings, and fine-tuning of the system. They can identify and address any potential issues before they lead to major breakdowns.

Remember to follow the manufacturer’s maintenance guidelines specific to your package unit HVAC system. Maintaining a maintenance schedule and keeping accurate records of performed tasks can help ensure that maintenance is performed on time and that the system operates at peak efficiency.

Regular maintenance not only helps to prolong the lifespan of your package unit HVAC system but also improves indoor air quality, reduces energy consumption, and enhances the overall comfort of your space. Don’t neglect this important aspect of HVAC system ownership.

Common Problems with Package Unit HVAC

While package unit HVAC systems are designed to operate reliably, they may encounter occasional issues that require troubleshooting and repair. Being aware of common problems can help you identify and address issues promptly. Here are some of the most common problems that can occur with a package unit HVAC system:

- Lack of Maintenance: Failure to perform regular maintenance can lead to a range of problems. Dirty air filters, clogged coils, and obstructed airflow can result in reduced efficiency, poor indoor air quality, and increased energy consumption. Regular maintenance is vital to prevent these issues.

- Refrigerant Leaks: Refrigerant leaks can occur due to corrosion, aging components, or physical damage. Low refrigerant levels can cause the system to work harder and less efficiently. If you notice a decrease in cooling or heating performance, it’s important to have a professional HVAC technician inspect for refrigerant leaks and repair them.

- Faulty Thermostat: A malfunctioning thermostat can impact the performance of your HVAC system. This could lead to inconsistent temperatures, improper cycling, or the system not turning on or off as intended. Check the thermostat settings and battery levels, and if issues persist, consider replacing or recalibrating the thermostat.

- Electrical Problems: Electrical issues can cause the package unit HVAC system to malfunction or fail completely. Loose wiring connections, faulty capacitors, or damaged electrical components can result in intermittent operation, tripped breakers, or even system shutdown. These problems should be addressed by a qualified HVAC technician to ensure proper repairs and safety.

- Fan Motor Issues: The fan motor is responsible for circulating air throughout the system. Faulty bearings, motor failure, or worn-out belts can lead to improper airflow, reduced performance, or a noisy operation. Regular inspections and lubrication of moving parts are essential to prevent such issues.

- Ignition or Pilot Problems: Gas-powered package units may experience ignition or pilot problems. This can result in a lack of heat, inefficient heating, or a system that fails to start altogether. These issues should be inspected and repaired by a qualified technician to ensure safe and proper operation.

- Condensate Drainage Issues: Clogged or blocked condensate drain lines can cause the system to leak water or shut down. Regularly clearing the drain line and ensuring proper drainage is important to prevent water damage and maintain system operation.

- Poor Air Quality: If you notice reduced indoor air quality, such as excessive dust, odors, or allergies, it could be due to problems with the filtration system, dirty coils, or inadequate ventilation. Regular maintenance, including filter replacements and coil cleanings, can help improve air quality.

- Component Wear and Tear: Over time, various components of the package unit HVAC system may experience wear and tear. This can result in reduced efficiency, increased energy consumption, or system malfunctions. Regular inspections and maintenance can help identify and address worn-out components before they lead to larger issues.

If you encounter any of these problems with your package unit HVAC system, it is advisable to consult a professional HVAC technician. They have the knowledge and expertise to diagnose and repair the issues effectively, ensuring that your system operates efficiently and reliably.

Remember, timely maintenance and addressing problems promptly can help prolong the lifespan of your HVAC system, enhance performance, and keep your indoor environment comfortable and healthy.

Conclusion

Package unit HVAC systems provide a convenient and efficient solution for heating, cooling, and ventilation in residential and commercial buildings. These self-contained units offer a range of advantages, including space-saving design, ease of installation, energy efficiency, and flexibility in zoning. However, like any HVAC system, package units have their drawbacks, such as limited customization options, potential noise during operation, and the need for comprehensive repairs in case of system failure.

To ensure the optimal performance and longevity of your package unit HVAC system, regular maintenance is essential. This includes replacing air filters, cleaning coils, inspecting and lubricating moving parts, checking electrical connections, and scheduling professional maintenance at least once a year. By following these maintenance practices, you can prevent common problems, improve energy efficiency, and maintain good indoor air quality.

When considering the installation of a package unit HVAC system, careful planning and proper sizing are crucial to ensure optimal performance. It’s important to work with HVAC experts who can assess your building’s requirements and recommend the most suitable type of package unit HVAC system for your needs. Proper installation, including appropriate ductwork and electrical connections, will ensure efficient operation and performance.

In conclusion, package unit HVAC systems are a popular choice for many buildings due to their efficient operation, space-saving design, and ease of installation. While they do have some disadvantages and require regular maintenance, they offer an effective and reliable solution for heating, cooling, and ventilation needs.

By understanding the components, types, advantages, disadvantages, installation process, maintenance requirements, and common problems associated with package unit HVAC systems, you are equipped with the knowledge to make informed decisions about your HVAC system and effectively manage its maintenance and operation.

Remember, consulting with HVAC professionals and following manufacturer guidelines are essential to ensure the safety, efficiency, and longevity of your package unit HVAC system. With proper installation, regular maintenance, and timely repairs, your package unit HVAC system can provide reliable comfort and climate control for years to come.

Frequently Asked Questions about What Is A HVAC Package Unit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A HVAC Package Unit”