Articles

What Is The White Powder In Fluorescent Tubes

Modified: January 4, 2024

Discover the truth about the white powder in fluorescent tubes in our informative articles. Learn why it occurs and how to prevent it from affecting the performance of your lighting.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Fluorescent tubes have become an integral part of our everyday lives. We encounter them in various settings, from homes and offices to commercial establishments and even streetlights. These energy-efficient lighting fixtures offer numerous advantages over traditional incandescent bulbs, including longer lifespan and lower energy consumption.

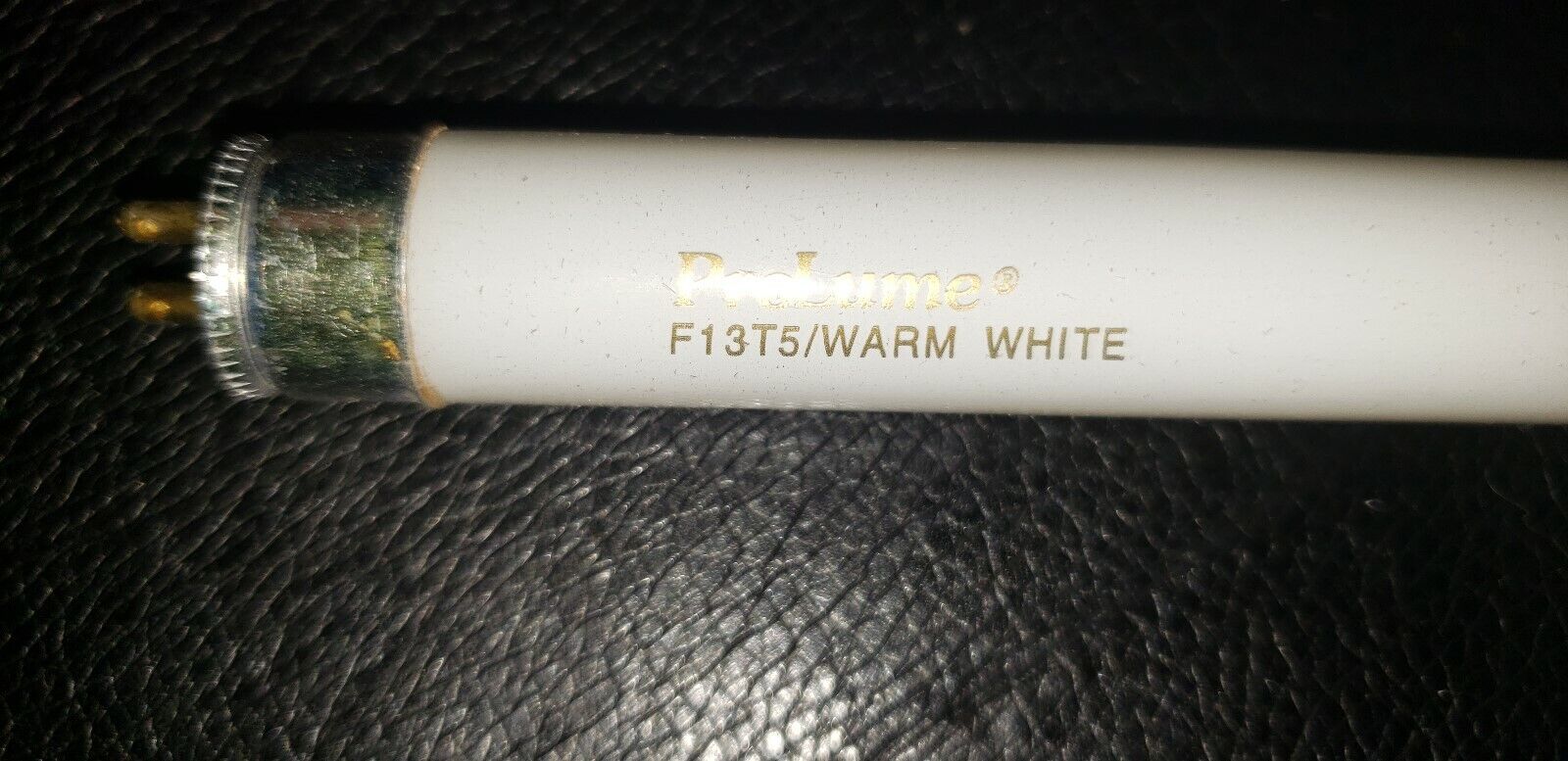

However, if you have ever taken a closer look at a fluorescent tube, you might have noticed a peculiar white powder coating the inner surface. This white powder plays a crucial role in the functioning of the tube, but its presence often raises questions about its composition and potential health concerns.

In this article, we will explore what exactly this white powder is and delve into its significance in fluorescent tubes. We will also address any potential health concerns associated with its use, providing you with a comprehensive understanding of this intriguing component.

So, let’s dive in and uncover the secrets behind the white powder in fluorescent tubes.

Key Takeaways:

- The white powder in fluorescent tubes is composed of phosphor compounds, playing a crucial role in converting UV light into visible light, ensuring even light distribution, and controlling color temperature.

- While fluorescent tubes offer energy-efficient lighting, proper handling and disposal are essential to minimize potential health risks associated with mercury vapor and allergic reactions to the white powder.

What are fluorescent tubes?

Fluorescent tubes, also known as fluorescent lamps, are a type of electrical discharge lamp commonly used for lighting purposes. They consist of a long, cylindrical glass tube filled with a mixture of gases, as well as a filament and electrodes at each end. When an electric current is passed through the electrodes, it excites the gases inside the tube, producing visible light.

Unlike incandescent bulbs, which rely on a glowing filament to emit light, fluorescent tubes utilize a process known as fluorescence. This process involves the conversion of electrical energy into ultraviolet (UV) light through the excitation of mercury vapor atoms within the tube. The UV light is then absorbed by a phosphor coating on the inner surface of the tube, causing it to emit visible light.

Fluorescent tubes offer several advantages over traditional incandescent bulbs. They are more energy-efficient, consuming up to 75% less electricity while producing the same amount of light. They also have a significantly longer lifespan, lasting around 10,000 to 20,000 hours compared to the 1,000 hours of incandescent bulbs. Additionally, fluorescent tubes emit less heat, making them safer to use and reducing the load on cooling systems.

Due to their efficiency and durability, fluorescent tubes have found widespread application in various settings. They are commonly used for general lighting in offices, schools, retail stores, warehouses, and other commercial spaces. They are also utilized in specialized lighting fixtures for specific purposes such as aquariums, plant growth, and ultraviolet (UV) or black light effects.

Now that we have a basic understanding of fluorescent tubes, let’s explore the intriguing white powder that coats their inner surface.

How do fluorescent tubes work?

To understand how fluorescent tubes function, we need to delve into the intricate process that occurs within the tube itself. The operation of fluorescent tubes involves a combination of electrical current, gas excitation, and phosphor conversion.

When an electric current is applied to the electrodes at each end of the tube, it creates an electrical discharge. This discharge ionizes the mercury vapor atoms present in the tube, causing them to emit ultraviolet (UV) light. However, UV light is not visible to the human eye, so an additional step is required to convert it into visible light.

To accomplish this, the inner surface of the glass tube is coated with a phosphor material. Phosphors are compounds that have the unique property of absorbing UV light and re-emitting it as visible light. When the UV light produced by the ionized mercury atoms strikes the phosphor coating, it excites the phosphor particles, causing them to emit visible light.

The type of phosphor coating used in fluorescent tubes can vary, depending on the desired color temperature and hue of the emitted light. Different combinations of phosphors can produce warm white, cool white, or daylight white light, allowing for customization to suit specific lighting requirements.

The presence of the white powder in fluorescent tubes is directly related to the phosphor coating. This powder consists of a finely ground mixture of the various phosphor compounds used in the tube. The powder is applied as a uniform coating on the inner surface of the tube, ensuring that the emitted light appears smooth and consistent.

In addition to the phosphor coating, fluorescent tubes also contain a small amount of mercury vapor. Mercury is a crucial component in fluorescent tubes, as it assists in the ionization process and facilitates the emission of UV light. However, it is important to handle and dispose of fluorescent tubes properly to prevent mercury pollution and environmental damage.

Now that we have explored the inner workings of fluorescent tubes, let us move on to understanding the role of the white powder in these lighting fixtures.

The white powder in fluorescent tubes

If you have ever examined a fluorescent tube closely, you might have noticed a fine white powder coating the inner surface. This powder is an essential component of the tube’s construction and plays a crucial role in its overall performance.

The white powder in fluorescent tubes is primarily composed of phosphor compounds. Phosphor is a special type of material that possesses the ability to absorb ultraviolet (UV) light and emit visible light. The specific composition of phosphors used in a fluorescent tube depends on the desired color temperature and quality of light produced.

The phosphor coating serves two important purposes. Firstly, it helps convert the UV light emitted by the ionized mercury vapor into visible light. Without the phosphor coating, the light produced by the fluorescent tube would remain in the UV spectrum and would not be visible to our eyes.

Secondly, the phosphor coating ensures that the emitted light appears smooth and uniform. By evenly dispersing the emitted light, the phosphor coating eliminates the occurrence of dark spots or uneven brightness along the length of the tube. It helps create a consistent and pleasing illumination, making fluorescent tubes ideal for various lighting applications.

The white powder is applied to the inside of the tube during the manufacturing process. It is carefully distributed and adhered to the glass surface to create a uniform and durable coating. The thickness of the phosphor coating is crucial in determining the overall light output and efficiency of the tube.

Different types of phosphor coatings result in variations in the color temperature and quality of light produced by fluorescent tubes. Warm white light, which resembles the soft glow of incandescent bulbs, is achieved using specific phosphor blends. Cool white light, on the other hand, emits a brighter and crisper illumination. Daylight white tubes mimic natural daylight, providing a color temperature similar to that of sunlight.

It is important to note that the phosphor coating in fluorescent tubes can deteriorate over time, resulting in a decrease in light output and a shift in color temperature. This is one of the reasons why fluorescent tubes may need to be replaced after a certain period.

While the white powder in fluorescent tubes is crucial for their functionality, there have been concerns about potential health hazards associated with its use. In the next section, we will explore these concerns and address any potential risks to human health.

The white powder in fluorescent tubes is called phosphor. It is used to convert ultraviolet light produced by the tube into visible light.

Composition of the white powder

The white powder coating found in fluorescent tubes is primarily composed of phosphor compounds. Phosphors are a class of materials that exhibit the unique property of absorbing ultraviolet (UV) light and emitting visible light in response. The specific composition of the white powder can vary depending on the desired characteristics of the emitted light.

The main component of the white powder is a mix of different phosphor compounds. Common phosphors used in fluorescent tubes include blends of calcium halophosphates, rare earth phosphates, and zinc sulfides. These phosphor compounds are responsible for converting the UV light emitted by the ionized mercury vapor into visible light.

Calcium halophosphates are widely used phosphor compounds in fluorescent tubes. They typically consist of a mixture of calcium phosphate and halides of elements like chlorine, bromine, or iodine. This combination results in a range of different color temperatures, allowing for the production of warm white, cool white, and daylight white light.

Rare earth phosphates are another group of phosphor compounds commonly used in fluorescent tubes. They contain various rare earth elements, such as europium, terbium, or cerium, which contribute to the specific color rendering properties of the emitted light. Rare earth phosphates are often utilized to achieve a higher color rendering index (CRI) and improved color accuracy in specialized lighting applications.

Zinc sulfides are sometimes added to the white powder mixture to enhance the efficiency of the phosphor coating. These compounds help improve the phosphor’s ability to absorb UV light and convert it into visible light, resulting in higher light output and energy efficiency.

In addition to the phosphor compounds, the white powder may also contain small amounts of other materials. These can include binders or resins, which help adhere the phosphor particles to the glass surface of the tube. Antistatic agents may also be added to prevent the accumulation of dust and static charge on the phosphor coating.

It is important to note that the composition of the white powder in fluorescent tubes can vary between manufacturers and different tube models. Each manufacturer may have their specific formulation to achieve the desired lighting characteristics. These formulations undergo rigorous testing to ensure the safety and performance of the fluorescent tubes.

Now that we have explored the composition of the white powder, let’s delve into the role it plays in the functioning of fluorescent tubes.

Read more: What Is T12 Fluorescent Tubes

Role of the white powder in fluorescent tubes

The white powder coating found inside fluorescent tubes serves several important roles in their overall functionality. Let’s explore the key roles played by this white powder:

1. Phosphor Conversion: The primary role of the white powder is to facilitate the conversion of ultraviolet (UV) light emitted by the ionized mercury vapor into visible light. The phosphor compounds in the white powder absorb the UV light and then re-emit it as visible light. This conversion process allows fluorescent tubes to produce the bright and illuminating light that we commonly associate with them.

2. Light Diffusion: The white powder also serves as a medium for distributing the emitted light evenly along the length of the fluorescent tube. The phosphor coating helps scatter the emitted light in all directions, ensuring uniform brightness throughout the tube. This diffusion of light eliminates the formation of dark spots or uneven illumination, providing a smooth and consistent lighting experience.

3. Color Temperature Control: The composition of the white powder can be adjusted to achieve different color temperatures of light. By using specific combinations and ratios of phosphor compounds, fluorescent tubes can produce warm white, cool white, or daylight white light. This flexibility allows for customization to suit different applications and preferences, whether it be a cozy ambiance or a bright working environment.

4. Energy Efficiency: The white powder also contributes to the energy efficiency of fluorescent tubes. By converting UV light into visible light, the phosphor coating ensures that a significant portion of the energy consumed is converted into usable light. This results in reduced energy waste and makes fluorescent tubes more energy-efficient compared to traditional incandescent bulbs.

5. Longevity of the Tube: The white powder helps protect the inner surface of the fluorescent tube from the direct impact of the ionized mercury vapor and electric discharges. It acts as a barrier between the reactive components inside the tube and the glass surface. This protective function enhances the overall longevity and durability of the fluorescent tube.

In summary, the white powder coating inside fluorescent tubes plays a vital role in converting UV light into visible light, distributing the emitted light evenly, controlling color temperature, improving energy efficiency, and safeguarding the longevity of the tube. It is the combination of these roles that makes fluorescent tubes an efficient and reliable lighting option for a variety of applications.

While the white powder coating itself is not directly visible to users, its impact on the performance and qualities of the emitted light is highly significant. Understanding the role it plays helps to appreciate the craftsmanship and engineering behind these popular lighting fixtures.

Potential health concerns of the white powder

The presence of the white powder coating inside fluorescent tubes has raised some concerns regarding potential health risks. While fluorescent tubes are generally considered safe for use, it is important to be aware of certain factors related to the white powder.

1. Inhalation of Mercury Vapors: One of the main components of fluorescent tubes is mercury vapor. Although the amount of mercury is relatively small, improper handling or disposal of broken tubes can release mercury vapors into the air. Prolonged exposure to high levels of mercury vapor can have detrimental effects on human health, particularly on the nervous system. It is crucial to adhere to proper handling and disposal guidelines to minimize the risk of mercury exposure.

2. Skin Contact: Direct and prolonged contact with the white powder itself is generally not a significant concern for health. However, it is recommended to avoid touching the powder unnecessarily and to wash hands thoroughly after handling fluorescent tubes. This precautionary measure ensures that any potential residue from the powder is removed from the skin and prevents inadvertent ingestion.

3. Allergic Reactions: In rare cases, individuals may experience allergic reactions to certain components of the white powder, such as specific phosphor compounds. Allergies can manifest as skin irritation, rashes, or respiratory symptoms. If you suspect an allergic reaction, it is advisable to consult a medical professional for appropriate evaluation and guidance.

4. Environmental Impact: The disposal of fluorescent tubes requires special attention due to the presence of mercury and other potentially harmful substances. Improper disposal, such as throwing them in regular waste bins, can lead to environmental contamination. It is recommended to recycle or dispose of fluorescent tubes at designated collection centers to ensure they are handled and processed properly.

To mitigate potential health concerns associated with fluorescent tubes and the white powder, several precautionary measures can be taken:

– Handle fluorescent tubes with care and avoid breaking them.

– Use gloves or other protective equipment when handling broken tubes.

– Clean up broken tubes promptly and ensure proper ventilation during the cleanup process.

– Follow local guidelines for the safe disposal of spent fluorescent tubes.

– Consider using LED lighting alternatives, which do not contain mercury or require phosphor coatings.

Overall, while there are potential health concerns associated with the white powder in fluorescent tubes, practicing proper handling, disposal, and ventilation can help minimize any risks. Fluorescent tubes continue to be a widely used and efficient lighting option, but it is important to be mindful of their potential impact on both human health and the environment.

Conclusion

Fluorescent tubes play a significant role in our daily lives, providing energy-efficient lighting solutions in various settings. The white powder coating found inside these tubes, composed mainly of phosphor compounds, is integral to their functionality and performance.

The white powder serves multiple important roles in fluorescent tubes. It facilitates the conversion of ultraviolet (UV) light into visible light, ensures the even distribution of light throughout the tube, controls the color temperature of the emitted light, enhances energy efficiency, and protects the tube’s inner surface. These qualities have made fluorescent tubes a popular choice for a wide range of lighting applications.

While there may be potential health concerns associated with the white powder, such as the inhalation of mercury vapors and the risk of allergic reactions, the overall safety of fluorescent tubes can be ensured through proper handling, disposal, and adherence to recommended guidelines. It is important to exercise caution when dealing with broken tubes, avoid unnecessary contact with the powder, and dispose of spent tubes responsibly.

As technology continues to advance, newer lighting alternatives such as LED lights have become available. LED lights offer energy efficiency, long lifespans, and environmentally friendly features without the use of phosphors or mercury. These alternatives provide a reliable and sustainable lighting solution, reducing potential risks and environmental impact associated with fluorescent tubes.

In conclusion, the white powder coating in fluorescent tubes plays a critical role in their functionality and performance by converting UV light into visible light and ensuring uniform light distribution. While there may be potential health concerns, responsible handling, disposal, and consideration of alternative lighting options can mitigate these risks. Fluorescent tubes remain a widely used lighting solution, but as technology evolves, it is important to explore and adopt more sustainable and environmentally friendly alternatives.

Frequently Asked Questions about What Is The White Powder In Fluorescent Tubes

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The White Powder In Fluorescent Tubes”