Tableware

How To Autoclave Glassware

Modified: December 13, 2023

Learn the proper way to autoclave glassware to ensure sterilization and safety. Follow these steps for effective sterilization of tableware.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of tableware sterilization! In the realm of laboratory and medical settings, ensuring the cleanliness and sterility of glassware is of paramount importance. One of the most effective methods for achieving this is through autoclaving. In this comprehensive guide, we will delve into the intricacies of autoclaving glassware, providing you with valuable insights and practical tips to ensure the safety and efficacy of this crucial process.

Autoclaving, a process that utilizes high-pressure steam to sterilize equipment and supplies, is a cornerstone of laboratory hygiene. Glassware, in particular, is a staple in scientific and medical environments, serving as vessels for various experiments, cultures, and analyses. As such, maintaining the pristine condition of glassware is essential for accurate and reliable results.

Throughout this guide, we will explore the step-by-step procedures for autoclaving glassware, from preparation and loading to running the autoclave cycle and proper storage post-sterilization. Additionally, we will highlight essential safety precautions to uphold a secure working environment for all personnel involved in the autoclaving process.

Whether you are a seasoned laboratory professional seeking a refresher or a newcomer eager to learn the ropes of glassware sterilization, this guide is designed to equip you with the knowledge and confidence to execute autoclaving procedures with precision and expertise. So, let's embark on this enlightening journey into the world of autoclaving glassware, where meticulous hygiene meets scientific ingenuity.

Key Takeaways:

- Autoclaving glassware involves thorough cleaning, proper loading, and monitoring the sterilization cycle to ensure safe and reliable use in laboratories and medical settings.

- Safety precautions, including protective equipment and equipment inspection, are crucial for maintaining a secure working environment during autoclaving operations.

Read more: How To Store Glassware

Understanding Autoclaving

Autoclaving is a highly effective method for sterilizing glassware, as well as other laboratory equipment and supplies. The process involves exposing the items to high-pressure saturated steam at elevated temperatures. This combination of heat and moisture effectively eradicates microorganisms, including bacteria, fungi, and spores, ensuring that the sterilized items are free from contamination.

The key to the efficacy of autoclaving lies in the ability of steam to penetrate porous materials such as glass, effectively reaching all surfaces and crevices to eliminate any potential contaminants. This thorough sterilization process makes autoclaving an indispensable tool in maintaining the integrity of laboratory experiments and medical procedures.

Autoclaves are designed to operate at specific temperatures and pressures, typically ranging from 121°C to 134°C and 15 to 30 pounds per square inch (psi) of pressure. These precise conditions are maintained for a specified duration, ensuring that the sterilization process is thorough and reliable.

It is important to note that not all materials are suitable for autoclaving. While glassware is generally compatible with this sterilization method, certain plastics, rubber, and other heat-sensitive materials may be damaged by the high temperatures and pressures involved. Therefore, it is crucial to carefully assess the compatibility of each item with autoclaving to avoid potential damage and ensure the safety of the process.

Understanding the principles of autoclaving is essential for ensuring the successful sterilization of glassware and other laboratory items. By comprehending the science behind this process, laboratory professionals can confidently implement autoclaving procedures, knowing that they are upholding the highest standards of cleanliness and hygiene in their work environments.

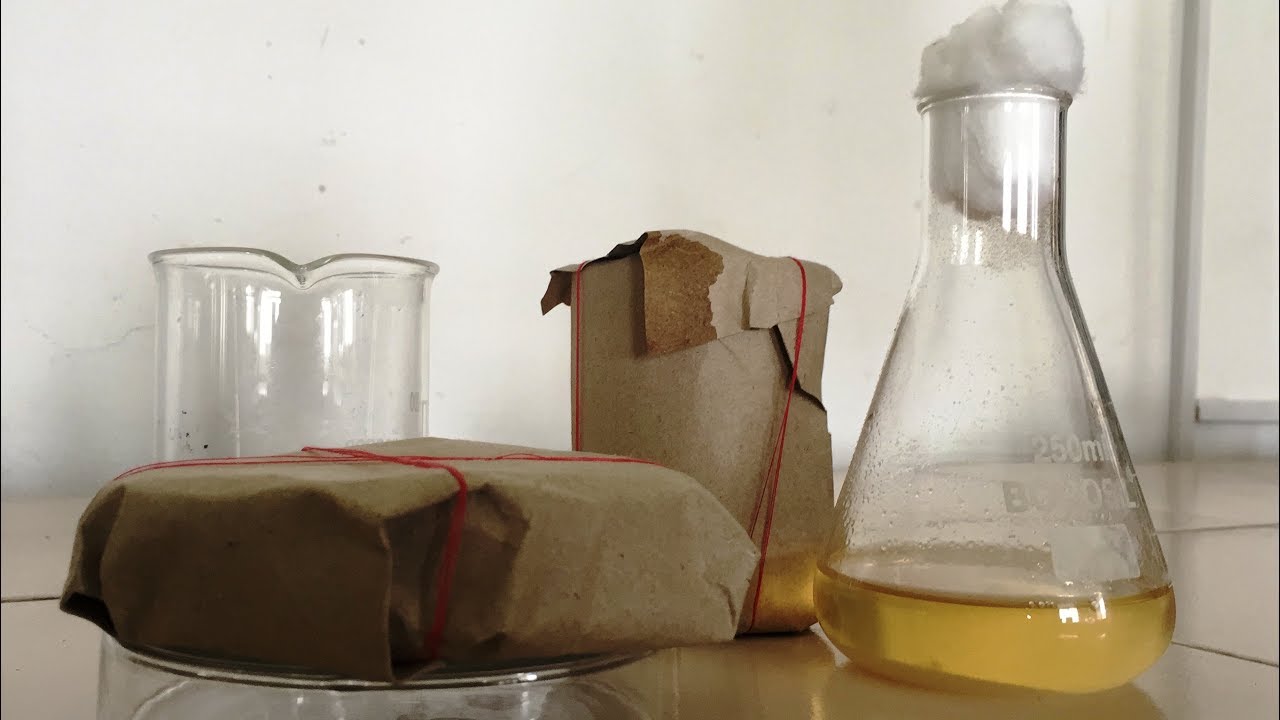

Preparing Glassware for Autoclaving

Proper preparation of glassware is a critical step in the autoclaving process, as it sets the foundation for effective sterilization. Before placing glassware in the autoclave, it is essential to ensure that each item is clean and free from any residual substances that could compromise the sterilization process.

The following steps outline the preparation process for glassware prior to autoclaving:

- Thorough Cleaning: Begin by thoroughly cleaning the glassware using an appropriate detergent or cleaning solution. This step is crucial for removing any visible debris, residues, or contaminants from the surfaces of the glassware.

- Rinsing: After cleaning, rinse the glassware with distilled or deionized water to remove any remaining cleaning agents. This step helps to prevent chemical residues from interfering with the autoclaving process.

- Drying: Once rinsed, allow the glassware to air-dry completely. Alternatively, specialized drying racks or ovens can be used to expedite the drying process, ensuring that the glassware is free from moisture before autoclaving.

- Assembling: If the glassware consists of multiple components or parts, ensure that they are properly assembled according to the specific requirements of the experiment or application. Secure any closures or lids to prevent steam from entering the glassware during autoclaving.

- Packaging: For certain applications, such as sensitive samples or materials, it may be necessary to package the glassware in autoclave-safe containers or pouches. This additional layer of protection can safeguard the contents from potential contamination during the autoclaving process.

By meticulously following these preparatory steps, laboratory personnel can ensure that the glassware is primed for successful autoclaving. Thorough cleaning, proper drying, and appropriate packaging, when necessary, are integral to maintaining the sterility and integrity of the glassware throughout the autoclaving process.

Furthermore, adherence to standardized cleaning and preparation protocols is essential for upholding the quality and reliability of experimental results and analyses conducted using the autoclaved glassware. Through meticulous preparation, glassware can be effectively sterilized, ready to serve its crucial role in scientific and medical endeavors.

Loading the Autoclave

Once the glassware is meticulously prepared for autoclaving, the next step is to load the items into the autoclave chamber. Proper loading of the autoclave is essential for ensuring the efficient and thorough sterilization of the glassware. Careful attention to the arrangement and positioning of the items can significantly impact the effectiveness of the autoclaving process.

The following guidelines outline the best practices for loading glassware into the autoclave:

- Even Distribution: Arrange the glassware in the autoclave chamber in a manner that promotes even distribution of steam and heat. Avoid overcrowding the chamber, as this can impede the penetration of steam into the glassware, leading to inadequate sterilization.

- Proper Orientation: Position the glassware with openings facing upward to prevent the accumulation of condensation or water droplets inside the items during autoclaving. This orientation facilitates the removal of air and ensures thorough steam penetration throughout the glassware.

- Separation of Items: If multiple pieces of glassware are being autoclaved simultaneously, ensure that they are adequately spaced to allow for uniform exposure to steam. Maintaining sufficient gaps between items prevents potential shadowing effects that could hinder the sterilization of adjacent surfaces.

- Consideration of Material: Take into account the specific properties of the glassware being autoclaved. Delicate or heat-sensitive items may require additional cushioning or protection to prevent breakage or damage during the autoclave cycle.

- Load Monitoring: Be mindful of the weight and load capacity of the autoclave. Avoid exceeding the recommended load limit to maintain the optimal performance and safety of the equipment.

By adhering to these loading principles, laboratory personnel can optimize the sterilization process, ensuring that the glassware is exposed to steam uniformly and thoroughly. Proper loading not only enhances the effectiveness of autoclaving but also minimizes the risk of breakage or damage to the glassware during the sterilization cycle.

Additionally, meticulous attention to the loading process reflects a commitment to upholding the highest standards of hygiene and safety in laboratory practices. By following these guidelines, laboratory professionals can maximize the efficacy of autoclaving, ultimately contributing to the integrity and reliability of scientific and medical endeavors.

Always ensure that glassware is properly wrapped or covered before placing it in the autoclave to prevent breakage. Additionally, make sure to follow the manufacturer’s instructions for the correct autoclave settings for glassware.

Running the Autoclave Cycle

With the glassware loaded into the autoclave, the next phase involves initiating and overseeing the autoclave cycle. This pivotal stage requires careful monitoring and adherence to established protocols to ensure the successful sterilization of the glassware. The autoclave cycle encompasses several key steps, each playing a crucial role in achieving the desired level of sterility.

The following are the essential steps involved in running the autoclave cycle:

- Setting Parameters: Configure the autoclave settings, including the desired temperature, pressure, and duration of the sterilization cycle. These parameters are determined based on the specific requirements of the glassware and the materials being sterilized.

- Purge and Preheat: Initiate the autoclave cycle, allowing the chamber to purge any residual air and preheat to the designated sterilization temperature. This preheating phase prepares the chamber for the introduction of steam and ensures uniform heating throughout the autoclave.

- Steam Exposure: Once the chamber reaches the specified temperature and pressure, steam is introduced to initiate the sterilization process. The glassware is exposed to high-pressure saturated steam, effectively eradicating microorganisms and achieving sterilization.

- Sterilization Duration: The duration of the sterilization cycle is determined by the specific requirements for the glassware and the materials being autoclaved. This period allows for the thorough penetration of steam and sufficient exposure to achieve the desired level of sterility.

- Depressurization and Drying: Following the sterilization phase, the autoclave chamber undergoes a depressurization process, allowing the steam to dissipate. Subsequently, the drying phase commences, ensuring that excess moisture is removed from the glassware before unloading.

Throughout the autoclave cycle, it is imperative to monitor the process closely, verifying that the parameters are maintained within the specified ranges and that the sterilization phase proceeds as intended. This vigilance helps to ensure the efficacy of the sterilization process, safeguarding the integrity of the glassware and the materials within.

By meticulously executing the autoclave cycle, laboratory professionals uphold the highest standards of sterilization and hygiene, fostering an environment conducive to accurate and reliable scientific and medical practices. The successful completion of the autoclave cycle marks the culmination of a meticulous process, resulting in glassware that is primed for safe and reliable use in laboratory and medical applications.

Read more: How To Identify Glassware

Unloading and Storing Autoclaved Glassware

Following the completion of the autoclave cycle, the careful unloading and subsequent storage of the sterilized glassware are crucial steps in maintaining the integrity and sterility of the items. Proper handling and storage procedures are essential for ensuring that the glassware remains free from contamination and ready for use in laboratory experiments, medical procedures, and other applications.

The unloading and storage process for autoclaved glassware involves the following key considerations:

- Cooling Period: After the autoclave cycle concludes, allow the glassware to cool inside the autoclave chamber for a specified duration. This cooling period helps to stabilize the items and reduces the risk of thermal shock when exposed to room temperature.

- Cautionary Measures: When unloading the glassware, exercise caution to prevent accidental breakage or damage. Use appropriate protective equipment, such as heat-resistant gloves, to handle hot items and minimize the risk of injuries or mishaps.

- Inspection: Thoroughly inspect the autoclaved glassware upon unloading to ensure that the sterilization process was successful and that the items remain intact and free from defects. Any abnormalities or concerns should be promptly addressed before the glassware is put into use.

- Storage Conditions: Store the autoclaved glassware in a clean and designated area, free from potential sources of contamination. Properly labeled storage containers or shelves help to organize the sterilized items and prevent mix-ups with non-autoclaved materials.

- Usage Guidelines: Clearly communicate any specific usage guidelines or restrictions associated with the autoclaved glassware. This information may include expiration dates for sterility, recommended handling procedures, and any additional precautions to maintain the integrity of the sterilized items.

By adhering to these unloading and storage practices, laboratory personnel can safeguard the sterility and functionality of the autoclaved glassware, ensuring that it remains suitable for its intended applications. Proper storage also facilitates efficient inventory management and traceability, contributing to the overall organization and safety of laboratory operations.

Furthermore, meticulous attention to unloading and storage underscores a commitment to maintaining the highest standards of cleanliness and hygiene in laboratory practices. By upholding rigorous protocols for handling and storing autoclaved glassware, laboratory professionals contribute to the reliability and integrity of scientific and medical endeavors, fostering an environment where precision and safety are paramount.

Safety Precautions

Ensuring the safety of personnel and maintaining a secure working environment are paramount considerations when engaging in the autoclaving of glassware. Adhering to established safety precautions not only safeguards individuals involved in the process but also contributes to the preservation of equipment and the integrity of the sterilization procedures.

The following safety precautions are essential for conducting autoclaving operations:

- Protective Equipment: Prior to loading or unloading the autoclave, personnel should don appropriate personal protective equipment (PPE), including heat-resistant gloves and eye protection. This safeguards individuals from potential heat-related injuries and exposure to steam or hot surfaces.

- Proper Ventilation: Autoclaving should be conducted in well-ventilated areas to prevent the accumulation of steam and heat. Adequate ventilation helps to dissipate excess moisture and maintain a comfortable working environment for personnel.

- Equipment Inspection: Regular inspection and maintenance of the autoclave equipment are crucial for identifying and addressing any potential malfunctions or safety hazards. This proactive approach ensures the reliability and safety of the autoclaving process.

- Temperature Monitoring: Throughout the autoclave cycle, personnel should monitor the temperature and pressure parameters to verify that they remain within the specified ranges. Any deviations should be promptly addressed to prevent safety risks and ensure the effectiveness of sterilization.

- Emergency Procedures: Personnel should be well-versed in emergency protocols, including the proper response to equipment malfunctions, steam leaks, or other unforeseen incidents. Clear communication of emergency procedures and the location of safety equipment is essential for a prompt and effective response to potential hazards.

By prioritizing safety precautions, laboratory professionals uphold a culture of responsibility and diligence, mitigating potential risks associated with autoclaving operations. This proactive approach not only safeguards personnel but also contributes to the longevity and reliability of laboratory equipment, promoting an environment where safety and efficiency coexist harmoniously.

Furthermore, fostering a safety-conscious mindset underscores a commitment to upholding the highest standards of professionalism and care in laboratory practices. By integrating safety precautions into autoclaving operations, laboratory professionals demonstrate their dedication to creating a secure and conducive environment for scientific and medical pursuits.

Conclusion

Autoclaving glassware is a fundamental practice in laboratory and medical settings, serving as a cornerstone of hygiene and sterility. Through meticulous preparation, loading, and running of the autoclave cycle, glassware is effectively sterilized, ready to fulfill its vital role in scientific experiments, medical procedures, and other applications. The careful unloading and storage of autoclaved glassware, coupled with stringent adherence to safety precautions, further contribute to the integrity and reliability of laboratory operations.

By embracing the principles and best practices outlined in this guide, laboratory professionals and personnel can approach autoclaving with confidence and expertise. The thorough understanding of autoclaving processes, coupled with a steadfast commitment to safety and hygiene, fosters an environment where precision, reliability, and safety converge seamlessly.

As we conclude this enlightening journey into the world of autoclaving glassware, it is evident that the meticulous execution of sterilization procedures is not merely a routine task but a testament to the dedication and professionalism of laboratory personnel. The significance of maintaining clean, sterile glassware reverberates across scientific and medical disciplines, underpinning the accuracy and credibility of experimental results and clinical practices.

Ultimately, the art of autoclaving glassware transcends the technicalities of sterilization, embodying a dedication to excellence, safety, and the pursuit of knowledge. By upholding these principles, laboratory professionals play a pivotal role in advancing scientific frontiers and ensuring the highest standards of quality and reliability in laboratory and medical endeavors.

So, as you embark on your next autoclaving endeavor, may the knowledge and insights gleaned from this guide empower you to navigate the intricacies of glassware sterilization with precision and confidence, knowing that you are contributing to the foundation of scientific and medical excellence through the meticulous practice of autoclaving.

Frequently Asked Questions about How To Autoclave Glassware

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Autoclave Glassware”