Home>Dining>Tableware>What Is The Best Glassware For Heating And Mixing

Tableware

What Is The Best Glassware For Heating And Mixing

Modified: March 2, 2024

Discover the best glassware for heating and mixing on the market. From durable tableware to heat-resistant options, find the perfect solution for all your culinary needs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Choosing the right glassware for heating and mixing is crucial in various scientific and laboratory settings. Whether you’re conducting experiments, running tests, or engaging in research, having the appropriate glassware can significantly impact the accuracy and reliability of your results. This article will explore the importance of selecting the right glassware for heating and mixing, factors to consider when choosing, and different options available for these purposes.

When it comes to heating and mixing substances, not all glassware is created equal. Different types of glassware have unique characteristics and are designed to withstand varying temperature ranges and chemical reactions. Using the wrong glassware can lead to breakage, contamination, or inaccurate results.

There are several factors to consider when selecting glassware for heating and mixing. The type of experiment or process you’re performing, the substances involved, and the required temperature range all play a role in determining the most suitable option. Additionally, factors such as durability, ease of cleaning, and availability may also influence your decision. By carefully considering these factors, you can ensure that you choose the best glassware for your specific needs.

Now let’s dive into the various glassware options available for heating and mixing purposes in scientific and laboratory settings.

Key Takeaways:

- Choose the right glassware for heating and mixing to ensure safety, accuracy, and efficiency in scientific experiments. Consider factors like temperature resistance, chemical compatibility, and durability for optimal performance.

- Beakers, Erlenmeyer flasks, test tubes, and other glassware options offer unique advantages and limitations for specific laboratory applications. Understanding their characteristics helps researchers make informed decisions for successful experiments.

Read more: What Is The Best Glassware Brand

Importance of Choosing the Right Glassware for Heating and Mixing

Choosing the right glassware for heating and mixing is of utmost importance in scientific and laboratory settings. The quality and suitability of the glassware can have a significant impact on the accuracy, reliability, and safety of experiments and processes. Here are a few reasons why selecting the right glassware is crucial:

1. Safety: Using the wrong glassware for heating and mixing can pose serious safety risks. Glassware that is not designed to withstand high temperatures or chemical reactions may shatter or break, leading to potential injury or exposure to hazardous substances. By selecting glassware specifically designed for heating and mixing purposes, you can reduce the risk of accidents and ensure the safety of yourself and those around you.

2. Accuracy: Different types of glassware have varying levels of accuracy. For precise measurements and reliable results, it is important to choose glassware that has been calibrated and validated for accuracy. This is especially crucial when working with sensitive experiments or when precise measurements are required. Using accurate glassware will help you achieve precise and reproducible results, enhancing the overall quality of your work.

3. Chemical Compatibility: Not all glassware is suitable for all types of chemicals or reactions. Some substances may react with certain types of glass, leading to contamination or unwanted reactions. It is crucial to consider the chemical compatibility of the glassware when selecting it for heating and mixing purposes. Choosing glassware that is resistant to the chemicals you’re working with will help prevent contamination and ensure the integrity of your experiment or process.

4. Temperature Resistance: Different experiments and processes require different temperature ranges. Glassware that is not designed to withstand high temperatures may crack, break, or deform under heat, rendering it unusable and potentially compromising the experiment or process. Selecting glassware that is specifically designed for heating and mixing applications ensures that it can withstand the required temperature range, providing you with reliable, consistent results.

5. Durability and Longevity: Investing in high-quality glassware for heating and mixing ensures its durability and longevity. Well-made glassware is less likely to break, chip, or degrade over time, offering a longer lifespan and saving you money in the long run. When the glassware is used and maintained properly, it can withstand repeated use and cleaning without compromising its structural integrity.

6. Ease of Use and Maintenance: Choosing glassware that is designed for heating and mixing streamlines your workflow and makes your experiments or processes more efficient. Glassware that is easy to handle, clean, and maintain reduces the risk of errors and ensures consistency in your work. Additionally, glassware that is compatible with common laboratory equipment makes it easier to integrate into existing setups, saving you time and effort.

By understanding the importance of selecting the right glassware for heating and mixing, you can make informed decisions that enhance the safety, accuracy, and efficiency of your scientific and laboratory work.

Factors to Consider in Selecting Glassware for Heating and Mixing

When choosing glassware for heating and mixing, there are several important factors to consider. Each factor contributes to the overall suitability and functionality of the glassware for your specific needs. Here are some key factors you should take into account:

1. Temperature Range: Consider the temperature requirements of your experiment or process. Different types of glassware are designed to withstand specific temperature ranges. Ensure that the glassware you choose can handle the temperatures required without compromising its integrity or performance.

2. Chemical Compatibility: Determine the type of substances you will be working with. Some chemicals may react with certain types of glassware, leading to contamination or adverse effects. Choose glassware that is chemically compatible with the substances you will be using to ensure accurate and reliable results.

3. Size and Capacity: Consider the volume of liquid or material you will be working with. Select glassware with an appropriate size and capacity to accommodate your needs. It’s important to ensure that the glassware is not too small, as it may cause spills or overflow during heating or mixing.

4. Accuracy and Precision: Depending on the nature of your experiment or process, accuracy and precision may be crucial. Some glassware is specially calibrated for accurate measurements. If precise measurements are required, choose glassware that offers high levels of accuracy and precision.

5. Durability: Glassware durability is essential for long-term use and reliability. Look for glassware made from high-quality materials that are resistant to breakage and thermal shock. Choosing durable glassware will save you money in the long run and minimize the risk of accidents or compromised experiments.

6. Ease of Cleaning: Consider the cleaning process for the glassware. Glassware with complex shapes or narrow openings may be difficult to clean thoroughly, potentially leading to contamination in subsequent experiments. Choose glassware that is easy to clean and compatible with common cleaning methods in your laboratory.

7. Availability and Cost: Consider the availability and cost of the glassware. Determine if the glassware you need is readily available or if it needs to be ordered. Additionally, assess the cost of the glassware, ensuring that it fits within your budget without compromising on quality or functionality.

8. Compatibility with Laboratory Equipment: Check if the glassware is compatible with any specialized laboratory equipment you may be using. This includes heating or mixing devices, adapters, or other accessories. Ensuring compatibility will streamline your workflow and prevent any compatibility issues or inefficiencies.

By carefully considering these factors, you can select the most suitable glassware for your heating and mixing needs, ensuring optimal performance, reliability, and safety in your scientific and laboratory activities.

Glassware Options for Heating and Mixing

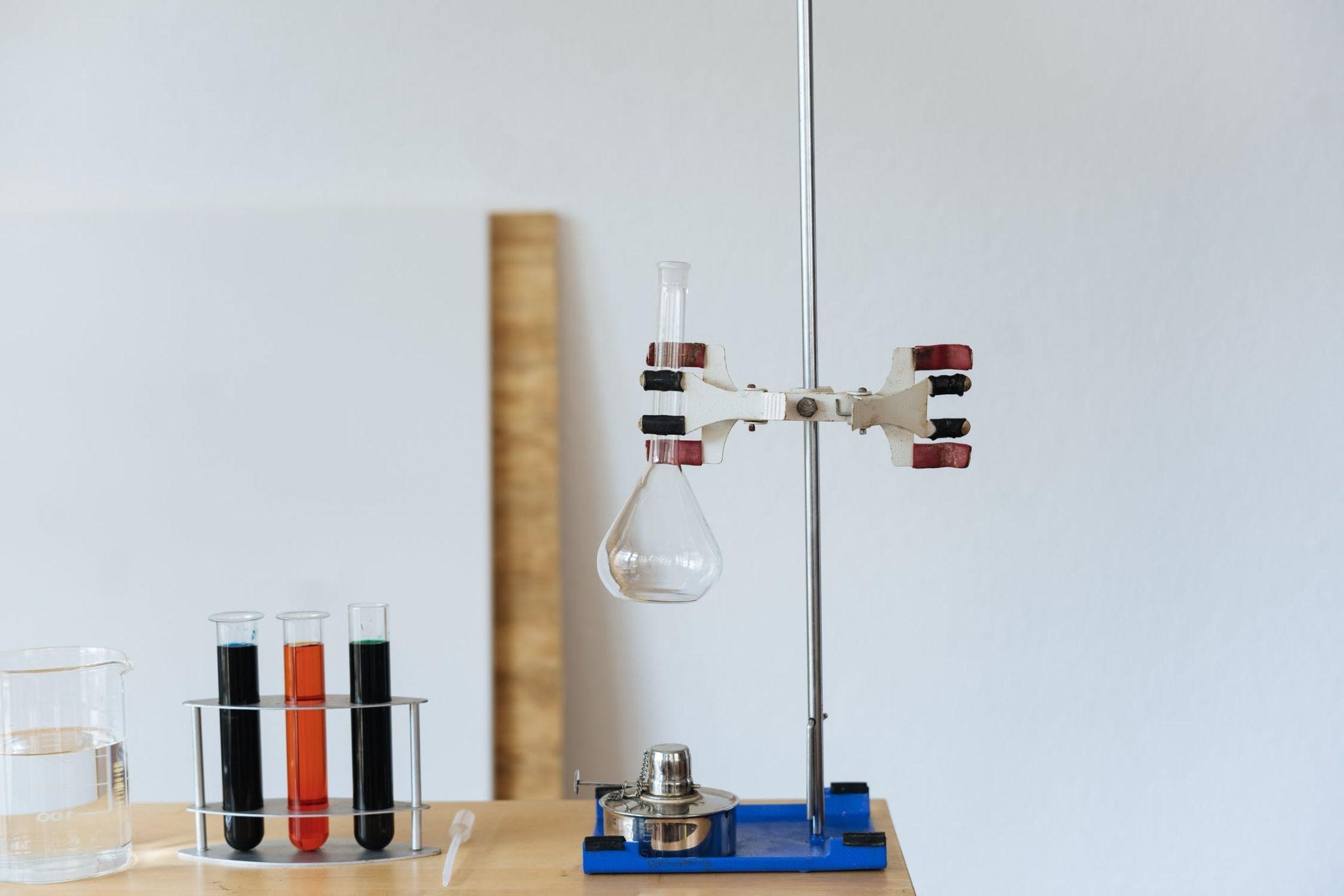

There are various glassware options available for heating and mixing substances in scientific and laboratory settings. Each type of glassware is designed with specific features to meet different experimental requirements. Let’s explore some common glassware options used for heating and mixing:

1. Beakers: Beakers are one of the most commonly used types of glassware in laboratories. They have a cylindrical shape with a flat bottom and come in various sizes. Beakers are suitable for general-purpose heating and mixing due to their stability and durability. They often have graduation marks to indicate approximate volumes.

2. Erlenmeyer Flasks: Erlenmeyer flasks are flask-shaped glassware with a flat bottom and a conical body. They are commonly used for mixing and heating solutions. The conical shape allows for better mixing while minimizing evaporation. The narrow neck of the flask also helps to avoid splashes during stirring or mixing.

3. Test Tubes: Test tubes are small cylindrical tubes, open at one end and closed at the other. They are used for heating small quantities of liquids or conducting reactions on a small scale. Test tubes are often held with a test tube holder and can be easily heated in a water bath or with a Bunsen burner.

4. Round Bottom Flasks: Round bottom flasks have a spherical or rounded bottom with a long neck. They are commonly used for solutions that need to be heated under reflux or that require a condenser to be attached. The round shape allows for more efficient heat transfer and swirling during mixing.

5. Burettes: Burettes are long, narrow, and cylindrical glass tubes with a stopcock at the bottom. They are used for accurate volumetric dispensing or titration experiments. Burettes provide precise control over the amount of liquid being added or dispensed and are commonly found in analytical chemistry laboratories.

6. Graduated Cylinders: Graduated cylinders consist of a long, cylindrical tube with incremental measurement markings along the side. They are used for precise measurement and mixing of liquids. Graduated cylinders come in various sizes and are ideal for measuring larger volumes accurately.

7. Crucibles: Crucibles are small, heat-resistant containers used for heating substances to high temperatures. They are typically made from porcelain or borosilicate glass and can withstand extreme temperatures. Crucibles are commonly used in processes such as melting, evaporation, or decomposition.

8. Glass Stirring Rods: Glass stirring rods are cylindrical or rod-shaped glass pieces used for stirring or mixing substances in various glassware. They are typically made from borosilicate glass and have rounded ends to prevent scratching or damaging the glassware. Glass stirring rods are essential for ensuring uniform mixing and dispersion of substances.

These are just a few examples of the glassware options available for heating and mixing in scientific and laboratory settings. The choice of glassware will depend on the specific requirements of the experiment or process, ensuring optimal performance, accuracy, and safety.

Option 1: Beakers

Beakers are widely used and versatile glassware in laboratory settings for heating and mixing substances. They have a cylindrical shape with a flat bottom and come in various sizes to accommodate different volumes of liquid or solid materials. Beakers are made from borosilicate glass, which is highly resistant to thermal stress and chemical reactions.

Beakers offer several advantages that make them a popular choice for general-purpose heating and mixing:

1. Versatility: Beakers can be used for a wide range of laboratory applications, such as mixing, heating, and storing substances. They are suitable for both qualitative and quantitative experiments and are commonly used for making solutions, conducting reactions, and measuring approximate volumes.

2. Stability: Beakers are designed with a wide base and a flat bottom, which provides stability and prevents tipping over. This makes them suitable for heating on hot plates or using them in conjunction with laboratory stands or clamps.

3. Graduation Marks: Most beakers come with graduation marks on the side, allowing rough measurements of volume. While not as precise as graduated cylinders, these markings provide a convenient reference for estimating liquid volumes or for diluting solutions without needing additional measuring tools.

4. Visibility: Beakers typically have a large diameter and a tall, straight sides that make it easy to see and observe the contents inside. This allows for visual inspection of color changes, precipitation, or other reactions occurring during heating or mixing.

5. Easy Pouring: Beakers are designed with a spout or a lip, allowing for easy pouring and transferring of substances. The spout helps to minimize spills and allows for controlled pouring during experiments or when transferring solutions to other vessels.

6. Easy Cleaning: Beakers are relatively easy to clean due to their simple design and wide opening. They can be easily washed by hand or cleaned in a dishwasher. Additionally, their wide diameter makes it easier to reach the inside for thorough cleaning and drying.

While beakers offer many advantages, it’s important to note their limitations:

1. Inaccuracy: Beakers are not designed for precise volume measurements. The graduation marks on beakers are approximate, and their accuracy can vary from one beaker to another. Therefore, if precise volumes are required, it’s advisable to use more accurate measuring devices, such as graduated cylinders or volumetric flasks.

2. Evaporation: Due to their wide opening, beakers are more prone to evaporation compared to other glassware, such as Erlenmeyer flasks or round bottom flasks. This may lead to concentration changes or loss of a volatile substance during heating or prolonged periods of mixing.

3. Heat Distribution: Beakers have relatively thick walls, which can affect the efficiency of heat transfer when placed on a hot plate or exposed to direct flame. Stirring or using a heating mantle can help improve heat distribution, but careful monitoring of temperature is still required.

Beakers are an essential and versatile glassware option for heating and mixing substances in scientific and laboratory settings. While they may have limitations for precise measurements, their ease of use, stability, and visibility make them a valuable tool for various applications.

Read more: What Is Crystal Glassware

Option 2: Erlenmeyer Flasks

Erlenmeyer flasks, also known as conical flasks, are commonly used glassware for heating and mixing substances in laboratories. They have a distinct shape, characterized by a flat bottom and a conical body with a narrow neck. Erlenmeyer flasks are typically made from borosilicate glass, which is resistant to thermal stress and chemical reactions.

Erlenmeyer flasks offer several advantages that make them a popular choice for heating and mixing:

1. Mixing Efficiency: The conical shape of Erlenmeyer flasks allows for efficient mixing of substances. When the flask is placed on a magnetic stirrer or shaken manually, the conical shape promotes better mixing and swirling of the contents compared to other glassware with straight sides.

2. Reduced Evaporation: The narrow neck of an Erlenmeyer flask helps minimize evaporation during heating or prolonged mixing. This is particularly beneficial when working with volatile substances or when precise concentration control is required.

3. Visibility: Erlenmeyer flasks have a wide base and a tapering conical body, which allows for easy visualization of the contents inside. This is useful for observing changes in color, precipitation, or other reactions occurring during heating and mixing.

4. Pouring Control: The flask’s narrow neck facilitates controlled pouring without causing spills or splashing. It allows for precise transfer of liquids to other containers or apparatus, reducing the risk of accidents or contamination.

5. Stability: Erlenmeyer flasks have a broader base compared to their neck size, providing stability during heating or when placed on a laboratory stand. This stability is particularly important when using magnetic stirrers or hot plates for mixing or heating.

6. Heat Distribution: The conical shape of Erlenmeyer flasks allows for more efficient heat distribution compared to other glassware with straight sides. This results in better temperature uniformity throughout the solution, especially when using hot plates or heating mantles.

Erlenmeyer flasks also have a few limitations to consider:

1. Accuracy: Erlenmeyer flasks are not designed for precise volume measurements. Although they may have approximate volume markings, their accuracy can vary, and they are not suitable for precise quantitative work. For accurate measurements, it is recommended to use more precise measuring devices like graduated cylinders or volumetric flasks.

2. Limited Accessibility: The narrow neck of Erlenmeyer flasks can make it challenging to access the contents, particularly when adding or retrieving solid materials or when cleaning the interior of the flask. Care should be taken to use appropriate tools or techniques for these tasks.

3. Risk of Breakage: The conical shape of Erlenmeyer flasks makes them prone to tipping over if not properly supported. Additionally, the narrow neck can be vulnerable to chipping or breaking if bumped or mishandled. It’s important to handle them with care and use appropriate clamps or stands when heating or mixing.

Erlenmeyer flasks are a versatile glassware option for heating and mixing substances in laboratories. With their efficient mixing capabilities, reduced evaporation, and good visibility, they are commonly used in many scientific applications. However, their limitations in precision and accessibility should be considered when selecting appropriate glassware for specific experiments or processes.

Option 3: Test Tubes

Test tubes are cylindrical glassware vessels commonly used in scientific laboratories for a variety of purposes, including heating and mixing substances. They have a simple design, consisting of a hollow tube that is open at one end and closed at the other. Test tubes are typically made of borosilicate glass, which is resistant to thermal stress and chemical reactions.

Test tubes offer several advantages that make them a versatile choice for heating and mixing:

1. Small-Scale Experiments: Test tubes are ideal for working with small volumes of liquids or conducting reactions on a small scale. They can accommodate small quantities of substances, making them suitable for qualitative testing, sample preparations, or small-scale reactions.

2. Heating Applications: Test tubes are designed to withstand moderate levels of heat. They can be safely heated using a Bunsen burner, a hot plate, or a water bath. This makes them suitable for processes such as boiling, evaporation, or gentle heating of solutions.

3. Versatile Mixing: Test tubes can be easily rotated or swirled by hand to promote mixing or dissolution of substances. They can also be used in combination with a vortex mixer or a shaker to enhance the mixing efficiency.

4. Observation and Analysis: The transparent nature of test tubes allows for easy visual observation of the substances or reactions taking place inside. This is particularly useful for monitoring color changes, precipitation, or other reactions during heating and mixing.

5. Easy Storage: Test tubes are compact and stackable, making them convenient for storage and organization. They take up minimal space in the laboratory and can be easily labeled or sorted for future reference.

While test tubes offer many advantages, it’s important to be aware of their limitations:

1. Limited Volume Measurement: Test tubes typically lack precise volume markings, which makes them unsuitable for accurate quantitative measurements. If precise volume control is required, it is advisable to transfer the contents to more accurate measuring devices, such as graduated cylinders or volumetric flasks.

2. Fragility: Test tubes are relatively fragile and can break easily if mishandled or subjected to thermal shock. Care should be taken when placing them on hot surfaces or when using them in conjunction with clamp or holder setups. Handling them with caution is essential to prevent breakage and potential injury.

3. Limited Accessibility: Due to their narrow opening, test tubes can be challenging to work with when adding or retrieving solid materials. Specialized tools, such as pipettes or spatulas, may be required to facilitate precise additions or extractions.

4. Evaporation: Test tubes have a relatively large surface area compared to their volume, which can result in increased evaporation. This can lead to concentration changes or loss of volatile substances during heating or prolonged mixing. It is important to cover the open end or use a stopper to minimize evaporation effects.

Despite their limitations, test tubes are a valuable glassware option for heating and mixing substances in laboratory settings. Their versatility, ease of use, and compactness make them an essential tool for various scientific applications, especially when working with smaller quantities of samples or conducting preliminary testing.

When heating and mixing liquids, it’s best to use borosilicate glassware such as beakers or flasks. This type of glass is resistant to thermal shock and chemical corrosion, making it ideal for laboratory use.

Option 4: Round Bottom Flasks

Round bottom flasks, also known as boiling flasks or Florence flasks, are common glassware vessels used for heating and mixing substances in laboratory settings. They are characterized by their round or spherical bottom and a long, cylindrical neck. Round bottom flasks are typically made from borosilicate glass, which is highly resistant to thermal stress and chemical reactions.

Round bottom flasks offer several advantages that make them a popular choice for heating and mixing:

1. Efficient Heat Transfer: The round shape of the flask allows for better heat distribution during heating. The large surface area of the round bottom facilitates efficient heat transfer, making round bottom flasks suitable for processes that require uniform heating or reactions that require prolonged exposure to heat.

2. Enhanced Mixing: The round shape of the flask also promotes efficient mixing of the contents. When the flask is placed on a stir plate or shaken manually, the swirling motion inside the round bottom flask ensures thorough mixing of the substances, making it easier to achieve homogeneity.

3. Condenser Attachment: Round bottom flasks are often used in conjunction with a condenser, allowing for reflux reactions or distillations. By attaching a condenser to the neck, the vapors generated during heating can be condensed and returned to the flask, enhancing efficiency and preventing the loss of volatile substances.

4. Chemical Resistance: Round bottom flasks are made from borosilicate glass, which is highly resistant to chemical reactions. They can withstand a wide range of chemicals and are suitable for various chemical processes without the risk of leaching or contamination.

5. Stability: The round bottom design of the flask provides stability, especially when placed on a heating mantle or clamped onto a stand. This ensures safety during heating or mixing processes, reducing the risk of accidental spills or breakage.

However, there are a few limitations to consider when using round bottom flasks:

1. Fragility: Due to their round shape and thin walls, round bottom flasks can be more fragile compared to other glassware. Extra care should be taken when handling and storing them to avoid accidental breakage.

2. Limited Visibility: Unlike other glassware with a wider opening, round bottom flasks have a narrower neck, which may limit visibility inside the flask during heating and mixing. This can make it challenging to observe reactions or changes in color, requiring the use of additional equipment, such as an external camera or a side-arm adapter, to monitor the progress.

3. Inaccurate Volume Measurements: Round bottom flasks lack precise volume markings, making them unsuitable for accurate quantitative measurements. If precise volume control is required, it is recommended to transfer the contents to more precise measuring devices like graduated cylinders or volumetric flasks.

Round bottom flasks are a versatile and essential glassware option for heating and mixing substances in scientific laboratories. Their efficient heat transfer, enhanced mixing capabilities, and chemical resistance make them well-suited for a wide range of applications, especially those involving reflux, distillation, or extended heating processes.

Option 5: Burettes

Burettes are long, narrow cylindrical glass tubes with a stopcock at the bottom, commonly used in laboratories for precise volumetric dispensing or titration experiments. They are typically made from high-quality borosilicate glass, which ensures accuracy and resistance to chemical reactions.

Burettes offer several advantages that make them an essential tool for precise measurements and controlled dispensing:

1. Accurate Volume Control: Burettes are designed for accurate volume measurements. The graduations along the length of the burette allow for precise measurement of liquid volume, typically in milliliters (mL) or cubic centimeters (cm³). This makes them ideal for titrations or other experiments that require precise additions of reagents or solutions.

2. Adjustable Flow Control: The stopcock at the bottom of the burette allows for precise control of liquid flow. The flow can be adjusted by simply rotating the stopcock, enabling slow and controlled dispensing of liquid during titrations or other experiments where precise addition rates are crucial.

3. Graduation Marks: Burettes have clear and precise graduation marks, typically marked at every 0.1 mL or even smaller increments. This allows for accurate readings and measurements, ensuring reliable and reproducible results.

4. Versatility: Burettes can be used for a wide range of applications, including acid-base titrations, complexometric titrations, and other volumetric analysis techniques. They are also commonly used in quantitative chemistry experiments and processes where precise volume control is crucial.

5. Chemical Compatibility: Burettes are made from high-quality borosilicate glass, which ensures excellent resistance to chemical reactions. They can be used with a wide range of chemicals without the risk of leaching or contamination, ensuring accurate and reliable results.

It’s important to be aware of the limitations of using burettes:

1. Fragility: Burettes are relatively fragile due to their long and narrow design. They should be handled with care to avoid accidental breakage or damage to the graduation marks. It’s important to use proper clamps or holders when mounting burettes to ensure their stability and prevent accidents.

2. Cleanliness: Burettes require thorough cleaning and rinsing to prevent cross-contamination between experiments. Deburring or rinsing with compatible cleaning solutions is necessary to remove any residue that may affect the accuracy of subsequent measurements.

3. Time-consuming: Burettes can be time-consuming to use compared to other glassware options for simple mixing or dispensing tasks. The precise flow control and the need to observe the meniscus carefully can slow down the experimental process. It’s important to consider the time required when selecting the appropriate glassware for a specific task.

Burettes are an essential glassware option for precise volumetric dispensing and titrations in laboratory settings. Their accurate volume control, adjustable flow, and versatility make them indispensable tools for quantitative analysis and experiments requiring precise measurements.

Read more: What Is The Best Brand Of Crystal Glassware

Option 6: Graduated Cylinders

Graduated cylinders are tall, narrow cylindrical glassware vessels with incremental measurement markings along the length, commonly used in laboratories for accurate measurement and mixing of liquids. They are typically made from borosilicate glass or other chemically resistant materials to ensure accuracy and durability.

Graduated cylinders offer several advantages that make them a reliable choice for measuring and mixing liquids:

1. Accurate Volume Measurement: Graduated cylinders are designed with precise measurement markings for accurate volume measurement. The graduations, typically in milliliters (mL) or cubic centimeters (cm³), allow for precise readings and enable accurate volume dispensing or measuring of liquid samples.

2. Wide Range of Sizes: Graduated cylinders are available in various sizes, accommodating different volume requirements. From small-scale applications to larger volumes, there is a graduated cylinder suitable for each specific need, ensuring versatility in laboratory experiments and processes.

3. Easy-to-Read Measurement: The graduation marks on graduated cylinders are typically clear and well-defined, making them easy to read and interpret. This allows for precise volume measurements, ensuring accurate and reproducible results in experiments or when preparing solutions.

4. Easy Mixing and Pouring: Graduated cylinders have a wide base and a narrow neck, facilitating efficient mixing of liquids by swift vertical movement. The narrow neck also helps control pouring, minimizing spills and accurately transferring liquids to other containers or apparatus.

5. Chemical Compatibility: Graduated cylinders are made from chemically resistant materials, such as borosilicate glass, that are compatible with a wide range of chemicals. They can safely contain and measure various substances without the risk of leaching or contamination, ensuring accurate results.

It’s important to be aware of the limitations of using graduated cylinders:

1. Graduation Accuracy: While graduated cylinders provide relatively precise volume measurements, the accuracy may vary between different cylinders. It is recommended to calibrate or verify the accuracy of the graduated cylinder before relying on its measurements for critical experiments or processes.

2. Surface Tension Effects: Graduated cylinders have a meniscus formed at the liquid’s surface due to surface tension. It is important to measure the volume at eye level while aligning the bottom of the meniscus with the graduation marks to avoid parallax errors and ensure accurate readings.

3. Limited Accuracy for Small Volumes: The accuracy of measuring small volumes (<1 mL) with graduated cylinders may be limited due to the relative size of the divisions compared to the volume being measured. In such cases, more precise measuring devices, such as micropipettes, should be used.

Graduated cylinders are a reliable glassware option for precise volume measurement and mixing in laboratory settings. Their accurate measurement markings, wide range of sizes, and chemical compatibility make them indispensable tools in a variety of scientific experiments and processes.

Option 7: Crucibles

Crucibles are specialized glassware containers used in laboratories for heating substances to high temperatures. They are typically made from porcelain or borosilicate glass, which can withstand extreme temperatures without breaking or deforming. Crucibles have a wide range of applications, including melting, evaporation, and decomposition processes.

Crucibles offer several advantages that make them essential for high-temperature heating:

1. Heat Resistance: Crucibles are designed to withstand exceptionally high temperatures. They can be heated directly by flame, placed on a hot plate, or used with specialized heating equipment like muffle furnaces. This resistance to high temperatures allows for various heating processes, such as sample fusion, calcination, or phase transitions.

2. Chemical Stability: Crucibles are chemically inert and highly resistant to chemical reactions. They can safely hold and heat a wide range of substances without causing contamination or leaching. This chemical stability ensures the integrity and purity of the sample being heated.

3. Durability: Crucibles are made from robust materials, such as porcelain or borosilicate glass, which provides exceptional durability and longevity. They can withstand repeated use and exposure to high temperatures without cracking or breaking, making them a long-lasting investment for laboratory applications.

4. Versatility: Crucibles come in various sizes and shapes to accommodate different experimental needs. From small-scale experiments to larger industrial processes, there is a crucible available for a range of applications. They can be used for melting metals, performing ashing procedures, or conducting high-temperature chemical reactions.

5. Easy Handling and Pouring: Crucibles are typically designed with a convenient pouring lip or spout, making it easy to transfer the heated substance to other containers or apparatus without spills or accidents. The spout ensures controlled pouring, minimizing the risk of burns or mishaps during transfer.

It’s important to consider a few limitations when using crucibles:

1. Limited Visibility: Crucibles are often opaque, limiting direct observation of the substance during heating. As a result, it may be necessary to use additional equipment or techniques, such as external cameras or temperature sensors, to monitor the process and ensure it proceeds as intended.

2. Limited Absorbency: Some substances heated in crucibles may require absorption of gases or vapor during the process. While some crucibles have porous properties, most do not, which means additional measures may need to be taken to remove gases or vapors that evolve during heating.

3. Fragility of Porcelain Crucibles: Porcelain crucibles are more fragile compared to those made from borosilicate glass. They can crack or break when exposed to rapid temperature changes or mishandling. It’s important to handle porcelain crucibles with care to avoid damage.

Crucibles are indispensable glassware options for heating substances to high temperatures in laboratory and industrial settings. Their heat resistance, chemical stability, durability, and versatility make them essential tools for various processes, ensuring efficient and reliable heating of materials.

Option 8: Glass Stirring Rods

Glass stirring rods, also known as glass stirrers or stirring sticks, are essential tools used in laboratories for stirring and mixing substances during experiments or reactions. They are typically made from borosilicate glass, which makes them resistant to thermal stress and chemical reactions.

Glass stirring rods offer several advantages that make them a versatile choice for mixing and stirring:

1. Homogeneous Mixing: Glass stirring rods allow for efficient and effective mixing of liquids, ensuring homogeneity in the solution. They can be used to stir a variety of substances, from simple aqueous solutions to more viscous mixtures, enabling thorough blending of components.

2. Chemical Resistance: Glass stirring rods are chemically inert and resistant to most substances, making them suitable for use with a wide range of chemicals. They can be used with acids, bases, solvents, and other reactive substances without the risk of leaching or contamination, ensuring the integrity of the experiment or process.

3. Easy Cleaning: Glass stirring rods are easy to clean and sanitize. They can be rinsed with water or cleaned with suitable solvents to remove any residue from previous experiments. Their smooth surface allows for thorough cleaning, minimizing the risk of cross-contamination between experiments.

4. Heat Resistance: Glass stirring rods can withstand moderate heating. Although not designed for direct exposure to high temperatures, they can be used to stir solutions placed on a hot plate or heated vessel. This flexibility allows for efficient mixing during heating processes.

5. Versatility: Glass stirring rods come in various lengths and diameters, providing versatility for different purposes. Shorter stirring rods are suitable for small-scale experiments or when working with narrow-necked vessels, while longer stirring rods can effectively mix larger volumes or reach deeper into vessels.

It’s important to consider a few limitations when using glass stirring rods:

1. Fragility: Glass stirring rods can break or chip if mishandled or subjected to sudden impacts. Care should be taken when using them to avoid any accidents that could result in breakage and potential injury. Proper storage and handling are crucial to prevent damage to the stirring rods.

2. Limited Mixing Speed: The efficiency of mixing with glass stirring rods depends on manual manipulation. While effective, the speed at which mixing occurs is limited to the user’s hand movements. For more vigorous or rapid mixing, mechanical stirrers or magnetic stir bars are recommended.

3. Limited Visibility: The presence of a stirring rod in a mixture can obstruct clear visualization of the contents within a container. This limitation may require intermittent removal of the stirring rod or the use of additional tools, such as a separate glass pipette, for sampling or observation purposes.

Glass stirring rods are indispensable tools for mixing and stirring substances in laboratory settings. With their chemical resistance, ease of cleaning, and versatility, they offer efficient and effective mixing capabilities for a wide range of experiments and processes.

Conclusion

Choosing the right glassware for heating and mixing is crucial in scientific and laboratory settings. The selection of suitable glassware can significantly impact the accuracy, reliability, and safety of experiments and processes. Throughout this article, we explored various glassware options and discussed the importance of considering different factors when making the selection.

We learned that factors such as temperature resistance, chemical compatibility, size and capacity, accuracy, durability, and ease of cleaning should all be taken into account when choosing glassware for heating and mixing. Understanding these factors ensures that the chosen glassware meets the specific requirements of the experiment or process, leading to optimal performance, reliability, and safety.

We explored a range of glassware options, including beakers, Erlenmeyer flasks, test tubes, round bottom flasks, burettes, graduated cylinders, crucibles, and glass stirring rods. Each option has its advantages and limitations, making them suitable for specific applications. By understanding the characteristics of each glassware option, researchers and scientists can make informed decisions that align with their experimentation or process requirements.

Beakers, with their versatility and stability, are commonly used for general-purpose heating and mixing. Erlenmeyer flasks provide efficient mixing and reduced evaporation, while test tubes offer flexibility for small-scale experiments and precise heating. Round bottom flasks are efficient for heating and enhanced mixing, and burettes allow for accurate volume control during dispensing or titrations.

Graduated cylinders are valuable for precise volume measurement, while crucibles excel in high-temperature applications. Glass stirring rods offer efficient and homogeneous mixing of substances. Each glassware option serves a specific purpose and contributes to the success and accuracy of laboratory experiments and processes.

In conclusion, the selection of the right glassware for heating and mixing is crucial for obtaining accurate and reliable results in scientific and laboratory settings. By considering the unique characteristics and limitations of each glassware option, researchers can make informed choices that enhance the efficiency, reliability, and safety of their experimentation or processes.

Remember, when working with any glassware, it is important to handle them with care, follow proper safety protocols, and regularly inspect for any signs of damage or wear. By doing so, scientists and researchers can ensure the longevity and effectiveness of their glassware, ultimately leading to successful experiments and scientific advancements.

Frequently Asked Questions about What Is The Best Glassware For Heating And Mixing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Best Glassware For Heating And Mixing”