Home>diy>Building & Construction>What Are Construction Screws Used For

Building & Construction

What Are Construction Screws Used For

Modified: January 9, 2024

Discover the versatility and importance of construction screws for building and construction projects. Whether you're constructing a new building or undertaking a renovation, find out how these screws play a vital role in securing and fastening various materials.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

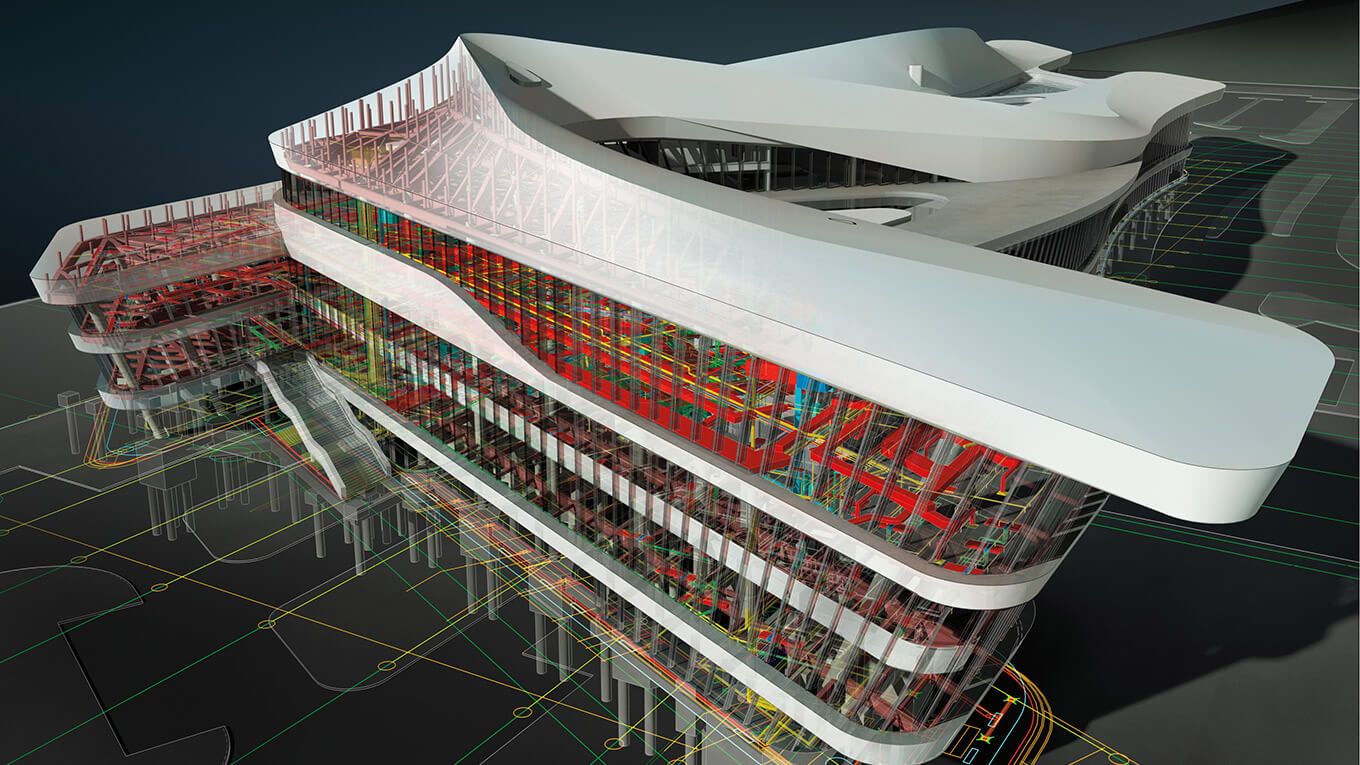

When it comes to building construction, the use of screws plays a crucial role in ensuring the stability, durability, and overall quality of the structure. Construction screws are versatile fasteners that provide a secure and reliable method for joining materials together. From framing to finishing, these screws are an essential component in numerous construction projects.

In this article, we will delve into the world of construction screws, exploring their definition, types, common uses, benefits, factors to consider when choosing them, proper installation techniques, and maintenance guidelines. Whether you are a construction professional or a DIY enthusiast, understanding the significance and applications of construction screws is paramount to the success of any building project.

Key Takeaways:

- Construction screws are essential for building stability, offering superior strength, durability, and versatility. Understanding their types, uses, and maintenance ensures reliable and secure construction connections.

- Proper selection, installation, and maintenance of construction screws are crucial for optimal performance and longevity. Consider material compatibility, strength requirements, and corrosion resistance to ensure successful construction projects.

Read more: What Screws Are Best For Outdoor Use

Definition of Construction Screws

Construction screws, also known as structural screws or building screws, are specialized fasteners designed for use in construction projects. Unlike traditional nails or regular screws, construction screws are engineered to provide superior strength, stability, and holding power. These screws are typically made from high-quality materials such as hardened steel or stainless steel, which ensures their durability and resistance to corrosion.

One distinguishing feature of construction screws is their unique thread design. Unlike the coarse threading of general-purpose screws, construction screws have a more aggressive and deeper thread pattern. This allows them to grip the materials tightly, providing increased holding power and preventing loosening over time.

In addition to their thread design, construction screws often feature other performance-enhancing features such as self-drilling tips or self-tapping threads. These features enable the screws to penetrate materials easily without the need for pre-drilling, saving time and effort during installation.

Furthermore, construction screws come in various lengths, diameters, and head types to suit different applications. Common head types include flat heads, pan heads, and hex heads, which offer different levels of flushness or surface contact depending on the construction requirements.

In summary, construction screws are specialized fasteners designed for use in construction projects. They offer superior strength, durability, and holding power through their unique thread design and high-quality materials. With their various sizes and head types available, construction screws can be tailored to meet the specific demands of each building application.

Types of Construction Screws

Construction screws come in a variety of types, each designed for specific applications and materials. Understanding the different types of construction screws will help you choose the right screw for your project. Here are some of the most common types:

- Wood Screws: Wood screws are designed for securing wood to wood or wood to other materials. They have sharp, pointed tips and deep threads that provide excellent grip in wood. These screws come in various lengths, diameters, and head types to accommodate different woodworking applications.

- Drywall Screws: As the name suggests, drywall screws are specifically designed for installing drywall panels. They have a bugle-shaped head that sits flush with the surface of the drywall and a coarse thread that helps to securely fasten the panels. Drywall screws are available in different lengths, with some designed to resist corrosion.

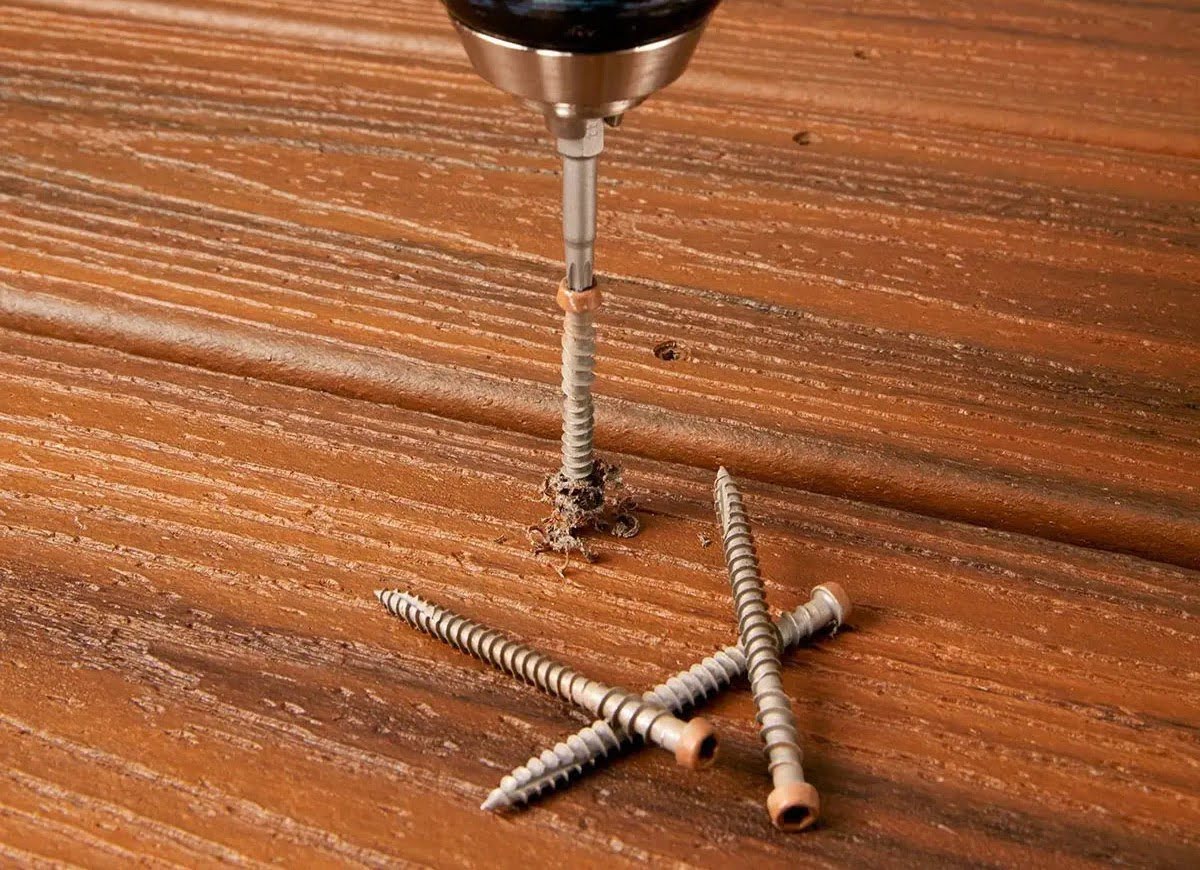

- Deck Screws: Deck screws are specially designed for outdoor decking applications. They are typically made of stainless steel or coated with corrosion-resistant materials to withstand exposure to the elements. Deck screws often have a sharp, self-drilling tip and a coarse thread pattern to provide excellent holding power in wood and composite decking materials.

- Metal Screws: Metal screws are primarily used for joining metal materials together. They are made from hardened steel or stainless steel to ensure strength and resistance to corrosion. These screws may have self-tapping threads or fine threads, depending on the type of metal being fastened.

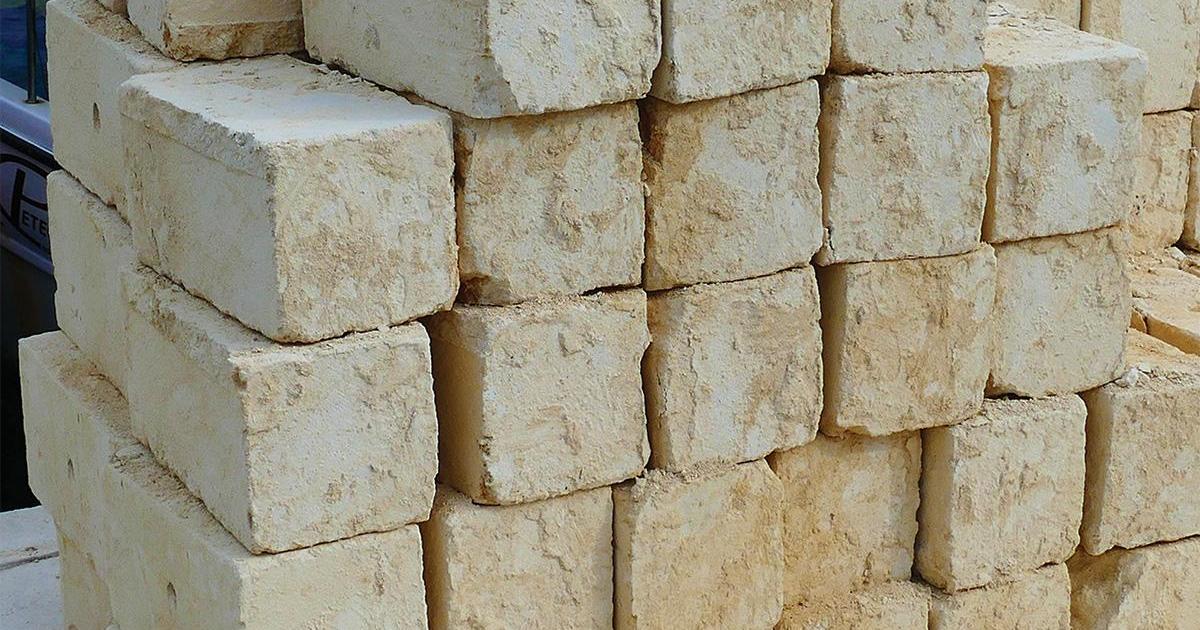

- Masonry Screws: Masonry screws, also known as concrete screws or anchor screws, are designed for attaching materials to concrete or masonry surfaces. They have a unique thread design that allows them to cut through the masonry while providing a secure and sturdy connection. Masonry screws are often made of hardened steel or coated to resist corrosion.

- Self-Drilling Screws: Self-drilling screws, also known as Tek screws or self-tapping screws, have a drill-like point that eliminates the need for pre-drilling pilot holes. They can penetrate and fasten materials such as metal, wood, and plastic without the need for additional tools or drilling equipment.

These are just a few examples of the numerous types of construction screws available in the market. It’s important to consider the specific requirements of your project and consult with professionals to determine the most suitable screw type for your construction needs.

Common Uses of Construction Screws

Construction screws are versatile fasteners that find a wide range of applications in the construction industry. From framing to finishing, these screws offer reliable and secure connections for various materials. Here are some common uses of construction screws:

- Wood Framing: Construction screws are commonly used in wood framing applications, such as building walls, floors, and roofs. They provide strong connections between the framing members, ensuring the structural integrity of the building.

- Drywall Installation: Drywall screws are specifically designed for attaching drywall panels to wall studs or ceiling joists. These screws have a bugle-shaped head that sits flush with the surface of the drywall, creating a smooth and seamless finish.

- Decking: Deck screws are essential for securing decking boards to the substructure. They offer excellent grip and hold the decking materials firmly in place. Deck screws are resistant to corrosion, making them ideal for outdoor applications.

- Cabinetry and Furniture: Construction screws are commonly used in the assembly of cabinets and furniture. These screws provide strong connections between the different components, ensuring stability and longevity.

- Metal Fabrication: Metal screws are extensively used in metal fabrication projects. They offer reliable fastening solutions for joining metal sheets, brackets, and other metal components.

- Concrete Anchoring: Masonry screws are ideal for anchoring materials to concrete or masonry surfaces. They are used to secure items such as handrails, shelving brackets, or electrical equipment to walls, floors, or ceilings.

- Exterior Trim Installation: Construction screws are widely used for installing exterior trim, such as window and door casings or siding. These screws provide a secure and durable attachment, even in outdoor environments.

These are just a few examples of the many applications of construction screws. Their versatility and reliability make them a popular choice for a wide range of construction projects. Whether you are working on residential buildings, commercial structures, or even DIY projects, construction screws are an essential component that ensures the longevity and integrity of the construction.

Benefits of Construction Screws

Construction screws offer several advantages over traditional fasteners like nails or regular screws. These benefits make them a preferred choice in the construction industry. Here are some key advantages of using construction screws:

- Strong and Reliable: Construction screws provide a strong and secure connection between materials. Their unique thread design and high-quality materials ensure superior holding power and prevent loosening over time. This makes them suitable for structural applications where strength and stability are paramount.

- Easy Installation: Many construction screws have self-drilling or self-tapping features, eliminating the need for pre-drilling pilot holes. This saves time and effort during the installation process. Additionally, the sharp points and aggressive threads of construction screws allow for quick and easy penetration into various materials.

- Versatility: Construction screws come in a variety of sizes, lengths, and head types, making them suitable for a wide range of construction applications. Whether you are working with wood, metal, drywall, or masonry, there is a construction screw specifically designed for the job.

- Durability: Construction screws are typically made from hardened steel or stainless steel, providing excellent durability and resistance to corrosion. This ensures that the fasteners will withstand the test of time, even in harsh environmental conditions.

- Secure Fastening: The deep threads of construction screws create a tight grip between the materials, improving the overall stability and security of the connection. This makes them less prone to loosening or pulling out, ensuring the longevity and safety of the construction.

- Adjustability and Reusability: Unlike nails, construction screws can be easily removed and reused if adjustments or repairs are needed. This flexibility is particularly beneficial in construction projects that require modifications or renovations.

- Enhanced Aesthetics: Construction screws offer a neater and more aesthetically pleasing appearance compared to nails. The countersunk heads of many construction screws can be easily concealed or filled with wood filler, creating a smooth and seamless finish.

These benefits highlight the importance and advantages of using construction screws in building projects. Their strength, ease of installation, versatility, and durability make them an indispensable component in the construction industry.

When using construction screws, it’s important to choose the right type and size for the job. Consider factors such as the material you’re working with and the load the screw will need to support. Always pre-drill pilot holes to prevent splitting and ensure a secure fit.

Read more: What Type Of Screws For Outdoor Use

Factors to Consider When Choosing Construction Screws

Choosing the right construction screws for your project is essential to ensure optimal performance and longevity. Several factors should be taken into consideration when selecting construction screws. Here are some key factors to keep in mind:

- Material: Consider the materials you will be fastening together. Different construction screws are designed for specific materials such as wood, metal, drywall, or masonry. Ensure that the screws you choose are compatible with the materials you are working with.

- Application: Determine the purpose and application of the screws. Are they for framing, decking, drywall installation, or another specific use? Each application may require screws with different characteristics, such as length, thread type, or corrosion resistance.

- Strength Requirements: Assess the strength requirements of your project. If you’re working on a structural application, such as framing or decking, prioritize screws with high tensile strength and load-bearing capacity. For lighter-duty applications, such as cabinetry or furniture assembly, screws with lesser strength may be suitable.

- Length and Diameter: Select the appropriate length and diameter of the screws based on the thickness and type of materials being fastened. The length of the screw should be sufficient to penetrate both materials and provide a secure connection without penetrating the opposite side.

- Head Type: Consider the head type of the screws based on the desired finish and the tools available for installation. Common head types include flat heads, pan heads, and hex heads. Flat heads provide a flush finish, while pan heads and hex heads may allow for easier installation or increased torque.

- Corrosion Resistance: Evaluate the environment in which the screws will be used. For outdoor applications or high-humidity areas, opt for screws that are specifically designed to resist corrosion, such as stainless steel or coated screws. This will ensure the longevity of the fasteners and prevent degradation over time.

- Brand and Quality: Consider the reputation and quality of the brand when selecting construction screws. Established and reputable manufacturers often produce screws that conform to industry standards and undergo rigorous testing for strength and durability.

By considering these factors, you can choose the most suitable construction screws for your specific project needs. It is recommended to consult with professionals or follow industry guidelines to ensure the proper selection of construction screws for optimal performance and safety.

Proper Installation Techniques for Construction Screws

Proper installation of construction screws is crucial to ensure optimal performance and longevity of the fasteners. Follow these guidelines for a successful installation:

- Preparation: Start by gathering all the necessary tools and materials. Ensure that you have the correct screwdriver or drill bit for the type of screws you are using.

- Marking and Pre-Drilling: Mark the locations where the screws will be inserted, ensuring they are aligned properly. Depending on the material, you may need to pre-drill pilot holes to prevent splitting or cracking.

- Screw Insertion: Align the screw with the pre-drilled hole or the desired location. Apply steady pressure and begin turning the screw clockwise using a screwdriver or drill. Ensure that the screw is perpendicular to the surface and does not wobble or strip the material.

- Thread Engagement: Drive the screw until the threads fully engage with the material. Avoid over-tightening the screw, as this can lead to stripped threads or damage to the material. Use caution and pay attention to any resistance or signs of the material becoming compromised.

- Flush or Countersink: Depending on the application, you may need to ensure that the screw head is either flush with the material surface or countersunk below it. This step can improve the aesthetics and provide a smooth finish.

- Reinforcement: For applications that require added strength, consider using additional measures like the use of washers or structural adhesives to reinforce the joint.

- Spacing and Quantity: Pay attention to the recommended spacing and quantity of screws based on industry standards or the specific guidelines of the project. Proper distribution and quantity of screws will ensure uniform load distribution and prevent structural failures.

- Quality Control: Regularly inspect the installed screws to verify that they are secure and properly aligned. If any screws are loose or have shifted, re-tighten or adjust them as needed.

- Documentation: Keep a record of the type and location of screws installed for future reference and maintenance purposes. This can assist in identifying and addressing any issues that may arise later on.

Remember to follow the manufacturer’s instructions and adhere to industry best practices while installing construction screws. If you are unsure about the proper installation techniques, consult with professionals or seek guidance from experienced individuals to ensure a successful and secure installation.

Maintenance and Upkeep of Construction Screws

Proper maintenance and upkeep of construction screws are essential for ensuring their continued performance and longevity. Here are some important considerations for maintaining and caring for construction screws:

- Regular Inspection: Periodically inspect the screws to check for any signs of damage, corrosion, or loosening. This can be done during routine maintenance checks or after any significant weather events or structural shifts.

- Tightening: If you notice any loose screws, tighten them immediately to restore their holding power. Use the appropriate screwdriver or drill bit to ensure a secure fit without stripping the screw head or damaging the material.

- Corrosion Prevention: Construction screws exposed to outdoor or high-humidity environments are susceptible to corrosion. Applying a protective coating or using screws specifically designed for corrosion resistance, such as stainless steel or coated screws, can help prevent rust and degradation.

- Replacement: If you encounter screws that are damaged beyond repair or no longer provide sufficient holding power, replace them promptly. Using compromised screws can compromise the structural integrity of the construction.

- Surface Protection: Consider using protective coverings or coatings on screws that are exposed to harsh weather conditions, chemicals, or excessive moisture. This can help extend their lifespan and prevent premature deterioration.

- Proper Storage: Store construction screws in a dry and well-ventilated area to prevent moisture damage and corrosion. Keep them in separate labeled containers to maintain organization and easy access.

- Follow Manufacturer’s Guidelines: Always follow the specific recommendations and guidelines provided by the screw manufacturer. This includes information on load capacities, installation techniques, and any maintenance requirements.

- Keep Records: Maintain a record of the screw types, sizes, and installation locations. This information can be invaluable for future maintenance, repairs, or renovations.

- Consult Professionals: If you are unsure about any maintenance or upkeep procedures, seek advice from professionals or experts in the construction industry. They can provide guidance on best practices and recommend specific maintenance techniques for your unique application.

By following these maintenance guidelines, you can ensure the reliability and longevity of your construction screws. Regular inspections, proper tightening, corrosion prevention measures, and adherence to manufacturer’s recommendations will help keep your construction screws in optimal condition and ensure their continued performance in supporting your construction projects.

Conclusion

Construction screws are indispensable components in the building construction industry, providing secure and reliable connections between various materials. Their strength, durability, and ease of installation make them a preferred choice for professionals and DIY enthusiasts alike. From wood framing to metal fabrication, construction screws offer versatility and performance across a wide range of applications.

Understanding the different types of construction screws, such as wood screws, drywall screws, deck screws, metal screws, masonry screws, and self-drilling screws, allows you to choose the appropriate screw for your specific project requirements. Factors such as material compatibility, strength requirements, and corrosion resistance should all be considered when selecting construction screws.

Proper installation techniques, including pre-drilling, screw insertion, and tightening, are crucial for ensuring the secure and reliable performance of construction screws. Routine maintenance, such as regular inspections, tightening loose screws, and corrosion prevention, helps to prolong the lifespan and efficacy of these fasteners. Keeping records and consulting professionals further contribute to the proper upkeep and long-term success of construction screw installations.

In conclusion, construction screws play a vital role in the stability, durability, and overall quality of building construction. Their exceptional strength, ease of installation, versatility, and durability make them an indispensable component in various construction projects. By understanding their applications, selecting the right type, following proper installation techniques, and implementing routine maintenance practices, construction screws will continue to serve as reliable and robust fasteners, contributing to the longevity and integrity of construction projects.

Frequently Asked Questions about What Are Construction Screws Used For

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Construction Screws Used For”