Home>Furniture>Outdoor Furniture>What Kind Of Screws To Use With Trex Decking

Outdoor Furniture

What Kind Of Screws To Use With Trex Decking

Modified: April 23, 2024

Discover the perfect screws for your Trex decking project. Find out which screws are best suited for outdoor furniture and ensure a secure and long-lasting installation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of outdoor furniture! If you’re looking to create a relaxing and inviting outdoor space, investing in high-quality furniture is essential. One popular option is Trex decking, a durable and low-maintenance material that replicates the look and feel of natural wood. But when it comes to installation, choosing the right screws is crucial for the long-term stability and aesthetic appeal of your Trex deck.

In this article, we’ll explore the factors to consider when selecting screws for Trex decking and discuss the various types of screws available. We’ll also offer some valuable tips for proper installation, ensuring that your deck remains sturdy and beautiful for years to come.

So, let’s dive in and discover what kind of screws you should use with your Trex decking!

Key Takeaways:

- Choose stainless steel screws for Trex decking for corrosion resistance, strength, and durability. Follow manufacturer’s guidelines for proper installation to ensure a secure and long-lasting deck.

- Consider composite deck screws for Trex decking to prevent mushrooming and provide a clean finish. Colored screws offer customization options, while hidden fastening systems provide a sleek and seamless installation.

Factors to consider when choosing screws for Trex decking

When it comes to choosing screws for your Trex decking, there are a few important factors to consider. By taking these factors into account, you can ensure that you select the right screws for your specific project, providing a secure and visually appealing finish.

1. Material compatibility: One of the most crucial factors is the compatibility of the screws with the Trex decking material. It is essential to use screws that are specifically designed for use with composite materials like Trex. These screws are usually corrosion-resistant and have a coating that helps prevent damage to the decking material.

2. Size and length: The size and length of the screws are also important considerations. You’ll want to choose screws that match the thickness of your Trex decking boards. It is recommended to use screws that are at least 2.5 inches long to ensure a secure installation. Additionally, make sure to check the manufacturer’s guidelines for the specific size and length recommendations.

3. Color match: Since Trex decking is available in a variety of colors, you may want to consider using screws that match or at least complement the color of your decking boards. While it may seem like a minor detail, using screws that blend seamlessly with the decking material can enhance the overall aesthetic appeal of your outdoor space.

4. Environmental factors: Consider the climate and environment where your deck is located. If you live in an area with high humidity or near saltwater, it’s crucial to choose screws that are resistant to corrosion and rust. Stainless steel screws are an excellent option in such environments, as they offer superior durability and longevity.

5. Budget: Finally, it’s important to consider your budget when choosing screws for your Trex decking. While there are various options available, the cost may vary depending on factors such as material, size, and brand. It’s recommended to strike a balance between quality and cost-effectiveness to ensure the best results.

Now that we’ve covered the essential factors to consider let’s explore the different types of screws that are suitable for Trex decking.

Types of screws suitable for Trex decking

When it comes to choosing screws for Trex decking, there are several options available that are specifically designed for composite materials. Let’s take a look at some of the most common types:

- Stainless steel screws: Stainless steel screws are highly recommended for Trex decking due to their excellent corrosion resistance. They are durable, long-lasting, and can withstand exposure to various elements, including moisture and UV rays. Stainless steel screws are available in different grades, with higher-grade stainless steel offering superior strength and durability.

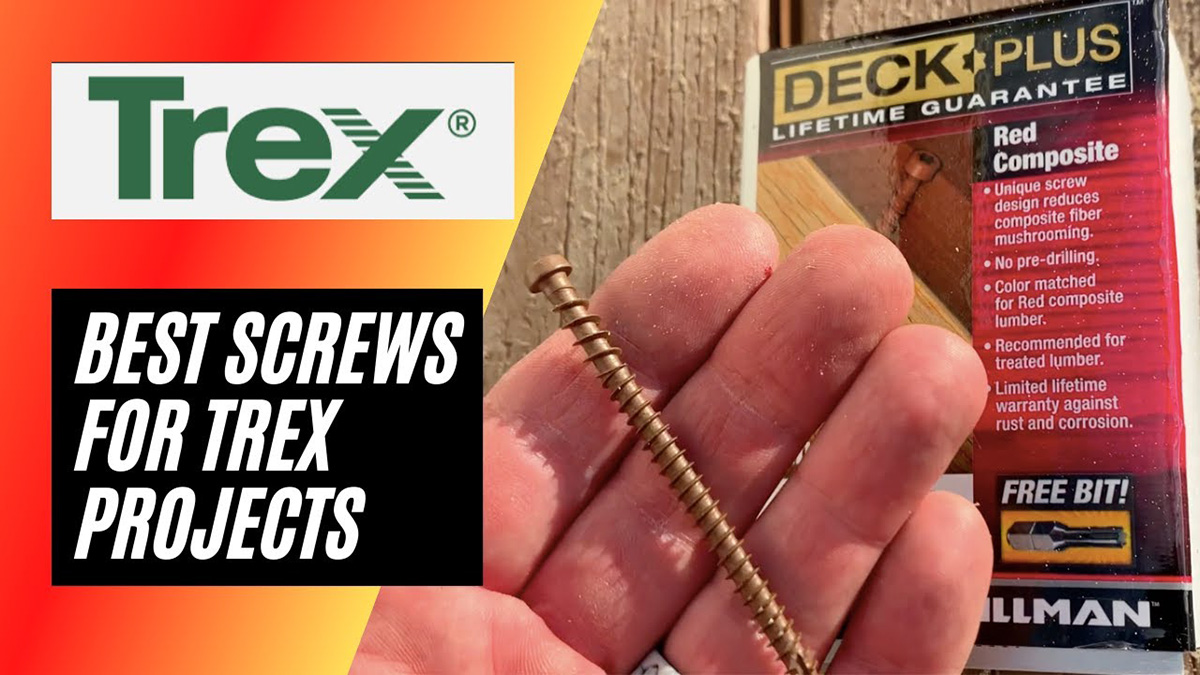

- Composite deck screws: Composite deck screws are specifically designed to fasten composite decking materials like Trex. These screws often feature a reverse-thread design, which helps prevent mushrooming and damaging the deck surface. They are available in a range of colors to match your Trex decking, providing a seamless and polished look.

- Colored screws: If you’re looking to achieve a clean and sleek appearance for your Trex decking, colored screws can be an excellent option. These screws are coated or painted to match the color of your decking boards, creating a uniform and visually appealing finish.

- Hidden fastening systems: Another option for Trex decking is to use hidden fastening systems. These systems utilize clips or connectors that are hidden between the deck boards, eliminating the need for visible screws. Not only do hidden fasteners provide a clean aesthetic, but they also allow for better airflow and expansion/contraction of the boards.

Each of these screw options offers specific benefits and aesthetic choices, so it’s essential to consider your preferences and project requirements when making a selection. It’s also a good idea to consult the manufacturer’s guidelines or seek advice from a professional to ensure you choose the most suitable screws for your Trex decking.

Now that we’ve explored the types of screws available, let’s delve into some additional tips for installing screws on Trex decking.

Stainless steel screws

When it comes to choosing screws for your Trex decking, stainless steel screws are widely considered one of the best options available. Trex decking is designed to withstand the harsh outdoor elements, including moisture, UV rays, and temperature fluctuations. Stainless steel screws provide the necessary strength and durability to ensure a secure and long-lasting installation.

Here are some key advantages of using stainless steel screws for Trex decking:

- Corrosion resistance: Stainless steel screws are highly resistant to corrosion, making them ideal for outdoor applications. They can withstand exposure to moisture, rain, snow, and other environmental factors without rusting or deteriorating over time. This corrosion resistance ensures that your deck will maintain its structural integrity and aesthetic appeal for years to come.

- Strength and durability: Stainless steel screws are known for their strength and durability. They can effectively fasten the decking boards to the underlying substructure, providing a secure and stable deck surface. Additionally, stainless steel screws are less likely to snap or break during installation, ensuring a hassle-free and efficient process.

- Ease of maintenance: One of the significant advantages of using stainless steel screws is the minimal maintenance required. Unlike other materials that may require regular cleaning or replacement, stainless steel screws can maintain their appearance and functionality with simple cleaning and occasional inspections.

- Aesthetic appeal: Stainless steel screws offer a sleek and polished look that complements the overall aesthetic of your Trex decking. They blend seamlessly with the decking boards and do not distract from the natural beauty of the outdoor space.

When using stainless steel screws for Trex decking, it’s important to ensure that you choose the appropriate grade of stainless steel. Grades such as 304 or 316 are commonly recommended for outdoor applications due to their enhanced corrosion resistance.

It’s important to note that while stainless steel screws are an excellent choice for Trex decking, they can be more expensive than other options. However, the long-term benefits and peace of mind that come with using stainless steel screws often outweigh the initial investment.

Before installing stainless steel screws, it’s crucial to follow the manufacturer’s guidelines and recommendations. This includes using the correct size and length of screws and following the recommended spacing between the decking boards. Proper installation techniques will ensure optimal performance and longevity of your Trex deck.

Now that we’ve covered stainless steel screws, let’s explore another type of screw suitable for Trex decking – composite deck screws.

Composite deck screws

When it comes to installing Trex decking, using the right type of screws is essential for a secure and visually appealing finish. Composite deck screws are specifically designed for use with composite decking materials like Trex and offer several advantages over traditional screws.

Here are some key features and benefits of composite deck screws:

- Reverse-thread design: Composite deck screws often feature a reverse-thread design. This design helps to prevent mushrooming, which can occur when a screw pushes the decking material up around the screw head. By reducing mushrooming, composite deck screws provide a cleaner and more professional finish.

- Color options: Composite deck screws come in a variety of colors to match or complement the color of your Trex decking boards. This allows for a seamless and cohesive appearance, ensuring that the fasteners are not visually distracting from the overall aesthetic of your outdoor space.

- Corrosion resistance: Like stainless steel screws, composite deck screws are designed to resist corrosion, ensuring the longevity and structural integrity of your deck. They are often coated or treated to provide enhanced resistance to moisture, UV rays, and other environmental factors.

- Ease of installation: Composite deck screws are designed for easy and efficient installation. They typically have self-drilling tips, which eliminate the need for pre-drilling, making the installation process faster and more convenient.

- Long-lasting performance: Composite deck screws are engineered to withstand the outdoor elements. They are durable and provide a secure hold, ensuring that your Trex decking boards remain firmly in place for many years to come.

When using composite deck screws, it’s important to follow the manufacturer’s guidelines and recommendations. These guidelines may include the recommended spacing between the boards, the specific size and length of screws to use, and any other installation instructions.

It’s worth noting that while composite deck screws are an excellent option for Trex decking, they may be more expensive than traditional screws. However, the benefits they provide, such as a professional finish, proper performance, and longevity, make them a worthwhile investment.

Before installing composite deck screws, it’s recommended to double-check the compatibility with your specific Trex decking material. While they are generally designed for use with composite decking, it’s always a good idea to verify with the manufacturer to ensure a perfect match.

Now that we’ve explored composite deck screws, let’s move on to another option – colored screws.

Use stainless steel or high-quality coated composite decking screws to prevent rust and corrosion. Make sure the screws are the right length to securely fasten the decking boards without causing damage.

Read more: How To Install Trex Decking With Screws

Colored screws

When it comes to installing Trex decking, paying attention to the small details can make a significant difference in the overall appearance of your outdoor space. Colored screws are an excellent option for those seeking a clean, polished, and visually appealing finish for their Trex decking project.

Here are some key benefits and considerations when using colored screws:

- Aesthetic appeal: Colored screws are specifically designed to blend seamlessly with the color of your Trex decking boards. Whether you have a traditional wood-tone deck or a more modern and vibrant color palette, colored screws can match or complement the overall aesthetic, providing a cohesive and eye-catching look.

- Match or contrast: Colored screws offer versatility in customizing your deck’s appearance. You can choose to use screws that perfectly match the color of your decking boards for a subtle and seamless look. Alternatively, you can use contrasting colored screws to create a unique design element, making a statement and adding visual interest to your outdoor space.

- Material compatibility: When selecting colored screws for your Trex decking, it’s essential to ensure they are designed specifically for use with composite materials. These screws are usually made with materials that are resistant to corrosion and damage, ensuring the long-term durability and performance of your deck.

- Weather resistance: Just like other screws used for Trex decking, colored screws are often treated or coated to provide excellent resistance to moisture, UV rays, and other outdoor elements. This weather resistance helps to maintain the integrity and appearance of both the decking boards and the screws themselves.

One important consideration when using colored screws is to follow proper installation techniques. It’s essential to ensure that the screws are inserted at the correct depth, preventing them from protruding or sinking too deep into the decking boards. This will help maintain a uniform appearance and ensure a secure installation.

It’s worth mentioning that colored screws are typically a bit more expensive than traditional screws. However, the enhanced aesthetic appeal they provide makes them a popular choice for those seeking a premium and custom look for their Trex decking.

When purchasing colored screws, it’s important to check with the manufacturer or supplier to ensure that the colors will remain vibrant and resistant to fading over time. This will ensure that your deck’s appearance remains stunning and vibrant for years of enjoyment.

Now that we’ve explored colored screws, let’s move on to another installation option for Trex decking – hidden fastening systems.

Hidden fastening systems

Hidden fastening systems offer a sleek and seamless installation option for Trex decking, providing a clean and unobstructed surface without visible screws or nails. With hidden fasteners, the deck boards are attached from below the surface, creating a smooth and polished look.

Here are some key advantages of using hidden fastening systems for Trex decking:

- Clean aesthetic: One of the main benefits of hidden fastening systems is the clean and uncluttered appearance they offer. Without visible screws or nails on the surface of the deck, the focus remains on the beauty of the decking boards themselves, providing a more polished and streamlined look.

- Improved safety: Hidden fastening systems eliminate the risk of tripping or catching your feet on protruding screws or nails. This makes your Trex deck safer and more comfortable for walking, especially for children and those with mobility challenges.

- Better airflow and expansion/contraction: Hidden fasteners allow for better airflow between the deck boards, which can improve the overall ventilation of your deck. Additionally, the hidden fasteners accommodate the natural expansion and contraction of the decking boards due to temperature changes, preventing buckling or warping.

- Easy maintenance: With hidden fastening systems, maintenance becomes more straightforward. Cleaning the deck surface is easier since there are no screws or nails to work around. Additionally, if any deck boards need to be replaced in the future, they can be easily removed and replaced without the hassle of unscrewing or removing fasteners.

Although hidden fastening systems offer many benefits, it’s important to note that they may require additional time and effort for installation compared to traditional screwing methods. Hidden fasteners often consist of clips or connectors that need to be carefully positioned and aligned with the deck boards, following specific manufacturer instructions.

When choosing hidden fastening systems for Trex decking, it’s crucial to select the ones that are recommended by the manufacturer. Different types of hidden fasteners are designed to work specifically with certain decking materials and profiles. Choosing the appropriate fastening system will ensure optimal performance and compatibility with your Trex decking.

It’s also worth mentioning that hidden fastening systems may come with a higher upfront cost compared to traditional screwing methods. However, the enhanced aesthetics and ease of maintenance they provide can outweigh the initial investment.

Now that we’ve explored hidden fastening systems, we’ll move on to some general tips for installing screws on Trex decking.

Pre-drilling and countersinking screws

When it comes to installing screws on Trex decking, pre-drilling and countersinking are important techniques to ensure a proper and secure installation. These steps help to prevent splitting, cracking, and surface damage to the decking boards, resulting in a clean and professional finish.

Here are some key tips for pre-drilling and countersinking screws on Trex decking:

- Pre-drilling: Pre-drilling involves creating a small pilot hole before inserting the screw into the decking boards. This helps to prevent the boards from splitting or cracking when the screw is driven in. It’s recommended to use a drill bit slightly smaller in diameter than the screw to ensure a snug fit.

- Spacing: Proper spacing between the decking boards is crucial for the structural integrity and overall appearance of your Trex deck. When pre-drilling, make sure to align the holes evenly and maintain the recommended spacing provided by the manufacturer. This will ensure that the boards are securely fastened without any gaps or unevenness.

- Countersinking: Countersinking involves creating a small recess or indentation on the surface of the decking boards to allow the screw head to sit flush with the surface. This prevents any protruding screw heads, reducing the risk of trips or catches. Countersinking can be done using a countersink bit or a larger drill bit that matches the size of the screw head.

- Depth control: When countersinking, it’s important to control the depth of the countersink hole to ensure a consistent and even surface. This can be done by adjusting the drill or countersink bit, or by using a stop collar to limit the depth. Countersinking the screws to the appropriate depth will provide a seamless and professional finish.

By pre-drilling and countersinking the screws on your Trex decking, you not only ensure a secure and stable installation but also enhance the overall appearance of your deck. These techniques help to maintain the integrity of the decking boards while minimizing any potential surface damage.

It’s also important to note that the specific pre-drilling and countersinking requirements may vary depending on the type of screws and decking material you are using. Be sure to refer to the manufacturer’s guidelines and recommendations for the most accurate and up-to-date instructions.

Now that we’ve covered pre-drilling and countersinking, let’s move on to some additional tips for installing screws on Trex decking.

Tips for installing screws on Trex decking

Proper installation of screws is crucial for ensuring the stability and longevity of your Trex decking. Here are some helpful tips to ensure a successful installation process:

- Follow manufacturer’s guidelines: It’s essential to carefully review and follow the manufacturer’s guidelines and recommendations for installing screws on Trex decking. These guidelines typically include information on the recommended screw size, spacing, and installation techniques specific to the decking material.

- Use the correct screw type: Selecting the appropriate type of screw for Trex decking is paramount. Consider factors such as material compatibility, weather resistance, and aesthetic preferences. Stainless steel screws, composite deck screws, or colored screws are commonly recommended options.

- Choose the right size and length: Ensure that the screws you choose are the correct size and length for your Trex decking boards. Using screws that are too short may not securely fasten the boards, while using screws that are too long may cause damage or splitting of the boards.

- Space the screws correctly: Proper spacing of the screws is essential for the overall structural integrity and appearance of your Trex deck. Follow the manufacturer’s recommendations for screw spacing, ensuring that the screws are evenly and appropriately placed across the decking boards.

- Pre-drill and countersink: Pre-drilling pilot holes and countersinking the screws can prevent splitting, cracking, and surface damage to the decking boards. This step also ensures that the screws sit flush or slightly below the surface, providing a clean and professional finish.

- Use caution when tightening: Take care not to overtighten the screws as it may cause the decking boards to deform or create stress points. Tighten the screws until they are snug, but avoid excessive force that could potentially damage the boards.

- Check for any board movement: After installing the screws, check for any movement or shifting of the decking boards. If you notice any boards that are not properly secured, adjust the screws accordingly to ensure a stable and even surface.

- Maintain consistent depth: When inserting the screws, maintain a consistent depth for a uniform appearance. This will help create a professional finish and minimize any visible inconsistencies.

- Regularly inspect the screws: Periodically inspect the screws on your Trex decking to ensure they remain secure and in good condition. Replace any damaged or loose screws promptly to maintain the structural integrity of your deck.

By following these tips, you can achieve a secure, visually appealing, and long-lasting installation of screws on your Trex decking.

As a final reminder, always refer to the manufacturer’s guidelines and recommendations for the most accurate information specific to your Trex decking and the screws you are using. Proper installation and maintenance will ensure the optimal performance and beauty of your outdoor space for years to come.

Now that we’ve covered the tips for installing screws, let’s wrap up our discussion.

Read more: What Is Trex Decking

Conclusion

Selecting the right screws for your Trex decking is essential for achieving a secure and visually appealing outdoor space. By considering factors such as material compatibility, size and length, color options, and environmental factors, you can make an informed decision when choosing screws.

Stainless steel screws offer excellent corrosion resistance, strength, and durability, making them a popular choice for Trex decking. Composite deck screws are specifically designed to prevent mushrooming and provide a clean finish. Colored screws offer the option to match or contrast with your decking boards for a customized look. Hidden fastening systems provide a sleek and seamless installation with no visible screws on the surface.

When installing screws on Trex decking, pre-drilling and countersinking techniques help prevent splitting and create a professional finish. Following proper spacing, tightening with caution, and regularly inspecting the screws contribute to the long-term stability and beauty of your deck.

By combining the right screws, proper installation techniques, and regular maintenance, you can create a Trex deck that is not only sturdy and durable but also visually stunning. Remember to consult the manufacturer’s guidelines for specific instructions and recommendations for your decking material.

Now that you have a comprehensive understanding of the different types of screws, installation tips, and factors to consider for Trex decking, you are ready to embark on your outdoor furniture journey. Enjoy the process of creating and relaxing in your inviting outdoor oasis!

Frequently Asked Questions about What Kind Of Screws To Use With Trex Decking

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Kind Of Screws To Use With Trex Decking”