Home>diy>Building & Construction>What Is Foam Block Construction

Building & Construction

What Is Foam Block Construction

Modified: January 4, 2024

Learn about the benefits and process of foam block construction, an innovative building-construction method that provides energy efficiency and durability.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of foam block construction! In this article, we will explore the fascinating world of building structures using foam blocks. Foam block construction has emerged as a revolutionary technique in the field of building construction, offering a range of benefits and advantages over traditional construction methods.

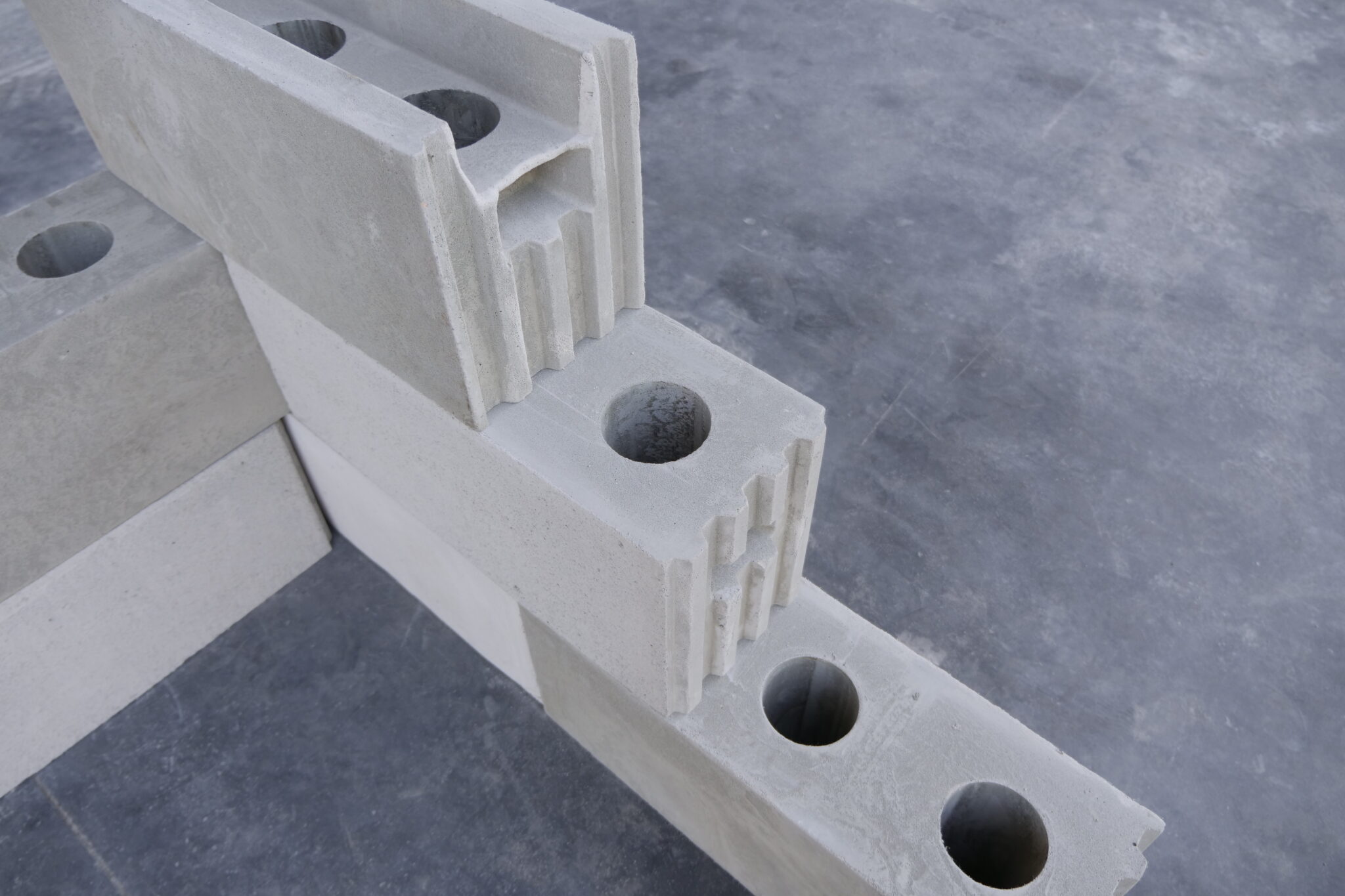

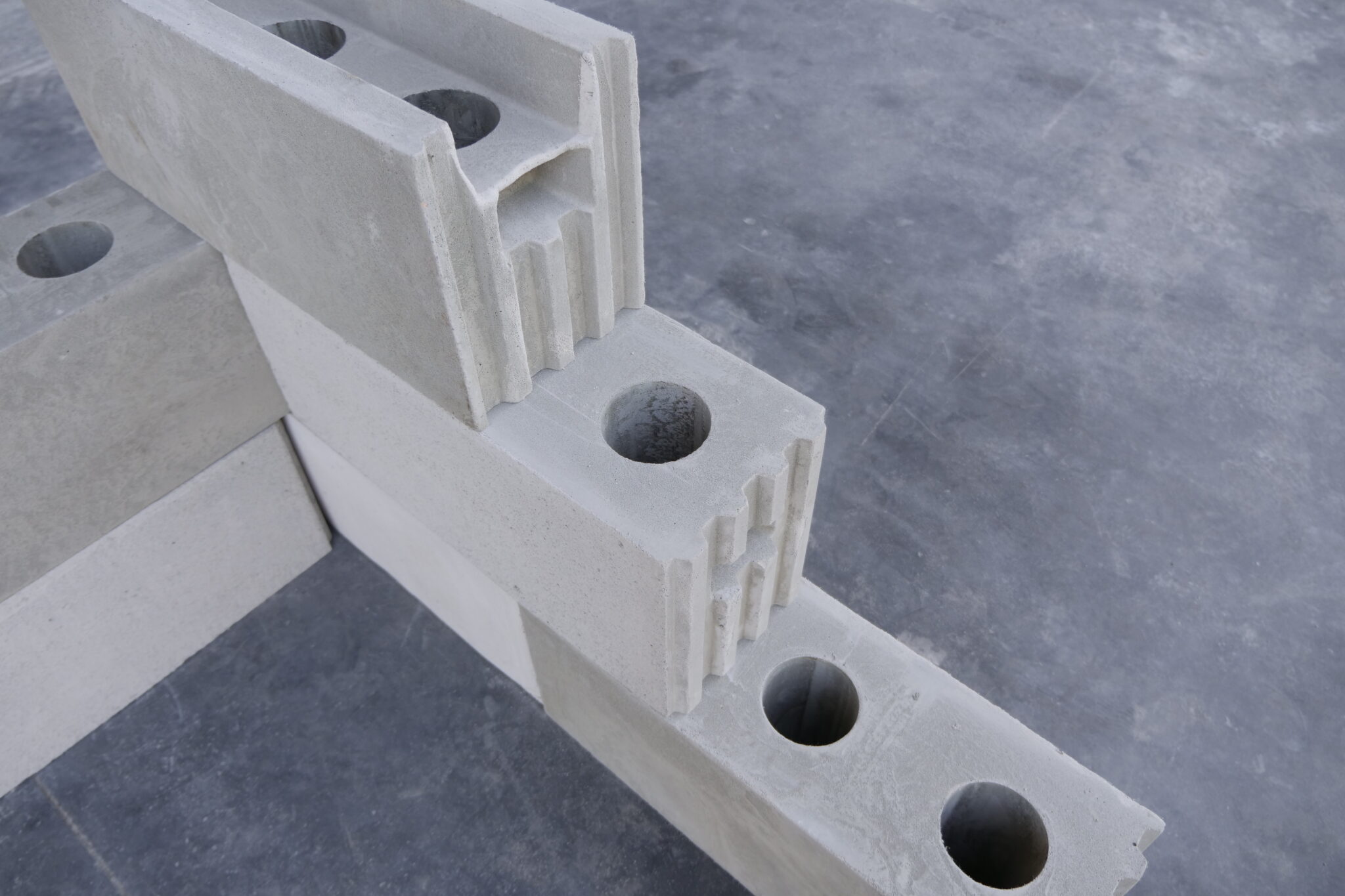

So, what exactly is foam block construction? Also known as Insulating Concrete Form (ICF) construction, foam block construction involves the use of interlocking foam blocks that are filled with concrete to create strong and durable building walls. These foam blocks act as permanent formwork for the concrete, reducing the need for traditional formwork systems.

Now that we have a brief overview, let’s dive deeper into the definition, benefits, process, applications, and more aspects of foam block construction. Whether you are a construction professional or simply curious about innovative building techniques, this article will provide you with a comprehensive understanding of foam block construction.

Key Takeaways:

- Foam block construction offers exceptional insulation, soundproofing, and sustainability, revolutionizing building methods for energy-efficient and durable structures in various sectors.

- Despite initial costs, foam block construction provides long-term energy savings, reduced maintenance, and potential resale value increase, making it a compelling choice for sustainable building projects.

Read more: What Is Block Construction

Definition of Foam Block Construction

Foam block construction, also known as Insulating Concrete Form (ICF) construction, is a building construction method that utilizes interlocking foam blocks to create the structural walls of a building. These foam blocks are made of expanded polystyrene (EPS), a lightweight and rigid material that provides excellent insulation properties. The blocks are typically cut to specific sizes and shapes, allowing for easy assembly and customization.

The foam blocks are assembled together like building blocks, forming a wall system that acts as permanent formwork for the concrete. Once the blocks are in place, concrete is poured into the cavities, creating solid walls that are reinforced with steel bars for added strength. The foam blocks remain in position and become an integral part of the wall system, providing insulation, structural stability, and durability.

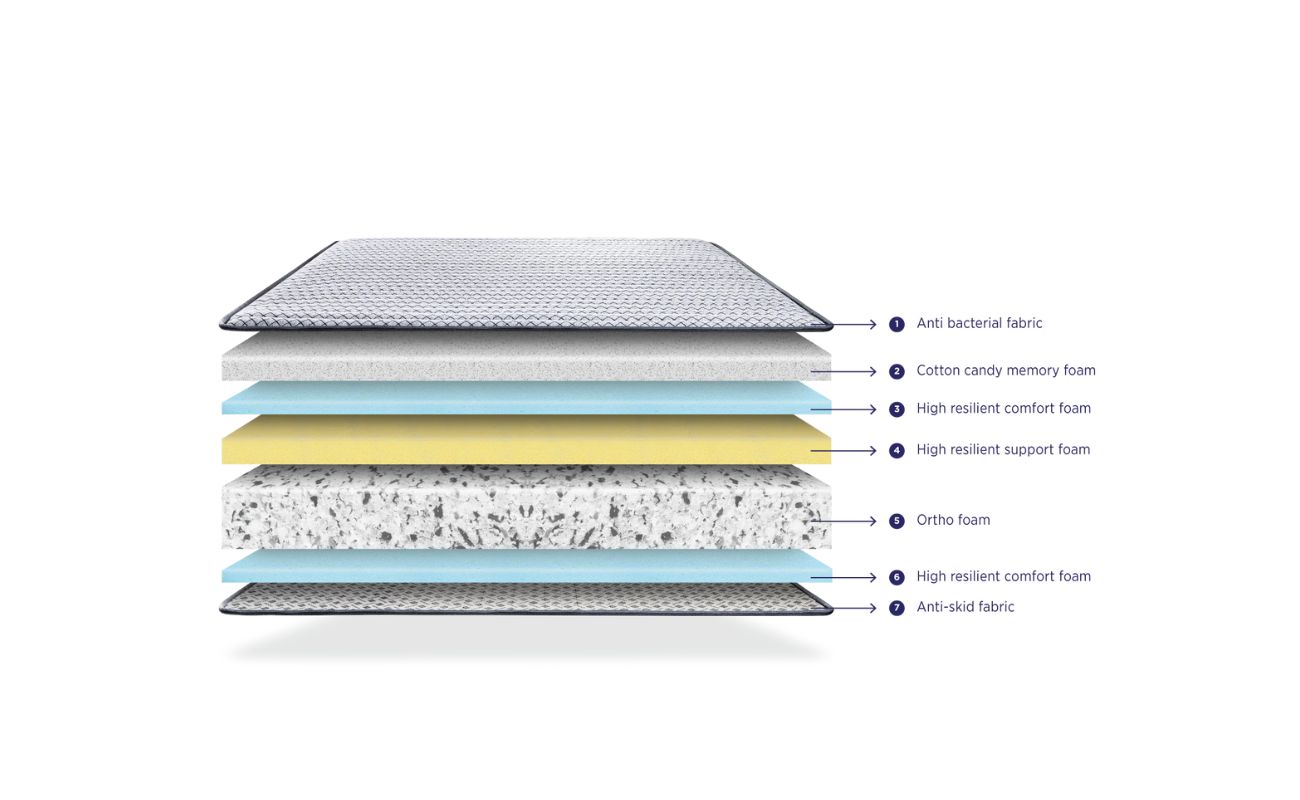

One of the key features of foam block construction is its exceptional insulation capabilities. The foam blocks offer excellent thermal resistance, significantly reducing heat transfer and energy loss. This results in improved energy efficiency and lower heating and cooling costs for the building. Additionally, foam block construction provides enhanced sound insulation, creating a quieter and more comfortable indoor environment.

In terms of sustainability, foam block construction is considered eco-friendly compared to traditional construction methods. The use of foam blocks reduces the need for excessive timber and formwork materials, minimizing the environmental impact. Moreover, the insulation properties of the foam blocks help reduce the reliance on heating and cooling systems, further reducing energy consumption and greenhouse gas emissions.

Overall, foam block construction offers numerous advantages, including excellent insulation, soundproofing, structural strength, and sustainability. It is gaining popularity in various building sectors, including residential, commercial, and industrial applications. As we delve deeper into the topic, we will explore these benefits in more detail.

Benefits of Foam Block Construction

Foam block construction offers a wide range of benefits that make it an attractive choice for building projects. From improved energy efficiency to reduced construction time, here are some of the key advantages of foam block construction:

- Excellent Insulation: Foam block construction provides exceptional insulation properties, resulting in significant energy savings. The foam blocks act as a continuous thermal barrier, reducing heat transfer through the walls. This helps maintain a comfortable indoor temperature and reduces reliance on heating and cooling systems.

- Enhanced Soundproofing: The dense and insulated nature of foam block walls effectively reduces sound transmission between rooms and from external sources. This creates a quieter and more peaceful living or working environment.

- Structural Strength: The combination of reinforced concrete and foam blocks results in highly durable and strong walls. Foam block construction can withstand extreme weather conditions, earthquakes, and other external stresses, offering increased structural stability and resilience.

- Fire Resistance: Foam block walls have a high level of fire resistance due to the inherent properties of the materials used. This provides added safety and protection for occupants, giving them more time to evacuate in the event of a fire.

- Customizable Design: Foam blocks can be easily cut and shaped to accommodate various architectural designs and building requirements. This flexibility allows for creative design possibilities, making foam block construction suitable for both modern and traditional architectural styles.

- Speed of Construction: Foam block construction significantly reduces construction time compared to traditional methods. The interlocking foam blocks are quick to assemble, eliminating the need for extensive formwork and reducing labor hours. This can result in faster project completion and cost savings.

- Environmental Sustainability: Foam block construction is an eco-friendly building method. The insulation properties of foam blocks reduce energy consumption, resulting in lower carbon emissions and a smaller environmental footprint. Additionally, the use of recyclable materials contributes to a more sustainable construction approach.

- Long-Term Cost Savings: Although foam block construction may have slightly higher upfront costs compared to traditional methods, the long-term benefits and cost savings outweigh the initial investment. Energy-efficient buildings with reduced maintenance and operating expenses translate into significant savings over the lifespan of the structure.

These benefits highlight the advantages of foam block construction in terms of energy efficiency, durability, safety, design flexibility, and sustainability. As a result, this innovative construction method is gaining popularity in a wide range of building projects.

Process of Foam Block Construction

The process of foam block construction involves several key steps that ensure the successful implementation of this building method. Here is an overview of the typical process:

- Design and Planning: The first step is to design the structure and create a detailed plan for the foam block construction project. This includes determining the size and layout of the building, as well as the specific requirements for the foam blocks and concrete filling. The design phase may also involve collaborating with architects, engineers, and contractors to address any structural or design considerations.

- Foundation Preparation: Before the foam block installation begins, the foundation for the building must be prepared. This involves excavation, leveling, and preparing the site to ensure a stable base for the construction process.

- Installation of Foam Blocks: Once the foundation is ready, the foam blocks can be installed. The interlocking foam blocks are stacked and aligned according to the approved design plan. The blocks are secured in place using adhesive or mechanical connectors, creating a solid and stable wall system.

- Reinforcement and Electrical Installations: Steel reinforcement bars are placed within the cavities of the foam blocks to provide additional structural strength. This reinforcement helps the walls withstand external forces and reinforces the stability of the structure. Additionally, electrical conduits and plumbing pipes can be installed within the foam block walls, ensuring ease of access for wiring and plumbing systems.

- Pouring Concrete: Once the foam blocks and reinforcement are in place, it is time to pour the concrete. The concrete is typically poured in layers, starting from the bottom and working upwards. Special attention is given to consolidating the concrete and ensuring its proper distribution within the foam block cavities.

- Finishing and Construction Completion: After the concrete has cured, any necessary finishing touches can be made to the walls. This may include smoothing the surface or applying a decorative finish. Once the construction is complete, the building can undergo further interior and exterior finishing work, such as electrical and plumbing installations, insulation, drywall, flooring, and painting.

Throughout the foam block construction process, it is important to follow local building codes, regulations, and industry standards to ensure the safety and quality of the structure. Working with experienced professionals, including architects, engineers, and contractors, can help ensure a smooth and successful foam block construction project.

Applications of Foam Block Construction

Foam block construction, with its numerous benefits and advantages, can be applied to a wide range of building projects. Here are some of the common applications of foam block construction:

- Residential Construction: Foam block construction is increasingly popular in residential projects, including single-family homes, multi-family dwellings, and even custom-built houses. The insulation properties of foam blocks contribute to energy-efficient homes, reducing heating and cooling costs, and creating a comfortable living environment.

- Commercial Buildings: Foam block construction is well-suited for various commercial structures, such as office buildings, retail centers, and industrial facilities. The speed of construction and excellent insulation provided by foam blocks make it an attractive option for commercial projects, promoting energy efficiency and reducing operational costs.

- Institutional Buildings: Foam block construction is also suitable for institutional buildings, including schools, hospitals, and government facilities. The enhanced soundproofing capabilities of foam block walls contribute to a quiet and conducive learning or healing environment, while the durability of the construction method ensures long-lasting structures.

- Hotels and Resorts: Foam block construction can be utilized in the hospitality industry, providing energy-efficient and soundproof structures for hotels, resorts, and lodges. The customizable design options of foam blocks allow for unique architectural styles and aesthetic appeal, offering guests a comfortable and enjoyable experience.

- Industrial Facilities: Industrial buildings, such as warehouses, storage facilities, and manufacturing plants, can benefit from foam block construction. The structural strength and durability of foam block walls can withstand heavy loads and harsh environments, ensuring a safe and functional workspace.

- Public Infrastructure: Foam block construction is also suitable for certain types of public infrastructure projects, such as bridges, retaining walls, and sound barriers. The lightweight nature of foam blocks makes transportation and installation easier, while the long-term durability ensures the longevity of these structures.

These are just a few examples of the diverse applications of foam block construction. The versatility, energy efficiency, and structural benefits of this construction method make it an attractive option for a wide range of building projects.

Read more: What Is Brick And Block Construction

Advantages and Disadvantages of Foam Block Construction

Foam block construction, with its innovative approach and unique characteristics, offers several advantages and disadvantages. It is essential to consider both sides when evaluating the suitability of this construction method for a specific project. Let’s explore the advantages and disadvantages of foam block construction:

Advantages:

- Energy Efficiency: Foam block construction provides excellent insulation, resulting in improved energy efficiency and reduced heating and cooling costs. The continuous thermal barrier created by foam block walls helps maintain a comfortable indoor temperature.

- Soundproofing: Foam block walls offer enhanced sound insulation, reducing noise transmission from both internal and external sources. This creates a quieter and more peaceful living or working environment.

- Strength and Durability: Foam block walls, reinforced with concrete and steel, offer high structural strength and durability. These walls can withstand extreme weather conditions, earthquakes, and other external stresses, providing increased stability and resilience.

- Fire Resistance: Foam block walls exhibit excellent fire resistance, providing additional safety and protection for occupants and allowing for more time to evacuate in the event of a fire.

- Design Flexibility: Foam blocks can be easily cut and shaped, allowing for creative architectural designs and customized building layouts. This flexibility makes foam block construction suitable for various styles and aesthetic preferences.

- Speed of Construction: Foam block construction significantly reduces construction time compared to traditional methods. The interlocking foam blocks are easy and quick to assemble, eliminating the need for extensive formwork and reducing labor hours.

- Environmental Sustainability: Foam block construction is considered eco-friendly due to its energy efficiency and reduced use of construction materials. The insulation properties of foam blocks reduce energy consumption, resulting in lower carbon emissions and a smaller environmental footprint.

Disadvantages:

- Initial Cost: Foam block construction may have slightly higher upfront costs compared to traditional methods due to the specialized materials and construction techniques involved. However, the long-term savings from energy efficiency can offset the initial investment.

- Skills and Training: Proper training and expertise are required to ensure the correct installation of foam blocks and the appropriate pouring of concrete. Contractors and construction workers may need specific training to work with foam block construction effectively.

- Moisture Management: Proper moisture management is crucial in foam block construction to prevent potential issues such as mold and degradation of materials. Effective waterproofing and proper construction techniques are needed to maintain the integrity of the walls.

- Limited Availability: Foam block construction may not be widely available in all areas, as it requires specialized equipment and knowledge. Availability may vary depending on the region and the availability of experienced contractors trained in foam block construction.

Considering both the advantages and disadvantages of foam block construction is essential in making an informed decision for a specific building project. It is important to assess the project requirements, budget, and the expertise available to determine if foam block construction aligns with the project goals and priorities.

Comparison with Traditional Construction Methods

When considering foam block construction as an alternative to traditional construction methods, it is helpful to examine the key differences and benefits. Here is a comparison of foam block construction with traditional methods:

Read more: What Is A CAD Block

Insulation and Energy Efficiency:

One of the most significant advantages of foam block construction over traditional methods is its superior insulation capabilities. Foam block walls provide excellent thermal resistance, resulting in improved energy efficiency and reduced heating and cooling costs. In contrast, traditional construction methods often require additional insulation materials to achieve the same level of thermal performance.

Construction Speed:

Foam block construction is known for its faster construction process compared to traditional methods. The interlocking foam blocks are quick and easy to assemble, eliminating the need for extensive formwork systems. The speed of construction can lead to cost savings and shortened project timelines.

Soundproofing:

Foam block walls offer enhanced sound insulation compared to traditional methods. The density of foam block walls contributes to reducing noise transmission, creating a quieter living or working environment. Traditional construction methods may require additional soundproofing techniques and materials to achieve the same level of acoustic performance.

Environmental Sustainability:

Foam block construction is considered more environmentally sustainable compared to traditional methods. The insulation properties of foam blocks reduce energy consumption, resulting in lower carbon emissions. Additionally, foam blocks can be made from recyclable materials, contributing to a more sustainable construction approach. Traditional construction methods often rely on more resource-intensive materials and may produce higher levels of waste.

Read more: What Is Memory Foam?

Strength and Durability:

Both foam block construction and traditional methods can provide strong and durable structures when properly executed. Foam block walls, reinforced with concrete and steel, exhibit significant strength and can withstand external stresses. Traditional construction methods may rely on different materials, such as wood or masonry, but can also offer durability when constructed according to building codes and standards.

Cost Considerations:

The cost of foam block construction can vary depending on factors such as project size, design complexity, and local market conditions. While the upfront cost of foam block construction may be slightly higher compared to traditional methods, long-term savings from energy efficiency and maintenance can offset the initial investment. Traditional construction methods may have lower upfront costs, but higher ongoing energy expenses and maintenance costs.

Overall, foam block construction provides significant advantages in terms of insulation, construction speed, soundproofing, sustainability, and potentially reduced long-term costs. However, it is essential to evaluate project requirements, budget, and expertise available to determine whether foam block construction is the most suitable option for a specific building project.

Cost Considerations of Foam Block Construction

When considering foam block construction for a building project, it is important to understand the various cost considerations involved. While foam block construction offers numerous benefits, it is essential to evaluate the financial aspects to make an informed decision. Here are some key cost considerations to keep in mind:

Initial Investment:

The initial cost of foam block construction can be slightly higher compared to traditional construction methods. This is primarily due to the specialized materials, such as foam blocks and connectors, required for the construction process. Additionally, specialized skills and training may be needed for the installation of foam blocks and pouring of concrete. It is important to budget for these higher upfront costs when considering foam block construction.

Read more: What To Write On Jenga Blocks

Energy Savings:

One of the major advantages of foam block construction is the energy efficiency it provides. Foam block walls offer excellent insulation, reducing heating and cooling costs over the lifespan of the building. While the initial investment may be higher, the long-term energy savings can offset the upfront cost. It is crucial to consider the potential energy savings when evaluating the overall cost-effectiveness of foam block construction.

Maintenance and Repairs:

Foam block construction typically requires minimal maintenance compared to traditional construction methods. The durability and strength of foam block walls, when combined with reinforced concrete, can reduce the need for frequent repairs or replacements. This can result in long-term cost savings by minimizing maintenance expenses over the lifespan of the building.

Construction Time and Labor Costs:

Foam block construction often leads to faster construction times compared to traditional methods. The interlocking foam blocks are easy to assemble, which can reduce labor hours and associated costs. The shorter construction time can also result in cost savings in terms of project management and overall construction timeline.

Long-Term Value:

While the initial investment for foam block construction may be higher, the long-term value of the building should also be considered. Energy-efficient buildings constructed with foam blocks can attract higher resale values and may be more desirable to potential buyers or tenants. The improved thermal performance, soundproofing, and durability of foam block construction can contribute to the long-term value and market appeal of the building.

It is crucial to conduct a comprehensive cost analysis that takes into account the upfront costs, energy savings, maintenance expenses, construction time, and long-term value when evaluating foam block construction. Considering these factors will provide a more accurate assessment of the financial viability and overall cost-effectiveness of foam block construction for a specific project.

Sustainability and Energy Efficiency of Foam Block Construction

Foam block construction is not only a durable and efficient building method but also offers significant sustainability and energy efficiency benefits. Let’s explore how foam block construction contributes to a more sustainable and energy-efficient built environment:

Sustainable Materials:

Foam blocks used in foam block construction are typically made of expanded polystyrene (EPS), a type of plastic foam. EPS is a recyclable material, which means that the foam blocks can be reused or repurposed at the end of their lifecycle. Using recyclable materials reduces the environmental impact associated with construction and helps mitigate waste generation.

Reduced Energy Consumption:

One of the key advantages of foam block construction is its exceptional insulation properties. The foam blocks create a continuous thermal barrier that significantly reduces heat transfer through the walls. This insulation helps regulate indoor temperatures and reduces the reliance on heating and cooling systems, thereby decreasing energy consumption. The reduced energy demand not only leads to cost savings but also reduces carbon emissions and environmental impact.

Improved Indoor Air Quality:

Foam block construction also contributes to improved indoor air quality. The tight thermal seal created by foam block walls prevents the infiltration of outdoor pollutants, allergens, and contaminants. This helps maintain a healthier and more comfortable indoor environment, benefiting the occupants’ well-being and reducing the risk of respiratory issues.

Read more: What Happens If Chimney Is Blocked

Sound Insulation:

Foam block construction provides excellent sound insulation, reducing noise pollution from external sources and between different areas within the building. This is particularly beneficial in high-density urban areas or buildings that require a quiet and peaceful environment, such as schools, hospitals, or residential complexes.

Reduced Construction Waste:

Foam block construction generates less construction waste compared to traditional methods. The foam blocks are precision-cut to fit specific dimensions, resulting in minimal offcuts or scraps. Additionally, the foam blocks can be recycled or repurposed at the end of their lifespan, further reducing waste sent to landfills.

Longevity and Durability:

Foam block construction creates strong and durable walls that are resistant to pest infestations, moisture damage, and rot. The longevity of foam block structures reduces the need for frequent repairs or replacements, thereby reducing resource consumption and waste generation over time.

Overall, foam block construction offers a more sustainable and energy-efficient building option. By utilizing recyclable materials, reducing energy consumption, enhancing indoor air quality, and minimizing construction waste, foam block construction aligns with the principles of sustainability and contributes to the creation of a greener built environment.

Conclusion

Foam block construction, also known as Insulating Concrete Form (ICF) construction, offers a versatile and innovative approach to building structures. Throughout this article, we have explored the definition, benefits, process, applications, and cost considerations of foam block construction. It is clear that foam block construction presents several advantages over traditional construction methods.

The exceptional insulation properties of foam block walls result in improved energy efficiency and reduced heating and cooling costs. The soundproofing capabilities of foam block construction create a quieter and more comfortable indoor environment. Additionally, foam block construction provides excellent strength, durability, and fire resistance, ensuring the safety and resilience of the structures.

Foam block construction has a diverse range of applications, including residential, commercial, institutional, and industrial buildings. Its flexibility in design allows for creative architectural expressions and customization. Furthermore, foam block construction contributes to sustainability by utilizing recyclable materials, reducing energy consumption, and minimizing waste generation.

When considering foam block construction, it is essential to evaluate both the advantages and disadvantages. While the initial investment may be higher compared to traditional methods, the long-term energy savings, reduced maintenance costs, and potential increase in resale value can offset the upfront expenses.

In conclusion, foam block construction offers a sustainable, energy-efficient, and durable building solution. Its benefits make it an attractive option for various construction projects. However, it is important to work with experienced professionals and follow proper construction practices to ensure the successful implementation of foam block construction.

With its insulation properties, soundproofing capabilities, strength, and environmental sustainability, foam block construction is revolutionizing the way we build structures. It provides a pathway towards a greener and more energy-efficient future in the construction industry.

Frequently Asked Questions about What Is Foam Block Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Foam Block Construction”