Home>Furniture & Design>Interior Design Trends>What Are Glass Bottles Made Of

Interior Design Trends

What Are Glass Bottles Made Of

Modified: October 18, 2024

Discover the latest interior design trends with a focus on what glass bottles are made of. Explore sustainable and stylish options for your home.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Glass bottles have been an integral part of human civilization for centuries, serving as vessels for storing and transporting various liquids, from water and beverages to pharmaceuticals and perfumes. The timeless allure of glass bottles lies in their versatility, durability, and aesthetic appeal. As we delve into the intricate world of glass bottle production, it's essential to understand the raw materials, manufacturing processes, and environmental impact associated with this age-old craft.

Glass bottles are not merely containers; they embody a harmonious blend of artistry and functionality. The allure of glass lies in its transparency, allowing the contents to be showcased in all their splendor. Whether it's the effervescent sparkle of a carbonated beverage or the rich hue of a fine wine, glass bottles elevate the presentation of their contents, adding a touch of elegance to everyday experiences.

Beyond their visual appeal, glass bottles offer unparalleled purity and preservation qualities. Unlike plastic or metal containers, glass does not leach harmful chemicals into its contents, ensuring that the flavor and integrity of the stored liquids remain unaltered. This makes glass bottles the preferred choice for preserving the essence of fine wines, premium spirits, and delicate essential oils.

The production of glass bottles is a testament to human ingenuity and craftsmanship. From the selection of raw materials to the intricate manufacturing processes, each step contributes to the creation of a vessel that seamlessly marries form and function. Understanding the journey of a glass bottle from its inception as raw materials to its transformation into a functional work of art unveils the meticulous artistry and precision involved in its creation.

In this exploration of glass bottles, we will unravel the mysteries of their composition, the intricacies of their manufacturing processes, and the diverse types of glass used for their production. Furthermore, we will delve into the environmental impact of glass bottle production, shedding light on the sustainability aspects associated with this time-honored tradition. Join us on this captivating journey through the world of glass bottles, where tradition meets innovation, and artistry converges with utility.

Key Takeaways:

- Glass bottles are made from silica sand, soda ash, and limestone, creating a durable and elegant vessel that preserves liquids without altering their flavor or integrity.

- The environmental impact of glass bottle production highlights the need for sustainable practices to minimize resource consumption and waste generation, ensuring the timeless elegance of glass bottles aligns with environmental stewardship.

Read more: What Is Glass Made Of?

Raw Materials for Glass Bottles

The production of glass bottles commences with the careful selection of raw materials, each playing a pivotal role in shaping the characteristics of the final product. The primary components used in crafting glass bottles are silica sand, soda ash, and limestone. These fundamental ingredients undergo a meticulous fusion process, culminating in the creation of molten glass, the building block of exquisite glass bottles.

Silica sand, a prevalent component in glass production, serves as the foundation of the glass matrix. Its high silica content, typically sourced from quarries or sand mines, imbues the glass with strength and resilience. Soda ash, also known as sodium carbonate, acts as a flux, lowering the melting point of the silica sand and facilitating the fusion process. This crucial ingredient enhances the workability of the molten glass, allowing it to be shaped and molded with precision.

Limestone, the third essential component, contributes to the stability and durability of the glass. Its calcium carbonate content aids in controlling the thermal expansion of the glass, preventing it from shattering under temperature variations. Additionally, limestone acts as a purifying agent, ensuring the removal of impurities from the raw materials, thereby enhancing the clarity and transparency of the glass.

In addition to these primary components, glass manufacturers may incorporate various additives to impart specific properties to the glass, such as colorants for tinted glass bottles or cullet, which is recycled crushed glass, to promote sustainability. The meticulous combination of these raw materials in precise proportions is a testament to the artistry and science behind glass bottle production.

The quality and composition of the raw materials significantly influence the characteristics of the glass bottles, including their clarity, strength, and thermal resistance. As the molten glass takes shape, the inherent properties of the raw materials converge to create a versatile and enduring material that transcends its humble origins. The synergy of silica sand, soda ash, limestone, and specialized additives harmonizes to form the foundation of glass bottles, encapsulating the essence of craftsmanship and innovation.

The journey of raw materials from their natural state to the refined elegance of glass bottles epitomizes the transformative power of human creativity and ingenuity. It is within this alchemy of earth and fire that the timeless allure of glass bottles begins, laying the groundwork for the artful fusion of tradition and modernity.

This section provides a comprehensive overview of the raw materials essential for the production of glass bottles, underscoring their indispensable role in shaping the timeless elegance and functionality of these iconic vessels.

Manufacturing Process of Glass Bottles

The manufacturing process of glass bottles is a meticulously orchestrated symphony of precision and artistry, encompassing a series of intricate steps that transform raw materials into exquisite vessels. This journey begins with the meticulous selection and blending of silica sand, soda ash, limestone, and specialized additives, culminating in the creation of molten glass, the elemental precursor to glass bottles.

The molten glass, resembling a radiant golden fluid, undergoes a transformative journey as it is carefully shaped and molded into the iconic form of a bottle. This process unfolds within the confines of a glass furnace, where the intense heat melts the raw materials into a viscous liquid, ready to be sculpted into the desired shape. The molten glass, akin to a molten canvas, awaits the skilled hands of glass artisans to breathe life into its form.

The shaping of the molten glass is a delicate dance of precision and expertise, often performed by skilled glassblowers or advanced automated machinery. The molten glass is carefully blown and shaped, taking on the distinctive contours and dimensions that define the silhouette of a glass bottle. This transformative process demands unwavering focus and dexterity, as the molten glass assumes its final form, embodying the timeless elegance and functionality of a glass bottle.

Once the glass bottle attains its desired shape, it undergoes a meticulous cooling process to solidify its structure and fortify its integrity. This controlled cooling phase is essential to ensure that the glass achieves its optimal strength and clarity, embodying the hallmark characteristics of fine craftsmanship. The gradual transition from a molten state to a solid form imbues the glass with resilience and durability, transforming it into a vessel capable of preserving and showcasing its contents with unparalleled grace.

Following the cooling phase, the glass bottles undergo rigorous quality checks to ascertain their structural integrity and visual appeal. Any imperfections or irregularities are meticulously addressed, ensuring that each glass bottle meets the exacting standards of quality and craftsmanship. This unwavering commitment to precision and excellence underscores the dedication of glass manufacturers to deliver products of uncompromising quality.

The culmination of this intricate manufacturing process yields glass bottles that embody the seamless fusion of tradition and innovation, bearing testimony to the timeless artistry and ingenuity inherent in their creation. From the radiant glow of molten glass to the refined elegance of the finished bottles, this journey encapsulates the transformative power of human creativity and craftsmanship, perpetuating the legacy of glass bottle production as an enduring testament to the union of art and utility.

Types of Glass Used for Bottles

Glass bottles are crafted from a diverse array of glass types, each possessing unique characteristics that cater to specific requirements and preferences. The selection of glass for bottle production is a nuanced process, influenced by factors such as the intended use of the bottles, desired aesthetic appeal, and functional attributes. Understanding the distinct properties of various glass types provides valuable insights into the versatility and adaptability of glass bottles across different applications.

-

Soda-Lime Glass:

- This ubiquitous glass type serves as the foundation for a myriad of glass bottles, owing to its versatility and cost-effectiveness. Soda-lime glass, composed of silica, soda ash, and lime, exhibits excellent clarity and is well-suited for a wide range of beverages, including carbonated drinks, juices, and spirits. Its resilience and transparency make it a popular choice for mass-produced bottles, striking a harmonious balance between functionality and affordability.

-

Borosilicate Glass:

- Renowned for its exceptional thermal resistance and durability, borosilicate glass is a preferred choice for bottles designed to withstand extreme temperature differentials. This specialized glass type, featuring a higher concentration of boron trioxide, is ideal for storing hot liquids, oils, and pharmaceutical products. Its ability to resist thermal shock and chemical corrosion elevates the suitability of borosilicate glass for applications requiring robust and reliable bottle solutions.

-

Flint Glass:

- Celebrated for its unparalleled clarity and brilliance, flint glass, also known as clear glass, exudes a timeless elegance that accentuates the contents of the bottles it adorns. This pristine transparency makes flint glass an ideal choice for premium spirits, fine wines, and luxury perfumes, allowing the captivating hues and textures of the contents to take center stage. The luminous allure of flint glass bottles adds a touch of sophistication to the products they house, enhancing their visual appeal and desirability.

-

Amber Glass:

- Recognized for its distinctive amber hue, this glass type offers superior protection against ultraviolet (UV) radiation, making it an ideal choice for light-sensitive contents such as pharmaceuticals, essential oils, and certain beverages. The inherent UV-blocking properties of amber glass safeguard the integrity and potency of its contents, ensuring that they remain unaffected by light exposure. This makes amber glass bottles a preferred option for preserving the quality and efficacy of light-sensitive substances.

-

Green Glass:

- Embodying a rich and vibrant hue, green glass bottles are often associated with the packaging of premium wines and specialty beverages. The deep green tint of this glass type not only bestows an air of sophistication and luxury but also offers moderate UV protection, making it suitable for products that benefit from light filtration without necessitating the opacity of amber glass. Green glass bottles exude a sense of refinement and exclusivity, making them a favored choice for upscale libations and artisanal concoctions.

The diverse array of glass types used for bottle production underscores the adaptability and versatility of glass bottles across a spectrum of applications. Whether it's the enduring clarity of soda-lime glass, the robustness of borosilicate glass, or the captivating allure of colored glass variants, each glass type contributes to the seamless fusion of form and function, perpetuating the timeless legacy of glass bottles as indispensable vessels that transcend utility to embody artistry and elegance.

Environmental Impact of Glass Bottle Production

The production of glass bottles, while emblematic of timeless craftsmanship and elegance, also entails a profound environmental footprint that warrants careful consideration. From the extraction of raw materials to the energy-intensive manufacturing processes, the lifecycle of glass bottles encompasses various facets that contribute to their environmental impact.

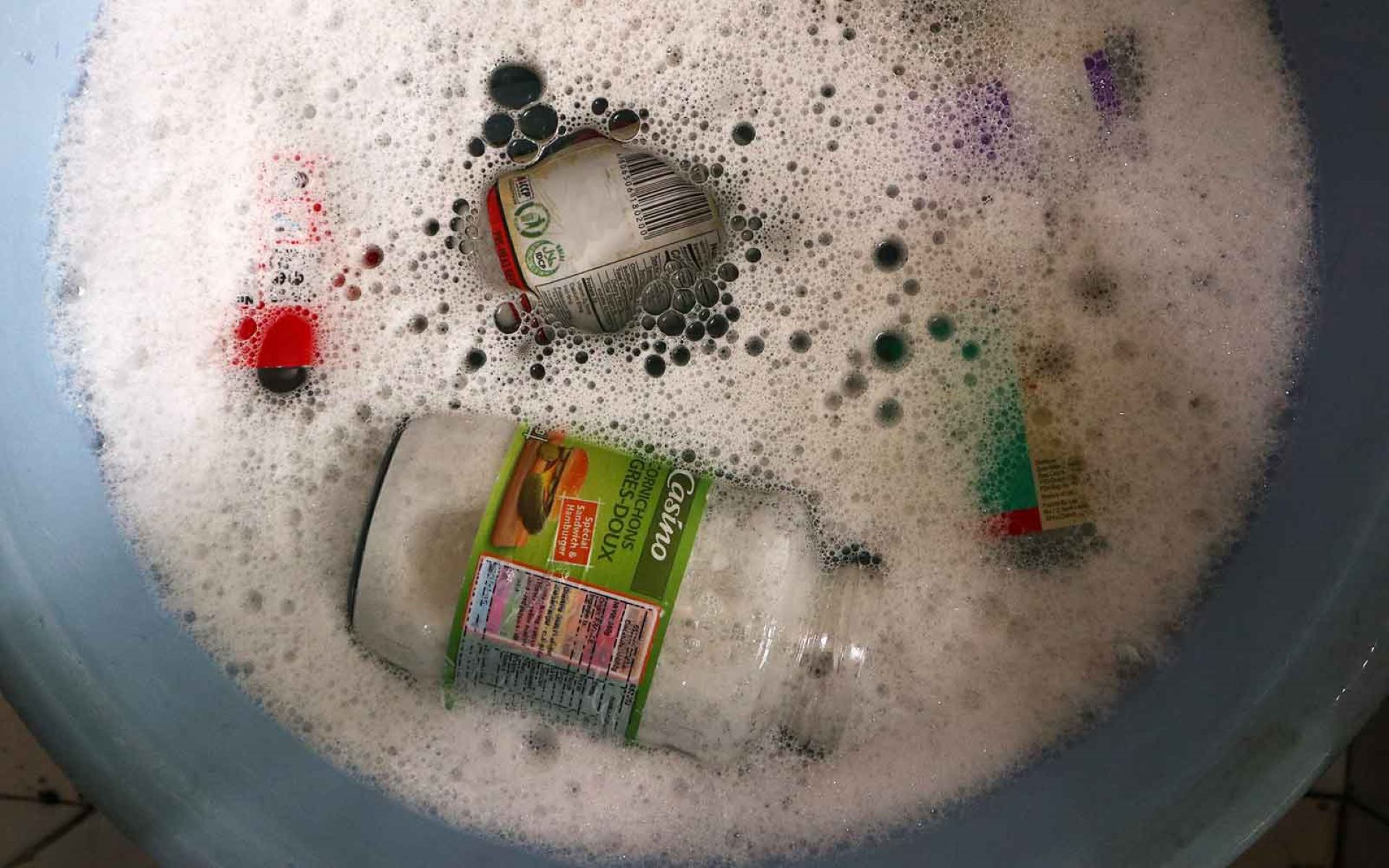

Read more: What To Do With Glass Bottles

Raw Material Sourcing

The procurement of raw materials, particularly silica sand and limestone, involves mining and quarrying activities that can exert pressure on natural ecosystems. The extraction of these resources may lead to habitat disruption, soil erosion, and landscape alteration, impacting the biodiversity and ecological balance of the surrounding areas. Additionally, the transportation of raw materials to manufacturing facilities contributes to carbon emissions and energy consumption, further amplifying the environmental implications of glass bottle production.

Energy Consumption

The energy-intensive nature of glass bottle manufacturing, characterized by the operation of high-temperature furnaces and intricate shaping processes, necessitates substantial energy inputs. The reliance on fossil fuels for powering glass furnaces and auxiliary machinery contributes to greenhouse gas emissions, thereby contributing to the carbon footprint associated with glass bottle production. Mitigating the energy demands of glass manufacturing through sustainable practices and technological advancements is essential for minimizing its environmental impact.

Waste Generation and Recycling

While glass is inherently recyclable and can be perpetually reprocessed without compromising its quality, the management of glass waste and the promotion of recycling infrastructure are critical considerations. Inadequate recycling initiatives may result in the accumulation of glass waste in landfills, posing challenges for waste management and resource utilization. Encouraging widespread glass recycling and integrating recycled glass, or cullet, into the production process can significantly reduce the environmental burden of glass bottle manufacturing.

Environmental Benefits

Despite its environmental challenges, glass bottle production offers notable sustainability advantages. Glass bottles are inert, non-toxic, and impermeable, ensuring that they do not leach harmful substances into the environment or the products they contain. Furthermore, the recyclability of glass bottles presents a compelling opportunity to conserve resources, reduce energy consumption, and minimize the need for virgin raw materials, thereby mitigating the environmental impact of glass bottle production.

Read more: What Are Glass Noodles Made Of

Sustainable Practices and Innovation

Embracing sustainable practices, such as optimizing energy efficiency, implementing closed-loop recycling systems, and exploring alternative raw materials, can significantly enhance the environmental sustainability of glass bottle production. Technological innovations, such as advanced furnace designs and eco-friendly manufacturing processes, hold promise for reducing the carbon footprint and resource intensity of glass manufacturing, paving the way for a more environmentally responsible approach to glass bottle production.

In essence, the environmental impact of glass bottle production underscores the imperative of adopting holistic strategies that prioritize resource efficiency, waste reduction, and ecological stewardship. By embracing sustainable practices and fostering a culture of environmental responsibility, the glass industry can navigate towards a future where the allure of glass bottles converges with conscientious environmental stewardship, ensuring that these timeless vessels continue to embody elegance and sustainability in equal measure.

Conclusion

The journey through the realm of glass bottles has unveiled a tapestry of artistry, innovation, and environmental considerations that converge to shape these timeless vessels. From the meticulous selection of raw materials to the transformative manufacturing processes, the creation of glass bottles epitomizes the harmonious fusion of tradition and modernity. The inherent elegance and functionality of glass bottles are a testament to the enduring legacy of craftsmanship and the enduring allure of these iconic vessels.

As we reflect on the diverse types of glass used for bottle production, from the enduring clarity of soda-lime glass to the specialized properties of borosilicate and colored glass variants, it becomes evident that glass bottles transcend mere containers, embodying a symphony of versatility and adaptability. Each glass type contributes to the seamless fusion of form and function, perpetuating the timeless legacy of glass bottles as indispensable vessels that transcend utility to embody artistry and elegance.

Moreover, the environmental impact of glass bottle production underscores the imperative of embracing sustainable practices and technological innovations to mitigate the ecological footprint associated with this time-honored craft. While the extraction of raw materials and energy-intensive manufacturing processes pose environmental challenges, the recyclability and inert nature of glass bottles offer compelling opportunities for resource conservation and waste reduction. By championing sustainable practices and fostering a culture of environmental responsibility, the glass industry can navigate towards a future where the allure of glass bottles converges with conscientious environmental stewardship, ensuring that these timeless vessels continue to embody elegance and sustainability in equal measure.

In essence, the journey through the world of glass bottles has illuminated the intricate interplay of tradition, innovation, and environmental stewardship that underpins their creation. As these iconic vessels continue to grace our lives with their timeless elegance and functionality, it is imperative to recognize and embrace the profound artistry and sustainability considerations that define the enduring allure of glass bottles. With a steadfast commitment to craftsmanship, innovation, and environmental responsibility, the legacy of glass bottle production will endure, perpetuating the timeless tradition of these exquisite vessels for generations to come.

Frequently Asked Questions about What Are Glass Bottles Made Of

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are Glass Bottles Made Of”