Home>Furniture & Design>Interior Design Trends>What Kind Of Vinyl To Use On Glass

Interior Design Trends

What Kind Of Vinyl To Use On Glass

Modified: October 19, 2024

Discover the latest interior design trends for using vinyl on glass. Find out what kind of vinyl is best for your glass projects. Elevate your space with these stylish ideas.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Vinyl has become a popular choice for adding a touch of personalization and creativity to glass surfaces. Whether it's for home decor, business signage, or DIY projects, the versatility of vinyl makes it a go-to material for transforming plain glass into eye-catching displays. When it comes to using vinyl on glass, understanding the different types of vinyl and the application techniques is essential for achieving professional-looking results.

In this comprehensive guide, we will explore the various types of vinyl suitable for glass applications, including adhesive vinyl, heat transfer vinyl, and static cling vinyl. Each type offers unique characteristics and benefits, catering to different preferences and project requirements. Additionally, we will delve into practical tips for applying vinyl on glass, ensuring a seamless and durable finish.

By gaining insights into the world of vinyl and mastering the art of application, you can unleash your creativity and elevate the aesthetic appeal of glass surfaces. Whether you're a seasoned crafter or a novice enthusiast, this guide will equip you with the knowledge and techniques needed to embark on exciting glass vinyl projects with confidence. Let's embark on this journey to discover the endless possibilities of using vinyl on glass and unleash your creativity in new and exciting ways.

Key Takeaways:

- Vinyl offers endless creative possibilities for transforming glass surfaces, with options like adhesive, heat transfer, and static cling vinyl. Each type caters to different preferences and project requirements, empowering creators to unleash their artistic vision.

- Mastering vinyl application techniques, such as surface preparation and precise cutting, ensures professional and enduring results on glass surfaces. Incorporating best practices like temperature consideration and proper alignment enhances the overall quality of vinyl applications.

Read more: What Kind Of Vinyl To Use On Car Windows

Types of Vinyl for Glass

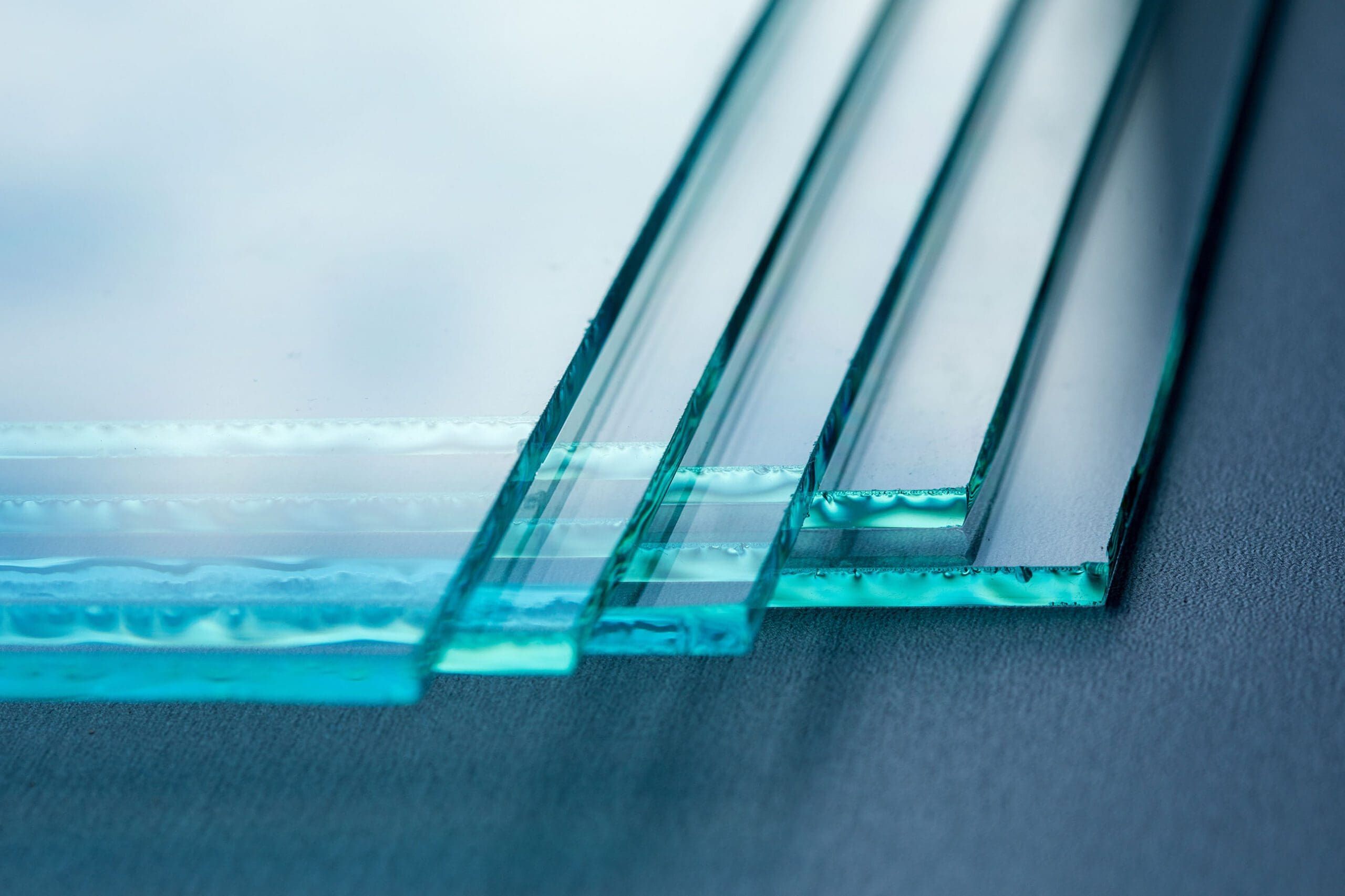

When it comes to enhancing glass surfaces with vinyl, it's crucial to understand the different types of vinyl available and their suitability for various applications. Each type of vinyl offers distinct characteristics, making it essential to choose the right one based on the specific project requirements. Let's explore the three primary types of vinyl commonly used for glass applications:

Adhesive Vinyl

Adhesive vinyl is a versatile option for decorating glass surfaces, offering a strong adhesive backing that ensures a durable and long-lasting bond. This type of vinyl is available in a wide range of colors, finishes, and textures, allowing for endless creative possibilities. Whether it's solid colors, metallic finishes, or even specialty effects like glitter or holographic designs, adhesive vinyl provides flexibility and customization options for glass projects.

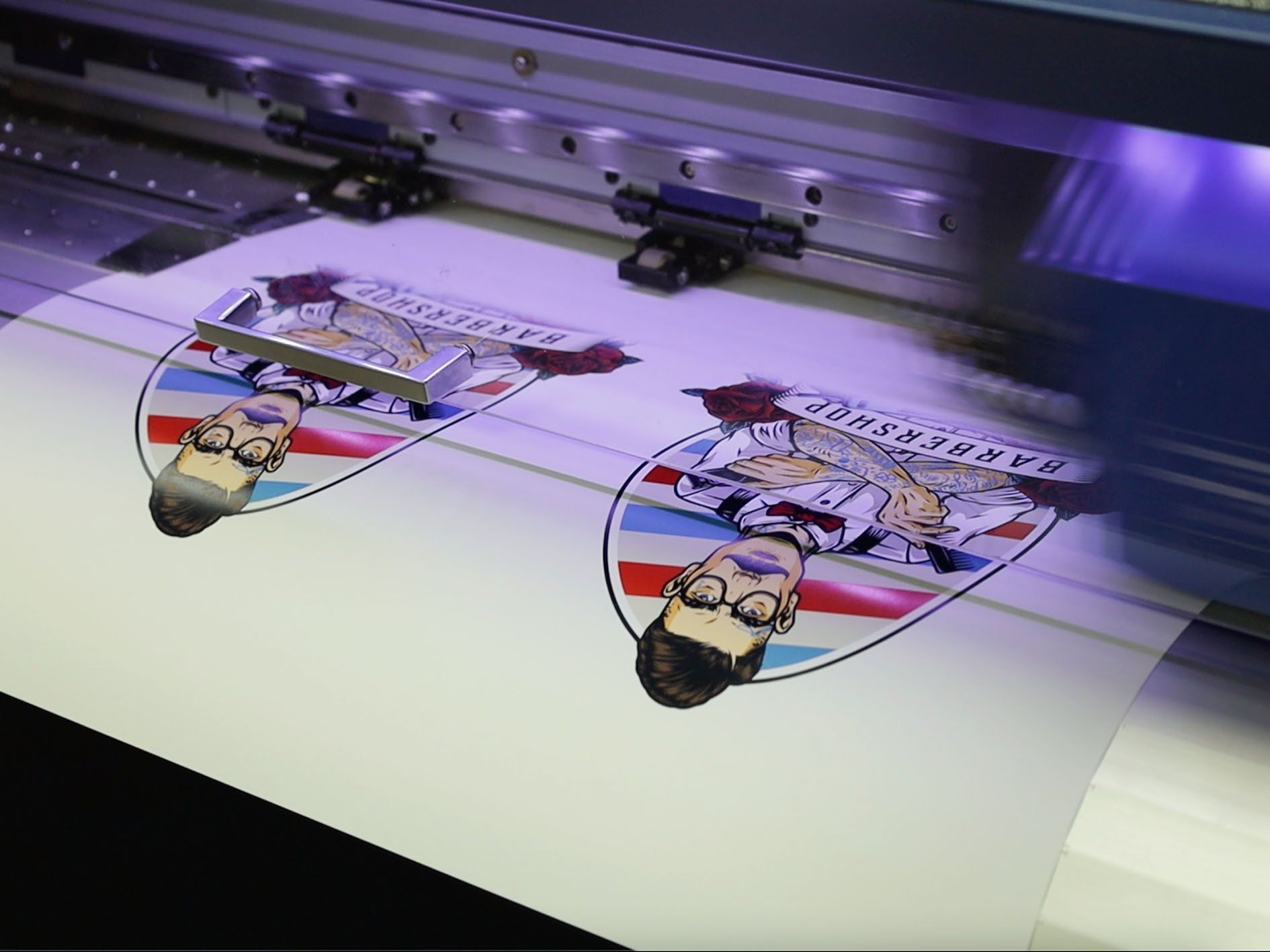

Heat Transfer Vinyl

Heat transfer vinyl, also known as HTV, is a popular choice for creating custom designs on glass surfaces through the application of heat. Unlike adhesive vinyl, which uses a sticky backing, heat transfer vinyl requires heat and pressure for application. This type of vinyl is commonly used for creating intricate designs, text, or graphics on glass items such as mugs, plates, and decorative pieces. With the right heat transfer techniques, HTV can result in vibrant and durable designs on glass surfaces.

Static Cling Vinyl

Static cling vinyl offers a unique alternative for temporary or repositionable applications on glass. Unlike adhesive vinyl, static cling vinyl adheres to glass surfaces through static electricity, allowing for easy removal and repositioning without leaving any residue. This makes it an ideal choice for seasonal decorations, promotional displays, or temporary signage on glass windows or doors. With its reusable nature, static cling vinyl provides flexibility and convenience for various glass projects.

Each type of vinyl offers distinct advantages and considerations, catering to different preferences and project requirements. Whether it's the permanence of adhesive vinyl, the heat application of heat transfer vinyl, or the reusability of static cling vinyl, understanding the characteristics of each type empowers creators to make informed decisions when embarking on glass vinyl projects. By selecting the right type of vinyl based on the intended use and desired outcome, individuals can unleash their creativity and transform ordinary glass surfaces into captivating works of art.

Read more: What Type Of Vinyl To Use On Glass

Adhesive Vinyl

Adhesive vinyl is a versatile and popular choice for enhancing glass surfaces with vibrant designs, personalized graphics, or decorative elements. This type of vinyl features a strong adhesive backing, ensuring a secure bond to glass, making it ideal for a wide range of applications. Whether it's adding a pop of color to windows, creating intricate patterns on glass doors, or crafting custom signage for businesses, adhesive vinyl offers endless possibilities for transforming plain glass into visually stunning displays.

One of the key advantages of adhesive vinyl is its extensive variety of colors, finishes, and textures. From bold solid colors to metallic finishes and even specialty effects like glitter or holographic designs, creators have the freedom to explore a diverse palette of options to suit their artistic vision. This versatility allows for the customization of glass surfaces to align with specific themes, branding requirements, or personal preferences, making adhesive vinyl a go-to choice for both professional and DIY projects.

In addition to its aesthetic flexibility, adhesive vinyl is known for its durability and longevity. Once applied to glass, the strong adhesive backing ensures that the vinyl remains securely in place, withstanding environmental factors such as sunlight, moisture, and temperature changes. This durability makes adhesive vinyl suitable for both indoor and outdoor applications, offering a reliable solution for long-term decorative or promotional displays on glass windows, doors, or storefronts.

Furthermore, the application process for adhesive vinyl is relatively straightforward, making it accessible to creators of all skill levels. With the right tools and techniques, such as a vinyl cutter, transfer tape, and a squeegee, individuals can easily cut and transfer intricate designs onto glass surfaces, achieving professional-looking results. Whether it's creating intricate patterns, lettering, or detailed graphics, adhesive vinyl empowers creators to bring their artistic concepts to life with precision and clarity.

Overall, adhesive vinyl stands as a versatile and durable option for embellishing glass surfaces with creativity and personalization. Its wide range of colors, finishes, and textures, combined with its strong adhesive properties and ease of application, makes it a preferred choice for a myriad of glass projects. Whether it's adding decorative accents to home interiors, showcasing branding elements on storefront windows, or crafting custom gifts, adhesive vinyl opens the door to endless opportunities for transforming glass into captivating visual expressions.

Heat Transfer Vinyl

Heat transfer vinyl, commonly referred to as HTV, offers a unique and versatile approach to adding custom designs and graphics to glass surfaces. Unlike adhesive vinyl, which utilizes a strong adhesive backing, heat transfer vinyl requires the application of heat and pressure to create a lasting bond with the glass. This distinctive method of application opens up a world of possibilities for creating vibrant and durable designs on glass items such as mugs, plates, and decorative pieces.

One of the key advantages of heat transfer vinyl is its ability to produce intricate and detailed designs with precision. Whether it's intricate patterns, text, or graphics, HTV allows creators to achieve sharp and vibrant visuals on glass surfaces, adding a personalized touch to various items. This makes it an ideal choice for crafting custom gifts, personalized glassware, or decorative accents that demand a high level of detail and clarity.

In addition to its precision, heat transfer vinyl offers exceptional durability, ensuring that designs remain vibrant and intact even after repeated use and washing. When properly applied and sealed onto glass surfaces, HTV designs exhibit resilience against external factors such as moisture, handling, and environmental exposure. This durability makes heat transfer vinyl a reliable option for creating long-lasting and visually striking designs on glass items intended for practical use or display.

Furthermore, the application process for heat transfer vinyl involves the use of a heat press or a household iron, allowing for precise control over the application temperature and pressure. This method ensures that the vinyl adheres securely to the glass surface, resulting in a professional and seamless finish. By following the recommended heat transfer techniques and utilizing the appropriate tools, creators can achieve consistent and durable designs on glass, elevating the aesthetic appeal of various items and surfaces.

Overall, heat transfer vinyl stands as a versatile and durable option for adding personalized and intricate designs to glass surfaces. Its ability to produce detailed and vibrant visuals, combined with its exceptional durability and precise application process, makes it a preferred choice for a wide range of glass projects. Whether it's customizing glassware, creating decorative accents, or adding personalized touches to glass items, heat transfer vinyl empowers creators to bring their artistic visions to life with enduring and captivating designs.

Static Cling Vinyl

Static cling vinyl offers a unique and versatile solution for temporary or repositionable applications on glass surfaces. Unlike adhesive vinyl, which relies on a strong adhesive backing, static cling vinyl adheres to glass through the natural force of static electricity, allowing for easy removal and repositioning without leaving any residue or damage. This distinctive characteristic makes it an ideal choice for a variety of glass projects, ranging from seasonal decorations and promotional displays to temporary signage on glass windows, doors, and storefronts.

One of the key advantages of static cling vinyl is its reusability and ease of application. When applied to glass surfaces, static cling vinyl adheres securely through static electricity, allowing for effortless removal and repositioning as needed. This feature makes it a practical option for temporary displays, promotions, or seasonal decorations, providing flexibility and convenience for both personal and commercial applications. Whether it's creating festive window displays for holidays, showcasing promotional messages, or adding temporary decorative elements to glass surfaces, static cling vinyl offers a hassle-free and adaptable solution.

Furthermore, static cling vinyl is available in a variety of finishes and textures, catering to different design preferences and project requirements. From transparent and frosted finishes to vibrant colors and custom prints, creators have the freedom to explore a diverse range of options to achieve their desired visual impact. This versatility allows for the customization of glass surfaces with temporary designs, messages, or decorative elements, providing an effective means of communication and expression for various occasions and purposes.

In addition to its reusability and versatility, static cling vinyl offers a non-permanent solution for glass applications, making it an ideal choice for environments where adhesive-based products may not be suitable. Whether it's for rented spaces, temporary events, or areas with strict adhesive restrictions, static cling vinyl provides a practical and non-invasive option for adding visual interest to glass surfaces without the need for permanent adhesion. This makes it a valuable resource for businesses, event organizers, and individuals seeking temporary yet impactful solutions for glass displays and decorations.

Overall, static cling vinyl stands as a versatile and convenient option for adding temporary and repositionable designs to glass surfaces. Its reusability, diverse finishes, and non-permanent nature make it a preferred choice for a wide range of applications, offering a practical and adaptable solution for creating captivating and temporary displays on glass windows, doors, and other glass surfaces. Whether it's for seasonal decorations, promotional messaging, or temporary branding, static cling vinyl empowers creators to achieve visual impact with ease and flexibility.

Application Techniques

Mastering the application techniques for vinyl on glass is essential for achieving professional and long-lasting results. Whether working with adhesive vinyl, heat transfer vinyl, or static cling vinyl, the application process requires attention to detail and precision. Here are the key techniques for applying vinyl to glass surfaces:

Read more: What Kind Of Glue To Use On Glass

Surface Preparation

Before applying vinyl to glass, it is crucial to ensure that the surface is clean, dry, and free of any dust, dirt, or residue. Using a mild glass cleaner and a lint-free cloth, thoroughly clean the glass surface to create an optimal bonding environment for the vinyl. Additionally, ensure that the glass is free from any oils or fingerprints that may hinder the adhesion of the vinyl.

Design Preparation

For adhesive vinyl and heat transfer vinyl, the design or pattern must be accurately sized and cut according to the dimensions of the glass surface. Utilizing a vinyl cutter or craft scissors, carefully cut the vinyl to the desired shape and dimensions, ensuring precise edges and details. In the case of heat transfer vinyl, the design must be mirrored before cutting to ensure the correct orientation when applied to the glass.

Application Process

When applying adhesive vinyl or heat transfer vinyl to glass, utilizing transfer tape is essential for transferring the design onto the glass surface. Carefully place the transfer tape over the vinyl design, ensuring that it adheres smoothly and uniformly. Once the vinyl is secured to the transfer tape, gently position it onto the glass surface, using a squeegee to remove any air bubbles and ensure a seamless bond.

Heat Application (For Heat Transfer Vinyl)

When working with heat transfer vinyl, the application process involves the use of a heat press or household iron. Place the glass item with the vinyl design onto the heat press or use an iron with a protective sheet to apply heat and pressure. Follow the recommended temperature and time settings for the specific type of heat transfer vinyl being used, ensuring that the design adheres securely to the glass surface.

Read more: What Kind Of Paint Do You Use On Glass

Repositioning and Removal (For Static Cling Vinyl)

For static cling vinyl, the application process involves gently pressing the vinyl onto the glass surface, allowing the static electricity to create a secure bond. If repositioning is needed, carefully peel off the vinyl and reapply it as desired. When removing static cling vinyl, simply lift the edges and peel it off the glass, leaving the surface clean and residue-free.

By mastering these application techniques, creators can achieve professional and visually striking results when applying vinyl to glass surfaces. Whether it's creating decorative window displays, personalized glassware, or temporary promotional signage, understanding and implementing these techniques ensures a seamless and durable application process, elevating the aesthetic appeal of glass through the art of vinyl application.

Tips for Using Vinyl on Glass

When working with vinyl on glass surfaces, incorporating the following tips and best practices can significantly enhance the application process and the overall quality of the finished result.

-

Precision Cutting: Utilize a high-quality vinyl cutter or precision craft scissors to ensure accurate and clean cuts for the vinyl designs. Attention to detail during the cutting process is crucial for achieving sharp edges and intricate patterns that enhance the visual impact of the finished application.

-

Test Application: Before applying the vinyl design to the intended glass surface, conduct a test application on a small area or spare piece of glass. This allows for adjustments to be made to the application technique, ensuring that the final placement and alignment of the vinyl design meet the desired outcome.

-

Temperature Consideration: When using heat transfer vinyl, carefully follow the recommended temperature settings and application duration specified by the vinyl manufacturer. Maintaining consistent heat and pressure during the application process is essential for achieving a secure and durable bond between the vinyl and the glass surface.

-

Smooth Surface: Ensure that the glass surface is smooth and free from any imperfections or irregularities that may affect the adhesion of the vinyl. Smooth surfaces provide an optimal foundation for the vinyl to bond effectively, resulting in a professional and polished finish.

-

Avoid Air Bubbles: When applying adhesive vinyl, use a squeegee to carefully remove any air bubbles trapped between the vinyl and the glass surface. Smooth and uniform application minimizes the risk of imperfections and ensures a seamless bond for the vinyl design.

-

Proper Alignment: Pay close attention to the alignment and positioning of the vinyl design on the glass surface. Precision in placement enhances the overall visual impact and ensures that the design complements the contours and dimensions of the glass item or surface.

-

Surface Compatibility: Consider the specific characteristics of the glass surface, such as its curvature or texture, when selecting the type of vinyl for the application. Certain vinyl types may be better suited for curved or textured glass, ensuring optimal adhesion and longevity.

-

Sealing and Protection: For long-term applications, consider using a clear sealant or protective coating over the vinyl design to enhance its durability and resistance to environmental factors. This additional layer of protection can prolong the lifespan of the vinyl application, especially for outdoor or high-traffic glass surfaces.

By incorporating these tips into the process of using vinyl on glass, creators can elevate the quality and longevity of their applications, resulting in visually stunning and enduring designs that enhance the aesthetic appeal of glass surfaces.

Conclusion

In conclusion, the use of vinyl on glass surfaces offers a myriad of creative possibilities, allowing individuals to transform ordinary glass into captivating displays, personalized gifts, and impactful promotional materials. By exploring the diverse types of vinyl, including adhesive vinyl, heat transfer vinyl, and static cling vinyl, creators can tailor their approach to suit specific project requirements and design preferences. Each type of vinyl presents unique characteristics, from the strong adhesive properties of adhesive vinyl to the precision application of heat transfer vinyl and the repositionable nature of static cling vinyl.

The application techniques for vinyl on glass, encompassing surface preparation, design preparation, and precise application methods, play a pivotal role in achieving professional and enduring results. Whether it's creating decorative window displays, customizing glassware, or adding temporary signage, mastering these techniques ensures a seamless and durable bond between the vinyl and the glass surface, elevating the visual impact of the designs.

Furthermore, incorporating best practices such as precision cutting, temperature consideration, and proper alignment enhances the overall quality of vinyl applications on glass, resulting in visually striking and long-lasting designs. These tips empower creators to navigate the intricacies of vinyl application, ensuring that each project reflects their artistic vision with precision and clarity.

Ultimately, the fusion of creativity and technical expertise in using vinyl on glass opens the door to endless opportunities for personalization, branding, and artistic expression. Whether it's embellishing home interiors, showcasing business branding, or crafting unique gifts, the versatility and durability of vinyl on glass surfaces empower individuals to unleash their creativity and leave a lasting impression through visually captivating designs.

As creators continue to explore the potential of vinyl on glass, the seamless integration of artistry and application techniques will drive the evolution of glass embellishment, offering innovative solutions for both personal and commercial endeavors. With a deep understanding of vinyl types, application techniques, and best practices, individuals can embark on glass vinyl projects with confidence, bringing their creative visions to life and transforming glass surfaces into captivating works of art.

Frequently Asked Questions about What Kind Of Vinyl To Use On Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Kind Of Vinyl To Use On Glass”