Home>Furniture>Bedroom Furniture>Where Are Simmons Mattresses Made

Bedroom Furniture

Where Are Simmons Mattresses Made

Modified: August 27, 2024

Discover where Simmons mattresses are made and learn about the manufacturing process. Explore our wide selection of bedroom furniture for a restful night's sleep.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of Simmons mattresses, where comfort and quality meet to provide you with a restful and rejuvenating sleep experience. With a rich history and a commitment to excellence, Simmons has become a household name in the bedroom furniture industry. In this article, we will explore the manufacturing processes and locations of Simmons mattresses, as well as the factors influencing their choice of manufacturing sites. We will also delve into the quality control measures implemented by Simmons and their sustainability efforts in mattress production.

A good mattress is essential for a good night’s sleep, and Simmons understands this better than anyone else. For over a century, they have been dedicated to creating innovative and luxurious mattresses that cater to the varying needs and preferences of sleepers. Whether you prefer a firm mattress for proper back support or a plush one for a cloud-like sensation, Simmons has a wide range of options to choose from.

Simmons mattresses are known for their exceptional comfort and durability, thanks to the meticulous manufacturing processes they undergo. Every step of production is carefully planned and executed to ensure that each mattress meets the high-quality standards set by Simmons. From the selection of premium materials to the final finishing touches, Simmons mattresses are crafted with precision and passion.

But where are Simmons mattresses made? Let’s dive into the company’s history and explore the locations of their manufacturing plants. In doing so, we’ll gain a deeper understanding of the factors that influence their choice of production sites.

Key Takeaways:

- Simmons mattresses are proudly manufactured in various locations across the United States, strategically chosen to ensure efficient production and distribution, meeting the demands of customers nationwide while maintaining quality and craftsmanship.

- Simmons is committed to sustainability, incorporating eco-friendly practices, materials, and technologies in their manufacturing processes, ensuring that their mattresses are not only comfortable but also environmentally responsible.

Read more: Where Is Dreamcloud Mattress Made

History of Simmons Mattresses

The story of Simmons mattresses begins in 1870, when Zalmon G. Simmons founded the company in Kenosha, Wisconsin. Initially, Simmons focused on manufacturing wooden insulators for cheese factories. However, it wasn’t until the late 19th century that the company ventured into the world of mattress production.

In 1889, Simmons revolutionized the mattress industry by introducing the patented Pocketed Coil® technology. This innovative design featured individually wrapped coils that provided enhanced support and reduced motion transfer, allowing for a more peaceful and undisturbed sleep. This breakthrough invention propelled Simmons to the forefront of the mattress market, solidifying their position as a leader in the industry.

Over the years, Simmons continued to innovate and refine their mattresses, striving to improve comfort and durability. In the early 20th century, they introduced the Beautyrest® mattress, which further enhanced the support provided by the Pocketed Coil® system. The Beautyrest® line quickly gained popularity and became synonymous with superior quality and luxury.

Simmons weathered the storms of economic recessions and industry changes, adapting to evolving consumer demands and technological advancements. In 2003, the company merged with another industry giant, Serta, forming the largest bedding company in the United States, named Serta Simmons Bedding.

Today, Simmons mattresses are renowned worldwide for their exceptional craftsmanship and innovation. They continue to push boundaries and set new standards in the industry, ensuring that sleepers around the globe experience the utmost comfort and restfulness.

Now that we have explored the rich history of Simmons mattresses, let’s delve into the fascinating manufacturing processes that bring these exceptional sleep surfaces to life.

Manufacturing Processes of Simmons Mattresses

The manufacturing processes of Simmons mattresses are a blend of traditional craftsmanship and cutting-edge technology. Each mattress undergoes a series of meticulously planned steps, ensuring that every detail is taken care of to create a product of utmost comfort and quality.

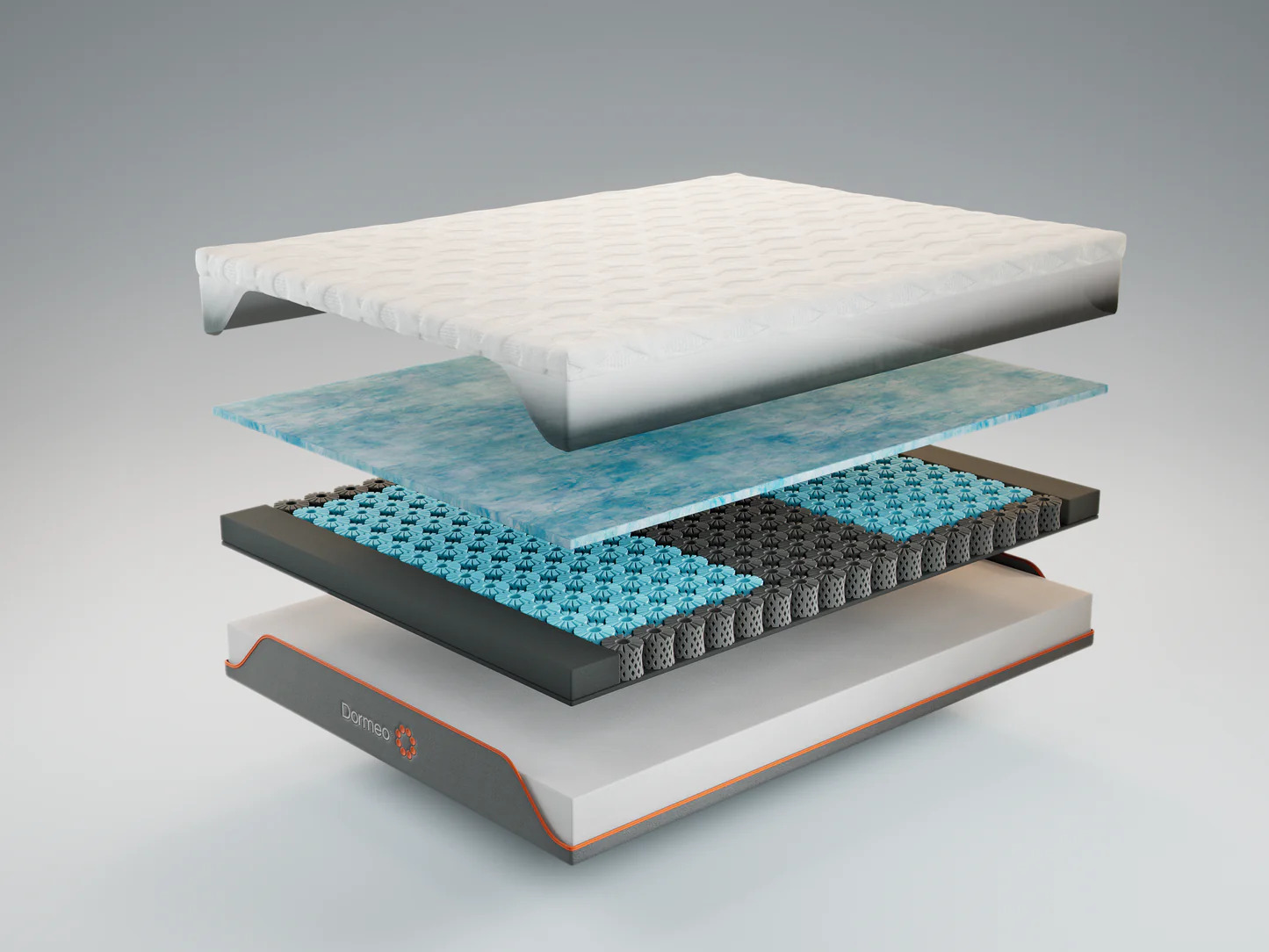

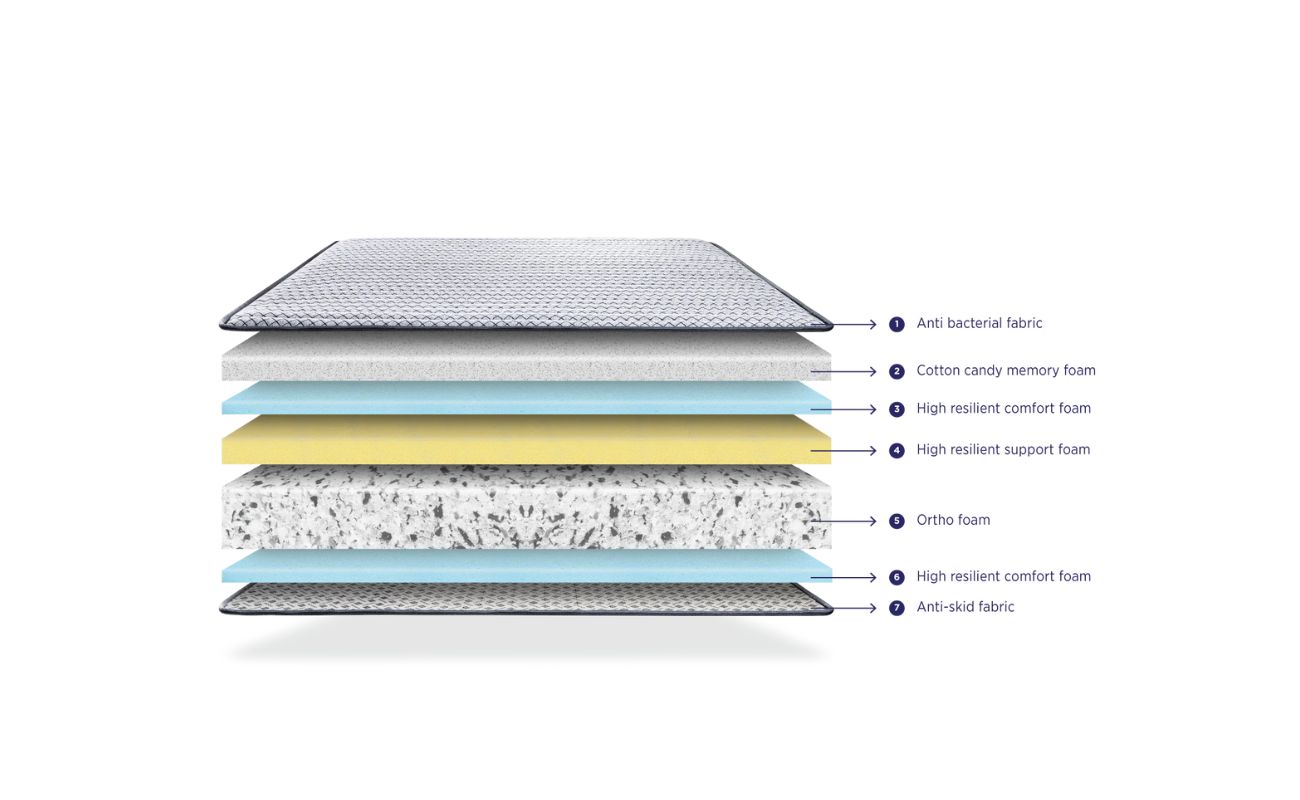

It all begins with the selection of the finest materials. Simmons sources top-grade fabrics, foams, and coils to ensure that each component meets their rigorous standards. From luxurious cover materials to high-density memory foams and innovative coil systems, every element is carefully chosen for its durability, comfort, and performance.

Once the materials are gathered, the true artistry begins. Skilled craftsmen and technicians work diligently to assemble the various components and create the core structure of the mattress. The patented Pocketed Coil® system, which forms the backbone of Simmons mattresses, is meticulously installed. Each coil is individually wrapped and placed strategically to provide targeted support and minimize motion transfer.

Next comes the comfort layer. Based on the specific mattress model, different combinations of foam layers, such as memory foam, latex, and gel-infused foam, are added to enhance the overall comfort and pressure relief. These layers are carefully contoured to provide optimal support and conform to the body’s natural curves.

Simmons mattresses are also known for their edge support systems. Foam encasements or reinforced steel rods are added to strengthen the edges, giving sleepers a larger usable sleep surface and preventing sagging over time.

Once the key components are assembled, the mattress goes through a meticulous inspection process. Quality control measures ensure that each mattress meets Simmons’ stringent standards for durability, comfort, and performance. Only after passing these rigorous tests are the mattresses deemed ready for the next stage.

The final step involves adding the luxurious finishing touches. The mattress cover, often made of high-quality fabrics, is carefully stitched and tailored to perfection. Embroidery, quilting, and other decorative details are added, giving the mattress an elegant and aesthetically pleasing appearance.

Throughout the entire manufacturing process, Simmons utilizes advanced machinery and technology to enhance efficiency and precision. However, it’s important to note that handcrafted attention to detail is still a crucial element in every Simmons mattress, ensuring that each piece is truly a work of art.

Now that we have explored the fascinating manufacturing processes behind Simmons mattresses, let’s uncover the locations of their manufacturing plants.

The Locations of Simmons Mattress Manufacturing Plants

Simmons mattresses are proudly manufactured in various locations across the United States. These strategically chosen manufacturing plants allow Simmons to efficiently produce and distribute their mattresses to meet the demands of customers nationwide.

One of the key manufacturing plants for Simmons mattresses is located in Agawam, Massachusetts. This facility has been producing mattresses for over 100 years and is known for its commitment to quality and craftsmanship. The Agawam plant specializes in manufacturing the renowned Beautyrest® line of mattresses, utilizing state-of-the-art technology and skilled workers to bring these luxurious sleep surfaces to life.

Simmons also has manufacturing plants in Reno, Nevada, and Tolleson, Arizona. These locations provide excellent logistical advantages, with easy access to transportation networks. The Reno plant focuses on producing a wide range of Simmons mattresses, catering to different comfort preferences and needs. The Tolleson plant, on the other hand, specializes in manufacturing hybrid mattresses, combining the best of innerspring and foam technologies for optimal comfort and support.

Additionally, Simmons operates manufacturing facilities in Lancaster, Texas, and New Paris, Indiana. These plants play a crucial role in meeting the growing demand for Simmons mattresses by efficiently producing a variety of models and sizes to cater to different markets and customer preferences.

With these strategically located manufacturing plants, Simmons ensures that their mattresses are readily available to customers across the country. These facilities are equipped with advanced machinery and utilize efficient production processes to meet the high demand without compromising on quality and craftsmanship.

Now that we have explored the various locations of Simmons mattress manufacturing plants, let’s uncover the factors that influence the choice of these production sites.

Simmons mattresses are made in the USA, with manufacturing facilities located in multiple states including Wisconsin, South Carolina, and Arizona.

Factors Influencing the Choice of Manufacturing Locations

The choice of manufacturing locations for Simmons mattresses is influenced by several key factors. These factors are carefully considered to ensure efficient production, maintain quality standards, and meet customer demands. Let’s explore some of the major factors that play a role in determining the optimal manufacturing sites for Simmons:

- Proximity to Raw Materials: One crucial factor is the proximity to the source of raw materials. By locating manufacturing plants near suppliers of high-quality fabrics, foams, and coils, Simmons can reduce transportation costs and ensure a steady supply of materials, resulting in a streamlined production process.

- Logistics and Infrastructure: Another important consideration is the logistics and infrastructure of the chosen location. Manufacturing plants need to have easy access to transportation networks, such as highways, railways, and ports, to facilitate the movement of raw materials in and finished products out. This helps reduce delivery times and costs.

- Workforce Availability and Skills: The availability of skilled labor is vital for maintaining the high standards of craftsmanship associated with Simmons mattresses. By selecting locations with a skilled workforce, the company can ensure efficient production processes and superior quality control.

- Market Reach: Manufacturing plants are strategically placed to ensure easy access to target markets. By having facilities in different regions, Simmons can efficiently distribute their mattresses to retailers and customers across the country, reducing shipping distances and improving customer satisfaction.

- Regulatory Environment: Compliance with industry regulations and environmental standards is a priority for Simmons. Manufacturing plants are chosen in locations with favorable regulatory environments and access to necessary permits, ensuring adherence to strict safety and sustainability guidelines.

By carefully considering these factors, Simmons can optimize their manufacturing processes, maintain quality control, and ensure timely delivery of their mattresses to customers across the United States. These factors, combined with the company’s commitment to craftsmanship and innovation, contribute to the exceptional reputation that Simmons mattresses enjoy.

Now that we have explored the influential factors behind the choice of manufacturing locations, let’s shift our focus to the quality control measures implemented by Simmons in their mattress production.

Read more: Where Is Nolah Mattress Made

Quality Control Measures in Simmons Mattress Production

Simmons takes great pride in delivering mattresses of exceptional quality, and to achieve this, they have implemented stringent quality control measures throughout the production process. These measures ensure that every Simmons mattress meets the high standards set by the company. Let’s take a closer look at the key quality control measures employed by Simmons:

- Testing of Raw Materials: Simmons conducts thorough testing on all incoming raw materials to ensure they meet the required specifications. This includes evaluating the durability, density, and performance characteristics of fabrics, foams, and coils. Materials that do not meet the standards are rejected, ensuring that only the finest components are used in the manufacturing process.

- Inspection of Components: Every component of a Simmons mattress is inspected to ensure they are free from defects and inconsistencies. From the coils to the foam layers and the edge support systems, meticulous checks are carried out to guarantee optimal performance and longevity.

- Quality Assurance Checks: At various stages of the production process, quality assurance checks are conducted to assess the overall quality of the mattress. This includes evaluating the alignment and placement of the coils, measuring the firmness and comfort levels, and inspecting the stitching and finishing of the mattress cover. These checks help identify any potential issues and address them promptly.

- Performance Testing: Simmons mattresses undergo rigorous performance testing to ensure they meet the company’s standards for comfort, support, and durability. This includes a series of simulated sleep trials that evaluate factors such as pressure relief, motion transfer, and spinal alignment. The mattresses are also subject to testing for durability and long-term performance, ensuring they will withstand years of use.

- Third-Party Certifications: Simmons seeks third-party certifications as further validation of the quality and performance of their mattresses. Certifications from organizations such as CertiPUR-US® for foam quality and safety, and OEKO-TEX® for textile and fabric purity, provide consumers with reassurance that the mattresses meet strict standards for environmental and health safety.

Through these stringent quality control measures, Simmons ensures that every mattress leaving their manufacturing plants is of exceptional quality, providing customers with a comfortable and long-lasting sleep surface.

Now that we are aware of the rigorous quality control measures implemented by Simmons, let’s explore their commitment to sustainability in mattress production.

Sustainability Efforts in Simmons Mattress Manufacturing

Sustainability is a core value for Simmons, and the company is committed to minimizing their environmental impact throughout the mattress manufacturing process. Simmons strives to incorporate sustainable practices, materials, and technologies to create mattresses that are not only comfortable but also environmentally responsible. Let’s delve into the sustainability efforts undertaken by Simmons:

- Material Selection: Simmons focuses on sourcing sustainable materials for their mattresses. They seek out suppliers who adhere to eco-friendly practices and use responsibly sourced materials. This includes selecting foams and fabrics that are certified for low emissions and environmental impact.

- Recycling and Waste Reduction: Simmons is dedicated to reducing waste and maximizing recycling efforts. They implement recycling programs at their manufacturing plants to ensure that materials, such as metal springs, foam scraps, and packaging materials, are recycled whenever possible. This helps minimize landfill waste and promotes a circular economy.

- Energy Efficiency: Simmons is committed to reducing energy consumption and increasing energy efficiency in their manufacturing processes. They invest in advanced machinery and technology that optimize energy use, such as energy-efficient lighting systems, automated production lines, and energy management systems. These measures help to minimize their carbon footprint and conserve valuable resources.

- Water Conservation: Water is a precious resource, and Simmons takes steps to conserve it during their manufacturing processes. They implement water-saving measures, such as utilizing water recycling systems and implementing efficient water management practices, to minimize water usage and reduce their environmental impact.

- Certifications and Compliance: Simmons strives to meet and exceed industry standards for sustainability. They seek certifications from recognized organizations, such as the Sustainable Furnishings Council, to ensure that their mattresses meet strict criteria for sustainability and environmental responsibility.

Simmons recognizes that sustainable practices not only benefit the environment but also contribute to the health and well-being of their customers. By prioritizing sustainability in their manufacturing processes, they ensure that their mattresses are not only comfortable but also aligned with the values of eco-conscious consumers.

With these sustainability efforts, Simmons continues to make strides towards a more sustainable and responsible future for the mattress industry.

Now that we have explored the sustainability efforts implemented by Simmons, let’s conclude our article.

Conclusion

Simmons mattresses have a long and storied history of providing comfort and quality to sleepers around the world. With a dedication to craftsmanship and innovation, Simmons has earned its reputation as a leading manufacturer of luxurious sleep surfaces. From their patented Pocketed Coil® system to the extensive range of materials and technologies used, Simmons mattresses are designed to deliver a restful and rejuvenating sleep experience.

Throughout their manufacturing process, Simmons implements stringent quality control measures to ensure that every mattress meets their high standards. From testing raw materials to inspecting components and conducting performance evaluations, Simmons leaves no stone unturned in guaranteeing the durability, comfort, and support of their mattresses.

Simmons carefully selects the locations of their manufacturing plants, considering factors such as proximity to raw materials, logistics, workforce availability, and market reach. By strategically placing their facilities, Simmons is able to efficiently produce and distribute their mattresses across the United States, ensuring quick delivery and customer satisfaction.

Sustainability is a core value for Simmons, and the company takes significant steps to reduce their environmental impact. From sourcing sustainable materials to implementing recycling programs and prioritizing energy efficiency, Simmons is committed to creating mattresses that are not only comfortable but also environmentally responsible.

With a blend of traditional craftsmanship and advanced technology, Simmons continues to push boundaries in the bedroom furniture industry. Their dedication to delivering exceptional comfort, quality, and sustainability sets them apart, making Simmons a trusted choice for sleepers seeking the perfect mattress.

In conclusion, a Simmons mattress is more than just a piece of bedroom furniture—it is a testament to the company’s unwavering commitment to excellence. Whether you choose a Beautyrest®, a hybrid, or another model, you can rest assured that a Simmons mattress will provide you with the comfort and support needed for a truly restful sleep night after night.

Frequently Asked Questions about Where Are Simmons Mattresses Made

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.