Furniture

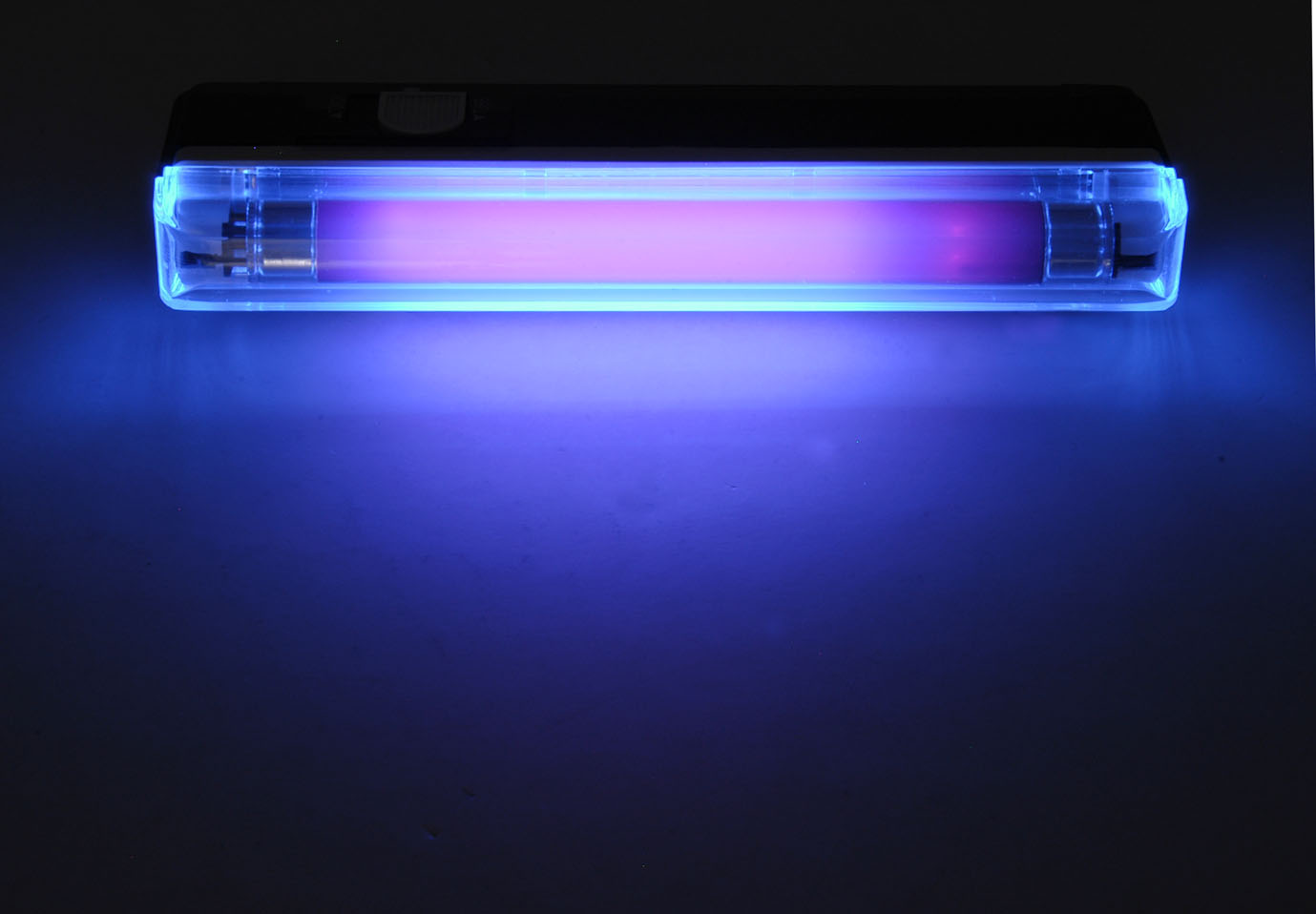

What Is A UV Lamp

Modified: January 19, 2024

Discover the benefits of using a UV lamp to sanitize your furniture. Protect your home from bacteria and harmful allergens with this innovative technology.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to furniture, there is a wide range of options available in the market. From traditional to modern designs, furniture adds functionality and style to any living space. However, it is not just the aesthetics that matter; the comfort and durability of furniture are equally important. That’s where UV lamps come into play.

UV lamps, also known as ultraviolet lamps, have gained immense popularity in the furniture industry for their ability to enhance the durability and quality of various materials. They utilize ultraviolet light to provide numerous benefits, including improved curing, disinfection, and protection against discoloration.

In this article, we will explore the world of UV lamps and shed light on their importance in the furniture industry. We will delve into their definition, working mechanism, applications, different types, and the pros and cons they bring to the table. Additionally, we will discuss the safety precautions one should take when using UV lamps to ensure a safe and efficient working environment.

So, let’s dive in and discover the intriguing world of UV lamps – an indispensable tool in the furniture manufacturing and maintenance process.

Key Takeaways:

- UV lamps are essential in the furniture industry, providing rapid curing, enhanced durability, and protection against discoloration. However, safety precautions must be prioritized to minimize health risks associated with UV radiation.

- The diverse applications of UV lamps, from curing finishes to disinfection and material testing, make them invaluable in furniture manufacturing. Understanding their benefits and drawbacks is crucial for informed decision-making.

Read more: What Is A UV Lamp On A Furnace

Definition of a UV Lamp

A UV lamp, or ultraviolet lamp, is a specialized light source that emits ultraviolet radiation. Ultraviolet radiation is a type of electromagnetic radiation that falls in the wavelength range between visible light and X-rays. UV lamps are designed to emit specific wavelengths of UV light, which can have various effects on different substances and materials.

UV lamps are commonly used in numerous industries, including the furniture industry, for a wide range of applications such as curing, disinfection, and material protection. They are primarily valued for their ability to initiate and accelerate chemical reactions, particularly in the process of curing or hardening materials.

In the context of furniture manufacturing, UV lamps are often employed for curing finishes and coatings. When furniture items are painted or coated with a UV-curable finish, the UV lamp emits ultraviolet light that activates and accelerates the chemical crosslinking process. This results in quick and efficient drying and hardening of the finish, creating a durable and resilient surface.

UV lamps are also used for disinfection purposes in the furniture industry. The ultraviolet radiation emitted by these lamps has germicidal properties, effectively killing bacteria, viruses, and other microorganisms that may be present on the surface of furniture items. This makes UV lamps a valuable tool in ensuring hygienic and clean furniture.

Furthermore, UV lamps are employed for protecting furniture from discoloration caused by sunlight. Ultraviolet light from the sun can fade or alter the color of furniture materials over time. By using UV lamps in furniture showrooms or residential settings, the harmful UV rays can be filtered out, reducing the risk of discoloration and maintaining the aesthetic appeal of the furniture.

In summary, UV lamps are specialized light sources that emit ultraviolet radiation. They are utilized in the furniture industry for curing finishes, disinfection, and protection against discoloration. By harnessing the power of UV light, these lamps provide a range of benefits that enhance the quality, durability, and aesthetics of furniture items.

How Does a UV Lamp Work?

UV lamps work based on the principle of using special phosphor coatings and low-pressure mercury vapor to emit ultraviolet light. The lamp consists of a glass tube that is filled with this mercury vapor and has electrodes at both ends. When an electric current is passed through the electrodes, it excites the mercury atoms, causing them to emit ultraviolet light.

The type of UV light emitted by the lamp depends on the phosphor coating on the inside of the glass tube. Different phosphors emit different wavelengths of UV light, such as UVA, UVB, or UVC. Each wavelength of UV light has specific properties and applications in the furniture industry.

When the UV lamp is turned on, it emits a steady stream of ultraviolet light. This light can then interact with various materials, causing different effects depending on the wavelength and duration of exposure. For example, UVA light can initiate the curing process of UV-curable coatings on furniture surfaces. The light penetrates the top layer of the coating, causing the molecules to crosslink and form a hard and durable finish.

In the case of disinfection, UV lamps emit UVC light, which has germicidal properties. The UVC light damages the DNA of bacteria, viruses, and other pathogens, rendering them unable to reproduce and effectively eliminating them from the surface of the furniture.

It is important to note that UV lamps should be used with caution due to the potential health risks associated with prolonged exposure to ultraviolet radiation. Special protective measures, such as wearing proper eyewear and ensuring proper ventilation, should be taken when working with UV lamps.

Overall, UV lamps work by utilizing low-pressure mercury vapor and phosphor coatings to emit ultraviolet light. The emitted UV light can be tailored to specific wavelengths for different applications in the furniture industry, such as curing finishes and disinfection. Understanding how UV lamps work is crucial for utilizing their benefits effectively and safely in furniture manufacturing and maintenance processes.

Applications of UV Lamps

The applications of UV lamps in the furniture industry are diverse and wide-ranging. UV lamps are valued for their ability to improve the quality, durability, and hygiene of furniture items. Let’s explore some of the key applications of UV lamps in the furniture industry:

1. Curing Finishes: One of the primary applications of UV lamps in the furniture industry is the curing of finishes and coatings. UV-curable finishes are commonly used in furniture manufacturing due to their fast drying time and excellent durability. UV lamps emit UV light in specific wavelengths, which activate the chemical reactions that cause the finish to cure quickly and form a tough, protective layer. This ensures efficient production processes and high-quality finishes.

2. Disinfection: UV lamps with germicidal properties are used for disinfecting furniture surfaces. The powerful UVC light emitted by these lamps effectively kills bacteria, viruses, and other pathogens that may be present on the surface of furniture items. This is particularly important in settings where cleanliness and hygiene are crucial, such as healthcare facilities, hotels, and restaurants.

3. Protection Against Discoloration: Sunlight contains harmful ultraviolet rays that can cause furniture materials to fade or change color over time. UV lamps can be used to filter out these harmful UV rays, protecting furniture from discoloration and maintaining its original aesthetics. This is especially beneficial for furniture displayed in showrooms or near windows where it is exposed to direct sunlight.

4. Surface Preparation: UV lamps are utilized in the furniture industry for surface preparation before finishing or painting. The UV light can be used to activate and promote adhesion between the surface and coatings, ensuring a strong and long-lasting bond. This results in improved paint adherence, preventing peeling or flaking of finishes over time.

5. Phototherapy: In the realm of custom furniture and interior design, UV lamps are often used to create unique and artistic effects. They are employed to highlight certain aspects of furniture pieces or to enhance the visual appeal of decorative elements. UV lamps can be used in combination with UV reactive materials, such as pigments or inks, to achieve vibrant and visually stunning results.

6. Material Testing: UV lamps are also used in the furniture industry for material testing and quality control purposes. They can be used to simulate accelerated aging and test the durability of furniture materials under UV exposure. This helps manufacturers ensure their products can withstand long-term use and maintain their appearance and structural integrity over time.

Overall, the applications of UV lamps in the furniture industry are diverse and valuable. From curing finishes and disinfection to protection against discoloration and material testing, UV lamps play a vital role in enhancing the quality, longevity, and visual appeal of furniture items.

When using a UV lamp, make sure to follow the manufacturer’s instructions carefully to avoid overexposure to UV radiation. It’s important to protect your eyes and skin while using a UV lamp.

Types of UV Lamps

UV lamps come in various types, each with its specific characteristics and applications. The choice of UV lamp depends on the desired wavelength of UV light and the intended use. Let’s explore some of the common types of UV lamps used in the furniture industry:

1. Low-Pressure Mercury Vapor Lamps: These are the most commonly used type of UV lamps. They emit a broad spectrum of UV light, including UVA, UVB, and UVC. Low-pressure mercury vapor lamps are versatile and can be used for curing finishes, disinfection, and protection against discoloration. They are available in different sizes and wattages to accommodate different furniture manufacturing needs.

2. Medium-Pressure Mercury Vapor Lamps: These UV lamps emit a high-intensity UV light across a broad spectrum, including UVA and UVB. They are widely used for curing finishes, particularly in applications where a high intensity of UV light is required. Medium-pressure mercury vapor lamps offer faster curing times, making them ideal for high-speed production processes.

3. LED UV Lamps: LED UV lamps have gained popularity in recent years due to their energy efficiency and long lifespan. They emit UV light in specific wavelengths, providing precise and targeted curing capabilities. LED UV lamps are often used in furniture manufacturing for curing UV-curable finishes, offering advantages such as instant on/off capability and minimal heat generation.

4. Excimer Lamps: Excimer lamps emit highly energetic UV light in the vacuum ultraviolet (VUV) range. They are commonly used in the furniture industry for surface modification and material treatment processes. Excimer lamps can effectively remove contaminants, improve adhesion, and enhance the surface properties of furniture materials to ensure better paint adherence and coating durability.

5. UVC Germicidal Lamps: As the name suggests, UVC germicidal lamps are designed specifically for disinfection purposes. They emit UVC light, which has strong germicidal properties and can effectively kill bacteria, viruses, and other harmful microorganisms. UVC germicidal lamps are commonly used in furniture manufacturing and healthcare settings to maintain a clean and hygienic environment.

It is important to consult with experts or lamp manufacturers to determine the most suitable type of UV lamp for specific furniture industry applications. Factors such as the desired wavelength, intensity, curing time, and surface area to be treated should be taken into consideration to ensure optimal results.

In summary, the types of UV lamps used in the furniture industry include low-pressure mercury vapor lamps, medium-pressure mercury vapor lamps, LED UV lamps, excimer lamps, and UVC germicidal lamps. Each type has its own capabilities and applications, making it crucial to select the right UV lamp for specific furniture manufacturing and maintenance requirements.

Read more: What Wattage Should A UV Lamp For Resin Be

Benefits and Drawbacks of UV Lamps

UV lamps offer a range of benefits in the furniture industry, but it is important to consider both the advantages and potential drawbacks before incorporating them into manufacturing or maintenance processes. Let’s explore the benefits and drawbacks of UV lamps:

Benefits of UV Lamps:

- Efficient Curing: UV lamps provide fast and efficient curing of UV-curable finishes, reducing production time and increasing productivity. The rapid curing process ensures shorter turnaround times and improved efficiency in furniture manufacturing.

- Enhanced Durability: The curing process facilitated by UV lamps creates a hard and resilient finish on furniture surfaces. UV-cured coatings offer excellent scratch resistance and durability, resulting in furniture items that can withstand daily wear and tear for an extended period.

- Hygienic Disinfection: UV lamps with germicidal properties effectively kill bacteria, viruses, and other pathogens, ensuring a hygienic environment. This is particularly important in settings where cleanliness is crucial, such as healthcare facilities or public spaces.

- Protection Against Discoloration: By filtering out harmful UV rays from sunlight, UV lamps can protect furniture from discoloration and fading. This helps to maintain the original color and aesthetic appeal of furniture items, especially when displayed in settings with significant sun exposure.

- Environmentally Friendly: UV lamps typically consume less energy compared to traditional curing methods, resulting in reduced energy consumption and environmental impact. LED UV lamps, in particular, are known for their energy efficiency and longer lifespan.

Drawbacks of UV Lamps:

- Potential Health Risks: Prolonged exposure to UV radiation emitted by UV lamps can be harmful to human health. It is important to follow safety precautions, such as wearing proper protective eyewear and ensuring proper ventilation, to minimize the risk of UV-related health issues.

- Higher Initial Investment: UV lamp systems and equipment can be more expensive upfront compared to traditional curing methods. However, it is important to consider the long-term benefits and increased efficiency that UV lamps bring to the furniture manufacturing process.

- Limited Penetration: UV light has limited penetration capabilities, which means it may not fully cure thick or opaque coatings. Proper adjustment of UV lamp intensity and wavelength may be required to ensure complete curing of thicker coatings.

- Surface Sensitivity: Some furniture materials may be sensitive to UV light and may require additional precautions during the curing process. It is important to test the compatibility of UV-curable finishes with various furniture materials to avoid any adverse reactions.

Understanding the benefits and potential drawbacks of UV lamps is important for furniture manufacturers and maintenance professionals. By weighing the pros and cons, industry professionals can make informed decisions regarding the integration of UV lamps into their processes while ensuring safety and maximizing the efficiency and quality of their furniture products.

Safety Precautions When Using UV Lamps

While UV lamps offer a range of benefits in the furniture industry, it is important to prioritize safety when working with these lamps. Exposure to ultraviolet radiation can have harmful effects on human health. By following proper safety precautions, you can minimize the risks associated with using UV lamps. Here are some important safety measures to consider:

1. Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment when working with UV lamps. This includes safety glasses with UV filters to protect your eyes from direct exposure to UV radiation. Additionally, wear gloves and long-sleeved clothing to minimize skin exposure.

2. Ventilation: Ensure proper ventilation in the workspace to minimize the accumulation of harmful fumes or gases emitted from the materials being cured. Good ventilation helps maintain a safe and comfortable working environment.

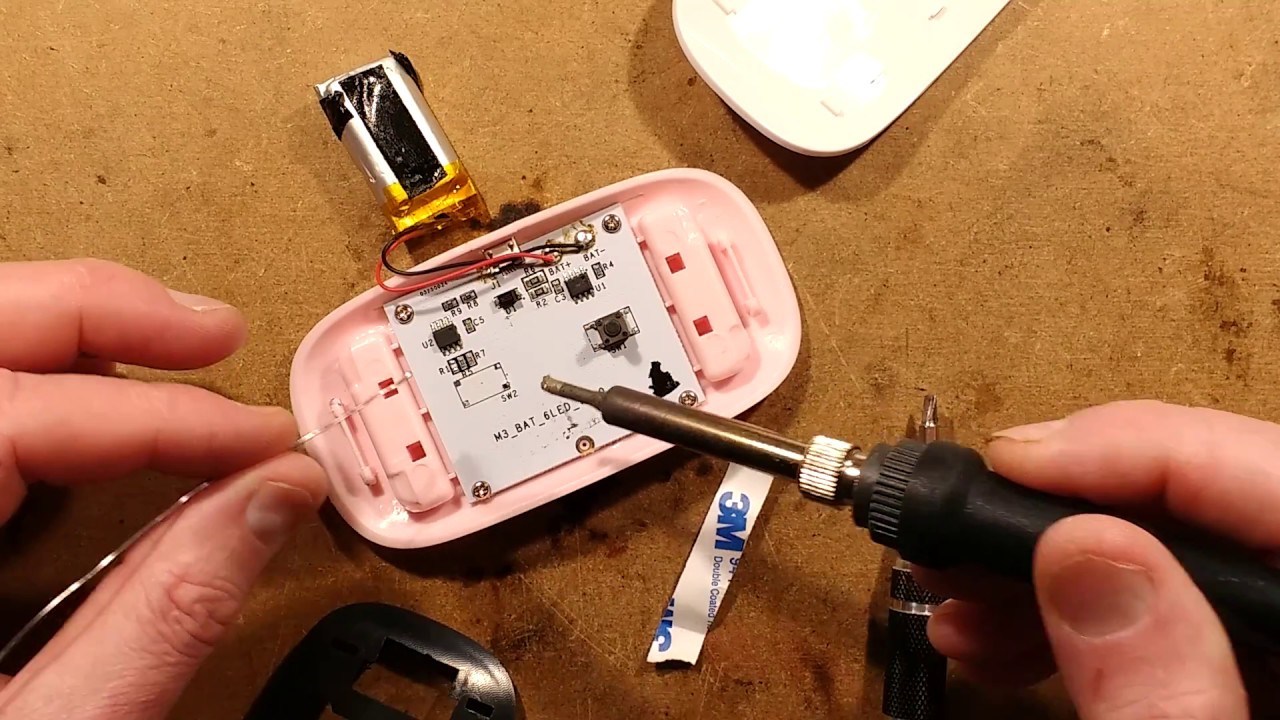

3. Proper Lamp Installation: Install UV lamps according to manufacturer’s instructions and ensure they are securely fitted in the fixtures. Improper installation can result in safety hazards, such as exposed wiring or potential electrical issues. Regularly inspect the lamps and fixtures for any signs of damage or wear, and replace them if necessary.

4. Keep a Safe Distance: It is essential to keep a safe distance between yourself and the UV lamp during operation. Stay at least the recommended distance specified by the manufacturer to prevent direct exposure to UV radiation.

5. Time Management: Limit the duration of exposure to UV radiation. If working with UV lamps for an extended period, schedule regular breaks to minimize the risk of overexposure. This is especially important for tasks that involve close proximity to the UV lamp.

6. Training and Education: Ensure that all personnel working with UV lamps receive proper training and education on the safe handling and use of these lamps. By understanding the risks associated with UV radiation and the necessary safety precautions, workers can protect themselves effectively.

7. Secure Work Area: Maintain a well-organized and clutter-free work area to minimize the risk of accidents. Ensure that the workspace is properly lit to avoid any potential tripping hazards.

8. Emergency Preparedness: Have an emergency plan in place in case of any accidents or incidents involving UV lamps. This includes knowing the location of emergency exits, having a first aid kit readily available, and understanding the procedures to follow in case of exposure or injury.

It is important to note that these safety precautions are general guidelines. It is recommended to consult the specific safety guidelines provided by lamp manufacturers and regulatory authorities to ensure compliance with industry standards and regulations.

By following these safety precautions, you can create a safer working environment when using UV lamps in the furniture industry. Prioritizing safety not only protects workers but also ensures the efficient and successful use of UV lamps in furniture manufacturing and maintenance processes.

Conclusion

UV lamps have become an indispensable tool in the furniture industry, offering a range of benefits that enhance the quality, durability, and hygiene of furniture items. Their ability to efficiently cure finishes, disinfect surfaces, and protect against discoloration has revolutionized the way furniture is manufactured and maintained.

UV lamps provide rapid and effective curing of UV-curable finishes, reducing production time and increasing productivity. This results in durable and resilient furniture surfaces that can withstand daily wear and tear. Additionally, the germicidal properties of UV lamps ensure a hygienic environment by eliminating bacteria, viruses, and other pathogens from furniture surfaces.

UV lamps also play a crucial role in protecting furniture from discoloration caused by sunlight. By filtering out harmful UV rays, they preserve the original color and aesthetic appeal of furniture items. Furthermore, UV lamps offer environmentally friendly advantages by consuming less energy and having a longer lifespan compared to traditional curing methods.

However, it is important to consider the potential drawbacks and prioritize safety when using UV lamps. Prolonged exposure to ultraviolet radiation can have adverse effects on human health. Therefore, following proper safety precautions, such as wearing protective eyewear and ensuring proper ventilation, is essential.

In conclusion, UV lamps have transformed the furniture industry with their ability to accelerate curing, enhance durability, and maintain the aesthetic appeal of furniture items. By utilizing the various applications of UV lamps, furniture manufacturers can produce high-quality products efficiently. However, it is crucial to prioritize safety and follow the necessary precautions to ensure the well-being of workers and maximize the benefits of UV lamp technology.

With continuous advancements in UV lamp technology and safety measures, the future looks bright for their role in the furniture industry. As furniture designers and manufacturers continue to explore innovative ways to enhance their products, UV lamps will remain a vital tool in achieving higher quality, durability, and cleanliness in the world of furniture.

Frequently Asked Questions about What Is A UV Lamp

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A UV Lamp”