Home>Gardening & Outdoor>Outdoor Structures>What Type Of Saw Blade To Use For Cutting Composite Decking

Outdoor Structures

What Type Of Saw Blade To Use For Cutting Composite Decking

Modified: January 14, 2024

Discover the best saw blade for cutting composite decking to ensure precision and efficiency for your outdoor structures. Choose the right tool for the job!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of composite decking, where the allure of a beautifully crafted outdoor space meets the practicality of low-maintenance, long-lasting materials. As a homeowner or contractor, embarking on a project to build or renovate a deck with composite decking opens up a realm of possibilities. However, before diving into the construction process, it's essential to understand the nuances of working with composite decking materials, including the crucial aspect of cutting them to size.

In this comprehensive guide, we'll delve into the realm of saw blades and their pivotal role in achieving precise and clean cuts when working with composite decking. Whether you're a seasoned professional or a DIY enthusiast, the insights shared here will equip you with the knowledge needed to select the right saw blade and master the art of cutting composite decking with finesse.

So, let's embark on this journey together, exploring the intricacies of composite decking and the key factors to consider when choosing the ideal saw blade for this purpose. By the end of this guide, you'll be well-versed in the art of cutting composite decking, empowering you to bring your outdoor visions to life with precision and proficiency.

Key Takeaways:

- Choose the right saw blade for cutting composite decking to ensure clean, precise cuts and preserve the material’s integrity. Consider tooth design, size compatibility, and manufacturer recommendations for optimal results.

- Master the art of cutting composite decking by investing in quality saw blades, securing the material, and adhering to safety measures. Precision, technique, and the right tools are essential for impeccable outdoor installations.

Read more: How To Cut Composite Decking

Understanding Composite Decking

Composite decking has revolutionized the outdoor living landscape, offering a harmonious blend of aesthetics, durability, and sustainability. Composed of a unique blend of wood fibers, recycled plastics, and bonding agents, composite decking presents a compelling alternative to traditional wood decking. This innovative composition imbues composite decking with remarkable strength and resistance to the elements, making it an ideal choice for outdoor structures.

One of the defining characteristics of composite decking is its low-maintenance nature. Unlike natural wood, composite decking does not require staining, sealing, or painting, significantly reducing the upkeep demands associated with outdoor structures. Furthermore, composite decking exhibits exceptional resistance to rot, mold, and insect infestations, ensuring longevity and structural integrity in various environmental conditions.

Another compelling aspect of composite decking is its eco-friendly appeal. By utilizing recycled materials, composite decking contributes to sustainable practices while minimizing the environmental impact of outdoor construction projects. This sustainability factor resonates with environmentally conscious homeowners and organizations seeking to integrate responsible materials into their outdoor environments.

Moreover, composite decking is available in a diverse array of colors, textures, and finishes, enabling homeowners and designers to unleash their creativity and personalize outdoor spaces to suit their preferences. Whether emulating the rich tones of exotic hardwoods or pursuing a contemporary aesthetic with sleek, monochromatic hues, the versatility of composite decking facilitates boundless design possibilities.

Understanding the unique composition and benefits of composite decking lays the groundwork for navigating the intricacies of working with this innovative material. As we venture into the realm of saw blades for cutting composite decking, this foundational knowledge will serve as a valuable compass, guiding us toward informed decisions and impeccable craftsmanship.

Types of Saw Blades

When it comes to cutting composite decking, the selection of the right saw blade is paramount to achieving precise, clean cuts and ensuring the overall quality of the project. Various types of saw blades are available, each designed to cater to specific cutting requirements and materials. Understanding the distinctions between these saw blades is crucial for identifying the optimal choice for working with composite decking.

1. Standard Circular Saw Blade: This versatile saw blade is a popular choice for cutting composite decking. Equipped with carbide-tipped teeth, it delivers reliable performance and is suitable for general-purpose cutting tasks. However, when working with composite decking, it’s essential to ensure that the blade is designed to minimize chipping and splintering, thus preserving the integrity of the decking material.

2. Composite Decking Saw Blade: Specifically engineered for cutting composite decking, this specialized saw blade features a tooth geometry and blade design optimized for clean and precise cuts in composite materials. With reduced tooth spacing and enhanced chip-clearing capabilities, composite decking saw blades minimize the risk of splintering and produce smooth edges, elevating the overall finish of the decking installation.

3. Fine-Toothed Blade: Blades with a higher tooth count, such as finish blades or plywood blades, are adept at producing smooth cuts in composite decking. The fine teeth contribute to reduced splintering and chipping, resulting in refined edges and minimizing the need for extensive sanding or edge refinement.

4. Multi-Material Blade: For projects that involve cutting a variety of materials in addition to composite decking, a multi-material blade offers versatility and convenience. These blades are engineered to handle different materials, including wood, plastic, and metal, providing a practical solution for diverse cutting requirements within a single project.

By familiarizing yourself with the diverse array of saw blades available for cutting composite decking, you can make informed decisions based on the specific needs of your project. The next step is to discern the most suitable saw blade for your composite decking endeavors, a process that involves considering various factors to ensure optimal cutting performance and exceptional results.

When cutting composite decking, use a carbide-tipped saw blade with more teeth to minimize chipping and ensure a clean cut.

Choosing the Right Saw Blade for Composite Decking

Amidst the array of saw blades tailored for cutting composite decking, the task of selecting the right blade entails a thoughtful evaluation of several key factors. By considering these essential elements, you can pinpoint the ideal saw blade that aligns with the specific requirements of your project, ensuring precision, efficiency, and a superior finish.

1. Blade Material: Opt for a saw blade constructed from high-quality materials, such as carbide, which offers exceptional durability and resilience. A robust blade material enhances the longevity of the saw blade and enables it to withstand the demands of cutting composite decking without compromising performance.

2. Tooth Design: Look for a saw blade with a tooth design optimized for cutting composite materials. Blades featuring specialized tooth geometry and chip-clearing capabilities are instrumental in minimizing splintering and chipping, resulting in clean, smooth cuts and impeccable edges on the composite decking.

3. Size and Compatibility: Ensure that the selected saw blade is compatible with your circular saw or miter saw, considering factors such as blade diameter and arbor size. The proper size and compatibility are essential for seamless integration and optimal performance during the cutting process.

4. Cutting Efficiency: Evaluate the cutting efficiency of the saw blade, considering factors such as tooth count and blade configuration. A saw blade designed for efficient material removal and reduced friction contributes to swift, precise cuts, streamlining the cutting process and enhancing productivity.

5. Manufacturer Recommendations: Refer to the manufacturer’s guidelines and recommendations for saw blades compatible with the specific composite decking material you are working with. Adhering to manufacturer specifications ensures that the selected saw blade is tailored to the unique properties of the decking material, optimizing cutting performance and preserving the material’s integrity.

By methodically assessing these considerations, you can make an informed decision when choosing the right saw blade for cutting composite decking. This deliberate approach empowers you to select a saw blade that harmonizes with the characteristics of the decking material, elevating the precision and finesse of your cutting endeavors while maximizing the overall quality of the project.

Tips for Cutting Composite Decking

Mastering the art of cutting composite decking entails a blend of precision, technique, and the utilization of appropriate tools. To optimize the cutting process and achieve exceptional results, consider the following tips and best practices that will elevate your proficiency in working with composite decking materials.

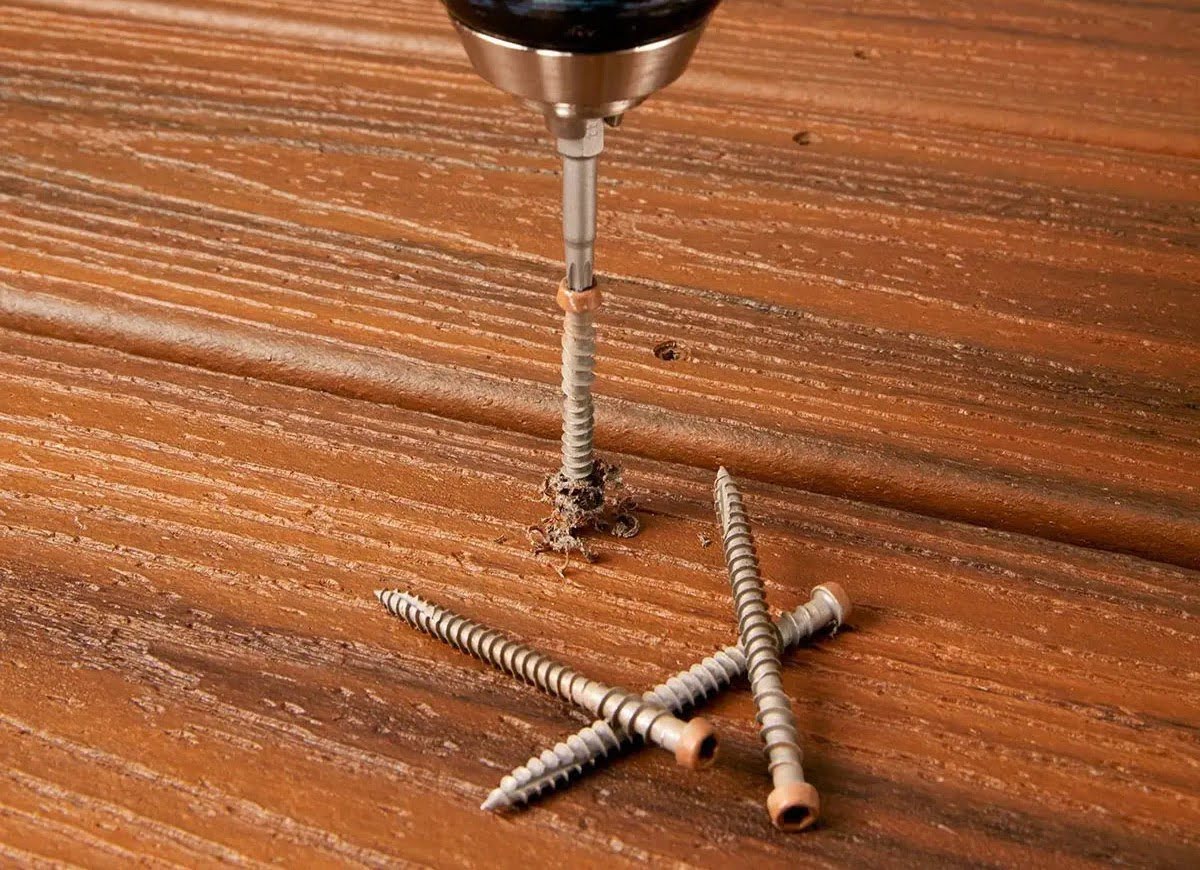

1. Invest in Quality Saw Blades: Prioritize the selection of high-quality saw blades designed specifically for cutting composite materials. Opting for blades with specialized tooth geometry and chip-clearing capabilities minimizes the risk of splintering and ensures clean, smooth cuts, enhancing the overall finish of the decking installation.

2. Secure and Support the Material: When cutting composite decking, ensure that the material is adequately secured and supported to prevent vibrations and movement during the cutting process. This stability is essential for achieving precise cuts and minimizing the potential for irregularities or damage to the decking material.

3. Adhere to Manufacturer Guidelines: Familiarize yourself with the manufacturer’s recommendations and guidelines for cutting the specific composite decking material being utilized. Adhering to these specifications ensures that the cutting process aligns with the material’s intended applications and properties, optimizing the results and preserving the material’s integrity.

4. Marking and Measuring: Accurate measurements and clear markings are crucial for achieving precise cuts in composite decking. Utilize appropriate marking tools and measuring instruments to delineate the cutting lines, ensuring accuracy and consistency throughout the cutting process.

5. Employ Appropriate Safety Measures: Prioritize safety by wearing protective gear, including eye protection and hearing protection, when operating power tools for cutting composite decking. Adhering to safety protocols minimizes the risk of injuries and promotes a secure working environment.

6. Optimize Cutting Techniques: Utilize steady, consistent movements when cutting composite decking, maintaining control and precision throughout the process. Employing appropriate cutting techniques, such as smooth, deliberate motions, contributes to achieving clean, uniform cuts and refined edges on the decking material.

7. Minimize Heat Buildup: To prevent heat-related damage to the composite decking, employ cutting techniques that minimize heat buildup, such as reducing the cutting speed and allowing the saw blade to efficiently dissipate heat during the cutting process.

By integrating these tips into your approach to cutting composite decking, you can enhance your proficiency, precision, and overall mastery of working with this innovative material. These insights will empower you to navigate the cutting process with confidence and finesse, culminating in impeccably crafted decking installations that exude quality and craftsmanship.

Read more: What Blade To Cut Trex Decking

Conclusion

Embarking on a project involving composite decking presents an opportunity to transform outdoor spaces with enduring beauty, functionality, and sustainability. As you venture into the realm of cutting composite decking, the pivotal role of selecting the right saw blade becomes evident, shaping the precision, quality, and finesse of the decking installation. By understanding the nuances of composite decking and the diverse array of saw blades tailored for this purpose, you equip yourself with the knowledge and insight needed to elevate your craftsmanship and achieve exceptional results.

From the specialized tooth geometry of composite decking saw blades to the meticulous considerations when choosing the ideal saw blade, this guide has illuminated the path toward mastering the art of cutting composite decking. It has underscored the significance of adopting best practices, prioritizing safety, and adhering to manufacturer recommendations, all of which converge to optimize the cutting process and uphold the integrity of the decking material.

As you set out to cut composite decking, remember that precision, technique, and the utilization of quality tools are fundamental to realizing your vision with finesse and proficiency. By integrating the tips and insights shared in this guide, you can navigate the cutting process with confidence, harnessing the potential of composite decking to shape captivating outdoor environments that endure the test of time.

Ultimately, the journey of cutting composite decking transcends the realm of construction; it embodies the convergence of craftsmanship, innovation, and the pursuit of outdoor excellence. With the knowledge and expertise gleaned from this guide, you are poised to embark on this journey with clarity and proficiency, poised to bring your outdoor visions to life with precision and mastery.

So, armed with the understanding of composite decking, the nuances of saw blades, and the best practices for cutting, venture forth into the realm of composite decking installations, where the artistry of cutting converges with the enduring allure of outdoor living.

Frequently Asked Questions about What Type Of Saw Blade To Use For Cutting Composite Decking

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Type Of Saw Blade To Use For Cutting Composite Decking”