Home>Home Appliances>Kitchen Appliances>How Do You Know When Jerky Is Done In The Dehydrator

Kitchen Appliances

How Do You Know When Jerky Is Done In The Dehydrator

Modified: January 5, 2024

Discover how to tell when jerky is perfectly dehydrated in your kitchen appliances. Learn the signs of doneness and enjoy delicious homemade jerky.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Dehydrating jerky in a dehydrator is a time-honored method of food preservation that not only enhances the flavor of the meat but also extends its shelf life. Whether you're a seasoned jerky enthusiast or a curious newcomer, achieving the perfect jerky texture can be a rewarding yet challenging endeavor. One of the most common dilemmas faced by jerky makers is determining when the jerky is perfectly dehydrated. This article aims to provide a comprehensive guide on how to discern the optimal doneness of jerky in a dehydrator, ensuring that every batch turns out just right.

Dehydration is a process that involves removing moisture from food items to inhibit the growth of bacteria, mold, and yeast, thereby preventing spoilage. When it comes to making jerky, the dehydrator offers a convenient and efficient way to achieve the desired dryness without sacrificing the meat's flavor and nutritional value. However, gauging the readiness of jerky can be subjective and influenced by various factors, making it crucial to understand the key indicators of doneness.

In this detailed guide, we will delve into the intricacies of the dehydrating process, explore the factors that impact dehydration time, and uncover the visual and tactile cues that signify the completion of the jerky-making journey. By gaining insights into these fundamental aspects, you will be equipped with the knowledge and confidence to consistently produce delectable, perfectly dehydrated jerky. So, let's embark on this flavorful expedition and unravel the secrets of achieving jerky perfection in the dehydrator.

Key Takeaways:

- Achieving perfect jerky in a dehydrator involves observing visual cues like color, texture, and uniformity, ensuring a satisfying and safe snacking experience.

- Factors like meat thickness, marinade, humidity, and dehydrator efficiency impact jerky dehydration time, requiring patience and attention to detail for consistent results.

Read more: How Do You Know When A Rice Cooker Is Done

Understanding the Dehydrating Process

Before delving into the nuances of determining jerky doneness, it is essential to grasp the fundamental principles of the dehydrating process. The dehydrator, a versatile kitchen appliance, operates by circulating warm air to gradually remove moisture from the meat, resulting in a concentrated and preserved product. This controlled dehydration not only intensifies the flavor of the jerky but also ensures its longevity without the need for refrigeration.

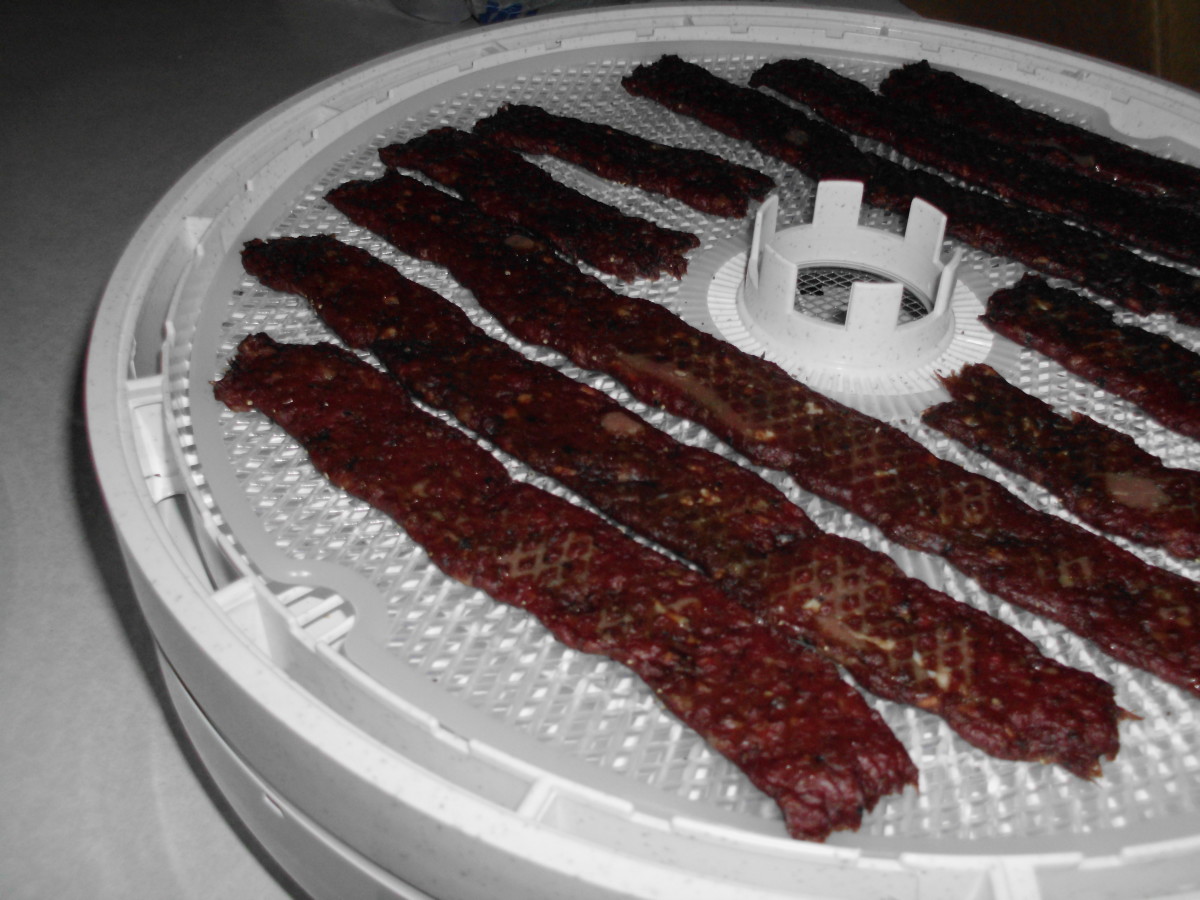

When preparing jerky, the dehydrator’s low heat setting facilitates the drying of the meat while retaining its natural essence. The consistent airflow within the dehydrator promotes uniform dehydration, a crucial factor in achieving evenly dried jerky slices. Understanding the mechanics of the dehydrator aids in comprehending the intricacies of jerky preparation, setting the stage for mastering the art of dehydrating.

Moreover, the dehydrating process is not solely about moisture removal; it is a delicate balance of preserving the meat’s savory qualities and enhancing its texture. As the moisture content decreases, the flavors intensify, resulting in a rich and robust jerky experience. Additionally, the controlled dehydration process ensures that the meat retains its nutritional value, making jerky a wholesome and protein-packed snack.

By comprehending the underlying principles of dehydration, jerky enthusiasts can appreciate the artistry behind this time-honored preservation method. The dehydrator serves as a reliable companion in this culinary journey, offering a controlled environment to transform raw meat into delectable, shelf-stable jerky. With a firm grasp of the dehydrating process, one can proceed to explore the factors influencing dehydration time and ultimately discern the optimal doneness of jerky in the dehydrator.

Factors Affecting Dehydration Time

Several factors influence the duration required to achieve the perfect dehydration of jerky in a dehydrator. Understanding these variables is instrumental in gauging the optimal drying time and ensuring consistent results with each batch. By considering these factors, jerky enthusiasts can fine-tune their dehydrating process and adapt to different conditions, ultimately mastering the art of jerky making.

- Meat Thickness: The thickness of the meat slices significantly impacts dehydration time. Thicker slices require longer drying periods, while thinner cuts expedite the process. It is essential to maintain uniform slice thickness to promote even drying.

- Marinade Composition: The composition of the marinade influences the moisture content of the meat. A high-sugar marinade or one with a significant liquid component may prolong the dehydration process, while leaner marinades can expedite it.

- Humidity Levels: Ambient humidity plays a pivotal role in dehydration. In humid conditions, the dehydrator must work harder to remove moisture from the meat, thus extending the drying time. Conversely, low humidity expedites the process.

- Dehydrator Efficiency: The efficiency and design of the dehydrator impact the overall drying time. Higher-quality dehydrators with consistent heat distribution and airflow facilitate faster and more uniform dehydration.

- Meat Type: Different types of meat, such as beef, turkey, or venison, possess varying fat and moisture content, influencing the duration of dehydration. Understanding the unique properties of each meat type is crucial for precise drying.

By acknowledging these influential factors, jerky makers can adapt their approach to suit specific circumstances, ensuring that the dehydration process is optimized for the best possible outcome. With a keen understanding of these variables, one can proceed to identify the visual signs of jerky doneness and refine their dehydrating technique to achieve consistently exceptional results.

Check the jerky for doneness by bending it – it should crack but not break. Also, it should be dry to the touch with no moisture.

Visual Signs of Doneness

Recognizing the visual cues that indicate the completion of the dehydration process is essential for achieving perfectly dehydrated jerky. While the precise drying time may vary based on factors such as meat thickness and marinade composition, there are definitive visual indicators that signify the readiness of the jerky. By keenly observing these cues, jerky enthusiasts can ascertain the optimal doneness, ensuring a satisfying and safe jerky-making experience.

Color Transformation: As the dehydration progresses, the color of the meat undergoes a noticeable transformation. The jerky evolves from a raw, vibrant hue to a deep, consistent color, indicating the removal of moisture and the concentration of flavors. For beef jerky, this often involves a shift from red to a rich, dark brown, signifying the completion of the dehydration process.

Firmness and Texture: When gently pressed or bent, properly dehydrated jerky exhibits a firm yet pliable texture. It should offer resistance without feeling brittle or crumbly. The surface of the jerky should appear dry and slightly tacky to the touch, indicating the removal of excess moisture and the development of the characteristic jerky texture.

Uniformity of Drying: An even drying pattern across all slices is a crucial visual indicator of doneness. Each piece of jerky should exhibit consistent color and texture, signifying uniform dehydration. Deviations in color or moisture content among slices may indicate uneven drying and the need for further dehydration.

By attentively assessing these visual cues, jerky makers can confidently determine the completion of the dehydration process, ensuring that the jerky is safe for consumption and possesses the desirable texture and flavor. However, visual indicators alone may not provide a comprehensive assessment of jerky doneness, making it essential to consider the texture and feel of the jerky as well.

Texture and Feel

The texture and feel of jerky serve as tactile indicators of its doneness, complementing the visual cues to provide a comprehensive assessment of the dehydration process. Achieving the ideal texture is crucial for ensuring that the jerky is not only safe to consume but also possesses the characteristic chewiness and tenderness that define this beloved snack. By paying attention to the texture and feel of the jerky, enthusiasts can refine their judgment and elevate their jerky-making prowess.

Chewiness and Tenderness: Properly dehydrated jerky strikes a delicate balance between chewiness and tenderness. When sampled, it should offer a satisfying resistance to the bite without being excessively tough or soft. The jerky should require a modest amount of effort to tear, providing a gratifying chewing experience that accentuates the meat’s flavors.

Consistency Across Slices: Consistency in texture among all jerky slices is indicative of thorough dehydration. Each piece should exhibit uniform chewiness and tenderness, ensuring a cohesive jerky experience. Deviations in texture may signify variations in moisture content and warrant further evaluation.

Moisture Content: While the jerky should be devoid of excess moisture, it should retain a subtle pliability, yielding to pressure without crumbling. The absence of excessive moisture is crucial for shelf stability, while a slight residual tackiness contributes to the jerky’s palatability.

By assessing the texture and feel of the jerky, enthusiasts can confidently ascertain its readiness for consumption, ensuring a delightful snacking experience. However, a holistic understanding of jerky doneness encompasses not only visual and tactile cues but also practical tips and considerations that can elevate the jerky-making process.

Final Tips and Considerations

As you embark on your jerky-making endeavors, incorporating these final tips and considerations will further enhance your ability to discern the optimal doneness of jerky in the dehydrator, ensuring consistently exceptional results.

- Patience is Key: While it may be tempting to expedite the dehydration process, exercising patience is crucial. Rushing the process can result in unevenly dried jerky or an underwhelming flavor profile. Embrace the gradual transformation of the meat as it develops into delectable jerky.

- Keep Detailed Records: Maintaining a log of the dehydration process for each batch of jerky allows you to track variables such as meat thickness, marinade composition, and dehydration duration. This practice facilitates the refinement of your technique and the replication of successful outcomes.

- Invest in Quality Meat: The quality of the meat directly influences the flavor and texture of the jerky. Opt for lean, high-quality cuts to yield superior jerky. Trim excess fat to enhance shelf stability and prevent rancidity.

- Regularly Inspect the Dehydrator: Periodically inspect the dehydrator during the drying process to ensure consistent airflow and heat distribution. This practice promotes uniform dehydration and minimizes the risk of unevenly dried jerky.

- Adapt to Environmental Factors: Be mindful of ambient humidity and temperature, as these factors can influence dehydration time. Adjust the dehydration duration and conditions based on the prevailing environmental variables to achieve optimal results.

By integrating these tips into your jerky-making routine, you can refine your approach and elevate the quality of your dehydrated jerky. Embracing the artistry of jerky making and honing your ability to discern doneness will undoubtedly result in a rewarding and flavorful experience, ensuring that each batch of jerky from your dehydrator is a testament to your expertise and dedication.

Frequently Asked Questions about How Do You Know When Jerky Is Done In The Dehydrator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Do You Know When Jerky Is Done In The Dehydrator”