Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Cedar Wood

Tools & Equipment

What Grit Sandpaper For Cedar Wood

Published: December 20, 2023

Discover the best grit sandpaper for cedar wood with our comprehensive guide. Find the right tools and equipment for your woodworking project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

When it comes to woodworking, especially with a beautiful and durable wood like cedar, achieving a smooth and flawless finish is essential. Sanding plays a crucial role in this process, and the right grit sandpaper can make all the difference. In this article, we will delve into the world of grit sandpaper for cedar wood, exploring the factors to consider and the recommended grits for achieving the best results.

Sanding cedar wood requires a nuanced approach to ensure that the natural beauty of the wood is preserved while achieving the desired level of smoothness. Understanding the intricacies of grit sandpaper and its impact on the sanding process is key to mastering this art. So, let's embark on a journey to discover the perfect grit sandpaper for cedar wood and unlock the secrets to a flawless finish.

**

Key Takeaways:

- Choose coarse grit sandpaper (40-80) for initial sanding, medium grit (100-150) for smoothing, and fine grit (180-220) for finishing cedar wood.

- Consider wood grain, surface condition, and final finish when selecting grit sandpaper for cedar wood to achieve a professional and refined outcome.

Read more: What Grit Sandpaper For A Wood Dresser

Understanding Grit Sandpaper

**

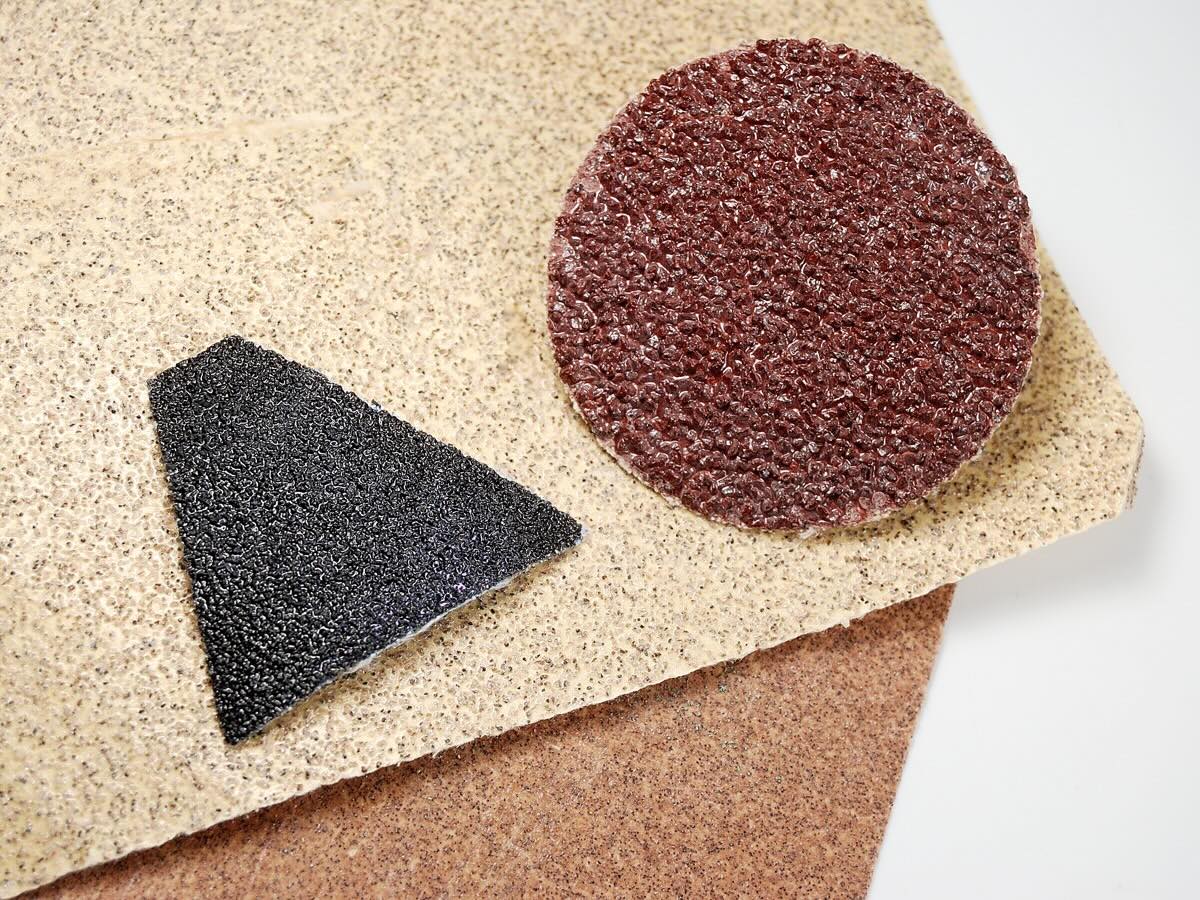

Before delving into the specifics of sanding cedar wood, it's essential to grasp the concept of grit sandpaper. Grit refers to the number of abrasive particles per square inch of the sandpaper. The higher the grit number, the finer the sandpaper. Conversely, lower grit numbers indicate coarser sandpaper. Common grit numbers range from 40 (coarse) to 3000 (extra fine).

Coarse sandpaper, with grit numbers typically ranging from 40 to 100, is ideal for removing rough surfaces, paint, or varnish from cedar wood. As the grit number increases, the sandpaper becomes finer, making it suitable for smoothing and polishing the wood surface. Fine sandpaper, with grit numbers between 120 and 220, is often used for intermediate sanding and preparing the wood for a finer finish.

Extra fine sandpaper, with grit numbers above 240, is perfect for achieving a smooth and flawless finish on cedar wood. This finer grit is crucial for removing small imperfections, smoothing out the surface, and preparing the wood for staining or sealing. Understanding the relationship between grit numbers and their respective applications is fundamental in achieving the desired results when sanding cedar wood.

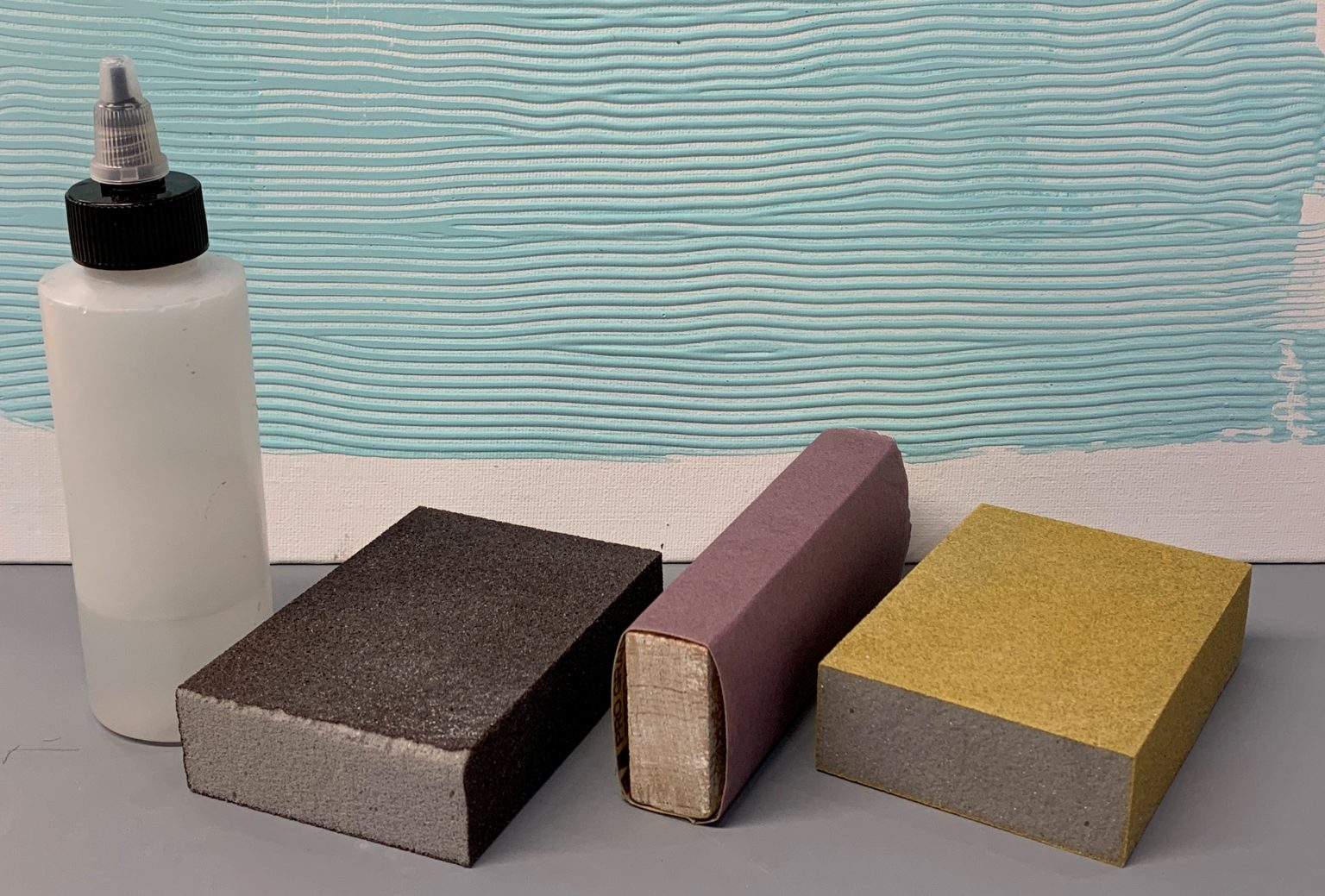

Moreover, the type of abrasive material used in the sandpaper, such as aluminum oxide or silicon carbide, also influences its sanding capabilities. Additionally, the backing material of the sandpaper, whether it is paper, cloth, or fiber, contributes to its durability and flexibility during the sanding process.

Now that we have a foundational understanding of grit sandpaper, let's explore the key factors to consider when sanding cedar wood to ensure a professional and refined finish.

**

Factors to Consider When Sanding Cedar Wood

**

When sanding cedar wood, several factors come into play to ensure a successful and high-quality finish. Understanding these factors is essential for achieving the best results and preserving the natural allure of cedar. Here are the key considerations:

- Wood Grain Orientation:

The direction of the wood grain significantly impacts the sanding process. Sanding with the grain helps prevent scratches and ensures a smooth and uniform finish. Cedar wood is known for its distinct grain patterns, and sanding in the direction of the grain is crucial for maintaining the wood’s natural beauty.

- Initial Surface Condition:

The initial state of the cedar wood surface dictates the starting grit of the sandpaper. If the wood has rough patches, old finishes, or paint, coarser grit sandpaper is initially used to remove these imperfections. Conversely, smoother surfaces may require finer grit sandpaper for a polished finish.

- Sanding Technique:

The sanding technique, including pressure, motion, and sandpaper direction, influences the final outcome. Applying even pressure and using long, smooth strokes with the grain of the wood yields the best results. Consistency in sanding technique is vital for achieving a uniform finish.

- Wood Preservation:

Cedar wood is prized for its natural oils and resistance to decay. When sanding cedar, it’s important to preserve these qualities. Using the appropriate grit sandpaper and avoiding over-sanding helps maintain the wood’s inherent properties while achieving the desired smoothness.

- Final Finish Requirements:

Consider the intended final finish, whether it’s staining, sealing, or painting the cedar wood. Finer grit sandpaper is often used to prepare the wood surface for staining or sealing, while coarser grits are suitable for surfaces that will be painted or receive a more rustic finish.

By taking these factors into account, woodworkers can tailor their sanding approach to the unique characteristics of cedar wood, ensuring a stunning and long-lasting finish. Now, let’s explore the recommended grit sandpaper for various sanding stages when working with cedar wood.

**

Use 80-100 grit sandpaper for rough sanding and removing imperfections on cedar wood. Use 150-220 grit for finer sanding and smoothing the surface before finishing.

Recommended Grit Sandpaper for Cedar Wood

**

Choosing the right grit sandpaper is crucial for achieving a flawless finish when working with cedar wood. The recommended grits vary based on the specific stage of the sanding process and the desired level of smoothness. Let’s explore the ideal grit sandpaper for different sanding stages:

- Initial Sanding and Smoothing:

When starting the sanding process on cedar wood, especially if the surface has rough patches or old finishes, begin with coarse grit sandpaper in the range of 40 to 80. This coarser grit effectively removes imperfections and evens out the surface, preparing it for subsequent sanding stages.

- Intermediate Sanding:

For intermediate sanding to further smooth the wood surface and prepare it for the final finish, opt for medium grit sandpaper with numbers ranging from 100 to 150. This grit level helps refine the surface, removing any remaining roughness and preparing the wood for the next phase.

- Final Sanding and Finishing:

As you approach the final sanding stage to achieve a polished and smooth finish on cedar wood, switch to fine grit sandpaper. Grits between 180 and 220 are ideal for this phase, ensuring that the wood surface is impeccably smooth and ready for staining, sealing, or painting.

- Pre-Stain or Sealer Preparation:

When preparing cedar wood for staining or sealing, extra fine grit sandpaper with numbers above 240 is recommended. This fine grit ensures that the wood surface is perfectly prepped, allowing the stain or sealer to adhere uniformly and enhance the natural beauty of the cedar.

By following these recommendations and using the appropriate grit sandpaper for each sanding stage, woodworkers can achieve exceptional results when working with cedar wood. It’s important to adapt the grit selection based on the specific condition of the wood and the desired final finish, ensuring that the natural allure of cedar is preserved while achieving a professional and refined outcome.

**

Conclusion

**

Mastering the art of sanding cedar wood involves a deep understanding of grit sandpaper and its application throughout the sanding process. By recognizing the nuances of grit numbers and their impact on the wood surface, woodworkers can achieve a flawless finish that accentuates the natural beauty and durability of cedar.

Understanding the factors to consider when sanding cedar wood, such as wood grain orientation, initial surface condition, sanding technique, wood preservation, and final finish requirements, empowers woodworkers to tailor their approach to the unique characteristics of cedar. This attention to detail ensures that the wood’s inherent qualities are preserved while achieving a professional and refined finish.

When it comes to selecting the right grit sandpaper for cedar wood, the recommended grits for different sanding stages provide a roadmap for achieving exceptional results. From initial sanding and smoothing to final finishing and preparing the wood for staining or sealing, the appropriate grit sandpaper plays a pivotal role in the sanding process, ultimately determining the quality of the end result.

As woodworkers embark on their journey of sanding cedar wood, they are equipped with the knowledge to make informed decisions regarding grit sandpaper selection, technique, and overall approach. This knowledge, coupled with a passion for woodworking and a commitment to excellence, paves the way for stunning and enduring creations that showcase the timeless allure of cedar wood.

So, whether it’s crafting a cedar chest, building outdoor furniture, or adding elegant touches to interior spaces, the right grit sandpaper for cedar wood serves as a trusted ally in the pursuit of woodworking mastery. With each stroke of the sandpaper, the natural beauty of cedar is revealed, honoring the rich legacy of this exceptional wood.

Frequently Asked Questions about What Grit Sandpaper For Cedar Wood

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Cedar Wood”